Table of Contents

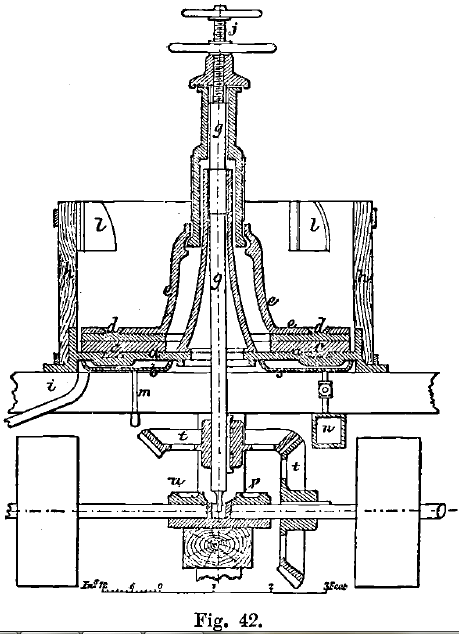

An amalgamation pan consists of a circular cast-iron pan, provided on the inside with a renewable false bottom of cast-iron—constituting the lower grinding surface—and a “muller,” of upper grinding surface (d, Fig. 42), attached to a vertical revolving spindle, g, which is set in motion by bevel wheels, t, placed below the pan. The muller grinds to impalpable pulp ore which has been already reduced to a coarse powder by stamps, and also mixes the ore with mercury, introduced into the bottom of the pan, and so amalgamates the gold and silver. The origin of the pan is probably to be traced to the Mexican arrastra, and some of the varieties of the pan are merely slightly modified arrastras. One variety consists of a sectional wrought-iron pan fitted with a granite grinding bottom and with granite mullers, which are attached to a vertical spindle rotated by hand or by animal power.

In work on gold ores the use of amalgamating pans was formerly mainly limited to regrinding skimmings, blanket sands, and concentrates obtained in working a stamp mill. Pans are now largely used at Kalgoorlie in grinding roasted sulpho-telluride ore. In this case some gold is amalgamated, but the main object of the pans is to prepare the ore for cyaniding.

Silver ores are often crushed in a battery, roasted with salt if necessary, and then amalgamated in pans. Silver ores containing considerable quantities of gold are often similarly treated, but with purely gold ores it is seldom necessary to resort to this process, and only a brief account is given below.

Gold ores which do not yield a fair percentage of their values when run over amalgamated plates are occasionally treated in pans. In such cases the ore may be roasted or treated raw. As already stated (p. 148) it is seldom advantageous to roast a gold ore before amalgamation, since, although in a roasted pyritic ore specks of free gold may often be detected where none were visible in the raw ore, a part of the precious metal usually appears after roasting to be difficult to bring in contact with mercury. The cause of this is not always easy to discover, but it may sometimes be due to the coating of gold by thin films of iron oxide or other mineral. Moreover, the addition of salt to a gold ore in the roasting furnace, as is pointed out in the chapter on chlorination, is often attended by appreciable losses by volatilisation. These two causes are sufficient to account for the low percentage of gold usually extracted when an auriferous silver ore is treated by roasting with salt and pan amalgamation. Under exceptional circumstances a gold ore may prove to be satisfactorily handled by roasting and amalgamation.

Pan-amalgamation, whether the ores treated are raw or roasted, may be conducted in one of two ways. The older system is to crush wet in the stamp mill, and collect the ore in large shallow settling pits or pointed boxes (see p. 172). A sufficiently dry pulp having been obtained by draining, it is dug out by hand and charged into the pans.

The amalgamating pans in use are very numerous, and vary greatly in form. The shape of the bottom was formerly much in dispute, flat, cone-shaped, and hemispherical bottoms each having its advocates, but it is now generally believed that flat-bottomed pans are the best, wearing more evenly and doing more work. The pans are often heated, so as to increase the rate of amalgamation, by means of steam led through a chamber below a false bottom in the pan, but the more economical device of introducing steam into the pulp itself has also at all times been in use. The objections to the latter course are that the pulp may be so much diluted that amalgamation is checked, and that oil is liable to be introduced with the steam with equally disastrous results. When the ore is roasted before being treated in the pan, it is in some mills charged in hot, hot water being added also, and as the pan is covered up and is still warm from the previous charge, it remains at a sufficiently high temperature throughout the operation without further treatment. The grinding of the ore by the muller is an additional source of heat.

One of the common forms of amalgamating pans is shown in Fig. 42. This pan is 5 feet in diameter, with cast-iron bottom, a, and wooden sides, h. The mullers are shown resting on the cast- iron dies, c, which protect the bottom from wear, whilst replaceable shoes attached to the lower surface of the mullers are also shown. The shoes and dies can be kept in contact while the spindle, g, is rotated, so that the ore can be ground, or the muller can be raised by rotating the hand-wheel and centre screw, j, on the top of the spindle, so that only circulation and mixing of the charge take place. In some pans copper plates, l, are introduced, being attached to the side walls and projecting into the interior. These plates are intended both to mix the pulp and to catch the amalgam, much of which is retained on them. The more usual system is to employ separate vessels called settlers for the collection of the quicksilver and amalgam, after the pans are discharged. The speed of the muller is usually from 65 to 75 revolutions per minute; below the muller the pulp is continually worked from the centre of the pan to the circumference, being returned towards the centre above the muller and passing down through the latter by inclined slots which terminate near the centre. In Fig. 42, which represents the form known as the Patton pan, n is the main through which steam is passed into the chamber, b, to heat the pulp, and m is the outlet pipe.

Amalgamation Pans Operating Principle

The charge of ore is introduced with the mullers raised slightly and kept revolving, water being added at the same time in quantities sufficient to make the pulp of a pasty consistency, so that globules of mercury remain suspended in it without subsiding. The mullers are then lowered and the ore ground for from two to four hours, after which the mullers are raised and the mercury added gradually, and thoroughly mixed with the pulp for six to eight hours longer. The object in raising the mullers is to prevent the sulphides from being ground up with mercury, which would cause considerable losses by flouring and sickening. Nevertheless this raising of the mullers is not an invariable practice. When the,amalgamation is thought to be complete, water is introduced to dilute the pulp, and the whole is discharged into a settler; or else the diluted pulp is stirred by the raised muller at a reduced rate of speed until the globules of mercury have re-united and sunk to the bottom, when the pulp is gradually run off, beginning at the top, usually by pulling out in succession plugs set, in the side of the pan at different levels. The discharge takes place into a bucket or tub, where some of the mercury accidentally carried over is caught. The bulk of the mercury in some mills is drawn off from the bottom of the pan before the pulp is discharged.

In order to facilitate amalgamation various chemicals have been recommended as desirable additions to the charge. At the present day it is recognised that most of these are either useless or absolutely harmful, and only salt, sulphate of copper, nitre, cyanide of potassium, lime, and sodium amalgam are now used. In treating gold ores, cyanide of potassium and sodium amalgam are added to keep the mercury clean and lively, but the latter chemical is now comparatively rarely resorted to. Salt and sulphate of copper are chiefly added to silver ores, their use having been suggested by the Patio process. They are believed to decompose certain base minerals, and so to prevent the sickening of mercury, which would otherwise be caused by their presence, and also to liberate silver from some of its compounds and thus render it capable of amalgamation. The use of lime is of course to neutralise any acid sulphates of iron, &c., which may be formed by the partial decomposition of the ore, and so to prevent the sickening of the mercury. If added when the pulp is diluted, lime is said to be efficacious in assisting the mercury to collect together and settle.

Boss Continuous System

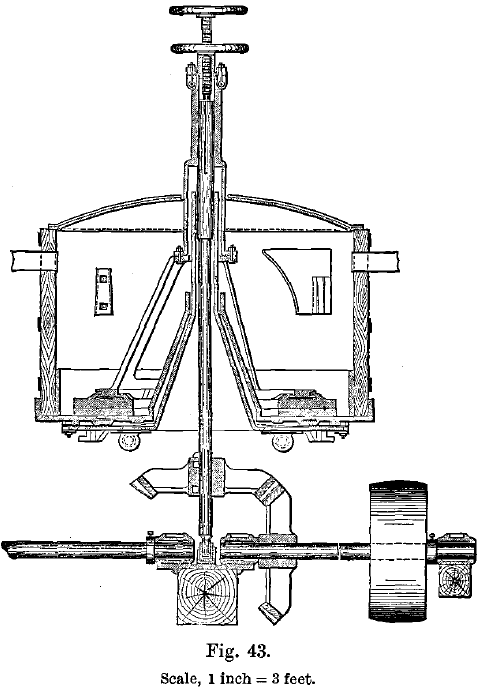

In this system of pan-amalgamation the pulp is continuously run direct from the stamp battery through a series of pans arranged so that each overflows into the next one, which is placed at a slightly lower level. The first two or three pans are arranged as grinders, the battery pulp not being fine enough for complete amalgamation, and the pulp is then passed through a series of amalgamating-pans supplied with mercury, after which the mercury and amalgam are separated from the ore in settlers, which are larger pans in which the pulp is diluted and stirred less vigorously. The tailings overflow from the settlers, and are run to waste or led over concentrators. The number of pans arranged in series through which the pulp must pass, in order to yield a fair percentage of its precious metals, is determined by experiment for each particular ore. It is obvious that the consistency of the pulp must be thinner than has usually been considered desirable for successful amalgamation, and, as a matter of fact, its volume is usually doubled by the introduction of the continuous process, but in spite of this the percentage of extraction is not lower than by the old method. By the Boss system there is a large saving in labour, fuel, and in wear and tear; the settling pits or pointed boxes are dispensed with, and no movement of the pulp by hand is needed. The mercury is collected in wells and pumped up into tanks, whence it is fed automatically into the amalgamating pans. One of the pans in use in this process is the Boss Standard Pan, shown in Fig. 43. It will be noticed that there is a steam chamber below the false bottom of the pan, extending up into the conical space in the centre, for warming the pulp.

Treatment of Concentrates in the Pan

The treatment of concentrates by pan-amalgamation is a survival of old methods, and does not represent the most modern practice, in which concentrates are either smelted or treated by wet methods. Whether they have been previously roasted or not, the treatment of concentrates in pans is seldom attended by the successful extraction of a high percentage of the gold. A stone arrastra usually gives better results in treating roasted concentrates than an iron pan. In Australia the method is often adopted of employing a large excess of mercury and little water, and of keeping the roasted material from contact with iron, and in some experiments conducted in Mexico, C. A. Stetefeldt found that by the use of gold amalgam instead of mercury, and by grinding in stone vessels, a high percentage of gold was extracted from low grade ores.

Among special forms of pans designed to treat concentrates are the Berdan pan and the Britten pan, which were both introduced about fifty years ago.

The Berdan pan is a shallow annular basin about 4 feet in diameter, surrounding a cone which is attached to a spindle set at an angle of about 15° to the vertical. The spindle is rotated by bevel gearing at 20 to 30 revolutions per minute, and carries the basin round with it. In the annular basin are one or two loose iron balls which remain at the lower side of the cone when the pan revolves. The pulp is fed in with mercury at the higher side, and is ground by the balls and discharged over the lower edge of the pan. The capacity of the Berdan pan is from 1 to 2½ tons per day. It is used chiefly in Australia.

The Britten pan is a deeper cast-iron stationary basin almost hemispherical in shape, in which a pear-shaped muller rolls round. It is used for grinding and amalgamating rich specimen ore and concentrates in Wales. It is of small capacity, and is not a continuous machine like the Berdan pan, but grinds the charge put into it as long as is desired.