Vor-Siv Dewatering & Classifying Device

The Vor-Siv Dewatering and Classifying Unit was developed by the Polish Coal Industry because of a need for a unit that would dewater and classify high volumes of solids in water slurry. To be practical, the unit needed to be relatively small in size, simple in design, involve low operating costs, and be able to […]

High Waste Dump Stability

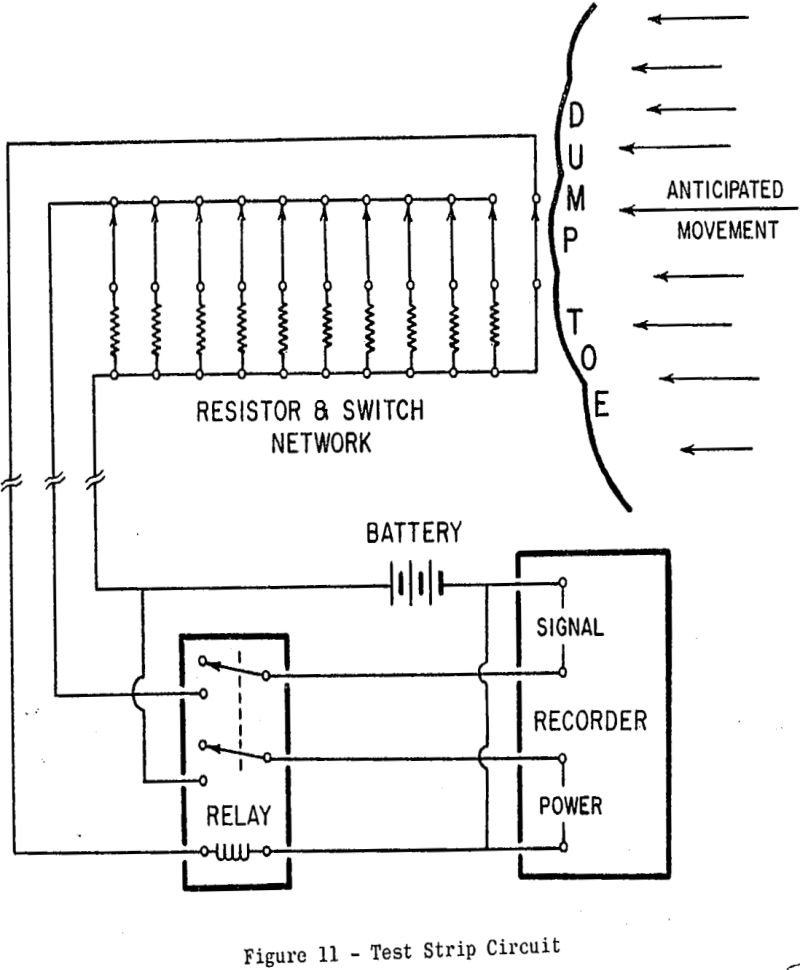

The height, structure, rapid rate of growth, and anticipated leaching suggested the possibility of dump failure. In order to evaluate this possibility, an outside consulting firm was retained in 1966 to investigate the stability of the growing dumps. Their investigation indicated that, other than superficial movement, the waste dumps would be stable under static loading, […]

How to Recover Zinc from Zinc Chloride by Electrolysis

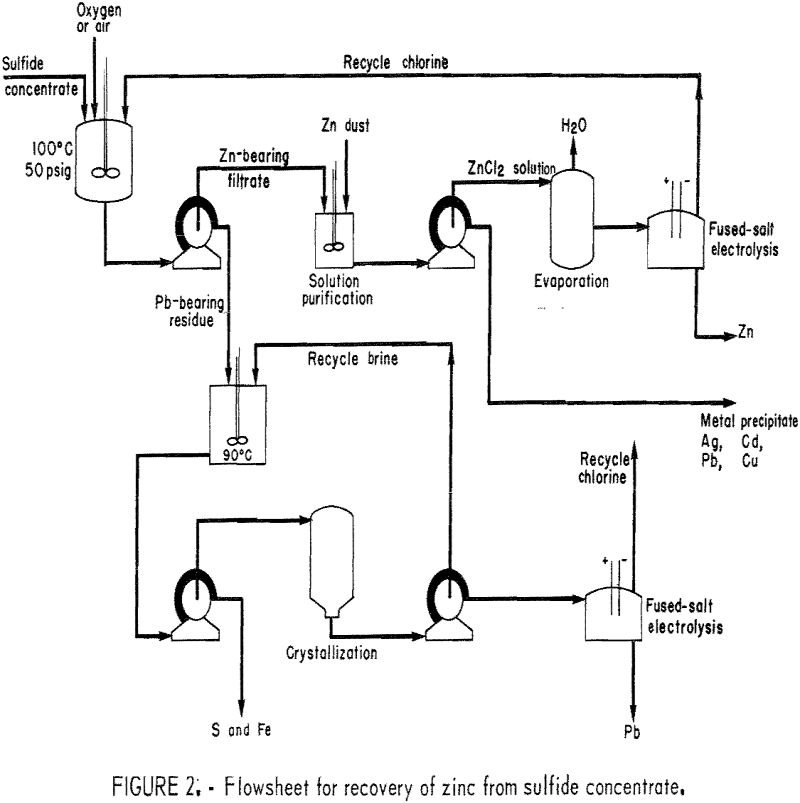

The closure of zinc plants has reduced smelting capacity in the United States from 1,300,000 tons in 1969 to approximately 700,000 tons in 1974. At the same time, U.S. consumption of zinc has increased, as shown in figure 1. As a result, the United States must import over 50 pct of its zinc supply from […]

Flotation Reagent Manufacturing

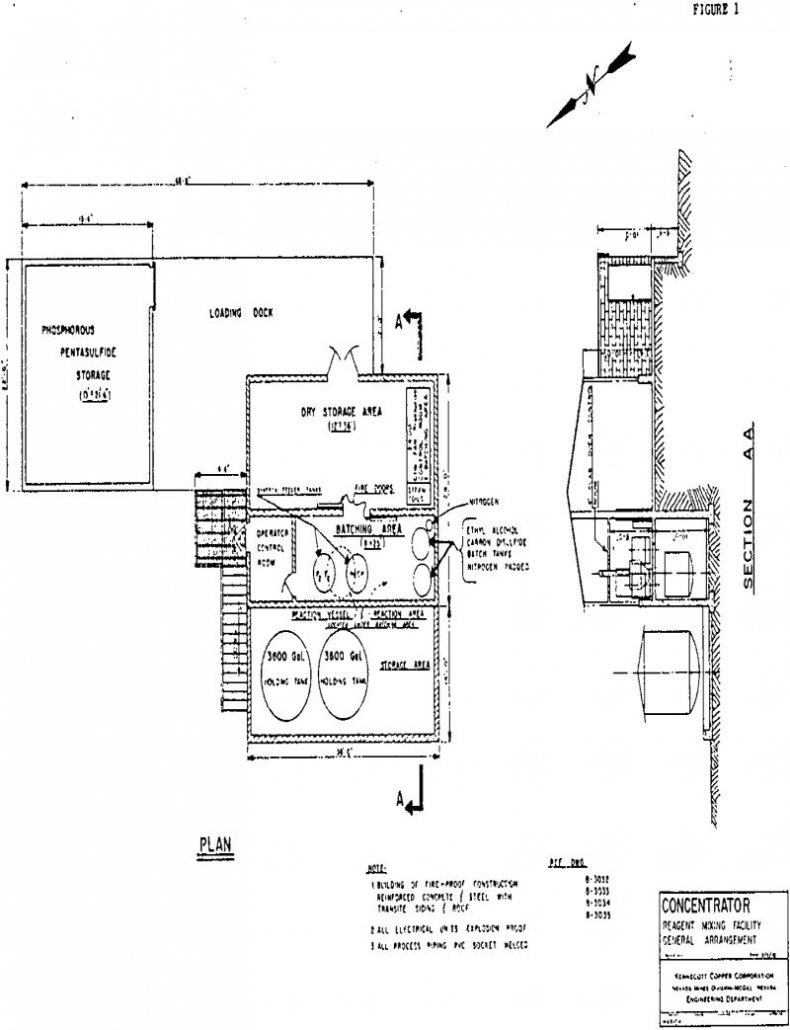

Manufacture and mixing of flotation reagents at the mill site provides an economic and convenient method of maintaining a continuous and fresh supply of reagents for concentrator operations. Kennecott Copper Corporation has designed and built a Reagent Mixing Facility which incorporates new ideas in construction and fail-safe operation at its Nevada Mines Division concentrator. Reagents […]

Optimising Ball Mill Liners to Maximise Tonnage

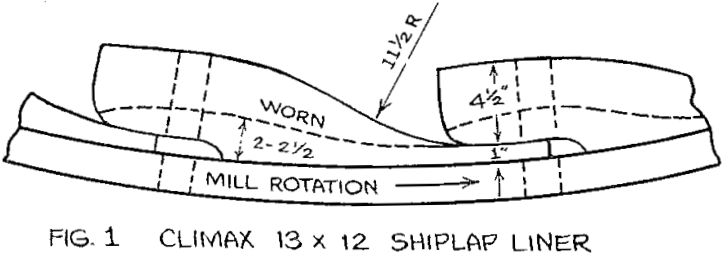

Mill liner design is an important factor in grinding. Testing and selection of the optimum liner profile for a given set of mill operating conditions can improve mill capacity, liner life, and liner wear rate. In testing four mill liner profiles for 13′ x 12′ overflow ball mills. Climax found that an improved design increased […]

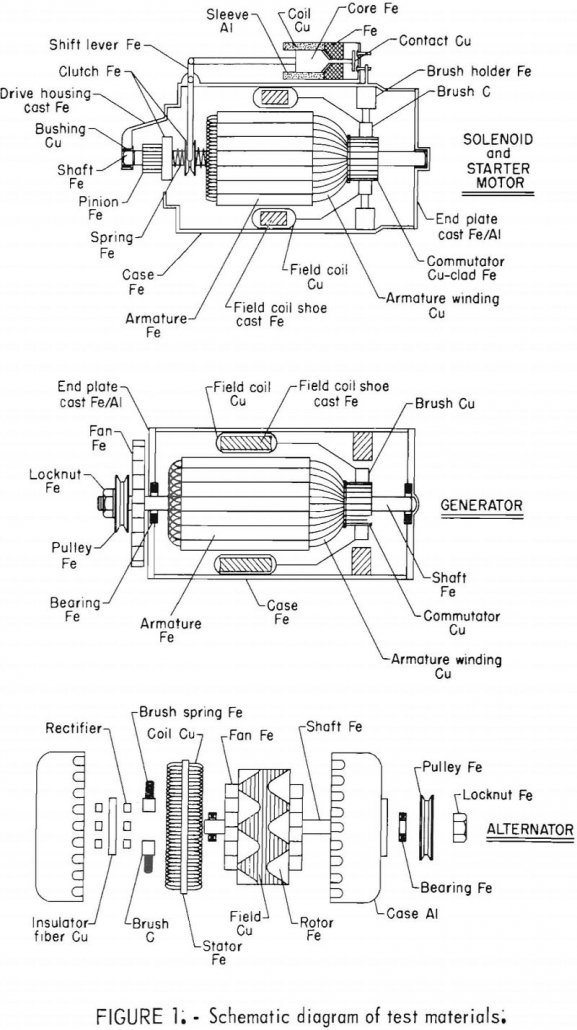

Scrapped Starter Motors & Alternators Recycling

There are two principal methods in use for processing the 8 million cars that are scrapped annually in the United States. About one-half of the cars are processed by shredding in which automobiles minus radiators, batteries, engines, gas tanks, and seats are ripped into fist-sized chunks and then magnetically separated to produce a ferrous scrap […]

How to Grind Finer

The minntac complex is a facility for production of iron ore pellets located on the mesabi range at mountain iron, minnesota. It consists basically of a mine, crushing plant, concentrator, and a pelletizer producing twelve and one-half million tons of pellets annually. This paper deals with some of the aspects of the grinding circuits; but […]

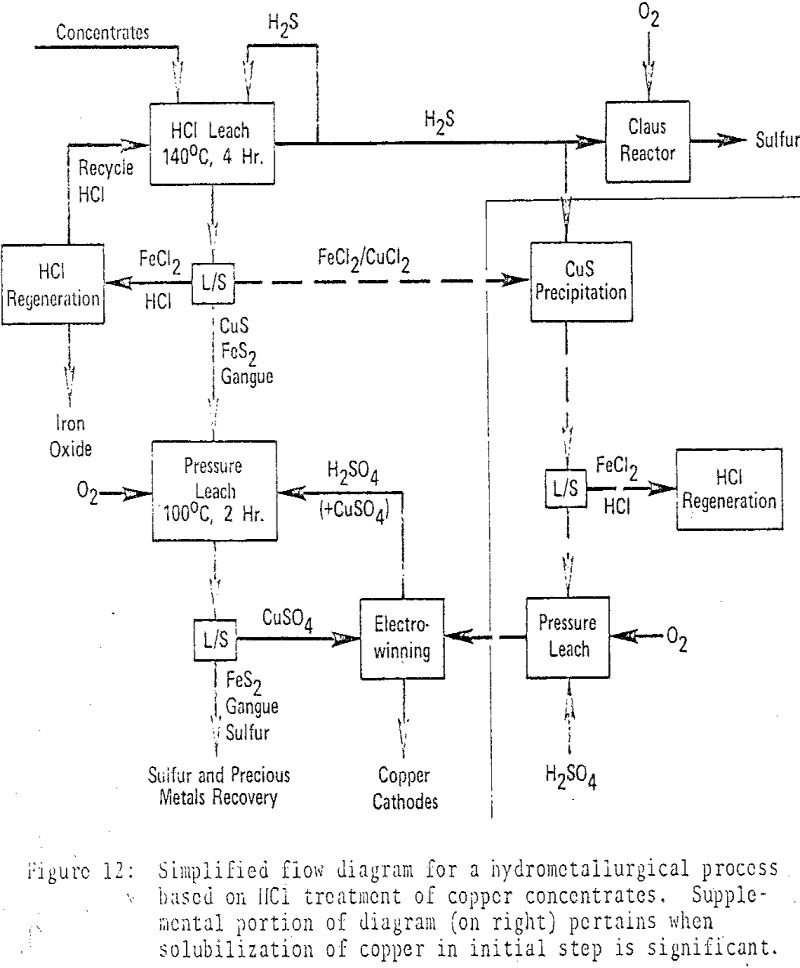

Hydrochloric Acid Copper Leaching

Experimentation with chalcopyrite concentrate in dilute hydrochloric acid, under reflux conditions (in Pyrex flasks) and with an inert purge gas, revealed substantial amounts of H2S production and iron solubilization, with negligible copper solubilization, after 2½-4 days. Under comparable condition the extent of reaction with dilute sulfuric, acetic and phosphoric acids was markedly less. Pertinent Chemistry […]

Magnetic Filtration of Kaolin Clay

The kaolin development brings together for the first time four concepts that make practical large scale use of high extraction magnetic filtration (HEMF). These include retention time, extreme gradients, high intensity fields, and efficient design of large high field magnets. Each of these elements was known and available but never refined and optimized in magnetic […]

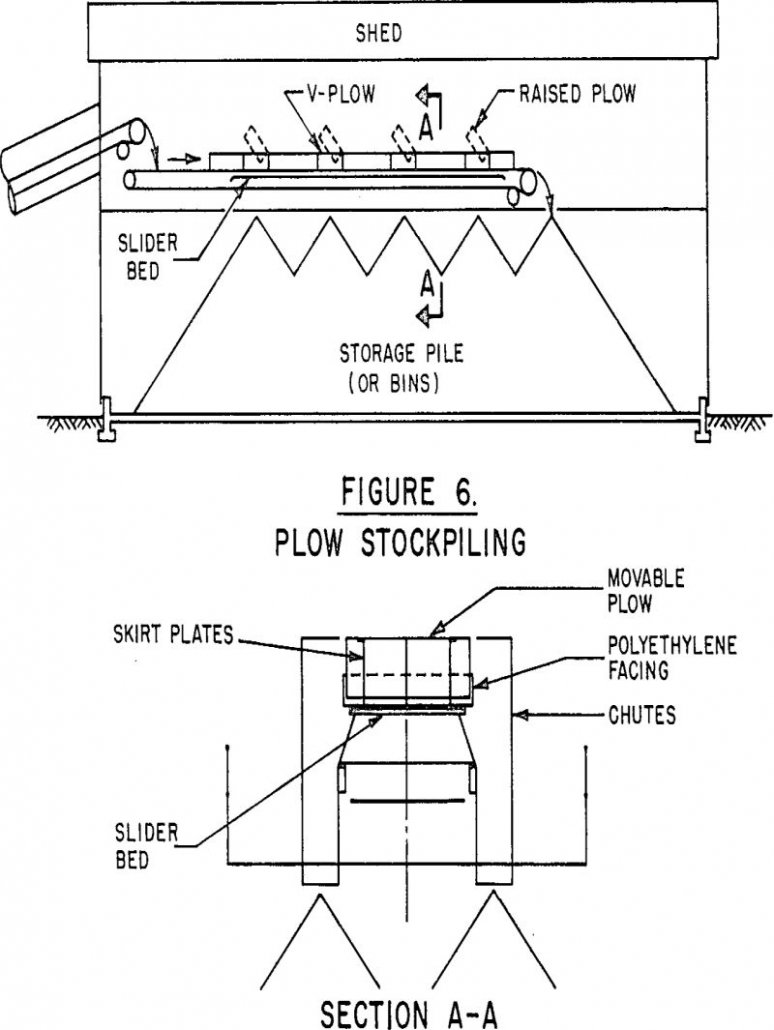

Handling Sticky Flotation Concentrates

The passage of an ore pulp through the froth flotation process results in the production, after dewatering, of a finely divided concentrate. This intermediate product must be handled to the subsequent process facilities via belt or other types of conveyors, hoppers, bins, chutes and feeders, and the like. Flotation concentrate has some difficult handling properties […]