Table of Contents

The modern anthracite breaker or washery uses almost exclusively a wet method of preparation, which requires, roughly, 1 gal. of water per minute per ton of production per day. The entire anthracite industry uses about 320,000 gal. per min. of water for this purpose or 800,000 tons of water per day. As this water leaves the breakers, it contains fine solids—coal, slate, pyrite, and clay—and is then called silt or slush; as slush is the term most commonly used, it will be employed throughout this paper. The solid content of the slush will be referred to as solids.

In the earlier days of anthracite mining, little coal was washed, less crushing was employed, and virgin coal was mined exclusively. As a result, the slush problem was not acute because of the relatively small quantity and the coarseness of the solids. Such slush as was produced could usually be easily impounded and retained or could be discharged into streams without any appreciable pollution being apparent.

The character of the fine waste from the breakers changed materially as its quantity increased until now about 40,000 tons of slush solids are produced daily. Second mining and robbing operations materially increased the quantity of fine solids delivered to the breaker in the mine car. The demand for chestnut, stove and egg sizes, to the exclusion of grate, steamboat, and lump sizes, requires finer crushing of the mine-run coal with a consequent increase of fine solids in slush. The use of rice and barley sizes removed a considerable tonnage of coarser solids from the slush but left great quantities of fine solids difficult to retain completely, and to store, and long considered of no possible fuel value.

Despite the efforts of the coal operators, the slush solids have found their way into the streams causing, in some cases, serious pollution. The Water Supply Commission of Pennsylvania published, in 1916, a report on Culm in the Streams of the Anthracite Region, from which the following is taken:

About 40,000,000,000 gal. of water carrying 10,000,000 tons of fine culm are discharged into the water-courses direct, flushed into the mines, or disposed of by various means on the surface. The extent to which the very small sizes of anthracite have been deposited in the rivers draining the coal fields is made evident by the fact that over a quarter of a million tons are recovered annually from the river beds by coal-washing operations.

The contamination of the streams has been in progress for more than 50 years and it is estimated that there are now 660 miles of creeks and small streams, which should be available for water supply but which are rendered useless for domestic and manufacturing purposes by the culm and sulfur water from the mines.

Since 1914, the quantity of solids reaching the streams has probably not increased, but it has changed in character. Due to the war demand for steam sizes, less of these sizes was lost from the breakers and many of the banks that could be washed into the streams by heavy rainfall and freshers were prepared for use and shipped. As a result, it is probable that far less coal of the buckwheat sizes is now finding its way into the streams.

The recovery of coal from the rivers increased enormously during the war period but the coal was largely obtained from deposits formed by the waste of earlier years. W. C. Webbert, in an address before the Engineers’ Club of Philadelphia, said: “The total output of coal for the Lehigh River for 1919 was 120,000 tons; adding to this 235,000 tons for the Schuylkill and 1,580,000 tons for the Susquehanna and its tributaries, the total output of river coal in eastern Pennsylvania for the year 1919 can be estimated at 1,935,000 tons. Approximately, the same amount of coal was reclaimed in 1918 but prior to that year the output was much less.”

CHARACTER OF Anthracite SLUSH

Slush, as now discharged from the breakers, contains practically no solids larger than 3/32 in. (2.3 mm.) diameter and often passes through a round mesh of 1/16 or 3/64 in- (1.5 or 1.19 mm.) diameter. It carries from 4 to 15 per cent, of solids by weight, and in isolated cases an even higher percentage. The solids will range, in size, down to particles that are colloidal and, under certain conditions, settle very slowly.

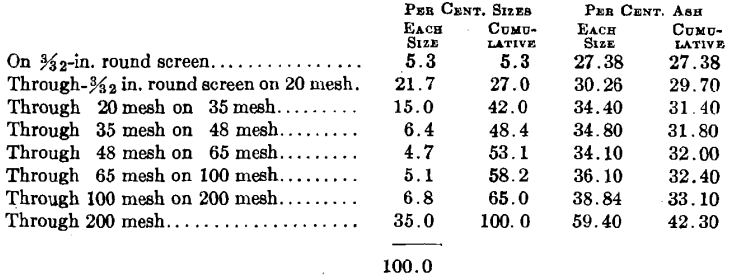

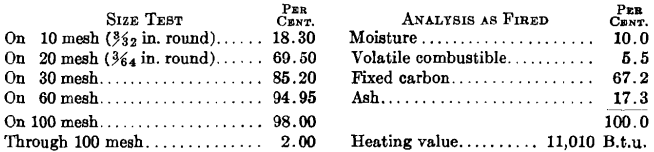

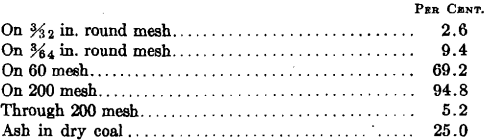

Analyses of the various sizes of solids in slush generally show that the ash content, that is impurities, increases with decrease in size. The following typical screen analysis illustrates this condition:

The granular solids that will remain on a 200-mesh screen are reasonably low in ash and consist of grains of fairly pure coal mixed with grains of slate, sand, pyrite, and, occasionally, calcite and gypsum. The slimes, which will pass a 200-mesh screen, consist largely of fine slate and fine clay and show a high ash content.

The quantity of solids in slush and their character varies greatly from breaker to breaker. A fairly extensive investigation permits the following generalizations;

- Steep-pitch mining produces a greater quantity of slush solids and generally causes a large quantity of slimes, as well as considerable impurities in the plus 200-mesh solids.

- Second mining and robbing operations, where crushing has taken place, have the same effect as steep-pitch mining and generally produce a colloidal slime, which settles with difficulty.

- A coal of soft and friable nature increases the amount of solids, which are relatively low in ash, even including the slimes.

QUANTITY OF Anthracite SLUSH PRODUCED

An accurate determination of the tonnage of slush solids made annually is quite difficult but a close approximation can be obtained by careful tests at breakers representing the various fields throughout the region and applying these figures to the total production of the fields.

In figuring the tonnage of recoverable coal, no solids passing through 200 mesh are included and the amount of refuse larger than 200 mesh that must be removed to reduce the ash content to 15 per cent, has been deducted.

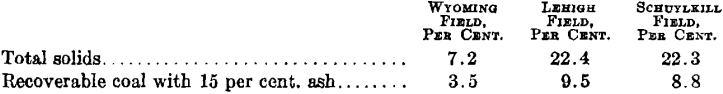

A summary of the determinations of the three fields shows the following amounts of solids in the slush, expressed as per cent, of shipments;

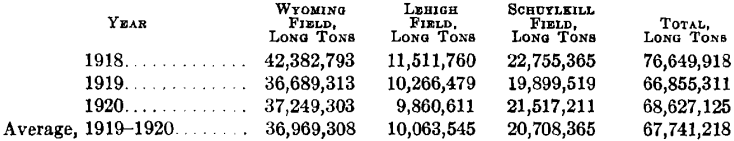

The Anthracite Bureau of Information states that the shipments for the past three years were as follows:

The shipments during 1918 were at an unusually high rate, while 1919 and 1920 are more nearly representative.

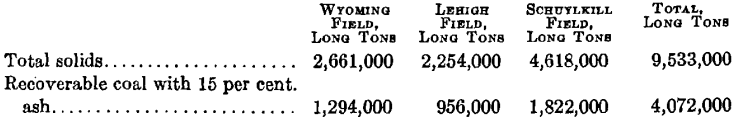

Applying the field averages for total solids and recoverable coal to the average shipments gives the following annual tonnages in the slush:

This indicates that 4,000,000 tons of coal can be recovered from the slush at present produced, leaving 5,500,000 tons of solids, a large part of which is finer than 200 mesh, which must be retained in some efficient way if serious pollution is to be prevented. It must be noted that the trend in mining anthracite indicates that the tonnage of solids in slush and recoverable therefrom will increase rather than decrease, for more and more robbing is being resorted to and much of the reserves from which future production must come lie in the Schuylkill field.

METHODS OF RECOVERING SLUSH SOLIDS

It is probable that the first efforts to retain the solids in slush consisted in allowing the solids to settle back of retaining dams, and were to prevent stream pollution. As the size of the dams increased, it became necessary to find other places for storage or a method that would hold a greater tonnage on a given ground area. Slush is now disposed of in the following ways: Run to slush dams; used for hydraulic mine filling; delivered to settling tanks of various types where the solids are removed and stocked, burned in mine-boiler plants, or shipped.

Much of the slush produced is still delivered to settling dams, which effect a more or less complete removal of solids. These dams are constructed in two ways: Either the slush is impounded to form a pond and the clarified water is allowed to overflow the top; or the retaining dam is constructed of porous material and the water is filtered in its passage through the dam. Either type, if given proper care, can be made very efficient and an almost complete removal of solids obtained so that the clarified water contains less than 0.1 per cent, solids.

Where the slush is impounded and clarified by sedimentation, a large dam must be constructed so as to give plenty of settling area and a depth of several feet of water should be maintained. This requires the labor of several men and often large quantities of lumber. Unless the men are carefully watched, the dam will not be properly maintained and only the coarsest solids will be retained. When the water is several feet deep, it is difficult to keep the slush and water from breaking through unless the dam is heavily reinforced with breaker slate, mine rock, ash, or lumber. At many collieries, slush dams must be located on territory that is broken and caved from mining operations and much of the water, and often slush solids, finds its way into the workings and seriously increases the pumping load.

Slush dams that clarify by filtering are usually constructed of a core of mine rock and breaker slate. Boiler ashes are dumped along the inside of this wall and act as a filtering medium. It is often difficult to seal all the large passageways so that slush solids will not pass. After these passages are sealed, however, the dam will deliver fairly clean water. The ashes finally become clogged with slush solids, so that the filtering operation stops; the dam walls must then be raised to offer new ashes for the filtering process.

Slush dams afford a fairly low-cost method of retaining slush solids to prevent pollution where the slush can be run to the dam by gravity. The retained solids are invariably so permeated with slimes and fireclay that they cannot be utilized for fuel without further preparation.

HYDRAULIC MINE FILLING WITH SLUSH

Slush was used as early as 1884 to extinguish a serious mine fire. It was early realized that such flushing, in addition to serving other purposes, gave a possible means of disposing of slush and preventing stream pollution. It is seldom, however, that mine flushing of slush can be applied solely for the prevention of pollution, as the cost generally is high. If, however, fires are to be extinguished, surface supported, or filling required to enable further extraction of pillar coal, mine flushing of slush may be economic. Tests made by Prof. F. B. McKibben and W. H. Conklin, at the Fritz Engineering Laboratory of Lehigh University, show that slush solids, when confined so as to prevent lateral expansion, will support heavy pressures per square foot. The use of slush for hydraulic mine filling creates many problems where the coal measures are steeply pitching, owing to the difficulty of holding the solids in place while the water is drained away.

Charles Enzian gives the cost of hydraulic mine filling with slush as from 9 to 33 c. per cu. yd. when operating at a rate of at least 400 cu. yd. daily. These costs are based on prices in force during 1911 and 1912 and should be corrected for present-day conditions. They do not include anything for the value of the coal in the slush. When there is a method of utilizing the coal in the slush that will return a greater revenue than the mine coal won by flushing with slush, this method of disposal will cease in all but exceptional cases.

SLUSH SETTLING TANKS

Settling tanks of various types were developed to recover as much of the solids as possible in a relatively dry condition, so that a large tonnage could be stocked on limited areas. Such tanks also enabled the recovery of a crude product for shipment, for which there has been but small demand for certain special uses—mainly in the metallurgical industries.

Intermittent Type

The earliest settling tanks installed work intermittently and consist of a series of hoppers or tanks with gates at the bottom. The slush is delivered into one tank until it is filled with solids and is then diverted into a second, while the solids in the first are discharged from the bottom into cars or a conveyor line by which they are delivered to the bank. These tanks remove solids plus 100 mesh rather completely, if made large enough and given proper attention. The solids recovered contain layers of fireclay and slime, which render them unfit for boiler fuel. One man’s time is required to regulate the flow of slush and to discharge each tank when filled. No power is taken for tank operation, but installations can be made only where the necessary headroom is available. The cost of repairs on these tanks is low as no machinery is employed, but due to the attention required, these tanks have given way to tanks where the operation is continuous.

Bucket Elevator Type

Various arrangements of bucket line, feed, and overflow are used. In some cases buckets with perforated sides are employed while in others a solid bucket is used; but the bucket is slightly tilted after leaving the water in order to decant off the excess water. Unless the bucket line is quite large and is operated at a low speed, only the coarsest solids will be removed. Many of these tanks lose some solids larger than 3/64 in. mesh, while at the same time some solids as fine as 100 mesh are removed. Due to the agitation of the bucket line, little slime and fireclay are found with the recovered solids, which can be used as fuel in properly designed boiler plants. The attention required is confined mostly to lubrication and repairs, but the construction costs are fairly high and repairs to the elevator are difficult and expensive. As the buckets and chain are submerged in the slush for much of the time, wear is heavy. At one colliery, where the water is acid, buckets last about 6 months and the chain a year.

Drag Flight Conveyor Type

A conveyor is installed in a shallow horizontal tank of some length. At the discharge end, the conveyor is carried out of the tank on a pitch that allows some drainage of the removed solids and returns over the top of the tank. The conveyor flight is operated at a speed not greater than 50 ft. per min.; the sectional area of the tank should be such that the speed of the slush through the tank will be the same as the speed of the flight; so that the agitation caused by the flight will be reduced to a minimum. The slush is fed near the tail wheel of the conveyor and the overflow is taken off toward the discharge end.

Some of these tanks make a good recovery of solids. One tank, with the horizontal part of the conveyor 60 ft. in length, using 6 by 18 in. (15 by 45 cm.) flights, spaced 18 in. apart and running 50 ft. per min. in a tank 2 ft. 8 in. inside width, handled 800 gal. per min. of slush through 1/16 in- round mesh, carrying about 13.5 per cent, by weight of solids, and reduced the solids in the overflow to 1.2 per cent., or a 91 per cent, recovery of solids. No data are available as to the size of the solids in overflow and recovered product, but it is probable that practically all solids larger than 200 mesh were recovered. This is the best performance record obtainable and tests were made shortly after the settling tank was first operated. Experience shows that the efficiency decreases after these tanks have been in service some time. The efficiency of this tank falls off if the slush feed is subject to heavy rushes, such as occur when a number of jigs in the breaker are slushed simultaneously.

The coal recovered usually contains all the plus 100-mesh solids in the slush, but it also contains sufficient finer solids to make its utilization uneconomic without further preparation. It is usual to assign one man to the operation of these tanks but he generally has time for additional duties.

The construction costs are moderate; one tank designed to handle 2000 gal. per min. of slush cost $9000, including the cost of pipe line to tank and stocking conveyor for the product. An installation erected during 1920-21, consisting of 8 by 18 in. (20 by 45 cm.) flights spaced 18 in. apart, 120 ft. long center to center of sprockets, in a tank 4 ft. wide by 4 ft. deep by 100 ft. long, with a stacking conveyor 65 ft. center to center on a 6 in. pitch and the same flights spaced 3 ft. apart, cost $10,253.

Repairs on this type of tank cost less than on the bucket elevator type but they amount to a considerable sum where acid water is employed, owing to the wear on chain and flights.

NEW TYPES OF EQUIPMENT

During the past two years several slush recovery plants, containing Dorr thickeners and classifiers, have been installed; they have shown the following advantages:

- Operation can be controlled so as to produce a product of given specification.

- Recovery of over 90 per cent, of the slush solids can be obtained or any lower percentage as desired.

- Maintenance costs are reduced to a minimum.

- Power and attendance costs are extremely low

- Additional equipment can be conveniently included in the plant to remove slate, sand, and other impurities from the recovered coal, giving a product analyzing 15 per cent, ash or less.

The equipment operates continuously and is so designed that no bearings are submerged in the material being treated. Because of the prevalence of acid water, wooden-stave tanks are used for thickeners up to 40 ft. in diameter, while for the larger sizes concrete tanks or tanks with wooden-stave sides and clay bottom built in the ground are used.

The plows rotate so slowly that no swirl or agitation is produced. Sufficient tank area can be provided to cause the settlement of all suspended solids, giving a practically clear overflow. In case only the coarser solids are to be removed, a tank of smaller area is provided, so that the finer solids are carried into the overflow with the water. A thickener operating under this condition is termed a hydroseparator. Rough separations can be made at any desired mesh.

On anthracite slush, the classifiers can be operated to recover a product that is practically all larger than 48 mesh; or any part of the solids between 48 mesh and 200 mesh can be included in the recovered product. Where solids smaller than 200 mesh must be completely recovered, a thickener is required.

Slush treatment is generally practiced to obtain the recovery of fine coal, prevent pollution, or to recover clarified water for breaker use.

In the recovery of fine coal, all the solids are sufficiently low in ash for use at the mines or for shipment; the slimes are too high in ash for present use; or the granular solids also carry so much impurities that removal of them is necessary to produce a useable product.

No installations of Dorr equipment have yet been put in operation in the anthracite fields to meet the first condition, as this condition is but seldom found except in the Lykens Valley district.

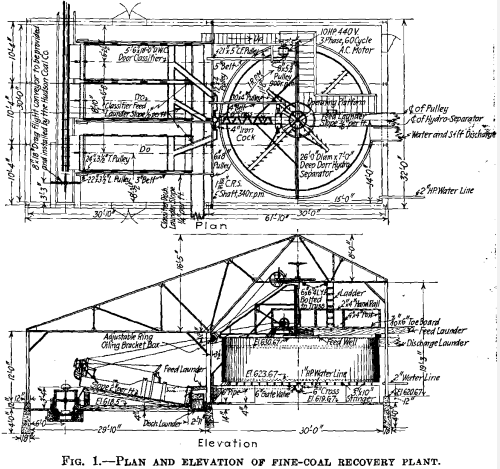

Several plants have been installed to recover the granular coal and more are in course of erection. The first plant of any size for this purpose was installed in the Wyoming field at a breaker producing 5000 to 6000 tons per day, and was designed to recover the solids larger than 60 mesh. A Dorr hydroseparator 26 ft. in diameter by 8 ft. deep and three Dorr classifiers were installed. A plan and an elevation of the installation are shown in Fig. 1. The slush amounts to about 4000 gal. per min., contains about 5 per cent, total solids, and is made through a 3/64-in. round-mesh screen. The plus 60-mesh solids form about 40 per cent. of the total solids, while the solids between 60 and 100 mesh amount to 20 per cent, additional. This installation is recovering the plus 60 mesh coal, with 15 to 20 per cent, undersize and with 40 per cent, moisture. On delivery to the stock pile, the product quickly drains to 18 per cent, moisture. With breaker shipments averaging 5000 tons per day, 200 dry tons per day are recovered from the slush. On a number of days, the breaker has shipped well over 6000 tons without taxing the Dorr equipment. The hydroseparator easily takes care of the material when a number of jigs in the breaker are slushed out. At such times, the slush will amount to 6000 gal. per min. for several minutes.

The plant is operated by one man and a 10-hp. motor. During 2 years of operation, no parts of the hydroseparator or classifiers have required replacement and now show little signs of wear. Total operating costs, including 10 per cent, of plant cost for fixed charges and 10 per cent, for amortization, have been from 9 to 10 c. per dry ton of product.

A slush plant to recover a low-ash granular coal, now being installed in the Wyoming field, consists of a 32 ft. diameter by 8 ft. deep Dorr hydroseparator, eight Deister-Overstrom coal-washing tables, and four Dorr classifiers. It is designed to treat 4000 gal. per min. of slush made through 3/64-in. round-mesh screen and recover the plus 200 mesh coal with an ash content of 15 per cent or less. The breaker ships from 4000 to 5000 tons of coal per day.

The slush will be delivered to the Dorr hydroseparator, where the bulk of the water and solids minus 200 mesh will be separated and discharged to waste in the overflow. All the plus 200 mesh solids will flow by gravity from the bottom of the hydroseparator to a distributing launder for feed to the eight tables. On the tables, the refuse will be removed and the washed coal will flow by gravity with the water used on the tables to four Dorr classifiers, where the coal will be recovered and dewatered. It is expected that about 200 dry tons per day of coal between 3/64-in. mesh and 200 mesh analyzing less than 15 per cent, ash will be recovered.

This equipment is being installed in a separate building of steel construction and, at present, construction costs are not available. The power consumption will amount to about 25 hp. Probably one man, and certainly not more than two, will operate the plant. Operating costs, excluding fixed charges and amortization, should amount to less than 10 c. per ton of product.

Dorr Plants to Prevent Pollution

Plants for prevention of stream pollution may be of various types, depending on the amount and size of solids that must be retained. One plant installed, in 1920, in the Lehigh field consists of a 30 ft. (9 m.) diameter by 7 ft. deep Dorr hydroseparator and two Dorr classifiers. It is recovering the granular solids from 2200 gal. per min. of slush made through a 1/16-in. (1.5 mm.) round-mesh screen. The purpose of the plant is to remove all the solids that would block the stream into which the breaker slush water must discharge.

Prior to the installation of Dorr equipment, two settling tanks of the bucket elevator and drag flight conveyor type had been used in series but the stream could not be kept free of slush solids. After the Dorr plant had been in operation only a few weeks, the stream bed for several miles below the breaker had become freed from the solids already deposited, and after 7 months operation no signs of deposit in the stream are apparent.

The construction cost of this plant is rather high because of the wooden pipe line, transmission line, and substation required.

This plant is operated by two men, who also look after the disposition of the product on the stock pile, to which it is delivered by an 8 by 18-in. conveyor, 120 ft. long. A 15-hp. motor drives the Dorr equipment and a 30-hp. motor the stacking conveyor. Although the slush water comes from the mines and is quite acid, the maintenance costs have been quite low. One casting on the hydroseparator, weighing not over 200 lb., wore out in 4 months and was replaced by a bronze casting; otherwise the equipment shows no signs of wear from the acid water and abrasive action of the solids. It is too early to figure accurate operating costs but operation to date indicate costs, exclusive of fixed charges and amortization, about 7 c. per ton of recovered coal. Based on breaker shipments, the cost of preventing pollution is slightly under 1 c. per ton shipped, if the recovered coal is considered of no value. If the recovered coal is valued at 18 c. per ton, the cost of preventing pollution is paid by the value of the coal.

A Dorr plant of a different type is planned for a breaker in the Schuylkill field; it will probably be erected during the summer of 1921. At this colliery the question of pollution is rather serious and an almost complete removal of solids is necessary. A Dorr thickener 90 ft. in diameter will be installed in a tank with wooden stave sides and clay bottom. The feed will amount to 2200 gal. per min. of slush made through a 1/16-in. round-mesh screen and containing about 320 tons of solids per 8-hr. day. The thickener should remove about 300 tons per day, leaving nothing in the water but the finest slimes. The recovered solids, with about 50 per cent, moisture, will be delivered to a conveyor line installed in a concrete tunnel under the thickener for delivery to the storage pile. The recovery of total solids in the slush will amount to more than 93 per cent.

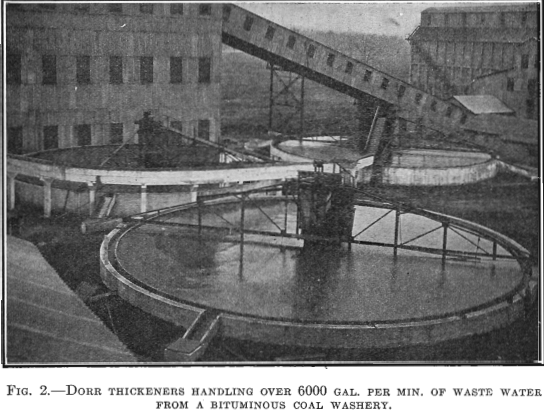

This thickener will produce a clarified water that will be suitable for all washing processes in the breaker. Fig. 2 shows three thickeners installed in the bituminous field for a similar purpose.

UTILIZATION OF FINE COAL RECOVERED FROM BREAKER SLUSH

It is our opinion that all anthracite shipped should, and eventually will be, converted into a form that can be used as a domestic fuel. The gradual exhaustion of the anthracite reserve tonnage and the increased cost of extraction will gradually force the conversion of the buckwheat sizes and the coal now lost in the slush into some form of fuel satisfactory for domestic use. The time will come when practically the only anthracite tonnage used for generation of power will be that required for mine fuel. During the past few years, considerable work has been done toward the utilization of the finer sizes of anthracite. It is the purpose of this paper simply to summarize the accomplishments to date.

Briquetting

Considerable progress has been made in the briquetting of anthracite; in 1920, nine plants were in operation and produced 330,125 short tons. This production was 50 per cent, higher than the output of any previous year. According to reports to the government, the average price received, during 1920, for all briquettes, whether of anthracite or other coals, was $7.50 per short ton.

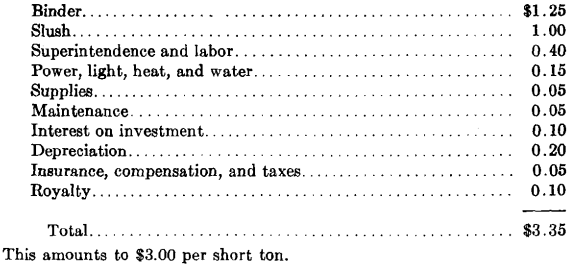

Operating costs, during 1918, for one plant of 50,000 to 75,000 tons annual capacity, using the Dutch oil process, were as follows per gross ton:

As 4,000,000 gross tons of fine coal carrying under 15 per cent, ash can be recovered from slush at an average cost of 30 c. per ton and delivered to the briquetting plant and dried for a total of 75 c. per ton, the above costs indicate an attractive margin of profit, provided a market for the tonnage can be obtained at prices approaching those of stove and chestnut. So far trouble has been experienced in producing an anthracite briquette that in all respects can be substituted for anthracite. The main difficulty has been to produce a briquette that could be fired like anthracite without producing smoke, soot and odor. Conversion of the 4,000,000 tons of recoverable low ash coal in the slush into briquettes would add approximately 9 per cent, to present shipment of domestic anthracite.

Anthracoal

During the last few years, a new fuel has been developed by heating, in a coking oven, a mixture of fine anthracite and coal tar pitch, or similar bituminous materials. This fuel has much the appearance of coke, but greater hardness, density and strength. Its volatile matter averages from 2.5 to 3.0 per cent, and it exhibits all the burning qualities of anthracite. Several carloads have been manufactured, shipped and burned as a domestic fuel with most satisfactory results. Tests made on a semi-commerical scale of operation, show that the cost of manufacture will not exceed that of furnace coke.

As the fine anthracite used as raw material can be cleaned so as to show an ash content less than 15 per cent., anthracoal can easily be produced carrying less ash than average domestic anthracite. As the domestic user is required to make no changes from his method of burning anthracite, one of the most serious marketing obstacles will not arise and prices should be received for anthracoal at least equal to those paid for domestic sizes of anthracite.

Utilization of Fine Coal as a Steam Fuel

Many of the larger anthracite companies have done considerable experimental work in developing the most economic method of burning anthracite smaller than barley size. These experiments have been conducted along the following lines: (1) Hand firing, (2) firing on Coxe stokers, (3) hand and stoker firing with mixtures of bituminous coal, (4) pulverizing and burning in suspension.

Hand Firing.—One of the large companies in the Wyoming field has experimented extensively with hand firing of coal from slush but has abandoned the idea in favor of stoker firing because of the labor problem involved. Stationary grates of the pinhole type and about 4 per cent, space were used.

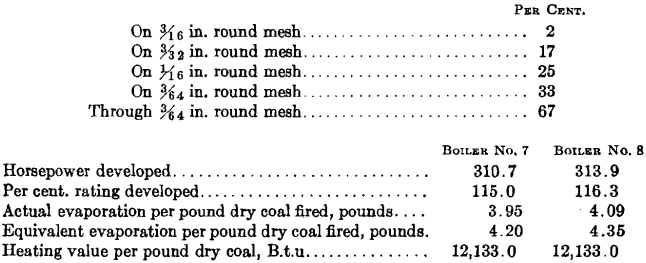

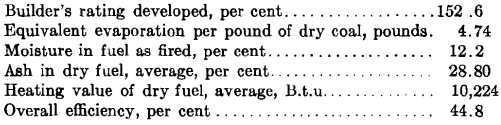

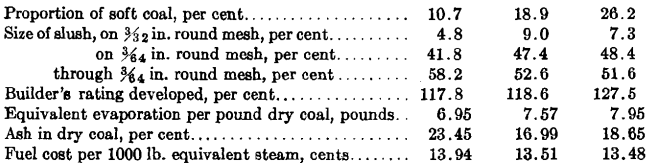

Mixing of coal from slush with barley size reduces the labor problem somewhat and increases the capacity and economy of the boiler. The following tests were run on a mixture of one-third barley and two-thirds coal minus 3/64-in. mesh. The size of fuel fired was as follows:

The results are about 60 per cent, of the performance usual on similar boilers burning barley size hand fired.

Stoker Firing.—A fairly large tonnage of coal finer than barley is used as fuel for Coxe stoker-fired boilers in the Wyoming field. One of the large companies in the field uses coal recovered from slush to the extent of nearly 50 per cent, of its boiler-plant fuel. The character of this slush, which it terms No. 2 barley, is as follows:

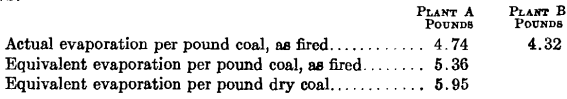

During the year 1920, 394,000 tons of No. 2 barley were used by this company for mine fuel. Two of this company’s plants use No. 2 barley exclusively and their average performance for the year 1920 was as follows:

These boiler plants are operated with ease at 150 per cent, rating for the day period of 8 hours.

This company used but 8.35 per cent, of its total production in 1920 for mine fuel. Coal recovered from slush, No. 2 barley, amounted to 4.10 per cent., leaving a net consumption of commercial sizes for mine fuel of only 4.25 per cent, of total production.

Recently tests were made on Coxe stoker-fired two-drum Sterling boilers using fuel recovered from the slush of a breaker situated in the Wyoming field. The fuel was recovered from the slush by Dorr equipment and ran in size from 3/64-in. round to 100 mesh, or considerably finer in size than No. 2 barley. The results of tests were as follows:

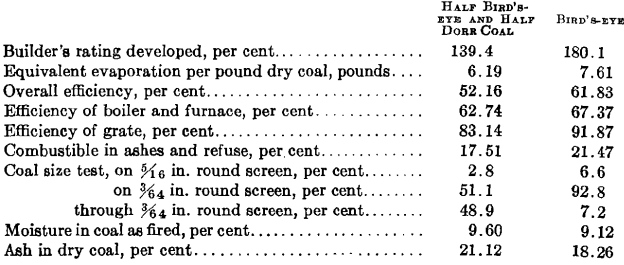

Tests with the same size coal that had been cleaned on a Deister-Overstrom concentrating table to 17.4 per cent, ash, failed as the moisture content was too high for proper combustion. The high moisture can be eliminated when the concentrated coal should show better performance than the high ash coal. The tests on Dorr coal were only preliminary. Tests run during 1918 on a 463-hp. four-drum Sterling boiler equipped with Coxe stoker using bird’s-eye and a mixture of half bird’s-eye and half Dorr coal gave the following results:

The quality of the Dorr coal used in the mixture was as follows:

Slush Coal Mixed with Bituminous Coal,—During the war period large tonnages of anthracite culm and slush were shipped to industrial plants for mixing with soft coal. As the anthracite usually contained considerable refuse and mud and the mixing often was not well done, the best results were not obtained. However, a number of plants operated fairly satisfactorily with this mixture. The following results of tests on hand-fired four-drum Sterling boilers of 400 hp. rating using various mixtures of slush and soft coal were obtained:

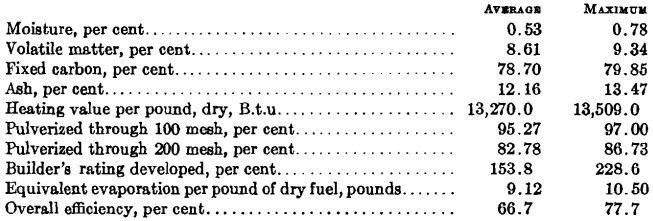

Pulverized Slush.—Burning of slush in a pulverized state has engaged the attention of a number of investigators and at least two of the important anthracite companies have made extended tests on a commercial scale. The most successful work has been done by the Susquehanna Collieries Co., which has been operating two plants—one at Lykens and the other near Minersville—for some time. The installation at Lykens has been quite successful, as shown by the results reported by J. R. Wyllie, Jr.

Mr. Wyllie points out that improvements made while the tests were being run added greatly to the efficiency and capacity obtained so that the maximum results shown are more nearly representative of the results they are now regularly getting.

Lykens slush is peculiarly adapted to burning pulverized because of its high volatile content, low ash, and friable nature. Most anthracite slush, however, carries one-half the volatile matter, is much harder, and, unless purified by concentration, carries over double the ash content. The slush at the Susquehanna’s Lytle colliery, near Minersville, is a good example of the average anthracite slush, and here difficulty was at first experienced. After some experimentation all combustion and boiler- operating difficulties were overcome but the pulverizing problem proved less easy of solution.

Recent operation with a Hardinge mill indicates that the pulverization of anthracite slush has been put on a practical and economical basis. Good capacity has been obtained and power, supplies, and maintenance costs are well within the margin allowable. As an additional improvement in the preparation of the slush for pulverized use, Deister- Overstrom concentrating tables have been installed at Lytle colliery to remove the refuse and so reduce pulverizing costs.

It now can be stated that coal can be recovered from slush, cleaned, dried, pulverized, and delivered to the boiler room at a cost approximating the average selling price of barley coal.

It is estimated that about 12 per cent, of total anthracite production, or approximately 9,500,000 tons, is used yearly for mine fuel. It is probable that the average efficiency of the boilers in use is 50 per cent. With the use of pulverized coal, this efficiency can be raised to 70 per cent., and thus reduce the tonnage of steam coal required to 6,800,000 tons annually. Nearly two-thirds of this tonnage, or 4,000,000 tons, can be recovered from slush so that a total annual saving of 6,700,000 tons is possible. The coal saved would be mostly barley and rice sizes and would have an average value of about $1.75 per ton. making the money saving over $10,000,000 annually. With the return of normal industrial conditions and because of the better demand for rice and barley sizes that have been concentrated to a uniformly low ash content, little difficulty should be experienced in selling this extra tonnage of steam sizes.

https://www.youtube.com/watch?v=Jo9qxONgd4s

https://www.youtube.com/watch?v=ylkdUuNOJzw