Beneficiation of the manganese oxide ores at Three Kids Mine near Henderson, Nev., has evolved over a period of years. Commercial application of the process is on a secure basis, and an effective working hypothesis has been formulated to help solve the problems encountered in flotation.

Ore Characteristics: Manganeses in the Three Kids ore occurs as a complex mixture of manganese oxides commonly known as wad. The manganese minerals have been identified as psilomelane, hollandite, coronadite, and, pyrolusite with minor amounts of rhodonite and rhodochrosite. The principal gangue minerals are quartz, opal, kaolinite montmorillonite, calcite, gypsum, celestite, and barite.

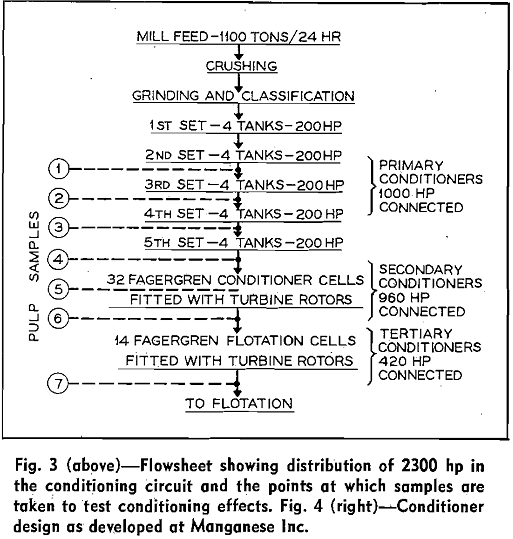

At Henderson the ore is crushed to —1 in. and ground with rod mills in a closed circuit with spiral rake classifiers and cyclones. Sulfur dioxide solution is added to the pulp as it leaves the grinding circuit, immediately followed by addition of a reagent mixture of soap, oil, and wetting agent in the form of an emulsion.

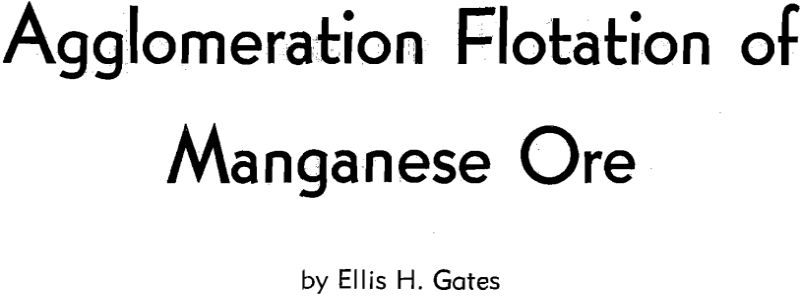

After conditioning, the pulp passes to a flotation circuit that consists of one roughing stage, a scavenging stage, and four cleaning stages. The manganese is recovered by filtration as a finely granulated concentrate of agglomerated manganese mineral particles which is sintered and nodulized for shipment in the subsequent kiln operation.

In the agglomeration flotation process the first reagent added is sulfur dioxide, which reacts with the ore minerals to form manganese ions in the pulp. It is assumed that these ions are adsorbed on the manganese minerals, forming active surfaces for reaction with the soap component of the emulsion. The role that hydrogen ion concentration plays in this activation mechanism is not yet well defined. Manganese minerals have been activated and floated over wide pH ranges under various test conditions. The emulsion, which is added after the sulfur dioxide, is composed of tall oil soap skimmings, petroleum oil, a petroleum sulfonate wetting agent, and water.

Mechanical energy is then applied to the pulp by vigorous agitation in conditioning tanks. The absorption of this energy by the pulp induces a random motion to the suspended oil-filmed manganese particles which apparently allows these particles to collide with others, and dense agglomerate particles are built by fusion of the oil films. In addition to the possible formation of manganese agglomerates by impact, the reagents used also produce a tendency for manganese flocculation to take place. This alone does not produce a clean, well mineralized froth, but the kneading action of these low density, weakly bonded flocs appears to consolidate them into dense agglomerates that make possible the heavy granular froth loads required for effective flotation.

According to the proposed explanation of the phenomenon of manganese mineral activation, manganese ions in the pulp solution are directly responsible. Sulfur dioxide is a convenient way to introduce these ions into a pulp by taking manganese oxides into solution. A chemical equivalent amount of manganese sulfate will serve as an activator almost as well. Other heavy metal ions such as copper, iron, and lead also act as activators with varying degrees of effectiveness.

Since the higher amount of conditioning required by some of the ores would have been impractical, a compromise was made by blending these with ores requiring less conditioning so that acceptable flotation could be obtained with the facilities available. This blend insured a well mineralized froth and good

A correlation of conditioning time in the laboratory cell with work input in full-scale equipment was made by comparing the laboratory results with those obtained using a 6-ft diam batch conditioning tank holding 50 cu ft of mill pulp. This tank was equipped with baffles, a 30-hp motor, V-belt drive, and shaft upon which variously designed turbine- type impellers could be tested. To extend the test data, the motor was operated at overload from 30 to 50 hp as calculated from ampere and voltage readings. The drive was fitted with turbine impellers of widely varying diameters but proportioned to transmit the required power to the pulp.