Table of Contents

Incineration has, in recent years, been considered by many as a major source of air pollution. However, a number of reports refute this belief. The former report states that the National Academy of Sciences has published data showing that refuse combustion accounts nationally for only 2.6 percent of air pollutants. The report also states that incineration is only one means of disposal under the Academy’s heading of “Refuse Combustion.” It includes on-site incineration and open-burning, as well as municipal incineration. The report further asserts that if all forms of open-burning were eliminated the contribution of incinerators to air pollution would drop to a fraction of 1 percent. In addition, if all currently operating on-site incinerators improved their combustion efficiency, sources of air pollution such as aerosol from spray cans, salt spray, ground dust, and even cigarette smoking would outweigh the pollutant effects of incineration.

“Concentration,” in mineral dressing terminology, is defined as the “separation and accumulation of economic minerals from gangue”. Incineration can be considered a concentration step. Generally after a thorough burning of the combustibles in a municipal incinerator the residue that is left occupies about 10 percent of the original volume. The weight reduction is approximately 4 to 1. After quenching to extinguish any flames, incinerator residues become a soaking wet complex mixture of metals, glass, slag, charred paper, and ash containing various mineral oxides. In 1966, the Bureau began research to establish exactly what values residues could reliably be expected to contain. This work revealed that metals and glass account for approximately 75 percent of the residues by weight, a proportion that varied surprisingly little from sample to sample when considering the heterogeneous character of residues.

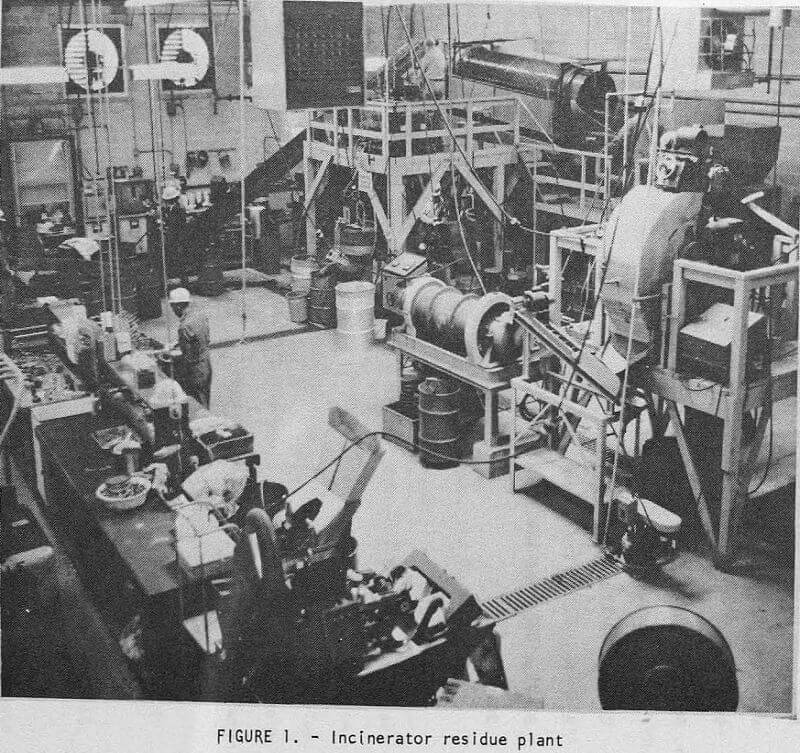

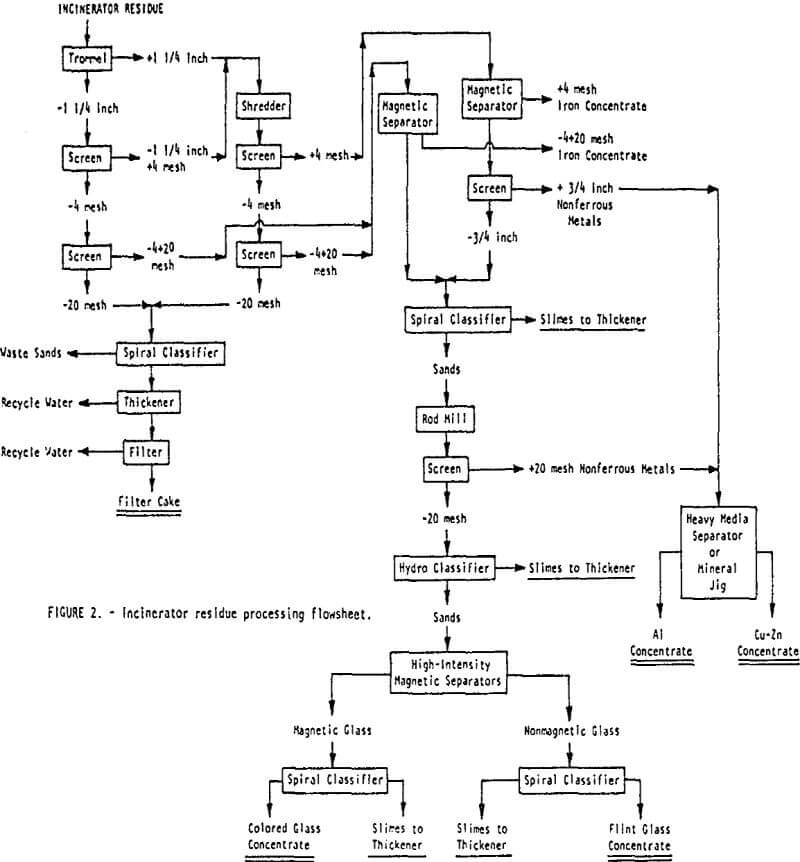

Upon establishing the general composition of residues, research was then focused on developing wet mechanical methods for recovering and separating the residues into fractions that, if necessary, could be further treated to produce products suitable for recycling. Relying exclusively on existing mineral engineering technology, various combinations of mineral beneficiation techniques were investigated. The most promising procedures that evolved from this research were incorporated into a continuous mechanical beneficiation plant which came on stream in November of 1965. During the following 2 ½ years of operation samples of residues from municipal incinerators in Connecticut, Illinois, Maryland, Massachusetts, New Jersey, New York, Pennsylvania, and Virginia were processed and the plant optimized. The plant, which was designed to process 1,000 pounds of residues per hour, utilizes continuous screening, grinding, magnetic separation, and gravity concentration techniques to produce metallic iron concentrates, clean nonferrous metal concentrates, clean fine glass fractions, and fine carbonaceous ash tailings. A view of the pilot operation is shown in figure I and a general process flowsheet is depicted in figure 2.

The first processing step as shown in figure 2 consists of screening the residue in a trommel having 1-¼-inch- diameter holes. During screening, the residue is sprayed continuously with wash water.

The minus 1-¼-inch material from the trommel is washed and screened on a primary vibrating screen having 4-mesh and 20-mesh screen decks. The plus mesh material is combined with the plus 1-¼-inch material from the trommel. The combined product is then shredded in a hammer mill.

The shredded product is screened on a secondary vibrating screen having 4-mesh and 20-mesh screen decks. The minus 4- plus 20-mesh material from the primary and secondary screening operations are combined. The combined minus 4- plus 20-mesh product and the plus 4-mesh material from the secondary screen are each underfed to drum-type magnetic separators where the iron is removed. The nonmagnetic portion from the plus 4-mesh screen is fed to a vibrating screen having ¾-inch openings where the massive nonferrous metals are collected. The minus ¾-inch material is combined with the minus 4- plus 20-mesh nonmagnetic material. This combined product is then dewatered in a spiral classifier. The classifier removes any slimes and fine organics as it conveys the glass and nonferrous metals to a peripheral discharge rod mill. The glass, being friable, is finely ground by the rod mill, and the non-ferrous metals, being malleable, are flattened. A separation of the nonferrous metals from the glass is easily made on a 20-mesh vibrating screen.

The mixed nonferrous metal product is further beneficiated in a drum-type heavy-media separator or in a conventional mineral jig to separate the aluminum from the other heavier non-ferrous metals. The quality of the aluminum concentrates obtained by both systems is virtually the same; products analyzing 99 percent aluminum have been produced by both processes. Although heavy-media separation yields a somewhat higher aluminum recovery, the use of a jig eliminates the possibility of contaminating the nonferrous products with unreclaimed media.

The minus 20-mesh glass screened from the rod mill discharge is deslimed in a hydroclassifier and then fed to a high-intensity wet magnetic separator. Here the glass is given a rough magnetic cleaning to remove highly magnetic particles including some colored glass. Cleaning of this rougher nonmagnetic concentrate is made by a second high- intensity wet magnetic separator to produce a final concentrate that is essentially colorless flint glass. This flint glass concentrate is dewatered in a spiral classifier and dried in a rotary drum-type dryer. The magnetic products from both separators are combined and dewatered in a screw classifier and collected as a concentrate.

The minus 20-mesh materials from the primary and secondary screening operations are classified to collect a waste sand product for disposal. All waste waters from the various classifying operations are combined and treated with flocculants in a thickener. The sediment is pumped to a vacuum filter to yield a filter cake for disposal. The water from the vacuum filter and the clarified thickener overflow is recycled throughout the plant.

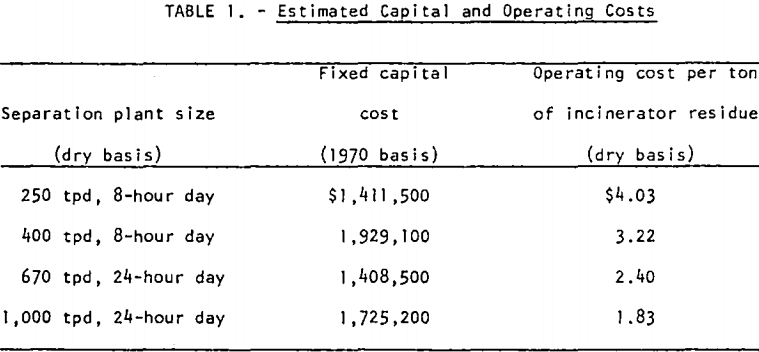

From engineering data developed during pilot plant testing, material balances and preliminary evaluations of the capital and operating costs for full-scale plants have been reported. Table 1 summarizes those estimates.

These capital and operating cost estimates are based on a scale-up of the actual pilot plant layout. A more recent report offers still another preliminary engineering design for a proposed commercial size operation. The new layout relies largely on gravity flow and minimizes the number of conveyors and pumps that would otherwise be required.

Unburned Refuse Flowsheet

The Bureau of Mines is now focusing its research efforts toward developing an economic process for mechanically separating metals, glass, plastics, and paper from raw, unburned urban refuse on a continuous basis. Even before the incinerator residue pilot plant flowsheet was finalized, various types of equipment were being tested to evaluate their potential for separating the unburned “urban ore.”

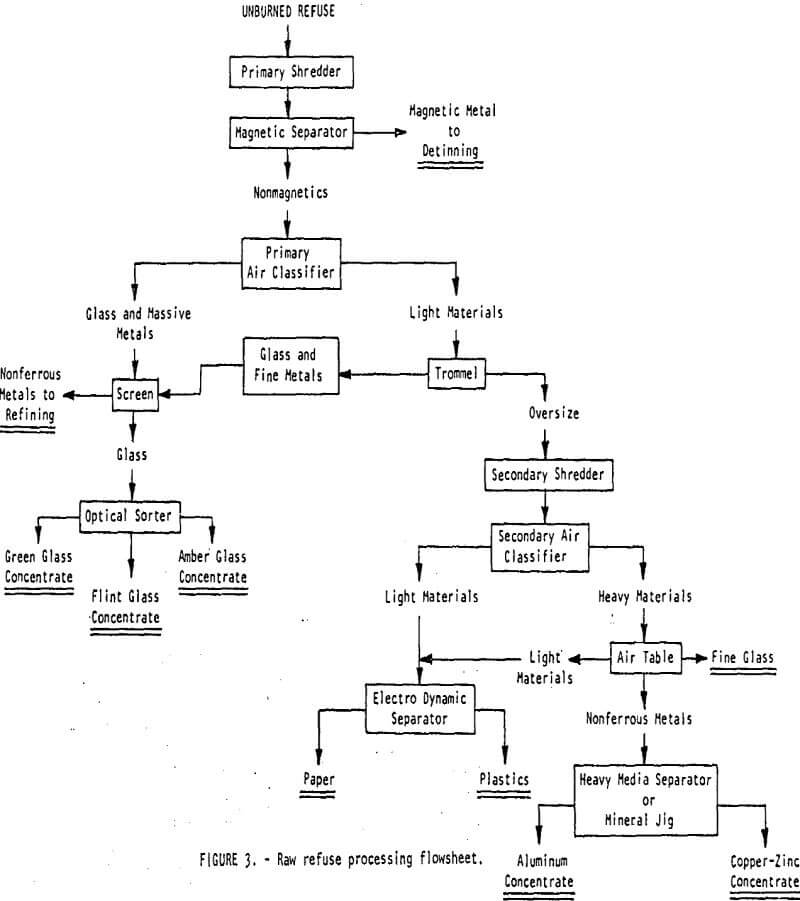

The Bureau’s concept in processing urban refuse again utilizes physical beneficiation techniques. These techniques include various combinations of milling or shredding, air classification, magnetic separation, screening, optical sorting, and electrodynamic separation. Every effort is made to take advantage of the differences in one or more of the physical properties of the various materials found in refuse. A flowsheet depicting the proposed process is shown in figure 3. The process illustrated is still somewhat conceptual, and major laboratory effort is still being devoted to prove, further develop, and refine these procedures.

The first processing step consists of liberating all of the components of refuse by coarse shredding to approximately 12 inches in size in a double-opposed chain mill. Most of the iron is then removed by a suspended belt magnet. The iron concentrate is treated separately to remove paper and residual food matter, leaving a clean iron product suitable for detinning.

The nonmagnetic portion is fed to a horizontal primary air classifier. The design of this unit is based on the prototype that was built and operated successfully by the Bureau’s Salt Lake City Metallurgy Research Center.

The primary air classifier removes the larger pieces of glass and massive pieces of nonferrous metals and stainless steel that could possibly cause damage to the secondary shredder. The heavy fraction is then screened to separate the glass and metals. The metal fraction is then treated separately to produce marketable metal products. The glass is fed to a commercial optical sorter to separate the mixed material into colorless, green, and amber concentrates. A report describing this phase of the Bureau’s research has been published.

The lighter material separated by the primary air classifier is screened in a trommel having 2-½-inch openings to remove any entrapped glass and metals The glass and metals are blended with the glass and massive metals separated by the primary air classifier. Oversize material from the trommel is shredded to between 1 and 3 inches in the secondary shredder. The shredded material is subsequently fed to a commercial air classifier that utilizes both mechanical and pneumatic action to separate metals, fine glass, plastics, rags, putrescible material, heavy paper, and cardboard from the lighter paper and plastic fraction. The heavy portion is further classified in a commercial air-gravity table separator (air table) to remove plastics, rags, heavy paper, and putrescibles, and to separate the heavier materials into a fine glass product and a metal composite. The metal product is beneficiated in either a heavy-media separator or conventional mineral jig to yield aluminum and mixed nonferrous metal concentrates.

The light fraction from each of the commercial air classifiers is combined and treated in an electrodynamic separator to yield a composite product of various plastics and a mixed paper product.

Capacity of the entire plant in continuous operation will be limited by the secondary air classifiers, which are purchased commercial units capable of processing from 1,000 to 1,500 pounds of light shredded material per hour. However, modifications are now being made to one of the units that may allow an increase in its capacity. The primary shredder, magnetic separator, and primary air-classifier have capacities in excess of several tons per hour, since the sizing of these units was dictated by the nature of the material fed to them. Data on maximum capacities for the primary separation section of the system will be developed, but in these tests it will not be possible to complete further processing of the products through the remainder of the plant.

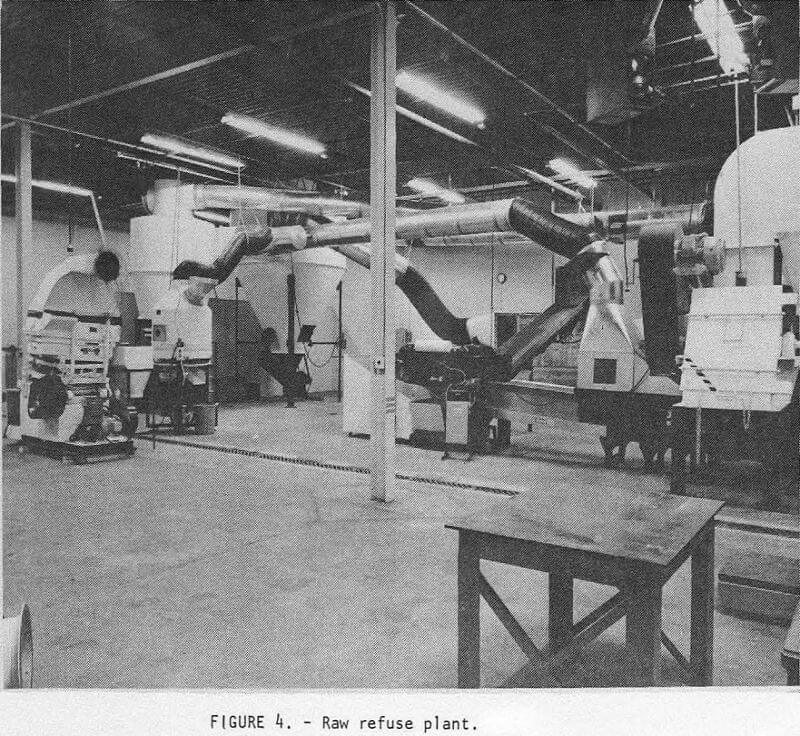

Major equipment for approximately three-quarters of the proposed flowsheet has been purchased and installed. A view of the plant is shown in figure A. However, before the entire proposed flowsheet is finalized, considerable testing is still required to establish the optimum air flow rates and sizes to which materials should be shredded for most efficient separation and recovery of the various products. It is not certain that the final flowsheet that evolves from this research will be identical to the one presented in figure 3.

It is anticipated that the greatest single problem to be overcome will be in the area of materials handling rather than in optimizing the performance of the various pieces of separation equipment.

Laboratory work to develop techniques for preparing clean iron products that are suitable as feed at existing commercial detinning plants has been completed. A number of major shredder manufacturers have demonstrated for the Bureau that their equipment can success-fully shred the tin can product to a form that will permit subsequent washing and delabeling using conventional screening procedures. The research has shown that the tin content of the washed scrap can be lowered to less than 0.01 percent tin using conventional detinning procedures. A report covering this phase of the Bureau’s research will be published in the near future.

Development of electrodynamic methods for separation of plastics from paper has advanced to the point where there is little doubt that a paper fraction essentially free of plastics and a plastic fraction essentially free of paper can be produced. However, it is still not certain that either of these materials will be of suitable quality for reuse in making new paper or plastic products. This will depend largely on the degree of soiling that occurs from waste foods and other putrescibles during earlier processing. In the event that neither the plastics nor the paper are suitable for utilization in new products, it is proposed that the combined materials can readily be converted to fuels by either pyrolysis or hydrogenation processes. Papers describing both of these processes have been published by the Bureau.

Procedures are also required for upgrading the nonmagnetic metal concentrates. Depending on the nature of these products, it may be necessary to develop cleaning and washing techniques to remove putrescibles. To upgrade these products even further, conventional mineral dressing and extractive metallurgical methods will also be investigated. These include heavy media separation, jigging, and selective sweating of the low-melting-point metals.

Summary and Future Plans

For the past 2-½ years the Bureau of Mines has successfully operated a continuous pilot plant designed to reclaim the metal and mineral fractions contained in the residues of incinerated urban refuse. The flowsheet is straightforward and utilizes conventional mineral engineering equipment and standard beneficiation practices. The information developed in the pilot plant has permitted the actual design of a commercial-size demonstration plant capable of processing 250 tons of residue in an 8-hour day. Tests are now being made to determine the amenability of the Bureau’s beneficiation process for processing residues from a variety of municipal incinerators. Laboratory research is also being done to study a number of other physical beneficiation techniques to further improve both recovery and grade of the products reclaimed from these residues.

The major solid waste research effort by the Bureau is now focused on the development of an economical process for mechanically separating metals, glass, paper, and plastics from unburned refuse-on a continuous basis. Here again, efforts will be made to utilize existing technology and equipment to take advantage of various physical properties in making separations. Although most of the equipment required for this new pilot plant has been purchased and installed and progress thus far has been encouraging, a great deal remains to be done to reach the ultimate objective of converting these materials into products suitable for recycling. Conceivably, the bulk of the materials contained in urban refuse can be reclaimed as useable products, and this so-called solid waste will become a desirable raw material instead of being wasted as landfill.