Effect of Air Flowrate on Flotation Column

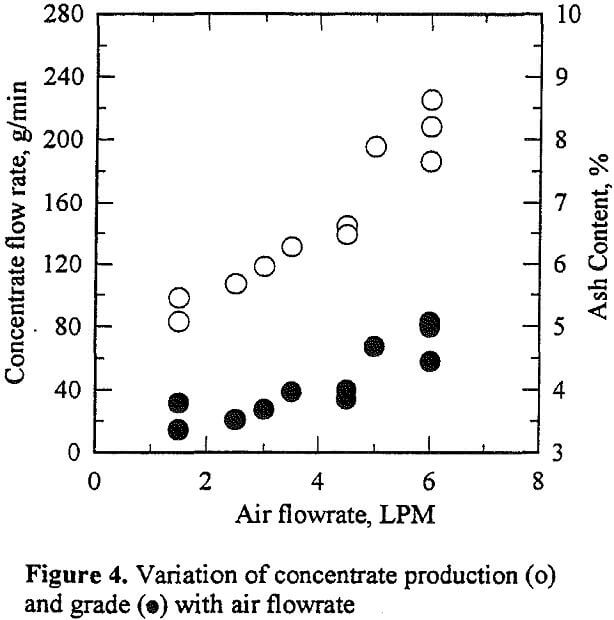

On a flotation column cell, the variation of concentrate flowrate, clean coal yield and product grade with air flow rate are shown in Figure 4. These tests were carried out using a 5 wt. % feed slurry. The results show that the concentrate flow rate, yield and product ash content increased with air flow rate. […]

Horizontal Cyclones

Horizontal cyclones can reduce the quantity of fines in the cyclone underflow as described by Hochshied (1984). A number of plants are now operating horizontal cyclones with a substantial reduction of the circulating load and the amount of fines returning to the mill. However, circuit capacity did not increase due to the reduction of fines […]

Visman’ General Sampling Theory

A comprehensive analysis of the entire range of related studies would require a lengthy discussion. Instead, this paper will focus only on the work of Visman (1962, 1969), because his work is part of the current ASTM D2234 standard on coal sampling (American Society for Testing and Materials, 1985). Visman’s work attempts to empirically determine […]

How to Reduce Ball Mill Overload Risk

Two different circumstances must be addressed for the reduction or elimination of overload risk: a) in existing operations, or b) in the design of new grinding circuits. The methods necessary are in the first case an adjustment of operating conditions; and in the second an adjustment of mill shapes. Existing Operations: from Equation (1) for […]

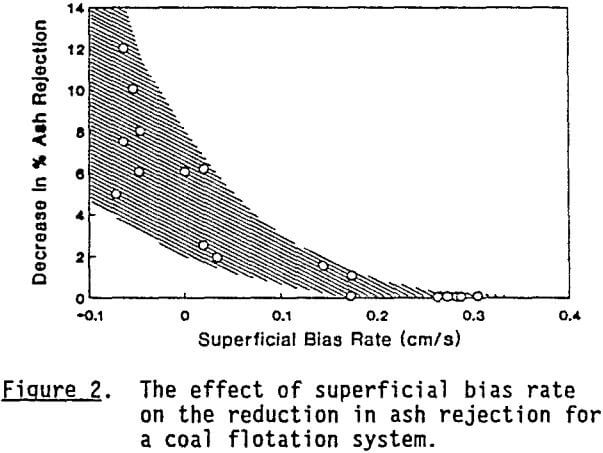

Column Flotation BIAS

Counter Current flow of mineralized bubbles & wash water The column underflow is always of slightly higher volume than the feed. This volume imbalance, called BIAS in the control system, is made up by wash water inserted at the top of the column. Part of this wash water travels down the column to exit with the […]

Gold Refining Contract

The operator’s relationship with the refinery depends entirely upon a well-defined written contract, good representation at the refinery and the use of reliable assay laboratories. While all contracts are similar in that they are meant to safeguard the interest of both refiner and miner, it is not unusual to find a single refinery writing a […]

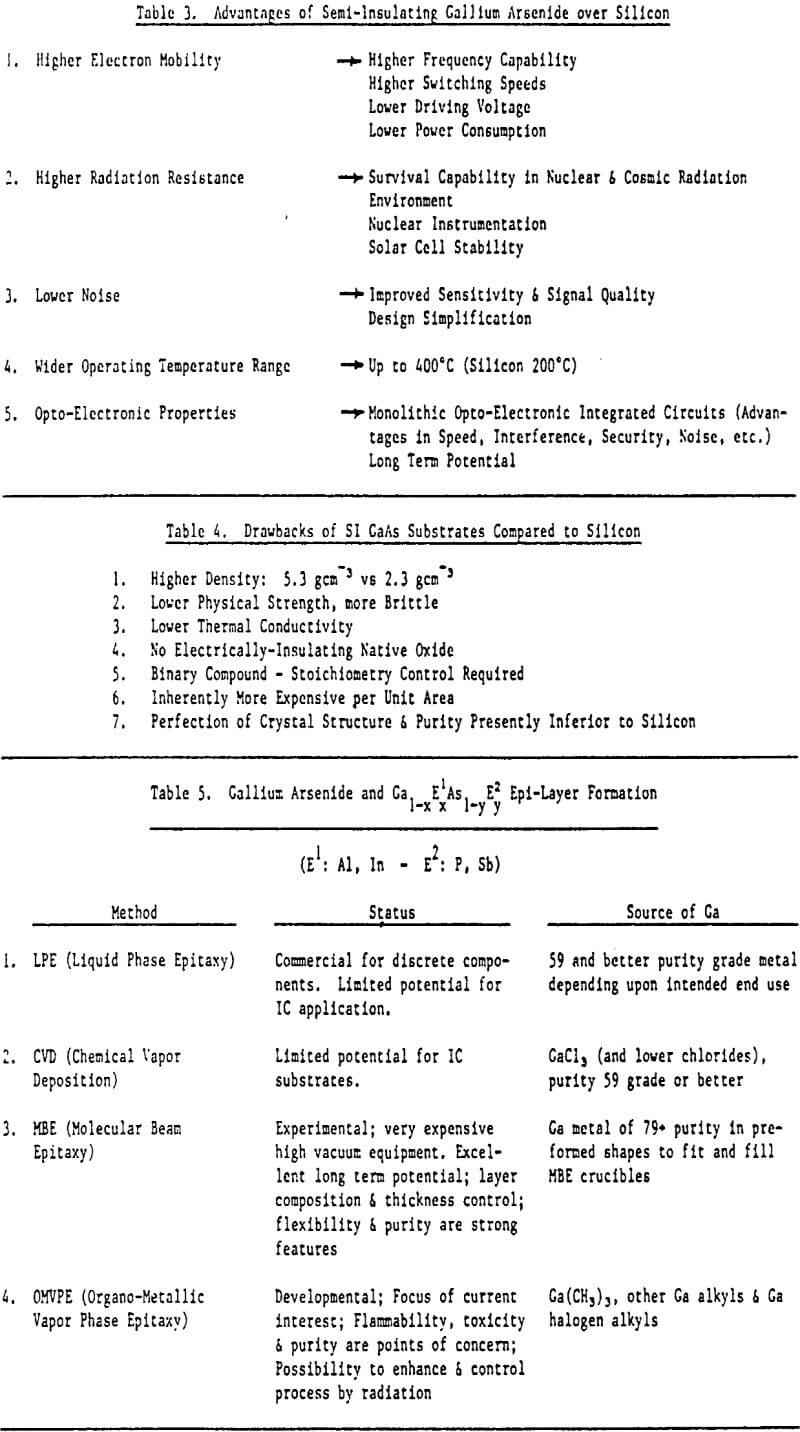

Gallium Uses

Gallium: Cominco has been at the interface between the semiconductor materials and the components industries since the commercialization of the transistor in the early fifties. Based on our commitment to R&D, we have become the largest merchant supplier of several specialty semiconductor substrates including LEC-grown semi-insulating gallium arsenide wafers on this continent. The following remarks are […]

Ball Mill Circuit Classification System Efficiency

Fines may be defined as any material smaller than a specified product size, and “coarse” as any material that is larger. The target 80 percent passing size of the grinding circuit product is a convenient reference point, as it is often used to express the grind size objective. This size is close to the modal […]

Crushing Finer to Reduce Grinding Cost

This new high energy or power rate crushing brings a different perspective to comminution flow sheet selection. Generally, up until the early 1960’s the classical flow sheet for a beneficiation plant was primary crushing followed by two stages of cone crushing in closed or open circuit, making feed for rod mills, followed by ball mills. The […]

Allis Chalmers Corporation

The Allis-Chalmers Corporation was founded in Milwaukee, Wisconsin, in 1847 as the E. P. Allis Company, which had an initial interest in manufacturing components in the grinding of flour. As such, its roots were started in reducing material size, which is covered by the generic term, comminution. The Corporation evolved by a series of mergers […]