Assaying Tin Ore

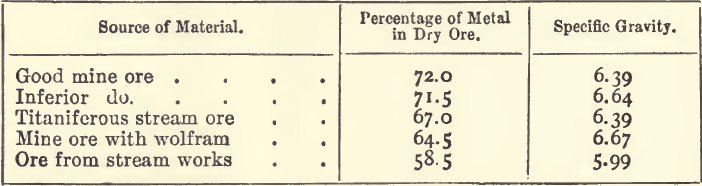

Tin occurs in nature as cassiterite (containing from 90 to 95 per cent, of oxide of tin), which mineral is the source from which the whole of the tin of commerce is derived. Tin also occurs as sulphide combined with sulphides of copper and iron in the mineral stannine or bell-metal ore. It is a […]

Assaying Nickel Determination Methods

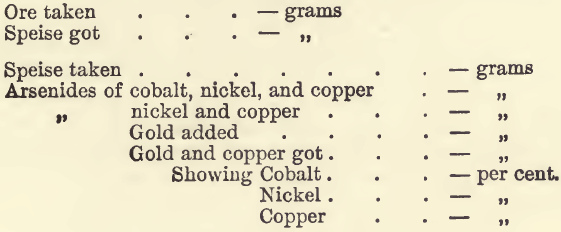

Nickel and cobalt are closely related in their chemical properties, and may best be considered together. Nickel is the commoner of the two, and is met with in commerce alloyed with copper and zinc as German silver; as also in the coinage of the United States and on the Continent. It is used for plating […]

Assaying for Iron Determination Methods

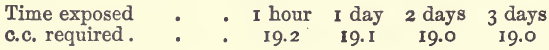

Iron rusts or oxidises very readily, and, consequently, is rarely found in the metallic state in nature; such native iron as is found being generally of meteoric origin or imbedded in basalt and other igneous rocks. It chiefly occurs as oxide, as in magnetite, haematite, and in the brown iron ores and ochres. Chalybite, which […]

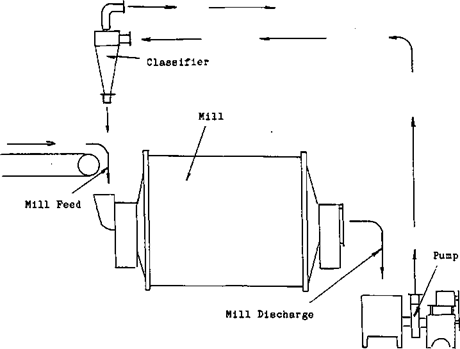

Ball Mill Drives

Several types of ball mill drives can be furnished, made up of various combinations of gearing, motors and transmission equipment. The correct combination to be selected takes into consideration power requirements, gear ratings, floor space, interference from other plant equipment and motor characteristics. The main types are described and illustrated on these pages. Motors considered […]

Pebble Mill Grinding

Essentially tube mills and pebble mills may be considered as ball mills, the basic difference being that the ratio of length to diameter is greater. Usually the shell length is between 2 and 5 times the diameter. These mills are primarily used to grind various materials to 100 mesh and finer. The Tube Mill uses […]

Cement Grinding

The principle of Grate Discharge grinding is nearly universally adapted in the cement grinding industry. Grate Discharge Ball Mills are the rule rather than the exception. Rod Mills for raw and finish grinding begin to enter the picture. Larger and larger diameter mills become common. Lengths tend to shorten. Cement grinding using Grate Discharge principles developed in […]

Concentrate Dewatering & Thickening

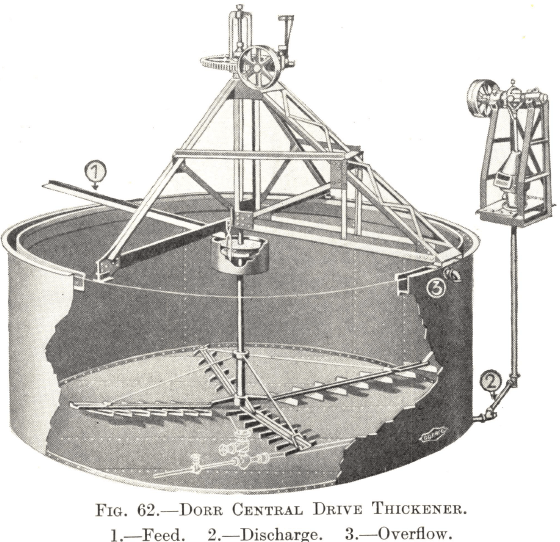

The concentrate from the flotation section usually contains only 20 to 30% of solids as it leaves the cleaning machine and must be dewatered before being sent to the next department. The operation of dewatering is performed in two stages. First, the bulk of the water is removed in a thickener, from which the concentrate […]

Comminution Theory & Process Equipment

This page is devoted to the subject “From the Comminution Theory to Practice by selection of the correct Process Equipment” by taking you step by step through some of the variables encountered in the specific part of Comminution called grinding and how each of these affect your operations. Should it be possible to reduce all of these variables to […]

Industrial Ball Mills

A symbol of dependable quality ore milling machinery manufacturing, industrial and mining equipment, ball mills and rod mills as well as supplies created for your specific needs. During this period thousands of operators have experienced continuous economical and unequalled service through their use. As an industrial ball mill manufacturer and supplier, we have continuously accumulated knowledge on grinding […]

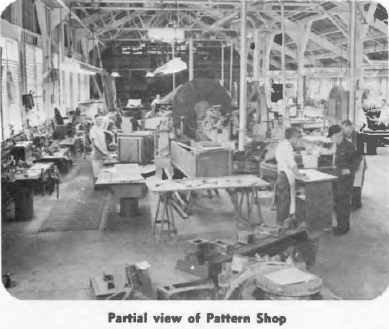

Mechanical Tools used in Metallurgy

The writer of this paper will realizes that the majority of engineering and metallurgical works have from time to time evolved mechanical devices which are of great value as regards application in an operating plant. Many of these devices would not be apparent to an individual making a brief inspection of works such as these, […]