Table of Contents

The secret to accident prediction is to utilize the tendency for history to repeat itself. The same circumstances and the same human behavior that produced accidents in the past tend to produce accidents in the present and the future. The ability to predict accident occurrence in the future by projecting from the past is a statistical process. In a bookmaker’s jargon this means “playing the odds” or “the percentages”. A horse or a sports team may be beaten on any given day, but by skillfully assessing the factors of past performance and assigning odds, many clever bettors make money in the long run.

The Potential Accident Situation – The PAS

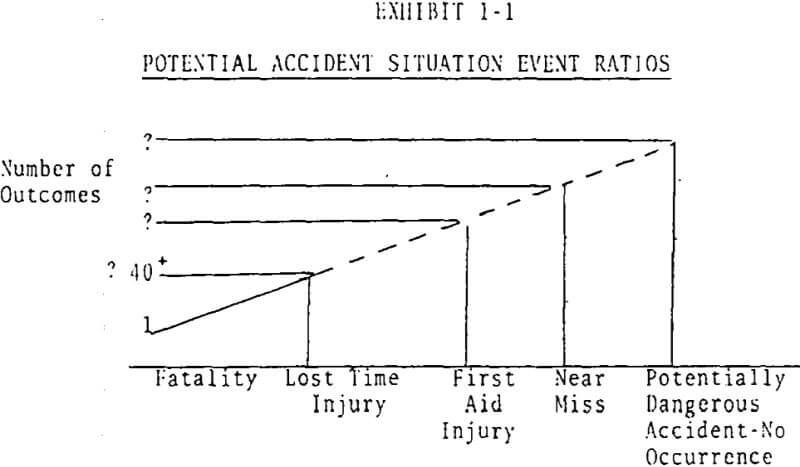

Every underground mine has associated with it a set of potentially important hazardous conditions such as a mine floor with a high degree of incline, coal that liberates substantial amounts of methane, a roof with a “brittle top,” equipment with an inherently high accident history, etc. In a similar fashion, there exists a set of behavorial acts which describe the movements and actions of the miners on the job. Included in this set would be activities such as walking out under unsupported roof, setting timbers, or operating a machine. Every Potential Accident Situation has associated with it a set of possible outcomes. Listed in descending order of severity, they are:

- Fatality: results in the subsequent death of the accident victim

- Lost Time Injury: prohibits the injured person from performing efficiently the work of a regularly established job, which is open and available to him, throughout a full shift.

- First Aid Injury: permits the injured worker to perform effectively throughout a full shift in a regularly established job.

- Near-Miss: involves a potential injury – producing occurrence, which does not result in bodily injury. (For example, a roof fall that occurs near the work place or in the work place while miner was eating lunch.)

Potentially Dangerous Incident.

The circumstances surrounding many accidents are sometimes so obscure or so unusual that they seem almost like acts of God. However the circumstances of most mining accidents are all too commonplace and the ability to predict and prevent most accidents is not difficult but it is hard work.

During the field visits of the safety studies conducted by Theodore Barry and Associates for the U.S. Bureau of Mines, numerous safety directors or safety inspectors of underground coal mines would advance their opinions about what the major safety problems were for underground coal mines. We would then go back and check these theories, and find that many of these opinions about major causes were actually minor problems in both the accident data base for their mine and in pooled accident data bases of several similar mines in their area.

Accident Analysis – Problem Definition

Analyzing industrial accident data can provide a regular goldmine of insights into the unique safety problems in the data base. If one has over one hundred accidents and more than ten or fifteen variables per accident case, computerized frequency cross-tabulation of accident factors is a very helpful tool. A number of commercial computer cross-tabulation programs are available either on commercial time sharing systems or at large service bureaus. The cost per cross-tabulation on commercial time sharing systems in most cities is about $.75 per cross-tabulation for a data base of about 1000 cases and 250 variables.

Normalized frequencies or relative accident frequencies are actually estimates of posterior probabilities of accident occurrence. If the future is like the past, the normalized accident frequencies will indicate the probabilities of future accident occurrence.

Since calculating rolling averages and standard deviations creates lots of tedious work, equivalent short cut calculations called exponential smoothing calculations arc highly recommended. An exponentially smoothed average and mean deviation can yield very effective predictive data on the next time period. Also seasonal and trend corrections can be applied if appropriate.

Critical Incident Technique

Closely related to both the mine inspection program and accident analysis techniques is the Critical Incident Technique. The Critical Incident Technique (CIT) is a mechanism for identifying factors which have contributed to actual or potential accident situations. The safety analyst prepares a data base of both lost time injury and fatal accidents, plus first aid near-miss and no occurrence incidents as well. Because the data base consists theoretically of potential accident situations in a very large data base can be collected in a very short period of time.

The CIT is an outgrowth of the Aviation Psychology Program of the U. S. Army Air Forces in World War II. Originally used as a method of collecting data to study psychological problems, its value as a method for determining the causes of industrial accidents was not established until 1963.