Since the majority of mines were then using direct current power systems, we were able to use controllers with 3 or more steps of starting resistance. The slow belt speeds coupled with relatively long starting cycles kept the rate of acceleration low and gave us smooth, easy starts.

The conveyor belts in common use were usually rather thick; they were stiff and hard to trough; and they stretched very little at the tensions involved. The combination of low tonnage, slow belt speeds, low horsepower, and stiff belt resulted in conveyors where little slack belt accumulated during starting and belt takeups of a special nature were not needed. Tail sections were usually anchored with a pair of pull jacks having 5 ft. of adjustment and, in most cases, this was sufficient.

From the foregoing facts, we may assume that a properly designed conveyor takeup should have as a minimum the following qualifications:

- It should provide the pulley travel necessary to absorb all of the slack belt produced during the starting cycle.

- It must operate with sufficient force and speed to absorb all slack belt as soon as it appears, while at the same time maintaining the required slack side tension.

- It must provide proper belt tension under all conditions of loading during normal running time.

- It should be low and compact so that it may be used in a wide variety of seam heights.

- It should be simple to install and adjust. Preferably, it should require no shooting of top or other special preparation of the operating site.

- It should be economical to produce, operate reliably with a minimum of attention, and require little maintenance.

There are three general types of takeup on the market today which will provide the required action. However, I believe that only one of the three types embodies all of the listed qualifications.

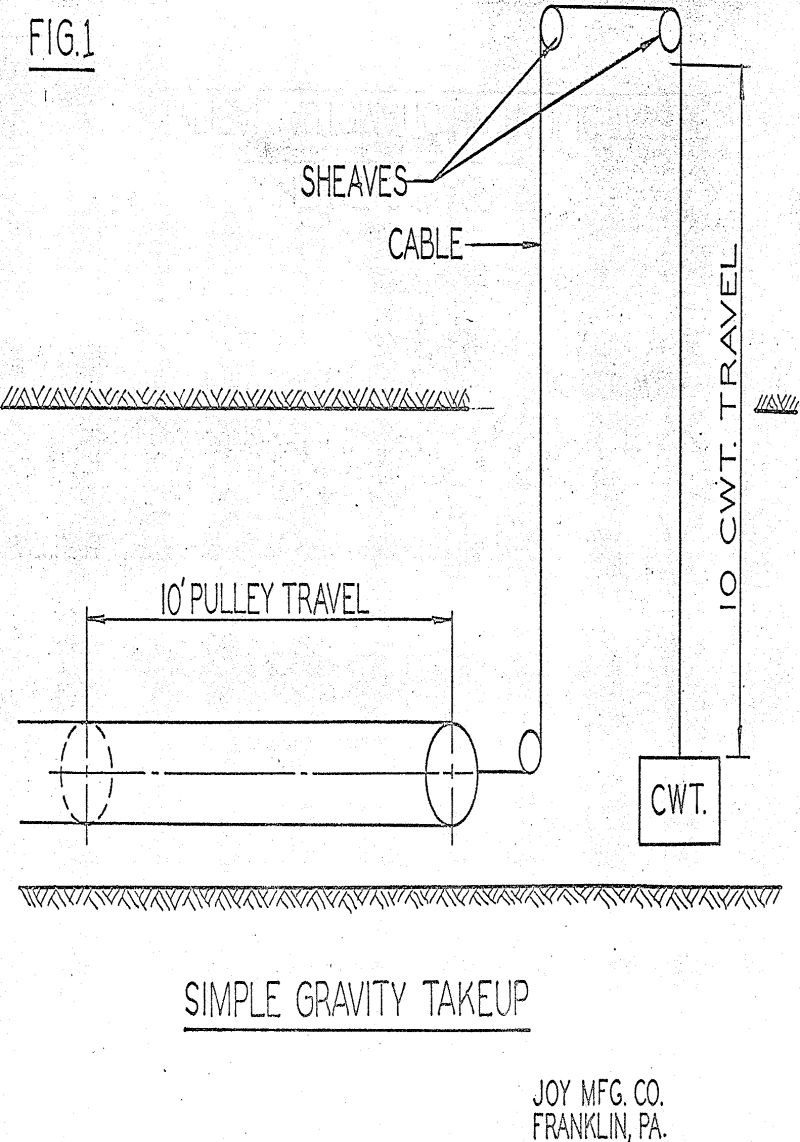

The first of these is the vertical gravity type which utilizes a large weight to move the takeup pulley, operating through a system of sheaves and cables. In its simplest form the counterweight must move 10 ft, vertically to provide 10 ft. of horizontal pulley travel. If multiplying cables are used to reduce the counterweight travel by 50% the weight must be doubled, and so on. Properly designed it will provide the needed travel, force, and speed. It is extremely reliable. It can be produced economically and requires little maintenance.

The automatic compressed air takeup uses a horizontal cylinder directly connected to the moving pulley. Since the air pressure used is seldom over 100 PSI, the cylinder must be quite large, often from 8 to 12 inches in diameter. Because of size and cost the cylinder stroke seldom exceeds 5 feet. If 10 feet of pulley travel was required, the attaching cable would have to be reset and only half of the 10 foot travel would be under control.

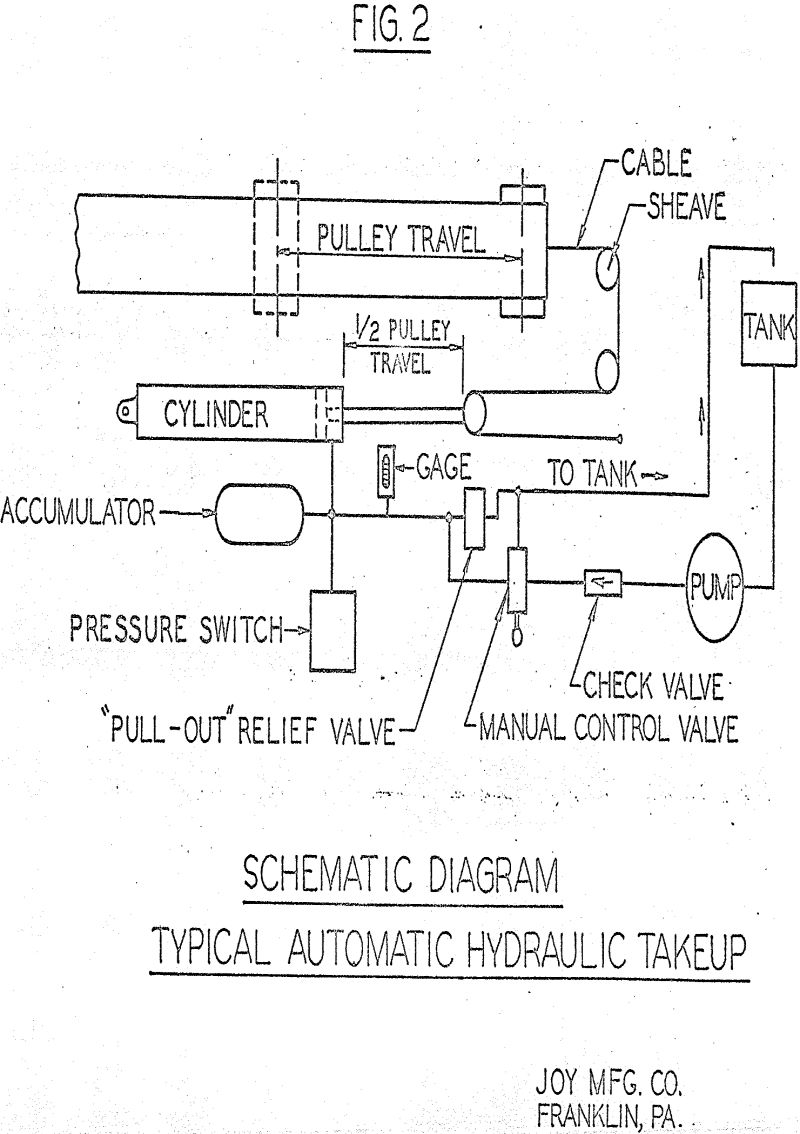

The third type is the automatic hydraulic takeup. It also uses a horizontal cylinder mounted parallel to the belt. Since it may operate at pressures of from 350 to 1500 PSI, it can provide more force than can the compressed air type with much smaller cylinders. Since plenty of force is easily available, multiplying cable systems may be employed to provide long pulley travels with full automatic control.

Since the moving pulley must handle two strands of belt, the computed slack side tension must be doubled to find the required force which the operating cable must supply. A further amount, determined by experience, must be added to cover friction losses and to allow for final adjustment of the unit under actual operating conditions. If multiplying cable systems are employed, the value is further increased to arrive at the final force the cylinder must supply. From this figure the cylinder area and operating pressure are calculated.