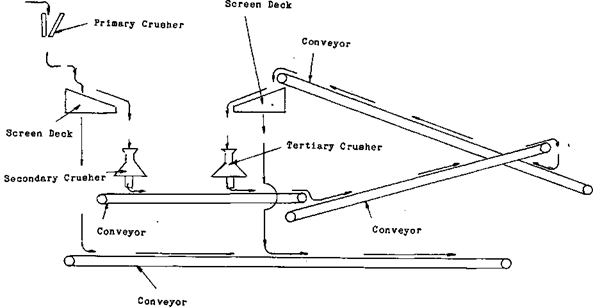

To understand the effects the plant has on itself during its actual operation is very important. There are three variables that the plant on a whole is affected by:

- VOLUME (or tonnage)

- SIZE OF FEED

- CIRCULATING GARBAGE (wood, plastic, rubber, etc.)

The first two the volume and the size of the feed effect one another, here is an example:

If you open the setting of the secondary crusher so that it will crush a higher tonnage, these are the two variables that will be going to the next piece of equipment larger feed and higher tonnage.

If you open the setting of the secondary crusher so that it will crush a higher tonnage, these are the two variables that will be going to the next piece of equipment larger feed and higher tonnage.

The next piece of equipment is a screen deck. For a screen deck to work properly every piece of ore must come into contact with the surface of the screen. To be sized the ore to have the opportunity of going through the screen mesh.

As the tonnage is increased the area, on the screen deck that is available for the ore to come into contact with, decreases. As the rock is piled deeper on the deck the efficiency of the screening is lowered.

Remember the secondary was opened to increase the through put of that crusher. This means that there will be more coarse material to crush again.

Adding that to the amount of crush that didn’t get sized properly will drastically increase the tonnage that the tertiary crusher will have to process.

If the tertiary is opened to compensate for the greater volume of feed that it is receiving the screen load will be increased again, which will cause even a greater amount of fines that are returned to the tertiary.

Eventually something has to give. In this case the tonnage or a plugged crusher.

By this example you can see that the best way to run a crushing plant is to balance all of your variables to the limiting factor. This could be TONNAGE, SIZE, SCREEN CAPACITY, or maybe CONVEYOR CAPACITY. Whatever it is, the crushers must be run to the capacity of the slowest piece of equipment in the plant.