Table of Contents

The basic factors, principles and variables affecting froth flotation are enumerated in condensed form below:

- Ore.

(a) Mineralogical character.

(b) Fineness of grinding.

(c) Method of grinding. - Agents.

(a) Principal flotation agent. (“Oil”)

α Character.

β Quantity.

(b) Minor agent.

α Character.

β Quantity. - Water.

(a) Quantity with respect to solids, i.e. pulp thickness.

(b) Character.

α Acidity or Alkalinity.

β Flotation agents.

γ Dissolved salts. - Apparatus

(a) Method of aeration.

Basic Principles of Froth Flotation (b) Method of froth removal.

- Agitation.

- Duration of treatment.

- Temperature.

The variable results to be watched for and recorded are:

- Recovery.

- Grade of concentrate.

- Rate of flotation.

- Froth.

(a) Copiousness.

(b) Consistency.

(c) Size of bubbles.

α At pulp surface.

β At froth surface.

(d) Solid load. - Appearance of tailing.

(a) Flocculation.

(b) Settling rate.

What are the Variables and Factors of Flotation’s Operation

The results to be obtained in flotation depend, more than in any other concentration process, on the proper coordination of a considerable number of operating variables. These variables are listed below:

- Ore

Mineralogical character.

Recoverable mineral content.

Size of particles.

- Principal reagent

Character.

Quantity. - Minor reagent

Presence.

Character.

Quantity. - Percentage of solids in pulp.

- Method of flotation employed.

- Temperature of pulp.

- Time of treatment.

- Recovery desired.

- Grade of concentrate desired.

Ore Characteristic & Mineralogy

The mineralogical character of the ore determines, in a way, the character of the principal flotation agent or “oil” to be used. From this statement it is not to be understood that for a given ore one and only one oil can be used or even, disregarding for the moment the commercial consideration of availability, can be best used. But the physical phenomenon upon which selection depends is specific to a considerable extent. By no means all minerals of metallic or adamantine luster are selected from all gangue minerals by a given oily substance, and by no means all oily substances will act successfully in all flotation processes. The mineralogical character of the ore in connection with the character of the principal flotation agent determines whether or not another agent is necessary. Thus ores containing a considerable portion of argillaceous matter will not respond successfully to flotation unless this material is, to a considerable extent, flocculated in the pulp. If the oil fails to produce this necessary flocculation another agent, usually an electrolyte, is necessary.

The mineralogical character of the ore determines also the extent to which grinding must be carried before flotation is applied. This matter has been previously discussed. In the agitation-froth process, the recoverable mineral content of an ore, the amount of a given oil necessary, the percentage of solids in the pulp treated, the grade of concentrate and the recovery attained are strictly dependent variables. This interdependence may be stated as follows:

- In order to recover a given percentage of the recoverable mineral in an ore in the form of a concentrate of a given grade, if the percentage of solids is fixed, the amount of a given oil necessary is in direct proportion to the amount of recoverable mineral in the feed.

- In order to recover a given percentage of the recoverable mineral in an ore in the form of a concentrate of a given grade, if the grade of the feed is kept constant, the amount of a given oil necessary is in almost direct proportion to the percentage of moisture in the pulp.

These relations have been proven conclusively for the agitation-froth process and should, therefore, hold for the other pulp-body-concentration processes. Some similar relation is indicated for bubble-column processes, but the writer is aware of no exhaustive and conclusive work in this direction, and the dissimilarity in the mechanism of the two types of processes forbids reasoning across from the one to the other.

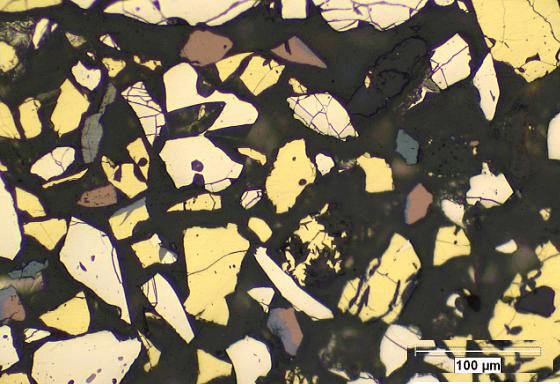

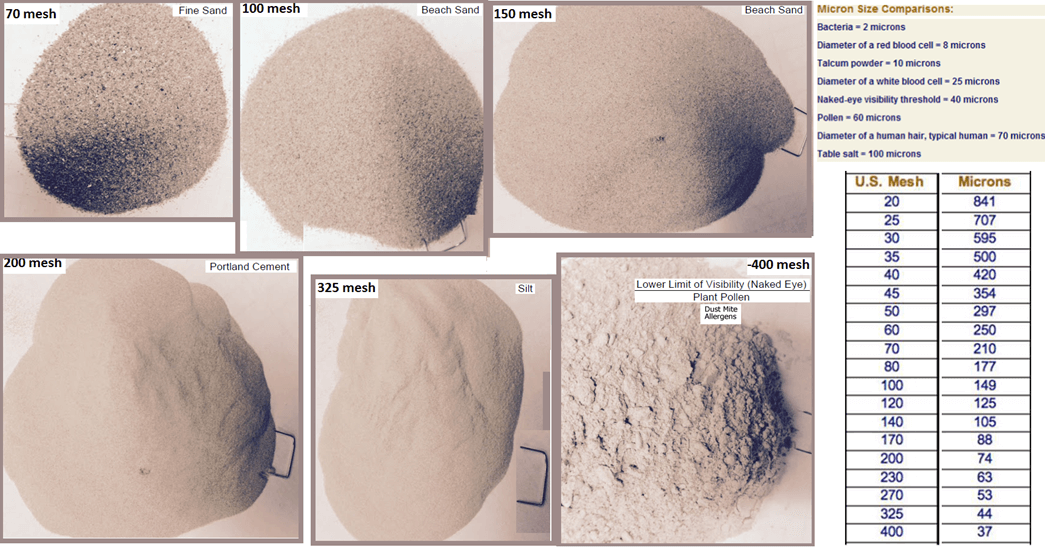

Particle Size

The size of the particles in a flotation pulp affects the percentage of solids and the amount of oil necessary. It is not unlikely, also, that it has some effect on the necessity for other agents. If the solids are coarse it is necessary to run with a thick pulp in order to attain a good recovery. A thick pulp, in general, results in a low-grade concentrate. Hence a coarse feed is likely to mean a low-grade concentrate.

More oil is, in general, necessary, if the feed is coarse. This is probably due to the fact that, owing to the lesser covering power of the coarse material, more of the stabilization of the froth must be done by the oil. The necessity for flocculation of very fine material is not present in the case of coarse feed. Hence the necessity of an electrolyte to produce such flocculation is lacking and the conclusion follows that a coarsely-ground pulp from a given ore is less likely to require the use of acid or alkali than a finely-ground pulp from the same ore.

Oil/Frother

“Oil” is a generic term which, in flotation terminology, is used to designate the organic substance that is used to produce frothing and to effect selection of the metalliferous mineral. The “oil” employed is usually an oily substance, but it may be a non-oleaginous organic substance. Rarely, as in the Potter-Delprat process and in certain applications of the agitation-froth and pneumatic processes an inorganic compound may take the place of the “oil.” The character or kind of oil used depends upon:

- the character of the ore;

- the fineness to which it is ground;

- the percentage of solids in the pulp;

- the method of treatment of the pulp following the introduction of the oil.

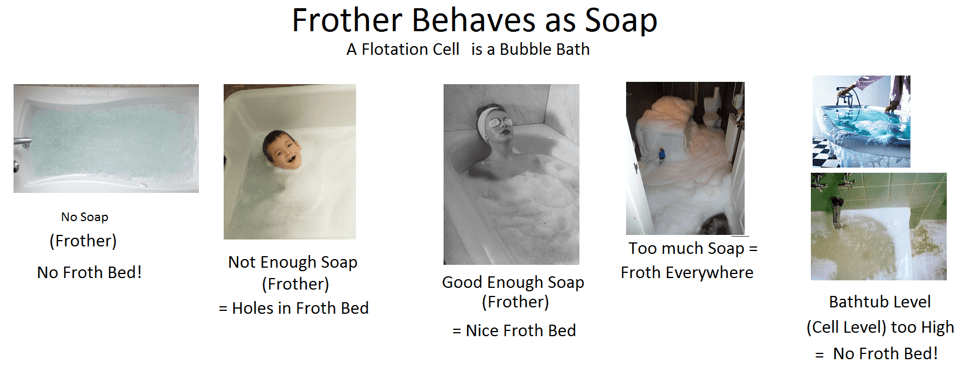

Why use Frothers

The purpose of the oil in froth-flotation is (1) to form, together with the water and solid of the pulp and the gas introduced into the pulp, a froth; and (2), to aid in the selection of the particles of mineral of metallic, resinous or adamantine luster in the pulp from the gangue minerals. Not all oils will perform both of these functions with all ores in all processes. Newly refined paraffin hydrocarbons, if pure, will not froth to a sufficient extent to make them efficient flotation agents in the agitation-froth or pneumatic processes. Certain other substances, although possessing the property of froth formation in these processes, exclude practically all solid matter from the froth. Saponin is such a substance. Certain other agents, such as soap, cause the formation of a froth containing solid matter, but this froth results in no useful concentration. Finally, a considerable number of oily substances such as essential oils and coal-tars and wood-tars and their fractions and derivatives cause not only copious frothing but, with certain ores, efficient selection of metalliferous mineral from gangue. With other ores the selection is nil or wholly inefficient. It may be put down as an axiom of the art that no one substance is universally applicable as an “oil” in froth-flotation concentration of all ores.

Grind Size

The fineness to which the ore is ground has a considerable effect on the kind of oil necessary. A certain degree of stability is essential in every froth, enough to allow for the removal of the froth from the flotation machine. Stability of froth is affected by the extent to which the bubble walls are covered by solid matter and by the strength of the liquid films of the bubbles themselves. The more closely particles of solid are packed together in the bubble walls and the thinner the layer of liquid between two adjacent pieces of solid, the stronger will be the bubble film. In order to get the greatest covering power from a given lot of ore, it should be ground as finely as possible. With such finely-ground ore little or no aid in stabilizing the bubble films is needed from the oil. If, however, the ore is not so finely pulverized and its covering power is thereby decreased, some agent capable of

adding stiffness to the froth must be used, in order to obtain the necessary stability. Pine-tar oil and some petroleum oils are usually used for this purpose.

The effect of slurry density

The percentage of solids in the pulp affects the character of oil necessary in a way similar to that in which it is affected by the degree of pulverization of the ore. A low percentage of solids in a pulp ground to a given degree of fineness means a greater distance between individual particles. It will result from this greater spacing of particles that a bubble will arrive at the surface less heavily loaded than in a thick pulp and will be, therefore, less stable. Such being the case, it will require the addition of an oil with froth-stabilizing power to make up for the lack of stability.

Another factor enters here also. If a given amount of solid matter is to be passed through a given machine in a given interval of time, say 24 hours, with a thin pulp a greater volume must pass through in each unit of time than with a thick pulp. This means that less time is afforded for the dispersion of the oil through each unit of volume of the thin pulp. The rate at which an agent can be dispersed is a specific function of the agent itself, depending principally on its viscosity and its solubility in water, and is also a more or less direct function of the agitation. With the degree of agitation and the rate of solid feed fixed, it follows that with a thin pulp a more mobile or more easily soluble oil, or both, will be necessary than with a thick pulp. The method of treatment of the pulp following the introduction of the oil determines also the kind of oil most suitable. This follows from a consideration of dispersion. If the pulp is to be subjected to a considerable amount of agitation, either violent or of long duration, or both, after the introduction of the oil and before flotation is to be attempted, then a viscous or only slightly soluble oil will be effective. If, on the other hand, flotation is to be attempted with but little agitation intervening following the introduction of the oil, a mobile and relatively soluble oil must be used.

The quantity of oil necessary in any froth-flotation operation depends upon:

- the kind of oil used;

- the recoverable mineral content of the ore;

- the percentage of solids in the pulp;

- the degree of pulverization to which the ore has been subjected;

- the treatment to which the pulp is subjected in the interval between the addition of the oil and flotation;

- the duration of the flotation operation;

- the mineralogical composition of the ore;

- the method of flotation employed.

Mobile and highly soluble oils can be employed in smaller quantity, all other conditions being equal, than viscous and relatively insoluble oil. This follows naturally from the preceding discussion. Mobile and highly soluble oils are easily dispersed in an extremely high state of subdivision, while viscous and slightly soluble oils are dispersed more slowly and to no such high degree. In pulp-body concentration the function of the oil is to coat the mineral particles. In bubble-column processes it is essential that the rising bubbles become oiled. An extremely thin film is all that is necessary. But in order to insure that the sulphide particles in the one case and the air bubbles in the other shall come into contact with oil, a certain minimum spatial distribution of the oil in the pulp is necessary. In order to insure this minimum spatial distribution with a viscous and relatively insoluble oil, necessarily in relatively large masses as compared with the particles of a mobile and highly soluble oil, a greater amount of the former must be used. Owing to the greater size of the masses of the viscous and insoluble oil the films on the particles and the bubbles will exceed the effective minimum, and further the amount of excess oil which does no coating but which is necessarily present in order to accomplish the required spatial relation will, in this case, exceed in bulk that unused in the case of the mobile or highly soluble agent. Above a certain minimum quantity, all other conditions being constant, the amount of oil necessary in the. agitation-froth process varies directly with the amount of recoverable mineral in the ore. This is easily proven experimentally and can be predicted from theoretical considerations as follows: The maximum surface that can be covered by a given quantity of a given oily substance is measured by the area of the film, one molecule thick, which can be obtained from the given amount of agent. In any successful agitation-froth flotation operation it is essential that all of the sulphide mineral particles be coated to at least this extent. This coating cannot be accomplished without the presence of an excess of the agent in the pulp. Hence the minimum quantity of agent necessary is some probably fixed excess over that required to coat the sulphide particles with a layer one molecule deep, which excess depends upon the degree and duration of agitation, the kind of agent and the thickness of the pulp. Any increase in the amount of metallic mineral in the pulp means an increase in the area to be covered by the oil and hence an increase in the amount of oil that must be provided.

Above a certain minimum quantity, all other things being constant, the amount of oil necessary in the agitation-froth process to make a given recovery from a given ore with a given grade of concentrate varies directly with the percentage of moisture in the pulp, within the efficient working range of moisture percentages which is from, say, 65 or 70 per cent to 90 or 95 per cent. This is confirmed by experimental data and follows logically from a theoretical analysis. As has been previously stated, a certain minimum spatial distribution of the particles of oil in the pulp is necessary in order that the metalliferous mineral particles may be coated during the time that the pulp is under treatment. If the volume of pulp carrying a given amount of solid matter is increased, then the number of particles of oil necessary to produce the minimum spatial distribution of the same throughout the

total volume of pulp will likewise be increased.

The following relations between quantity of oil and size to which the ore is ground are experimentally proven:

If a pulp containing solid matter ground to a given degree of fineness is being concentrated by flotation with a given minimum quantity of a given agent, the same metallurgical results can be obtained with a smaller quantity of agent, if the solids are more finely ground. Conversely more oil must be used, if the grinding is so changed that the product to be floated is coarser. The explanation of this observed phenomenon is, probably, that a certain degree of stability is essential in the froth and that this stability may be provided by either oil or solid matter. If the covering and hence stabilizing power of the solid is increased by finer subdivision, the oil is relieved of part of its duty and less of it, therefore, is necessary. Vice versa, if the covering and stabilizing power of the solid is decreased, as by coarser grinding, more burden is placed on the oil and it must be increased in quantity. The treatment to which the pulp is subjected in the interval between the addition of the oil and the actual operation of flotation has a considerable influence on the quantity of agent used. A certain minimum degree of dispersion of the agent is essential, as has been previously explained, in order to assure such spatial distribution of the agent that every air bubble or sulphide particle shall become coated.

It is necessary further that the agent be dispersed to such a degree that gravity will have little or no effect to cause it to collect together and that the tendency of the particles of the agent to coalesce shall be overcome. Otherwise the agent will collect on the surface of the pulp and break down the froth. Hence, if an oil of a given character is employed, the amount of agitation required to disperse it must be increased, as the amount of oily agent is either decreased or increased from a certain amount corresponding to a minimum degree of agitation for mixing.

The quantity of oil necessary and the duration of the flotation operation, all other conditions being constant, bear a close relation to each other. With any given minimum amount of agent and minimum duration of the flotation operation corresponding thereto required to attain a certain result, a lessening of the duration of the operation will require an increase in the amount of oil and vice versa.

The composition of the ore, particularly as regards the gangue, affects the quantity, of oil necessary. Clean, hard ores require less oil, all other conditions being constant, than do soft clayey ores. One reason for this difference probably lies in the fact that the clayey gangue matter from the soft ores acts to emulsify oil and thus prevents a certain amount of the latter from playing any part in the process. Some sulphides, also, require a less quantity of oil to separate them from a given gangue than do others. Thus galena can be separated from a given ore with less oil than can blend, and chalcocite is separated with the use of a less quantity of oil than pyrite. Some methods of differential flotation are founded on this phenomenon.

Pulp-Body

Pulp-body-concentration processes requires more oil to be employed, all other things being equal, than do bubble-column methods. This is due to the difference in the phenomena acting in the two cases. In the pulp-body processes using oil it is necessary that the sulphide particles become coated in the pulp before effective selection takes place and this necessitates thorough and quick dispersal of the oil. Further, a given particle of oil is effective only during the short time that it is below the pulp surface. In the bubble-column processes, where all of the work of the flotation agent is done above the pulp surface, coating of all the bubbles in the pulp is not necessary (since those that rise without coating will be coated in the bubble column itself) and hence the need for so large a number of oil globules floating around therein does not exist. Further, each oil-coated bubble serves to separate a considerably greater bulk of solid than is done by a corresponding area of bubble surface in the pulp-body processes. It should be noted also in this connection that, on account of the much larger size of the bubbles in the bubble-column processes, a bubble rising through a pulp containing particles of flotation agent in a given spatial distribution, is much more certain to meet such particles than the very much smaller bubble in the agitation process.

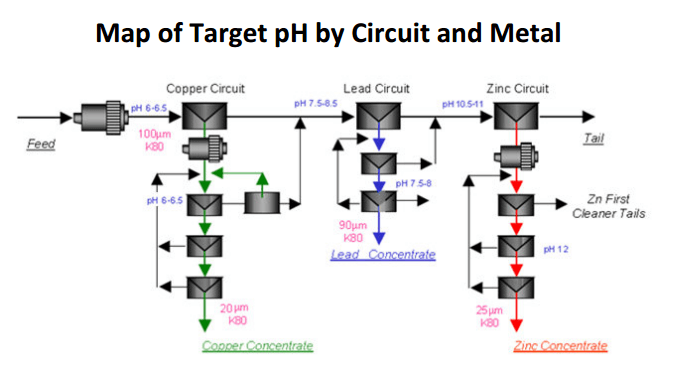

pH Modifiers AKA Minor Agents

The role of the minor agents (pH Modifiers) is to increase the grade of concentrate, i.e., aid in selection, and to a lesser extent, aid recovery. Various theories have been advanced to explain their action. In general they are electrolytes, and ingenious hypotheses have been based on assumed accentuation, due to their ions, in the difference in magnitude of the electrical charges said to exist at the surfaces of the solid particles in the pulps. Excluding for the present the cases in which the minor agent reacts chemically with the principal agent or oil, it is a commonly observed experimental fact that successful use of a minor agent is accompanied by increased flocculation of the flotation pulp, particularly of the flotation tailing. It is furthermore usually true that the tailing from an unsuccessful flotation operation is slow-settling, indicating a lack of flocculation. Hence we may set down as an empirical rule that a suitable minor agent will be one that flocculates the pulp.

When the pH Modifier reacts chemically with the principal agent, the cause to which its effect is to be ascribed is masked. It is not improbable that in such cases any improvement is as much due to the changed character of the principal agent as to the independent flocculating effect of the minor agent. Particularly is this true when the addition of the minor agent results in increased recovery accompanying increased frothing. Such chemical reaction is to be looked for where the principal agent is a vegetable or animal oil, and the minor agent an alkali.

The necessity for the use of a minor agent depends upon, (1) the mineralogical composition of the ore, and (2) the character of principal agent employed. If the ore is unaltered, hard and silicious, it is certain that with some principal agents no minor agent will be necessary. With other principal agents, however, the grade of concentrate may be improved by the use of a minor agent. If the ore is much altered with a resultant large amount of kaolinized gangue, a minor agent is likely to be necessary, although here, also, the character of the principal agent may be such that the use of a minor agent can be dispensed with. The minor agent most widely used is sulphuric acid. Sodium hydroxide, sodium carbonate, sodium sulphate, sodium silicate and lime are not uncommonly employed. It is the writer’s experience that so far as flotation itself is concerned, when a minor agent is needed, sulphuric acid is the cheapest and most effective. Its use may, however, as is the case with partially oxidized copper ores, be prohibited on account of the destructive effect of the resultant copper sulphate solution on the iron with which the pulp comes in contact in the mill, in which case an alkaline or neutral electrolyte may be effective.

Percentage of solids affects kind and quantity of principal flotation agent necessary, the quantity of minor flotation agent, the fineness of grinding, the grade of concentrate and the recovery attained. It is determined principally by the character of the ore. The effect on principal flotation agent and fineness of grinding has already been discussed.

The relation between percentage of solids and quantity of minor flotation agent seems to point to the conclusion that it is the concentration of the aqueous solution of the minor agent, rather than the quantitative relation between the minor agent and the solid, which determines its effectiveness. No systematic experimental work along these lines is reported but mill experience and laboratory experiment both indicate that the amount of minor agent necessary increases with decrease in the percentage of solids.

https://www.911metallurgist.com/effect-of-flotation-cell-size-laboratory

Grade of concentrate is, in general, improved by decrease in the percentage of solids in the pulp, and such improvement may be accompanied by improvement in recovery, but continued decrease in percentage of solids eventually results in decrease in recovery.

The character of the ore determines the maximum economic percentage of solids. With clean, sandy ores this is about 30 per cent., with clayey or slimy ores, about 15 per cent. Slimy pulps as thin as 5 per cent, solids can be treated, although generally at the expense of a low recovery.

Pulp or Slurry Temperature

Heat aids gas precipitation from the water of the flotation pulp; it also aids in dispersion of the more viscous oils. Temperatures above normal are, therefore, of distinct advantage in pulp-body concentration. Heating can be dispensed with, however, by increasing some other factor such as the concentration of gas in chemical-generation processes, the duration or intensity of agitation in the agitation-froth process or the pressure difference in pressure-relief processes. In bubble-column processes, where bubble precipitation from solution is not the essential phenomenon in furnishing the effective gas, heat is not one of the important factors, and the temperature of the pulp is, therefore, unimportant, except insofar as heat may be desirable to aid dispersion of the oil.

In the agitation-froth process, it is, in general, more economical to attain enhanced bubble precipitation by greater intensity and duration of agitation than by heating the pulp, and in bubble-column processes difficulties in dispersion of the oil are surmounted by adding the oil to the grinding mills, or using an oil easy to disperse. Heating is, therefore, rarely resorted to in present-day practice.

* Throughout the following discussion the phrases “mineral of metallic luster,” “metallic mineral,” “metalliferous mineral” and “sulphide,” or “sulphide mineral” will be used interchangeably, as is the usual case in flotation terminology, to designate minerals of metallic, adamantine or resinous luster.

A Manual of Flotation Processes P. 29-43