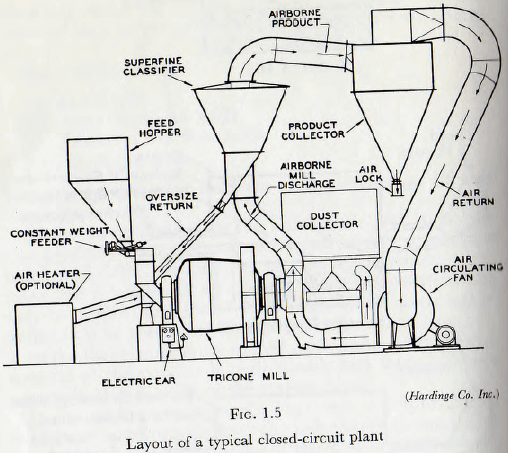

In an air-swept mill, the body of which does not differ significantly in general design from a trunnion overflow mill, a powerful stream of air is passed through the mill and removes the finer particles produced by the grinding process. This stream of powder-laden air is then passed through the classifier and the “oversize” material, rejected by the classifier, is returned to the mill with sufficient feed material to maintain the charge at the working level. The layout of such a closed-circuit plant is shown in Fig. 1.5.

The grinding in a batch mill, a grate discharge mill or trunnion overflow mill may be performed either “wet” or “dry” , but clearly in an “air-swept” mill the grinding must be carried out in the dry state.

In “wet” grinding the material to be ground is fed to the mill in the form of a “pulp” containing, perhaps, 50% by weight of water. In dry grinding, however, the granular material is fed into the mill in a sensibly dry condition; the only moisture present being the few percent normally held by the powder. Both the grate mill and the trunnion overflow mill may be operated in either of two distinct ways, known respectively as “open-circuit” operation and “closed-circuit” operation, and, furthermore, either of these methods of operation may be worked either “wet” or “dry”.

In open-circuit grinding the mill product is not subject to any classification, other than that which occurs within the mill by reason of selective grinding of the larger particles, and no part of it is returned to the mill for further treatment. In closed-circuit grinding, however, the product of the mill is conveyed to some form of classifier, and the material coarser than the required maximum size is returned to the mill feed; sufficient new feed material being added to maintain the charge within the mill at the operating level. For wet grinding a hydraulic classifier is used whilst for dry grinding an air separator, normally of the cyclone type, is necessary.

The “air-swept” method of operation of a mill eliminates the conveyor system which was often used in earlier types of plant to transport the product to the classifier and the oversize material from the classifier back to the mill.

It is clear, however, that such a system can only be used successfully when the material undergoing treatment is sufficiently light, and the particles produced are sufficiently small, for the desired final product to be entrained in the air stream. Furthermore, the removal of the powder from the air stream, or its utilization whilst suspended in the stream must be practicable and, for these reasons, a typical application of systems of this type is in connection with the grinding of coal for pulverized fuel firing, since, in this case, the fuel may be burnt directly in the air stream which carries it.

Related: Best Air Compressors for Home Garage