Table of Contents

Air-sparged hydrocyclone (ASH) flotation is one of the new promising technologies. Numerous applications have been successfully tested since its conception; nevertheless, research and development efforts have continued to provide for further improvements with respect to operating conditions and design considerations.

Bubble size is always of interest in the analysis of flotation separations. Many researchers believe that bubble size is a critical factor which controls the rate of flotation and the efficiency of separation. During ASH flotation, air is sparged through the porous tube wall and is sheared into numerous small bubbles by the high-velocity swirl flow of the slurry. In this regard, measurement of the size of the bubbles during ASH flotation is rather difficult.

Experimental

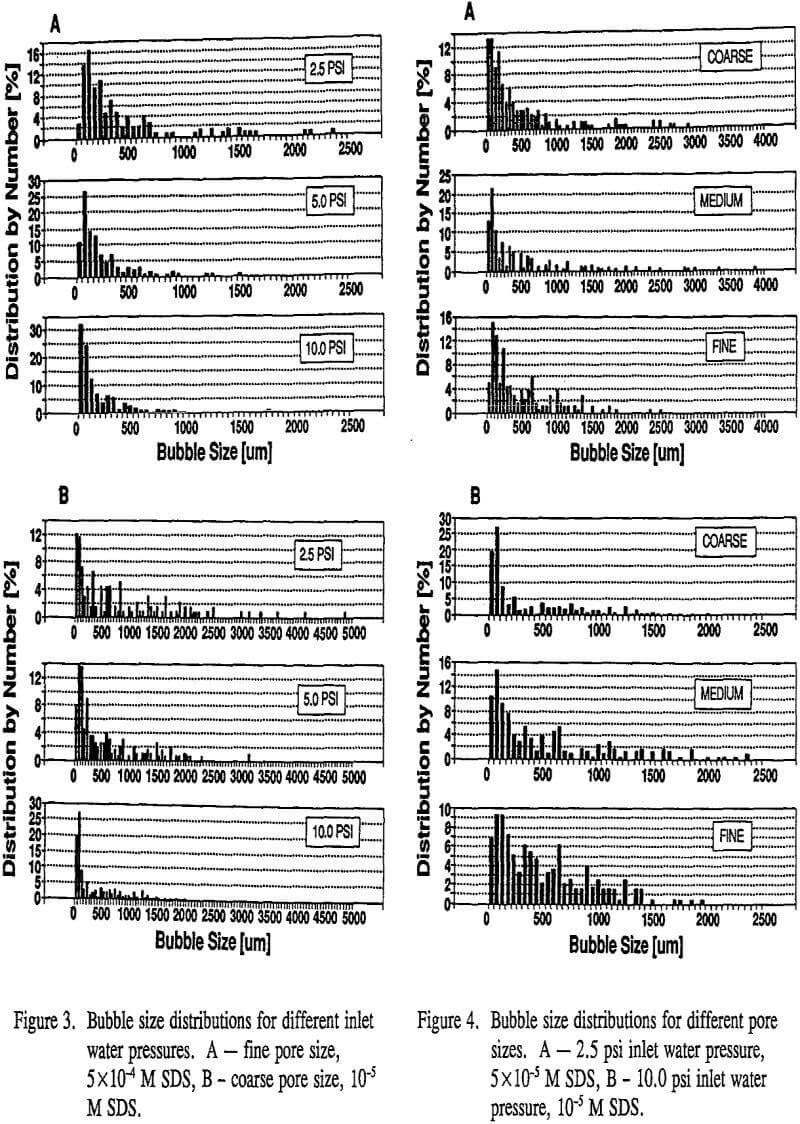

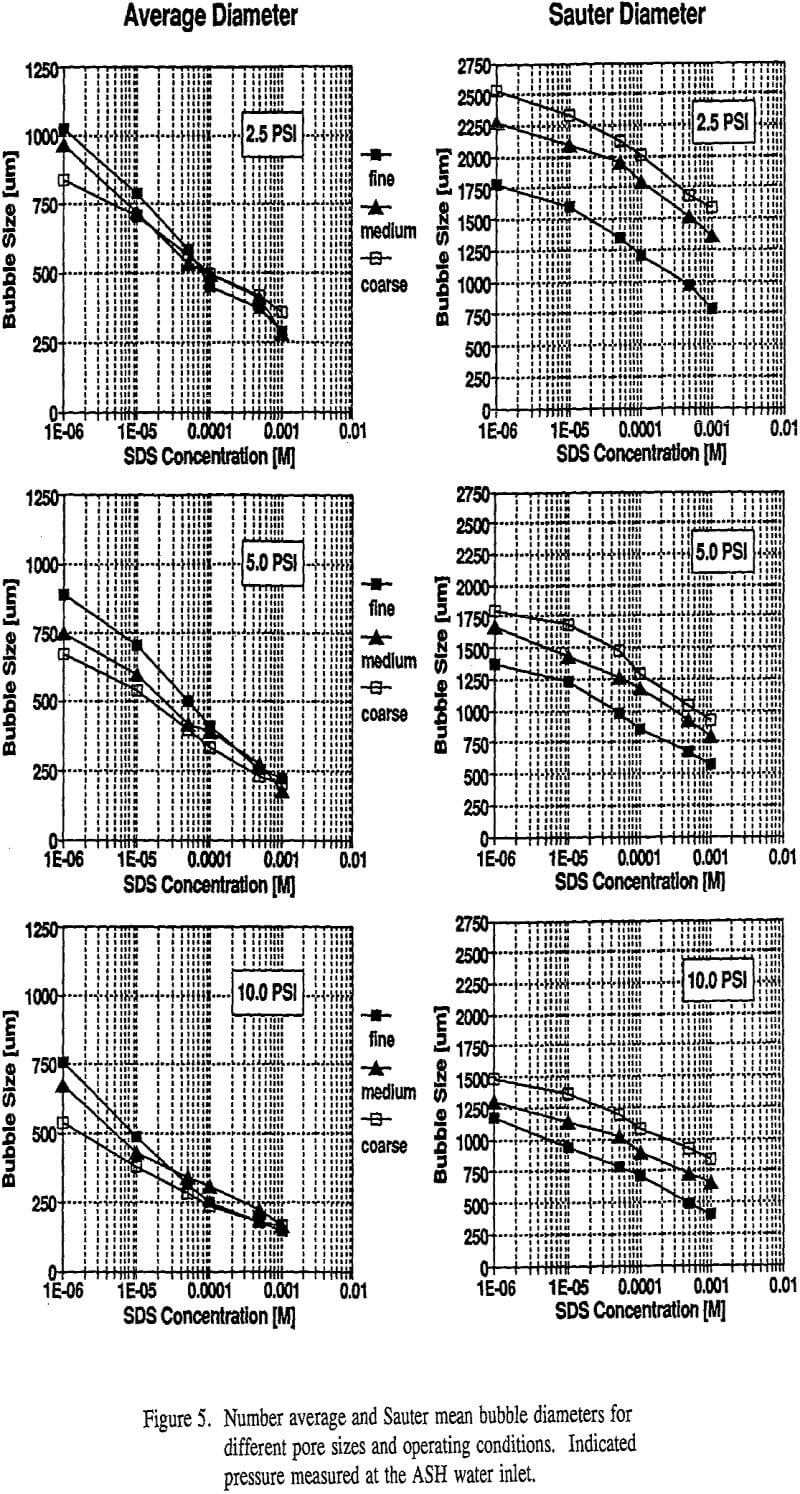

In most of the available literature a major emphasis has been placed on the necessity of counting a large number of bubbles in order to get a meaningful size distribution. Actually, however, statistically significant counts can be made with as few as 300 bubbles.

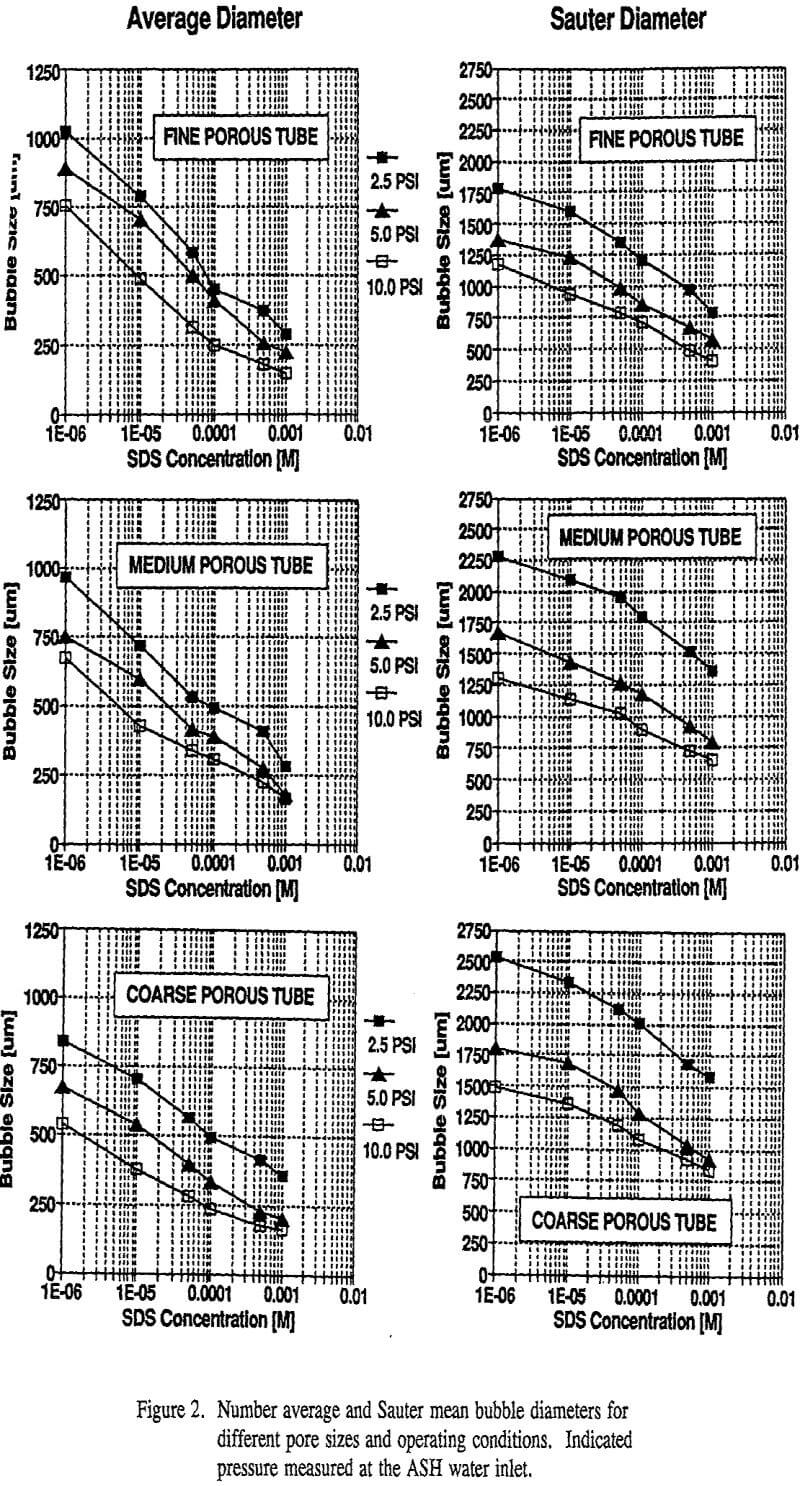

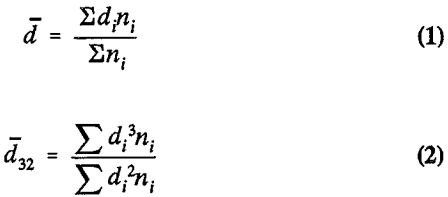

For discussion of bubble size distribution data, it is useful to consider the average size of each distribution. In this study two different average values were used:

Equation 1 provides a simple arithmetic mean by number, while equation 2 yields mean volume-surface diameter (often called Sauter diameter).

Results and Discussion

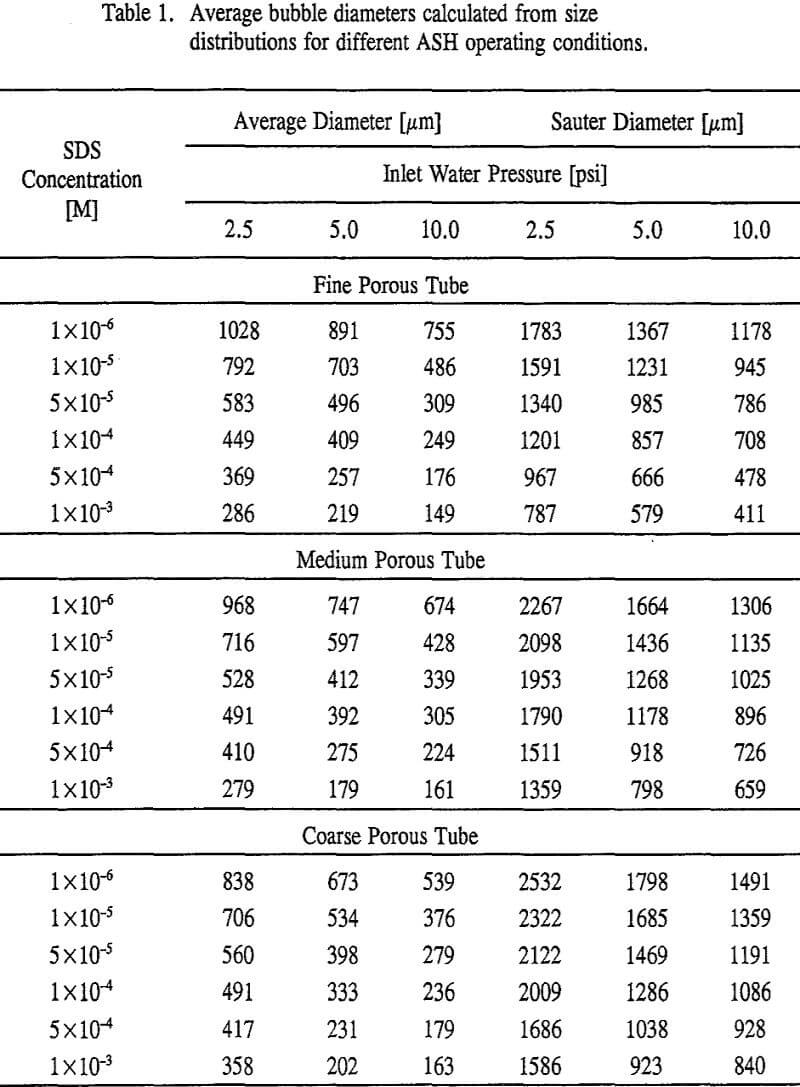

All average diameters were calculated from measured bubble size distributions and are presented in Table 1.

Surfactant Concentration

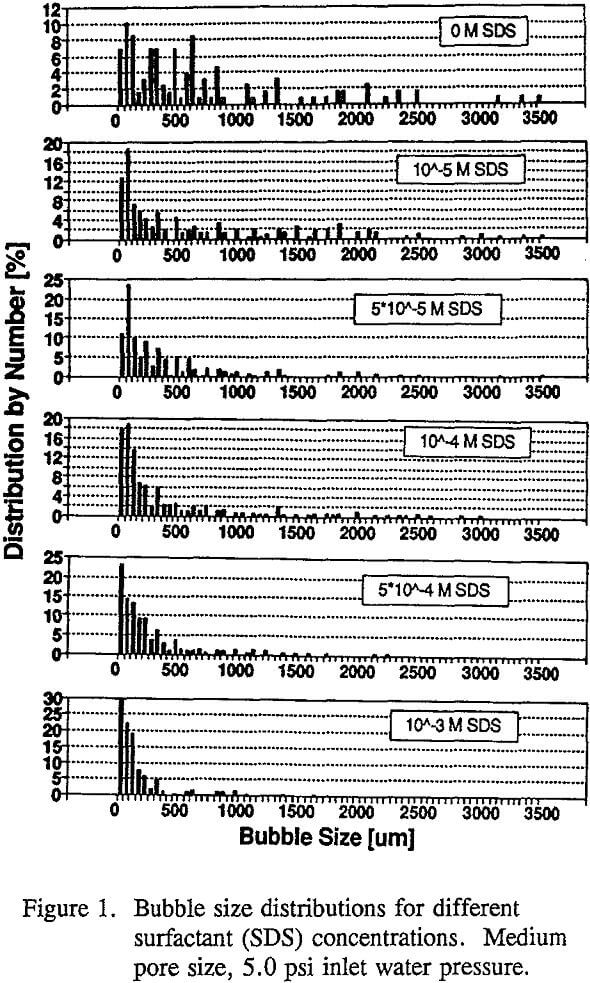

Large bubbles inside the ASH system are probably due to the coalescence of bubbles generated from adjacent pores. On the other hand, fine bubbles are those nascent bubbles which are not subjected to the above coalescence. In addition, coalescence of two or more bubbles can also result in the formation of some fine bubbles. Such fine bubbles are sometimes termed satellite bubbles, due to their close proximity to coarser bubbles.

Shear Force

At higher inlet pressures and higher surfactant concentrations the bubble size becomes less dependent on shear force. From one perspective this might be attributed to the fact that with smaller bubbles the thickness of the effective hydrodynamic boundary layer for the swirl flow is no longer of any significance. In the absence of surfactant the bubble size is sufficiently large that the bubble extends beyond the effective boundary layer into the shear flow.

Pore size

The role of pore size in establishing bubble size distribution is more complex in comparison with the other process variables examined. Some of the complexity can be explained by comparing calculated number average and Sauter mean diameters.