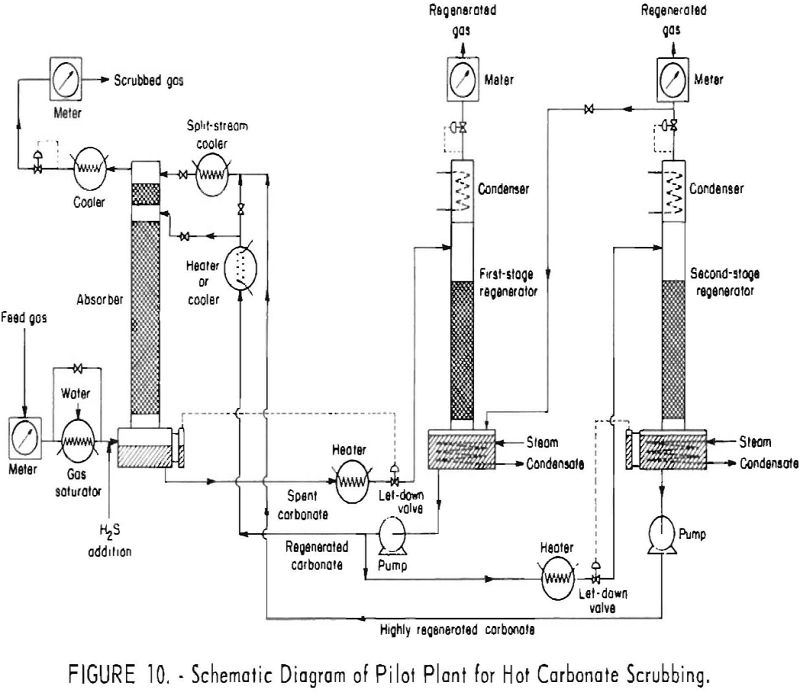

Hot Potassium Carbonate Absorption

Hot carbonate purification will remove hydrogen sulfide from gas mixtures of low or high concentration of this component. The presence of some carbon dioxide in the feed gas is necessary for regeneration of the solution. Carbon dioxide aids in decomposing the bisulfide and retards formation of potassium sulfide. Carbonyl sulfide is hydrolyzed by the hot […]

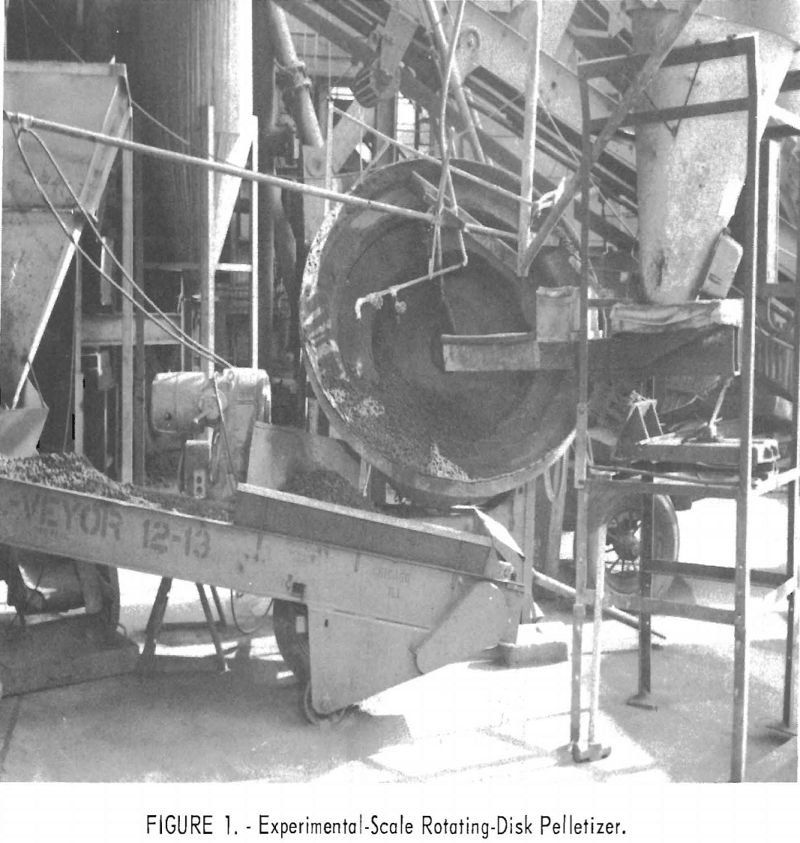

Smelting Unfired Iron Ore Pellets

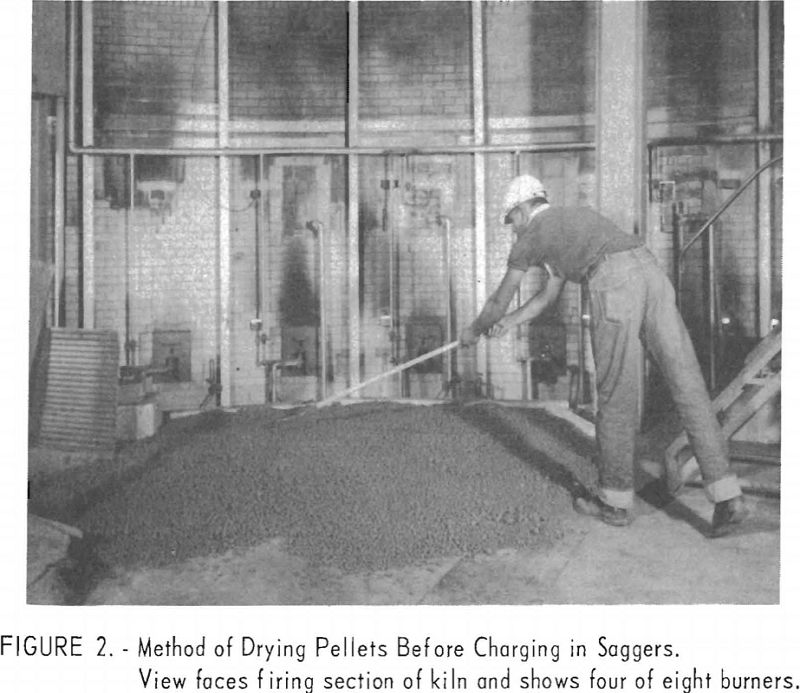

Fines and concentrates must be consolidated or agglomerated into larger masses before they can be smelted in a commercial blast furnace. Such agglomeration is usually done by sintering, pelletizing, nodulizing, or briquetting. Sintering has been the more common practice, but with the advent of taconite concentrates pelletizing is increasing in importance. Pellets in the blast […]

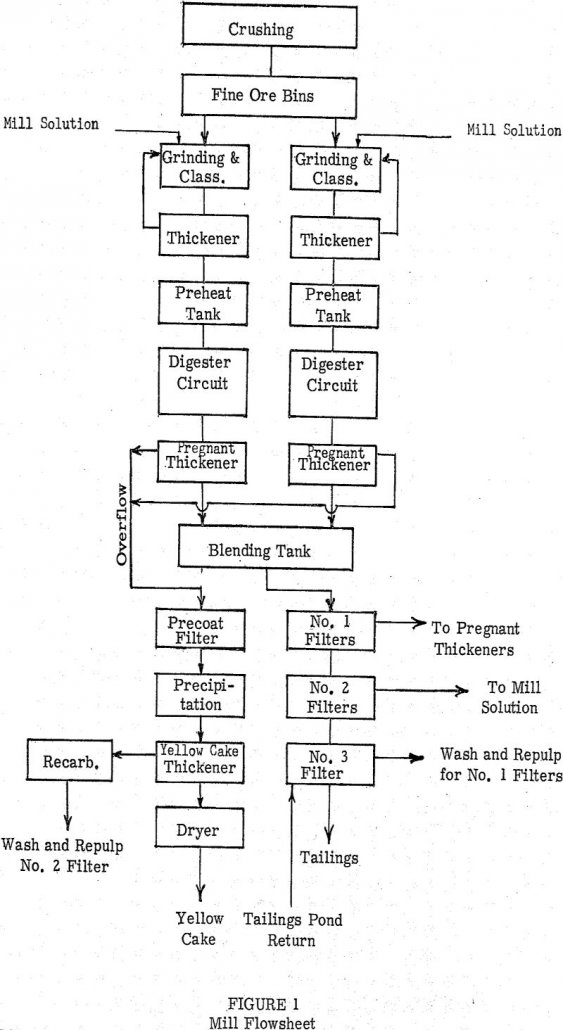

Pressure Leaching of Uranium

Early studies in the carbonate leaching of uranium ores led to the investigation of pressure leaching as a method to enhance the dissolution of the metal values in this system. The initial investigations conducted at the University of British Columbia supplemented by the work done by the group at the A.E.C. Grand Junction pilot plant, […]

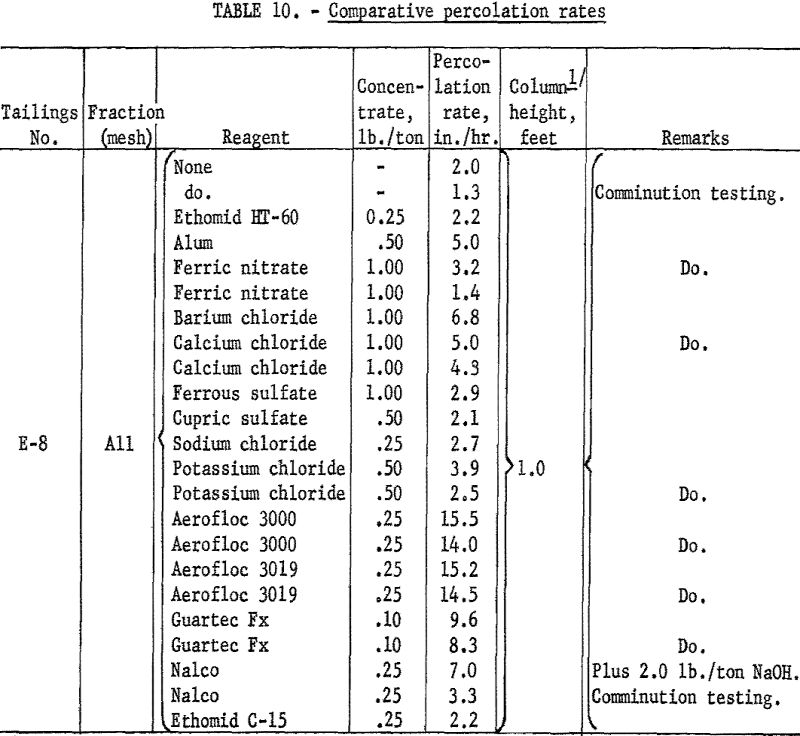

Hydraulic Backfill Characteristics with Flocculants

Two practical methods for controlling the physical properties of mill tailings for underground stope backfill may be used. The first is classification to remove objectionably fine size fractions, and is commonly employed. The second method, flocculation, has had very limited application. It is the subject of this investigation. This report covers preliminary laboratory studies of […]

Rare Earth Oxide Bastnasite

A bastnasite concentrate, containing about 60 percent rare earth oxides, was sulfated with concentrated sulfuric acid to eliminate the carbon dioxide, fluorine, and silica. Calcination at 1,200° F. made the gangue matter insoluble, thus permitting the separation of the soluble rare-earth sulfates. Essentially 100 percent of the rare-earth elements were recovered by this procedure. Since […]

How to Convert Nickel Oxide to Nickel Metal

Sponge nickel can be produced by gaseous or solid-fuel reduction or a combination of both. Although pelletized nickel oxide was reduced in a laboratory rotary furnace, about 40 percent of the pellets abraded; magnetic separation was required to remove the fine sponge nickel from the charred coal and dolomite; hence, rotary-kiln operations were not considered […]

High Speed Camera in Rock Blasting

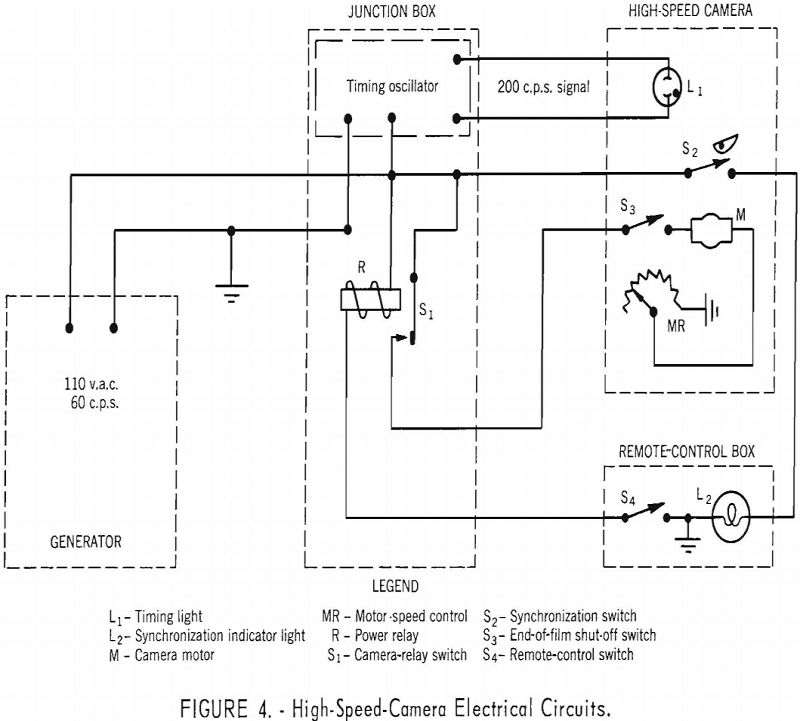

The breaking of rock by explosives occurs so rapidly that the details of the phenomenon cannot be observed by the unaided eye. High- (frame-) speed motion pictures offer a means of slowing down the blasting action so that the various phases of the process can be observed and studied. During the last 10 years, both […]

Boron Crystallography

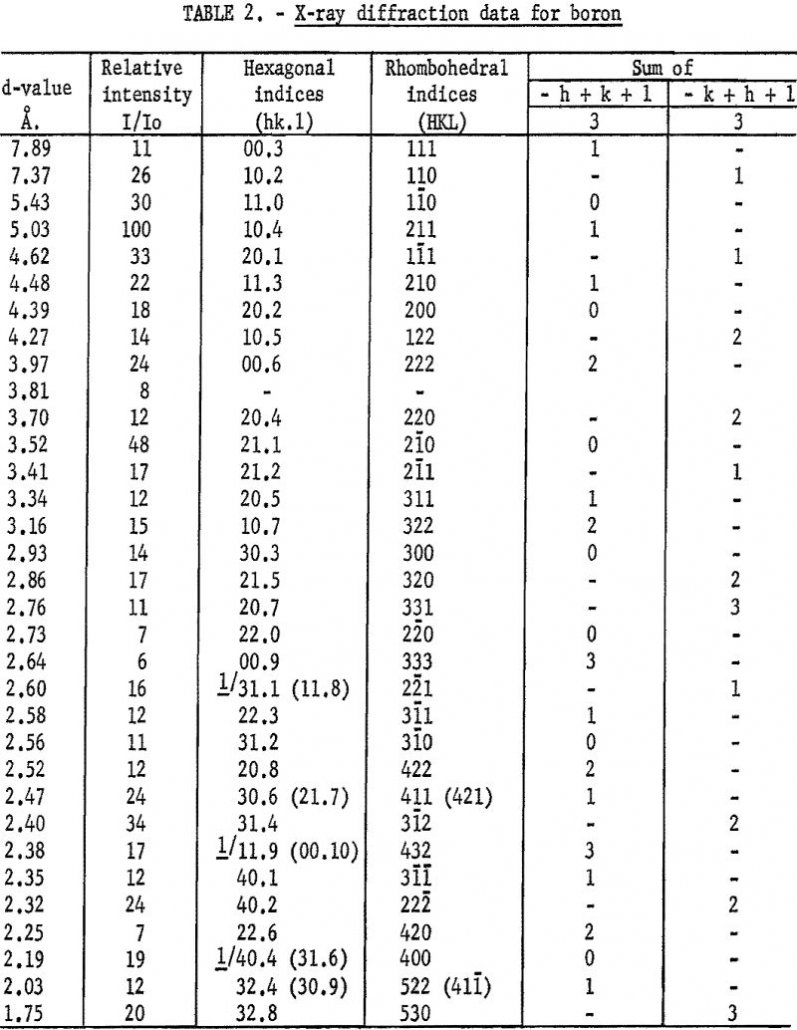

In connection with its continuing studies of the characteristics of alloys and alloying elements, we investigated the crystal structure of fused boron. This Boron Crystallography report describes how the structure of fused boron was found to be rhombohedral by the powder method for crystal-structure determinations by X-ray diffraction. The determinations of the crystal structure of […]

Euxenite Metallurgy

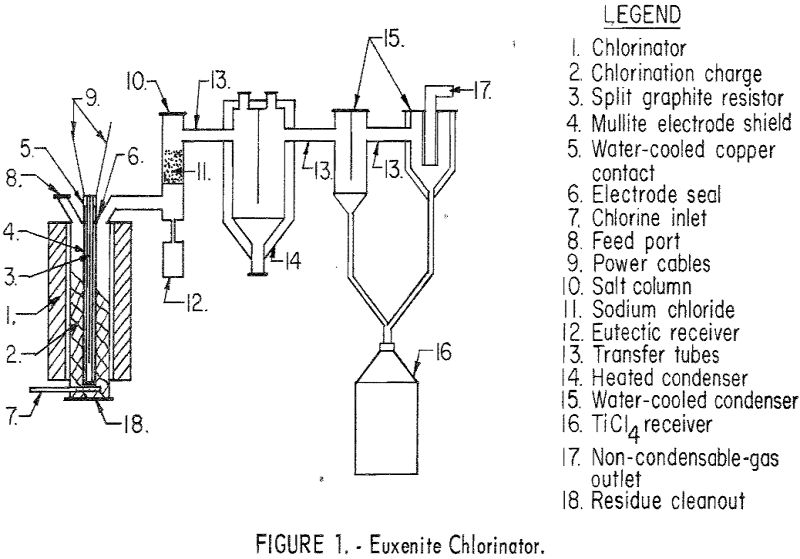

Results of this study demonstrate that multiple-oxide minerals can be processed to usable compounds by the techniques described in this paper. The chlorination procedure offers an efficient method for extracting tantalum, columbium, uranium, titanium, thorium, and the rare-earth elements from their ores. Separation of the chloride products into four groups is of additional benefit for […]

Electrowinning Molybdenum & Tungsten

Laboratory results of fused salt-bath electrolysis indicate that recovery of crystalline tungsten metal from scheelite may be commercially feasible; that purity of the product, although not extremely high, can be controlled to a considerable degree in accordance with varying requirements of cost, product specifications, and purity of raw materials. The selective deposition of molybdenum and […]