TON RECIPROCATED Antique JAW STONE BREAKER: Curved by owners in installing and operating individual pumping plants. The new mechanical filtration or rapid sand filter plant for Baltimore comprises 32 filters each of 1440 square feet area and a capacity of 4,000,000 gallons daily. The turbidity of the water led to the adoption of this system in preference to the slow sand system. At Trenton a rapid-sand plant now under construction has a capacity of 30,000,000 gallons daily, and can use coagulant, soda ash and hypochlorite. Treatment with copper sulphate continues to be used in the reservoirs at Philadelphia to prevent the growth of microorganisms. Sterilization by ultra-violet rays has been adopted at Niagara falls this being the first American city to adopt the process. The use of liquid chlorine instead of hypochlorite of lime is being adopted in several cities as being more economical and causing no odour such as sometimes leads to complaint from consumers where hypochlorite is used.

Treatment of sewage with hypochlorite of lime has been introduced in two or three cases, and some experiments with electrolytic treatment have been made. The sprinkling filters of the sewage treating plant at Aberdeen, South Dakota are equipped with covers to be applied in winter, owing to the extreme intensity and duration of the cold season. The new plant at Baltimore comprises 28 Imhoff tanks of radial-flow type 30ft, diameter 16 sludge digestion tanks 38ft. diameter and 20 ft. deep, and sludge drying-beds with a surface of 260,000 square feet. Investigations as to the utilizations of sewage sludge still continue, but while the sludge has some fertilising property the problem is to extract this at a cost less than a value of the product. Two or three cities are operating experimental sewage treatment plans preliminary to the adoption of some system of treatment. The sewage disposal plant for New York is estimated to cost £3,000,000 by 1916 and £10,000,000 by 1930 when it will be completed. The city of Chicago has its congested business district served by an antiquated and dilapidated system of small sewers, much too small and insufficient for present condition. Entire reconstruction must be undertaken before long, and will be a matter of considerable cost and difficulty.

At St. Louis a sewer relief tunnel is to be driven in solid rock for about four miles in the Mill Creek Valley: it will be about 45ft below the present sewers the storm water in which will overflow into shafts discharging into the tunnels. A novel feature in modern sewage is the Ownership and operations of sewers and sewage treatment plant at Vincennes by a private Corporation. The use of small granite blocks- 2in to 3in cube for paving has been tried in a few places and seems likely to be successful. Other places are using brick 2in and 3in thick, instead of the standard 4in brick, in order to have a substantial paving at reduced cost. This is where traffic is comparatively light. A Baltimore slag brick has been imported from England for lying along the rails to the tramway lines. A new idea in concrete paving is the rolling of the wet concrete with a 10 ton roller which rides on timbers forming the side of the forms. This has been employed for concrete highways in Oregon. A largely inaccessible part of a steep hillside in Portland, Oregon has been converted to residential purposes by excavating the material with powerful water jets and washing it into terraces and roadways according to a landscape engineering plan. About 3 million yards of material were handled in this way. The introduction of quantity surveying and the quantity surveyor is a feature of the past year, but the system is used but little as yet in the United States. Under ordinary practice each contractor intending to tender for competitive work has to take off the quantities for himself, so that there is often discrepancy in these quantities as represented by the tenders.

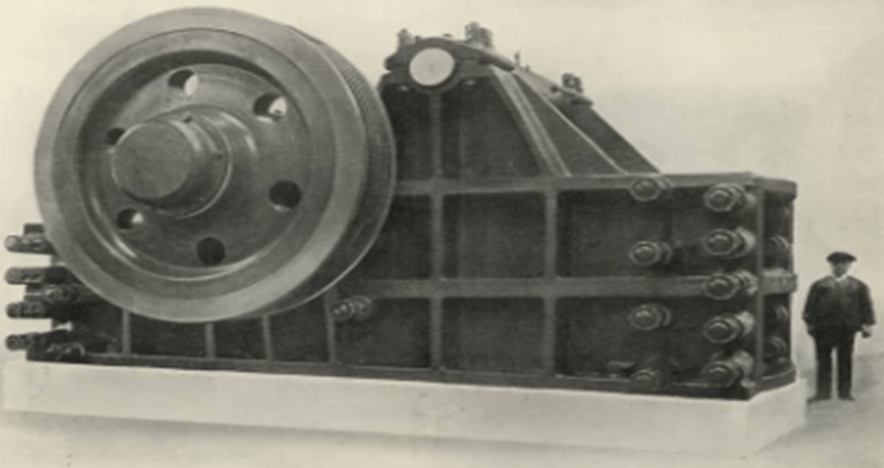

Antique Jaw Stone Breaker: The machinery necessary in the early stages of the manufacture of the Portland cement varies of course with the nature of the raw materials from which the cement is to be made. There are some substances which are easily quarried such for example as chalk, clay and soft marl. Hard marl and shale and limestone may offer difficulties both in quarrying and in subsequent operations. We do not propose as we said in the first article of this series to say very much concerning the machines actually used in quarrying. It is a well known fact that British makers are perfectly competent to supply the machinery required for the operations of quarrying any sort of material, no matter what its nature, and of conveying it in the most economical manner to the Work where it is to be converted into cement. No one need think of going abroad for a steam excavator.

For example nor yet for a locomotive nor say a rope way to carry the quarried material to the factory. Nor if it be decided to mix the raw material into a slurry and to pump it from quarry to works, need the cement manufacturer look elsewhere than at home for the necessary machinery. And in the works themselves the raw and semi-manufactured materials and final product can be handled just as well and cheaply by British made conveyors and elevators as by any foreign equivalents.

These facts are all well known and so it may be taken for granted that the British cement manufacturer if patriotism did not indicate what to do, would naturally choose British plant for these purposes. This is one reason why we have decided not to include reference to any such machinery and plant. Another is that the needs of each particular case are so diverse that without drawing out this service to an abnormal length, it would be impossible to deal adequately with every combination of circumstances. Hence we propose to begin by describing some British made machines which are used for breaking up and crushing the harder substances used in cement manufacture. Modern methods of quarrying have proved to be so advantageous both as regards output and reduction in cost that it may be taken as fairly certain that mechanical excavators will be more and more employed. Their use however has necessitated the employment of large and powerful crushing machines. It is no uncommon thing nowadays to find blocks of limestone weighing as much as from one to two tons dug up by the steam shovel and sent to the works.

In hand quarrying such blocks would have to be broken up in the quarry before being dispatched n lengthy and expensive process at the works however, the breaking can be performed exceptionally and economically, and the tendency nowadays is to employ machines of greater and greater capacity for doing this such a course permits of the use of raw material which it would be prohibitive to treat by other method. Naturally enough the raw material does not always occur in such large lumps. It may and frequently does, occur in comparatively small pieces and consequently it is by no means always necessary to employ crushing machinery of large dimensions: but in whatever form the raw material occur there are British machines to deal with it. And all that is needed is the exercise of judgment and common sense in choosing exactly the type of machine.