Heavy Minerals Recovery from Sand & Gravel

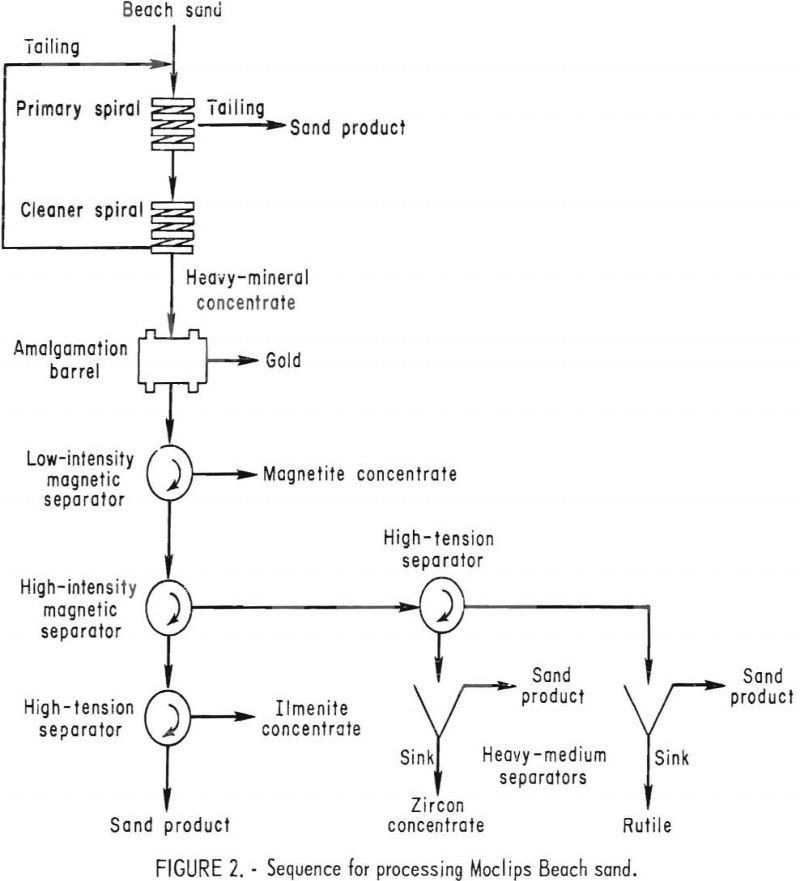

We investigated methods for the recovery of byproduct heavy minerals from sand and gravel operations in Oregon and Washington. These heavy minerals are not currently recovered except for gold in a few areas. The recovery of byproduct heavy minerals would provide a domestic source of minerals presently imported, and a more efficient use of domestic […]

Recover Scrap Chromium by Pyrometallurgy Process

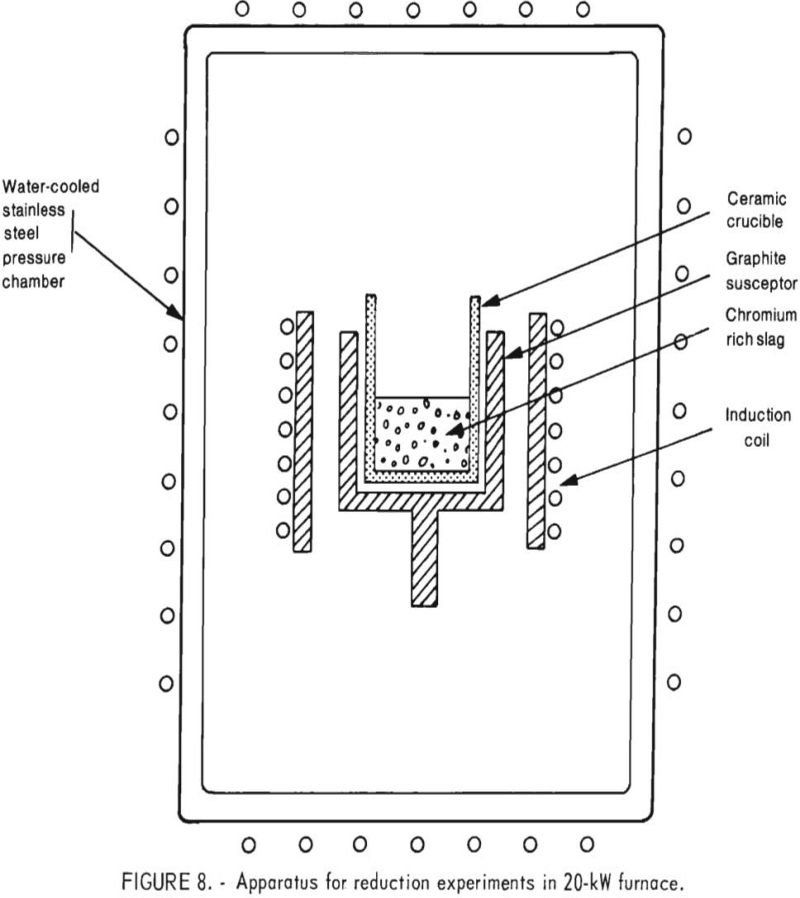

The experimental program described in this report demonstrated key process steps for the recovery of chromium as ferrochromium in a batch process. The process involves oxidation of chromium into a slag phase, subsequent separation of the slag phase from the remaining metal, followed by reduction of chromium from the slag phase to produce ferrochromium. Although […]

Ni-Cd Nickel Cadmium Recovery Method in Scrap Batteries

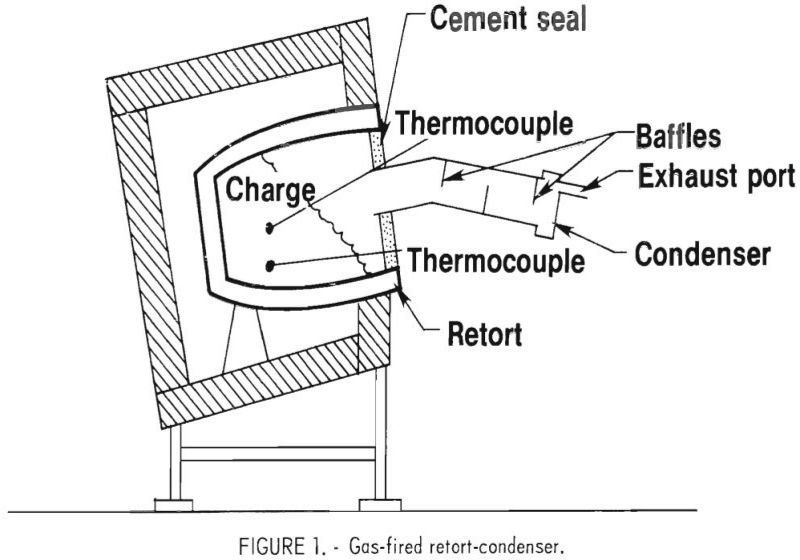

As part of a continuing effort to maximize metal recovery from domestic secondary resources, the Bureau of Mines investigated a process for recovering the metallic portion of scrap alkaline batteries. A pyrometallurgical method for recovering nickel and cadmium from Ni-Cd scrap batteries previously developed on a laboratory scale, was scaled up to 25- and 43-pound […]

Making Acid Iron Ore Pellet

In 1976 CVRD started the investigation of organic binders application for iron ore agglomeration. The ore was mixed in a Eirich Mixer with quantities of Peridur ranging from 0.1 to 0.4% and pellets were prepared in a laboratory disk. At first the results were not satisfactory at all. The wet and dry compressive strength and […]

How to Recover Chrome Metal from Scrap Alloy

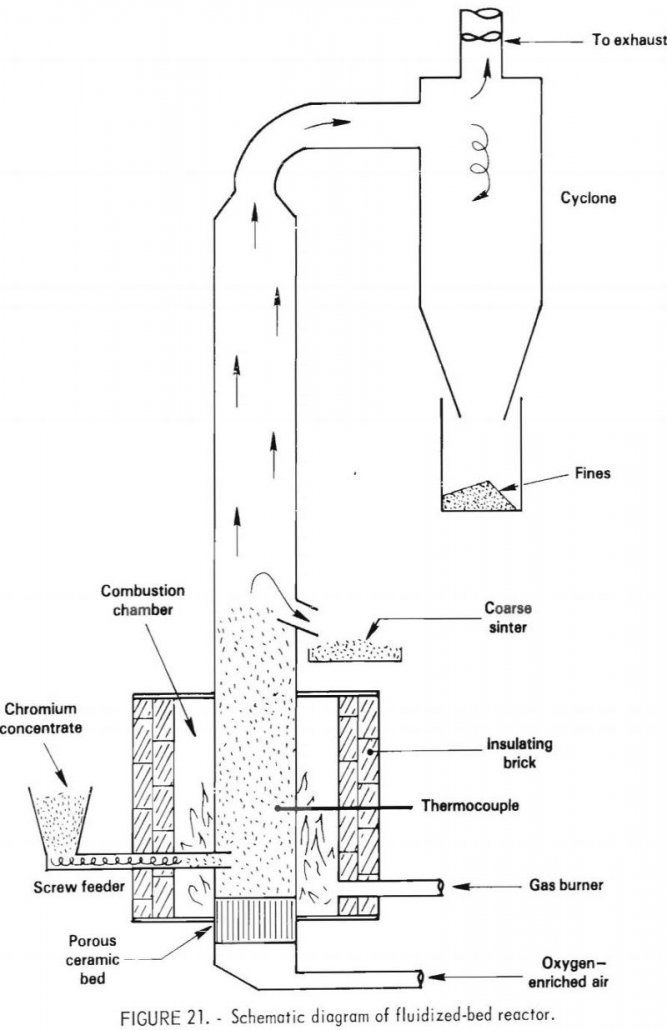

Fluidized-Bed Roasting of Chromium Sulfide The chromium concentrate produced either directly as flotation tails or indirectly as a leach residue is composed primarily of chromium sulfide with chromium comprising about 80 percent of the metal content. Nickel and molybdenum sulfides would be present in the flotation tails along with heavy metal oxides. The leach residue […]

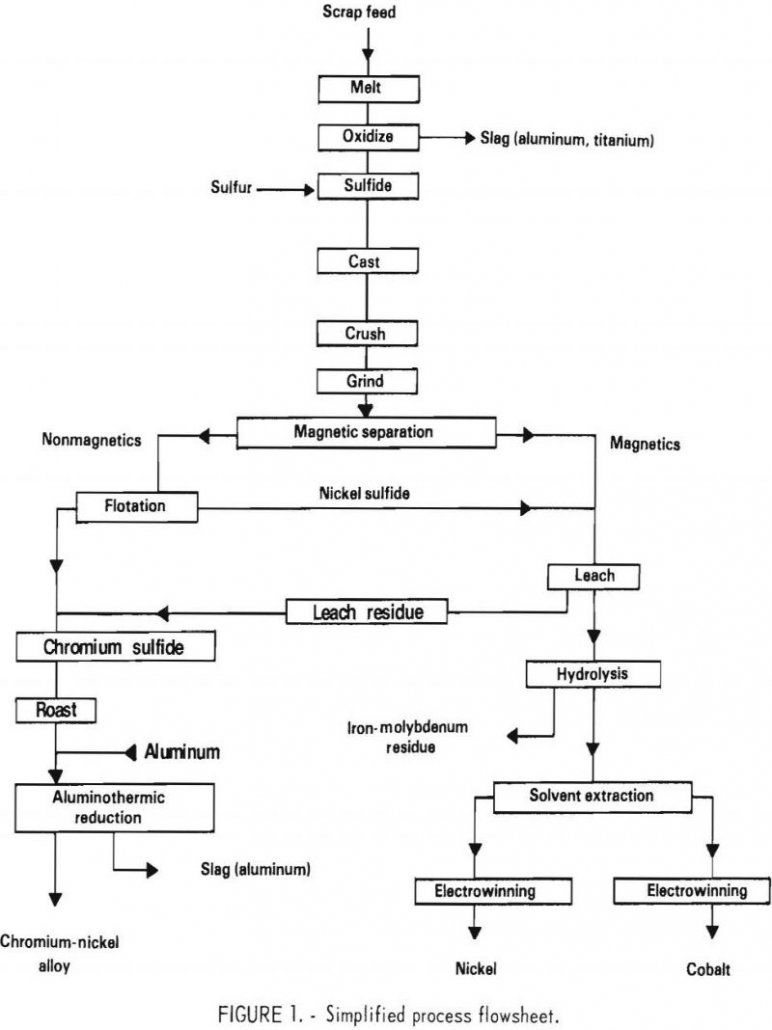

Process for Recovering Chromium Scrap

Described here is a process for recovering chromium and other metals from superalloy scrap. Laboratory-scale experiments were conducted to test a complex flowsheet utilizing a wide range of extractive metallurgical operations. The novel basis for the process is the formation of a sulfide matte in which chromium is concentrated in a discrete chromium sulfide phase. […]

AG Autogenous Grinding Power Efficient

The importance of efficient use of power in autogenous grinding circuits has been greatly neglected. It should be the fundamental factor in considering the design of an autogenous plant to grind a particular ore. The steps in the process used to arrive at a power efficient commercial autogenous plant for a particular ore are outlined. Before […]

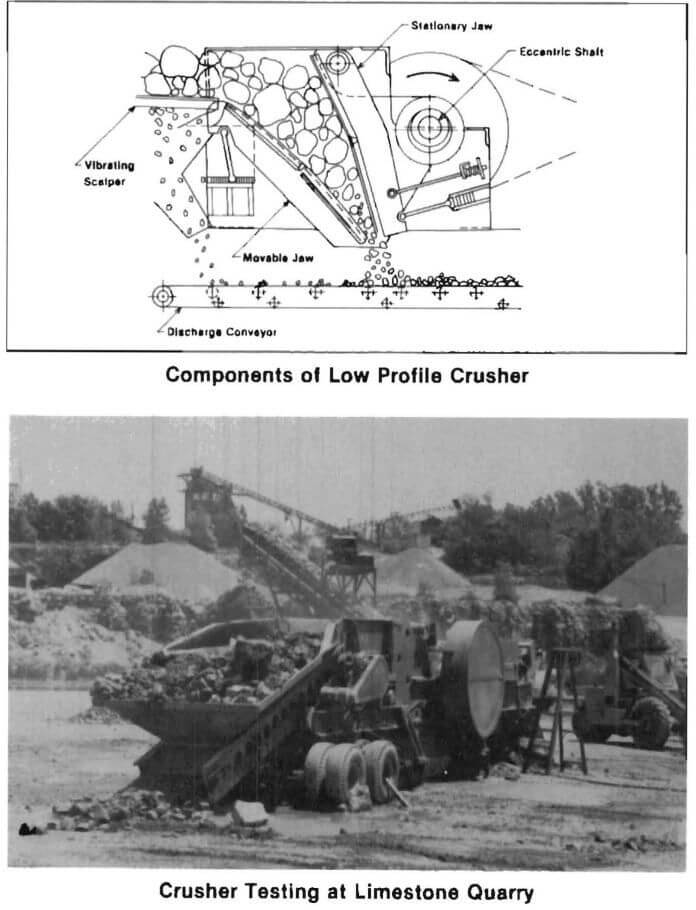

Mobile Rock Crusher

This Mobile Rock Crusher provides a portable crushing capability to keep conveyor haulage close to the working face and permit more efficient and safer ore handling in low headroom, hardrock mines. A readily portable jaw crusher is used which meets machine size, feed rock size, product size, and throughput requirements for low headroom, hardrock mines. How […]

Molybdenite Flotation

Factors Directly Affecting Molybdenite Flotation: The average molybdenite recovery in the copper concentrator for the first nine months of 1980 was 67.13%. In recent months, there has been approximately an 80% recovery of the molybdenite in the sand and slime rougher floats. The losses in the sand float are due mainly to fine molybdenite particles locked […]

Cold Vapor Determination of Mercury by AA

The Bureau of Mines once modified a commercial atomic absorption spectrophotometer to rapidly determine trace levels of mercury by cold-vapor atomic absorption spectrophotometry AA. Such diverse materials as ores, mill products, stream water, sediments, and flue dust have been analyzed. A very high dynamic range of 0.2 ng/ml to 1 µg/ml of mercury in solutions […]