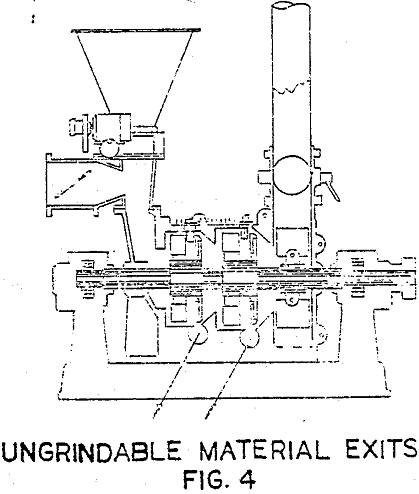

Regardless of the mechanical design features of a particular air classifier certain basic principles apply. Specifically, there are two forces at work:

- An air drag force

- An inertial or centrifugal force.

The air drag force has an increasing influence as particles become smaller. A very small low mass particle is easily carried along with an air stream even when turning a corner. Thus, fine particles follow the air away from the classifying zone.

The ideal method of operating an air classifier would be to feed one particle at a time into the system to avoid collisions and interference. Naturally, practical operation involves a substantial cloud of material in the classification zone at all times. This does result in some loss of sharpness because of two factors: (1) coarse particles can collide with fines and carry them along to the oversize outlet and (2) particle collisions can cause an occasional large particle to bounce through into the fines recovery system.

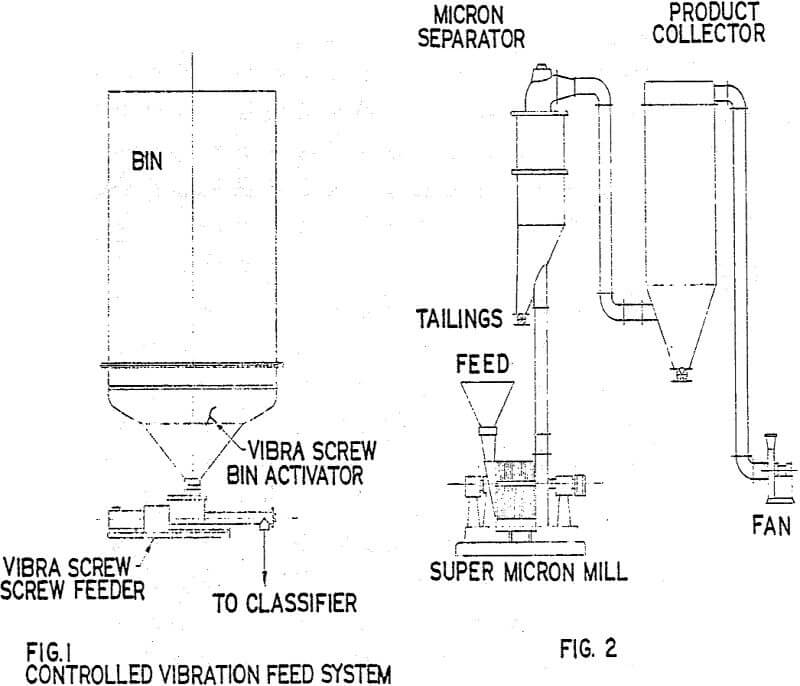

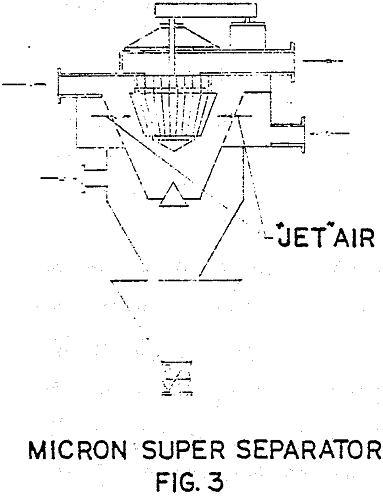

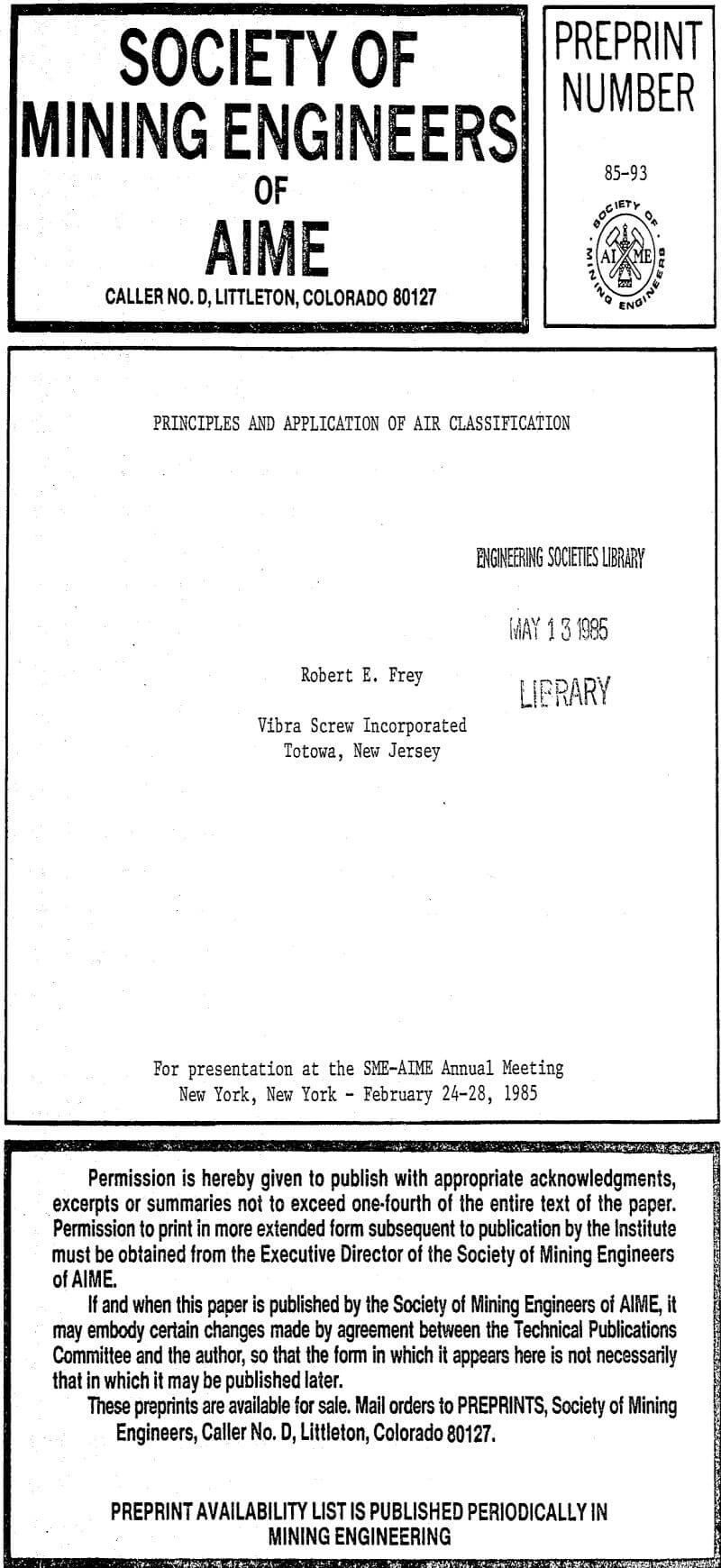

When an air classifier is used in a milling curcuit care must be taken to avoid overload in the event of increasing recirculating load. The pulverizer and the separator are both subject to overloading unless the feed system is adjusted to compensate for recirculation. This can become more difficult if a percentage of “ungrindable” material exists in the feed. Extraction of “ungrindable” material is possible in many cases, such as the technique of using extraction screws.

Related: Best Garage Air Compressors