Table of Contents

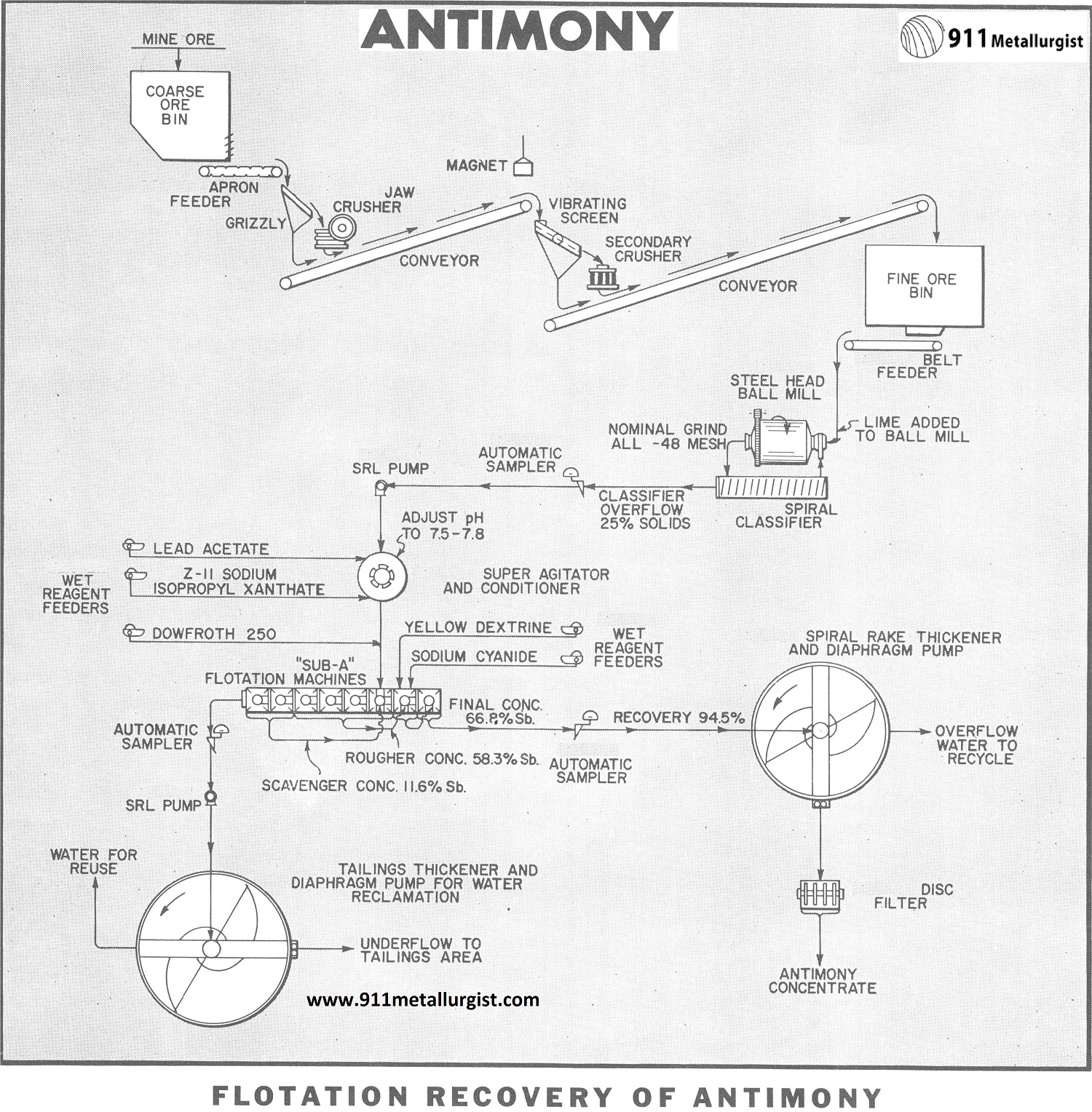

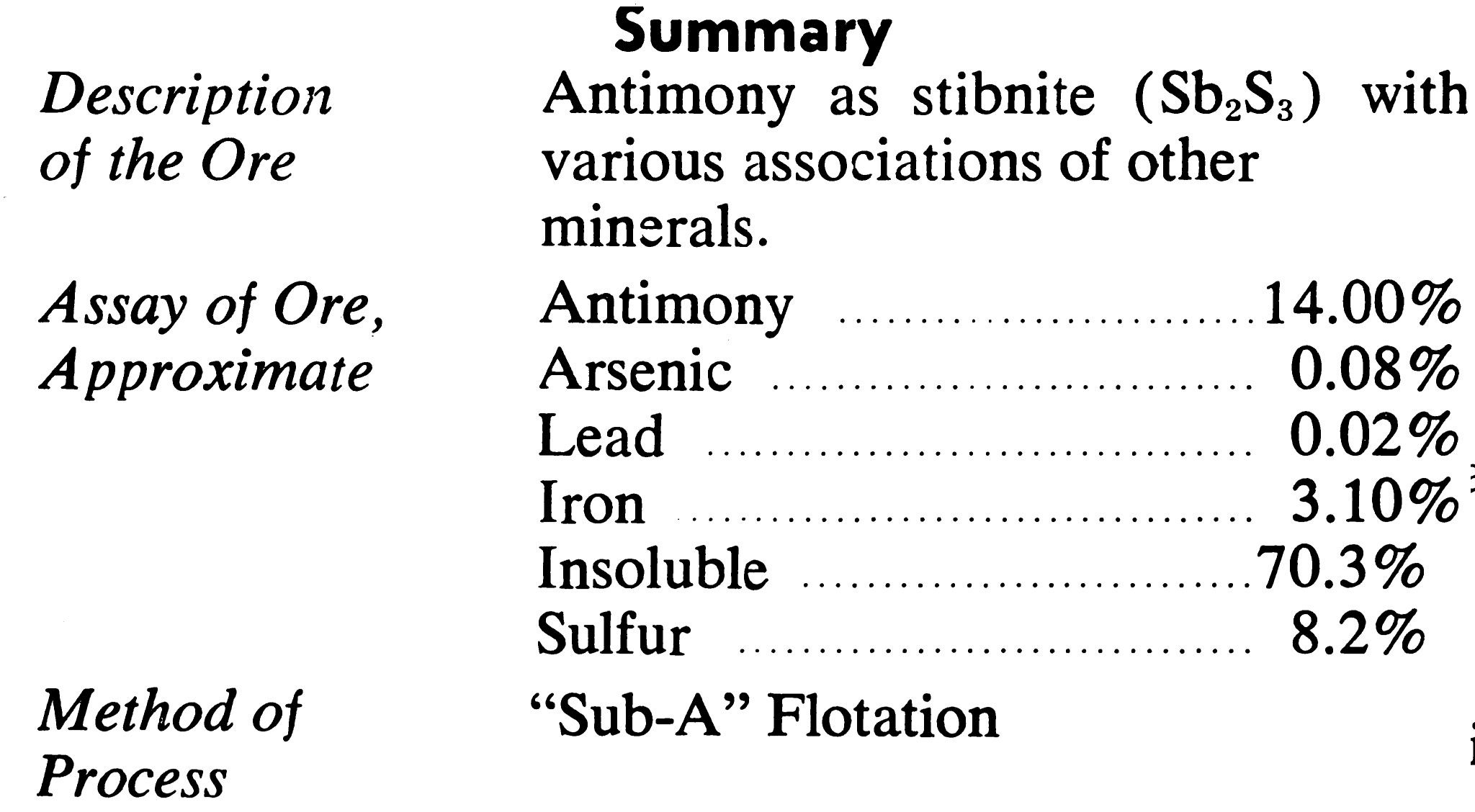

The problem discussed in this antimony process study is limited to a concentrator capable of beneficiating 150 tons per day of antimony ore. The antimony in this study occurs as the mineral stibnite (Sb2S3) in association with small amounts of pyrite, arsenopyrite, galena and lead sulfantimonides. The gangue is composed largely of quartz but contains, in addition, a small amount of talc. The talc mineral is particularly trouble some since it tends to float with the stibnite and hence lowers the grade of the final antimony concentrate.

Being a small operation every economy must be utilized to assure maximum operating profits.

CRUSHING SECTION

The crushing section with two-stage reduction is suitable for tonnages of from 100 to 300 tons of ore per 24 hours. It is designed to permit crushing sufficient ore during one 8 hour shift to operate the mill during a full 24 hours. Removing the fines with a grizzly before the jaw crusher and with a vibrating screen ahead of the secondary crusher increases the efficiency of size reduction since the crushers are working only on material that must be reduced. Removal of tramp iron to prevent damage to the secondary crusher is accomplished with an electromagnet and a magnetic head pulley.

GRINDING CIRCUIT

The crushed ore is fed from the fine ore storage bin at a controlled rate by a Adjustable Stroke or Variable Speed Ore Feeder. Fine grinding is accomplished in a Ball Mill operating in closed circuit with a Spiral Classifier. To reduce overgrinding of the friable stibnite it is generally desirable to carry a relatively large circulating load in the ball mill-classifier circuit. If necessary sufficient lime or soda ash should be added to the ball mill feed to provide the proper pH for subsequent conditioning and flotation operations.

A head-ore sample is cut from the classifier overflow to use as the flotation circuit control and metallurgical balance. A Automatic Sampler is used. Normally the sampling interval is one cut each 15 minutes which is collected each shift as a composite sample. A Unit Flotation Cell has not been included in the ball mill-classifier circuit of this study. However, in certain instances a Unit Flotation Cell may prove particularly effective in that it is capable of recovering a significant portion of the total stibnite as a relatively high grade grannular concentrate. Thus, overall plant recovery may be increased by reducing slime losses due to overgrinding of the soft, high specific gravity stibnite.

CONDITIONING AND FLOTATION

The classifier overflow adjusted to a pH of approximately 7.5 to 7.8 is conditioned with a stibnite activator such as copper sulfate or lead acetate and a collector such as Z-11 or a liquid type Aerofloat. Depending upon the mineralogy of the ore, other auxiliary reagents may also be required to depress sulfides which tend to float with and thus lower the grade of the stibnite concentrate. For example, bleaching powder has been used effectively for the depression of arsenopyrite and cyanide for the depression of pyrite.

The conditioner overflow passes to an 8-cell “Sub-A” Flotation Machine, arranged to provide four rougher cells, two scavenger cells and one cell for each of two stages of cleaning. The distinctive cell-to-cell design of “Sub-A” Flotation Machines permits the transfer of the various pulp streams within the flotation circuit without the use of pumps. Extremely fine talcose slimes which floated with the stibnite in the rougher cells are effectively depressed in the cleaners with the aid of a small quantity of yellow dextrine.

CONCENTRATE THICKENING AND FILTERING

The cleaned antimony concentrate is pumped to a Spiral Rake Thickener to remove excess water prior to filtering. A Adjustable Stroke Diaphragm Pump meters the thickened flotation concentrate to a Disc Filter.

Where water must be reclaimed for re-use, the rougher tailings are thickened in a Spiral Rake Thickener and the plant water is reclaimed.

SAMPLING

For the efficient control of milling operations, reliable sampling is required. For this purpose Automatic Samplers are used on the heads, concentrates and tailings. A metallurgical balance is run for each shift. Sampling interval of one cut each 15 minutes has proved adequate except where quality of ore is spotty or unusual conditions are encountered.

LABORATORY TESTING

The beneficiation of stibnite ores by flotation can frequently be a difficult problem because of the complex nature of the mineral associations often encountered. It is essential, therefore, that a comprehensive laboratory test program be carried out on a representative sample of the ore before planning a milling installation.

MARKET SPECIFICATIONS

While antimony concentrates assaying less than 50% antimony may be salable, such low-grade concentrates require special arrangements with the smelters. Smelter returns for antimony concentrates are based on a sliding scale which provides for 65% Sb content as the basis. Antimony payment is based on a short ton unit containing 20 lbs. antimony. A 1963 quotation for 65% antimony concentrate was $4.25 per short ton unit.

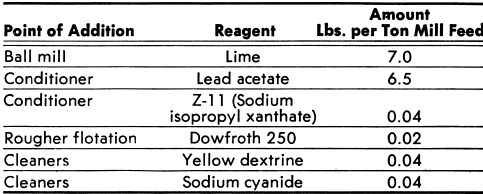

REAGENTS

Typical flotation reagent data for the beneficiation of a stibnite ore of the type described are as follows:

Miscellaneous data: Grind: all minus 48-mesh; pH: 7.5 to 7.8.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.