This machine is designed especially to make cast steel balls, utilizing the newly patented Payne hot top principle. This machine will produce solid cast alloy steel balls equal in quality to the best forged steel balls, at a very low cost.

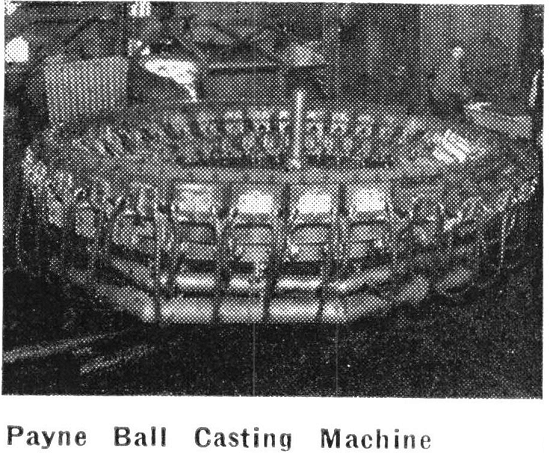

The Ball Casting Machine consists essentially of a rotary turntable and thirty-six copper ball molds, the inner half of each mold being attached to a stationary bracket, and the corresponding outerhalf attached to a movable bracket. Each mold section is interchangeable with any other section, and each section is cooled by circulating warm water. The outer mold section is held closed by means of a counterweight on the mold bracket operating arm and for approximately one hundred and eighty degrees of the rotation of the machine. At the discharge position of the molds the roller on the mold operating arm moves upon a cam to open the molds, drop the balls, and hold the molds in the open position for a short period. The molds then close again for the casting operation.

The machine is set on a slight incline. The molds are filled by pouring the molten steel down a green sand trough placed in blocks on top of the molds. Three to five balls are filling and cooling at the same time. The hot metal flowing over the heads of the balls during the cooling period allows the gases to escape and produces solid balls. Molds are made for 4″, 3½”, 3″, 2½” and 2″ diameter balls.

This machine can be furnished by itself or with the electric furnace and complete equipment for a ball casting foundry.