Compressed air in a mill is very desirable. It is used in cyanide agitators and solution tanks for supplying excess air required for efficient dissolving of gold values, air agitation of liquids, for elevating pulps by means of an airlift, agitation of pulps in filters, cleaning machinery, operating air hoists, forges, reciprocating and rotary air tools, spraying paint, transferring corrosive liquids, starting diesel engines, pinning of centrifugal pumps with suction lift, and many other applications. Compressed air has many useful applications in a mine: for operating jack-hammers, stope-hammers, mine-car loaders, jacks, scraper hoists, tugger hoists, air motors, core drills, furnace, etc.

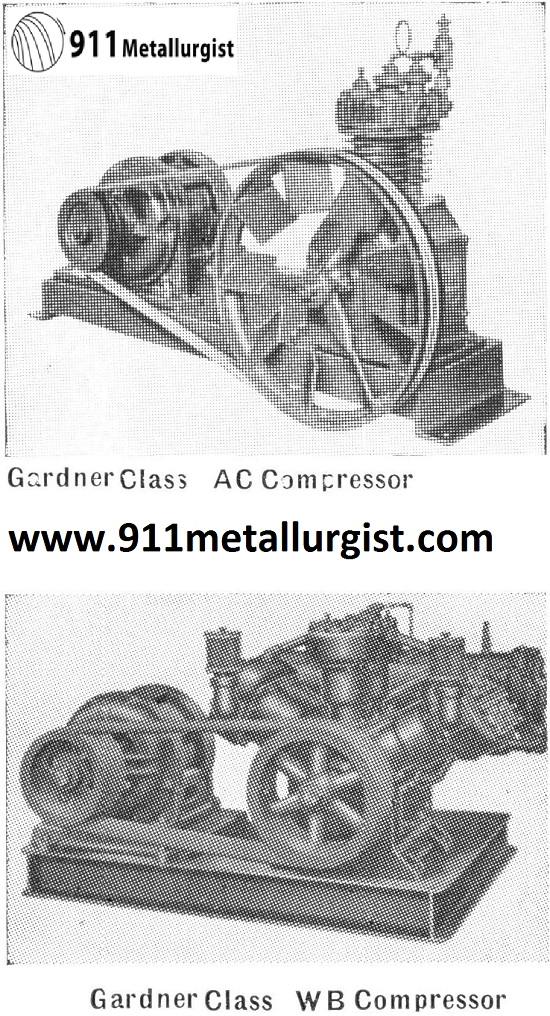

The Gardner Compressor may be obtained with piston displacements up to 1545 cubic feet per minute. Only two of the most representative sizes are described and tabulated in the next column.

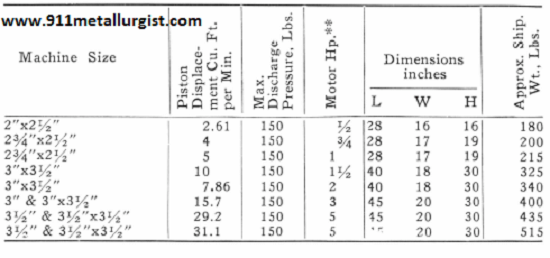

The Class “AC” Compressor is a single-stage air-cooled compressor, with one or two vertical and replaceable cylinders. The main bearings are the roller type. The steel crankshaft is drop forging. The bronze connecting rod is of substantial ‘I’-Section. Piston is light-weight automotive type fitted with snap rings. Air valves are plate type. Hand unloader for starting is furnished as standard equipment. The table in next column give dimensions and shipping weights on the compressor, motor, V-belt drives and a common base plate. Compressors can also be obtained mounted on a receiver tank, with motor or gasoline engine drive.

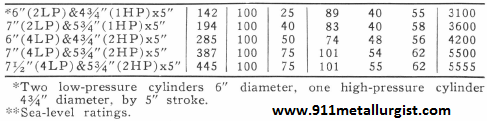

The Class “WB” Compressors are of the two-stage water- cooled type. Three-cylinder compressors have two low- pressure and one high-pressure cylinder; six-cylinder machines have four low-pressure and two high-pressure cylinders. Intercooler is of the shell type with nested tube and baffle assembly. Forced-feed pressure system is used to lubricate the crank pin bearings, while the roller main bearings, pistons and cylinder walls are lubricated by the oil spray from the crank pins. Crankshaft is chrome- nickel-molybdenum alloy. Connecting rods are heat-treated, drop forged steel. Pistons are light-weight automotive type with three compression rings and one oil ring, valves are of the “cushioned” noiseless automatic plate type. Unloading is automatic and is accomplished by the use of suction valve unloaders on all cylinders. The table below gives the overall dimensions and shipping weight of the motor-V-belt driven compressors mounted on structural steel base. Other types of drives can be obtained such as gasoline or diesel- V-belt drive, direct-motor with flexible coupling drive, and motor built integral with compressor frame.

GARDNER CLASS AC AIR-COOLED COMPRESSORS

GARDNER CLASS WB WATER-COOLED COMPRESSORS

Air Compressor

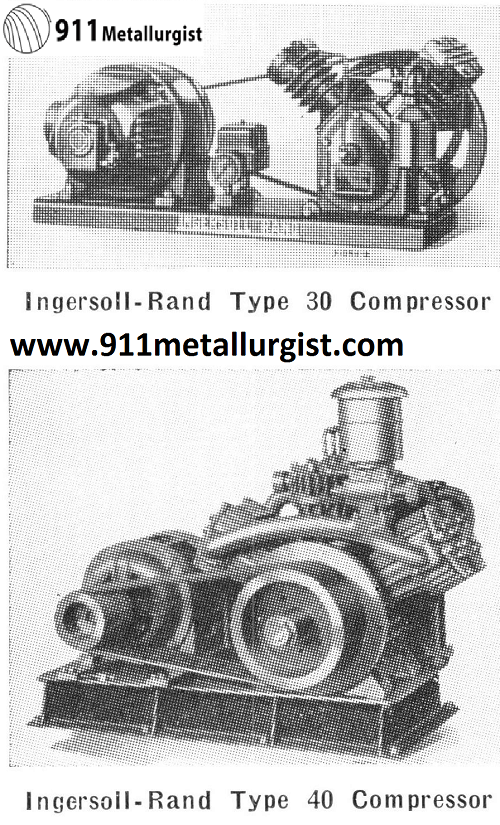

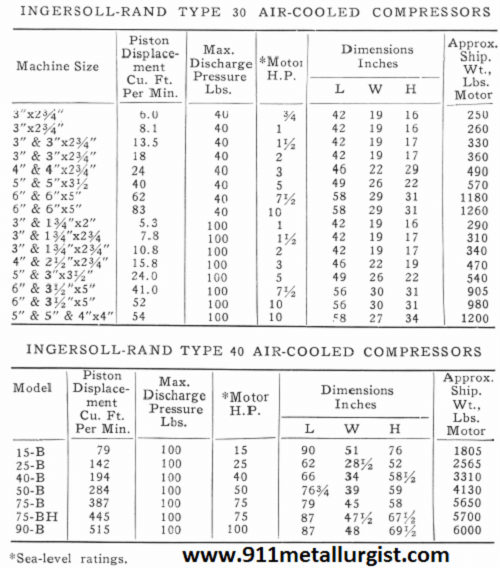

These compressors can be obtained in various sizes up to 3000 Hp., and for operation with various drives such as electric motors, gasoline engines, diesel engines, and steam engines. Only two of the representative types are described herein and listed in the tables on next page.

The Type 30 Ingersoll-Rand Compressor meets the specifications where a small compressor is required. The construction is with “V” type air- cooled cylinders and heads, finned intercooler on two- stage compressors, stainless steel finger valves, ball bearings on crankshaft, splash oiling, centrifugal governor, air filter and muffler, and crank case breather. The drive is by V-belts from an electric motor or a gasoline engine. Either base-plate or receiver-mounted units can be obtained. Automatic start- and-stop control is included on motor-driven compressors.

The Type 40 Ingersoll-Rand Compressor is a stationary, vertical, single-acting, two-stage machine with air-cooled cylinders and intercooler. Construction is with tapered roller bearings on the main shaft, “constant-level” oiling system which insures uniform lubrication regardless of the crankcase oil level, stainless steel valve channels and springs, replaceable intercooler sections, propeller type fan mounted on crankshaft, automatic unloader, and combined air-intake filter and silencer. Any type of motor, gasoline engine, or diesel engine can be used to drive the compressor at rated speed by means of V-belts employing the proper pulley ratio. Compressors can be obtained with the motor direct-connected to the compressor by a flexible coupling. The most compact drive is the “Motorcompressor in which the motor rotor is mounted directly on the compressor crankshaft, and the motor frame is bolted to the compressor crankcase, eliminating a flexible coupling and a common sub-base under the motor and compressor. When air is needed only at intervals, or an entirely automatic unit is desired, automatic “start-and-stop” control is recommended. The table below lists the various sizes of Type 40 Compressors with motor-V-belt drives.