Table of Contents

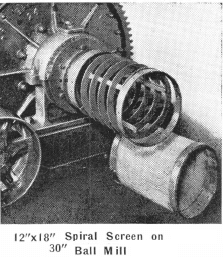

Ball Mill Discharge Spiral Screen

The Ball Mill Discharge Spiral Screen is designed to make a sized product, particularly for “Sub-A” Unit Flotation Cells and concentrating tables. It is also used to screen out and return to the ball mill any oversize in a ball mill-classifier circuit when using a (Selective) Mineral Jig.

This Ball Mill Discharge Spiral consists of a series of heavy steel bars made into one continuous, sturdy spiral. At the feed and discharge ends the spiral is supported by a steel flanged collar with heavy ribs to hold the flights as a single rugged member. The proper mesh screen cloth is placed around the spiral frame and held in position by bands which press against the outer surfaces of the flanges and spiral flights. This device eliminates short circuiting through the screen because the pulp is compelled to follow along the entire length of the steel spiral. A center screw can be furnished to automatically return the oversize into the mill.

Ball Mill Discharge Spiral Capacity

Ball Mill Discharge Trommel Screen

The Ball Mill Discharge Trommel Screen has wide application in practically every type of placer work, in gravel plants, and in ore-dressing. This type of screen is particularly adapted for screening at coarse sizes, or at finer sizes if spray water can be used freely without interfering with screening.

The Trommel Screen consists of a shaft, bevel gears and bearings; spiders for supporting the screen, and bands for holding the screen cloth in place; a hopper with arrangements for removing the products, both undersize and oversize; and a cone on the feed end. It can be furnished with any type of punched plate or screen cloth specified by the customer. The 48″ and 60″ diameter Trommel Screens are furnished with steel tire and roller drive. These screens are well adapted for operation in series, with a range of screen openings to give graded products for use in stage treatment of ores. Let us make recommendations for your proposed trommel screen installation or redesign your present flowsheet for greater efficiency through use of a trommel screen.