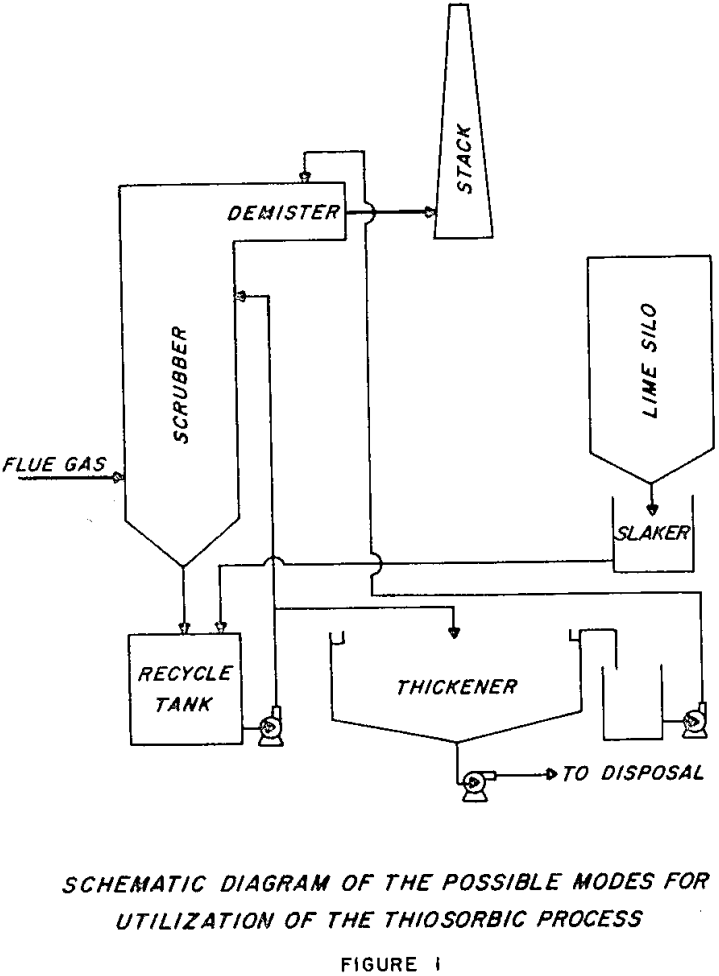

Thiosorbic SO2 Scrubbing Process

Lime and limestone-based SO2 scrubbing processes have demonstrated reasonably good success in removing low concentrations of SO2 from flue gases. While most of the operating problems experienced in the early days of scrubbing have been worked out, problems usually increase and removal efficiency drops with increased amounts of SO2 present in the gas stream. Thiosorbic […]

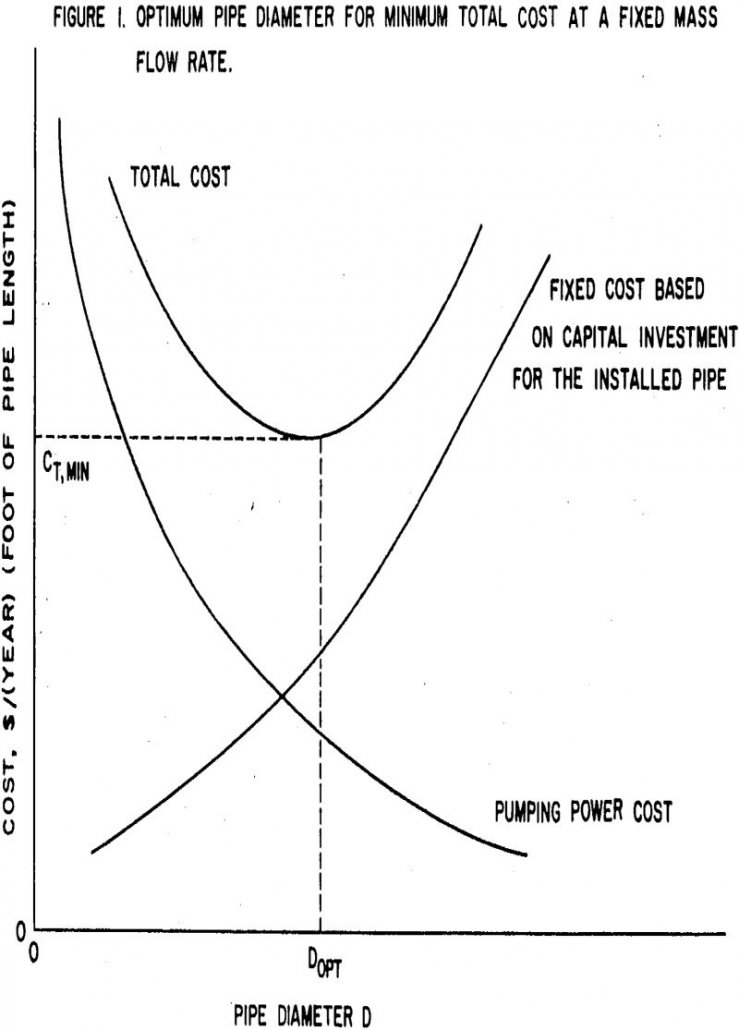

Slurry Pipeline Economics

A technique is presented for the economic selection of a slurry pipeline with the aid of a computer. Mathematical models for the flows of homogeneous slurries are utilized. Only the pipeline and its prime movers are considered. Slurry flow properties are first obtained from rheology and/or pipeline data measurements. A rheological model is then selected […]

Flotation Plant Simulation

Knowledge of the behaviour of flotation machines had developed and increased considerably over the last few years. Although much work remains to be done on the study of the fundamental processes that influence the collection of hydrophobic particles at an air-water interface, there is enough information to permit the building of realistic models of the […]

Recovery of High Grade Copper from Ammonical Solutions

The present process refers to a method for efficiently obtaining high purity metallic copper from copper ammonium sulfite. Essentially, this process consists of submitting the copper ammonium sulfite to the action of heat and pressure with the object of obtaining by the decomposition of it, metallic copper, ammonium sulfate, sulfur dioxide, and sulfuric acid. Detailed […]

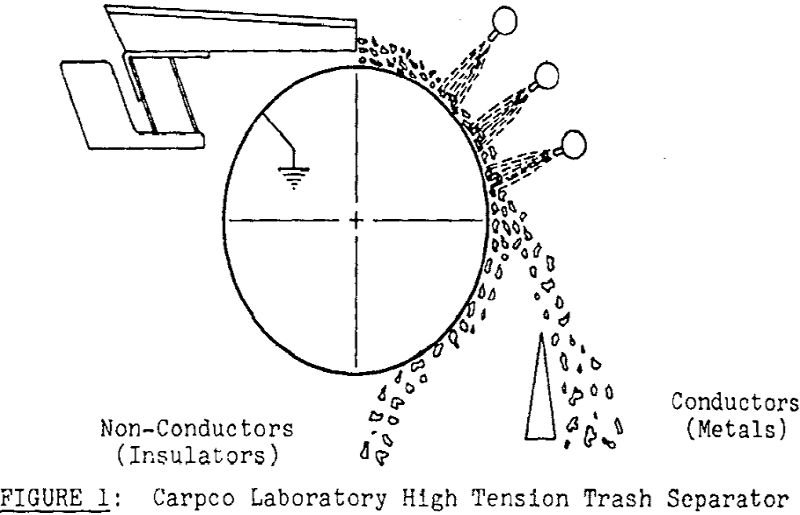

Recovery of Aluminum by High Tension Separation

The high tension process which separates materials based on relative differences in surface conductivity has been very successful in recovering non-ferrous metals from municipal waste. Aluminum is by far the largest constituent of the total non-ferrous metal fraction; accounting for >95% in most localities. Wire and insulation mixtures from industrial wastes have been treated commercially […]

Pre-Concentration by Sorting – Photometric

Pre-concentration by sorting is as old as the mining industry. Inevitably waste rock is broken with ore. Separation may take place in the stopes by selective mucking and transport, or selective loading and transport of ore and waste by 12-cu. yd. shovels and 100-ton trucks in large open pit operations. Hand sorting of 1″ to […]

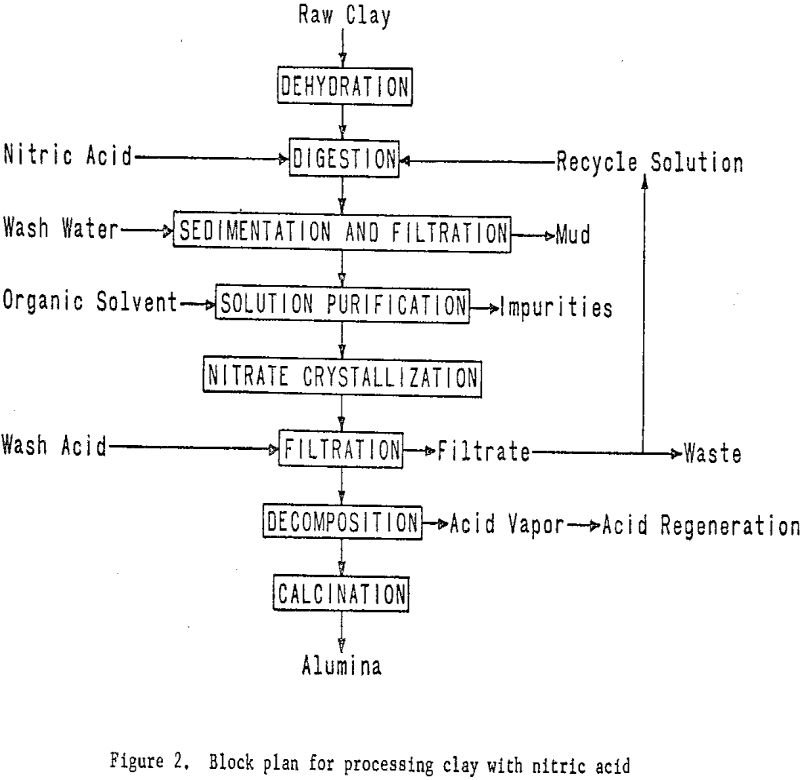

Miniplant Project to Evaluate Alumina Recovery Processes

Bureau of Mines forecasts of the aluminum situation show that U.S. demand for the metal in the 1960’s increased at a average annual rate of 9.4 percent, with a projected long-term growth rate of 6.5 percent, higher than any other metal. Conversely, the Nation is becoming increasingly dependent on imports for its aluminum needs. Of […]

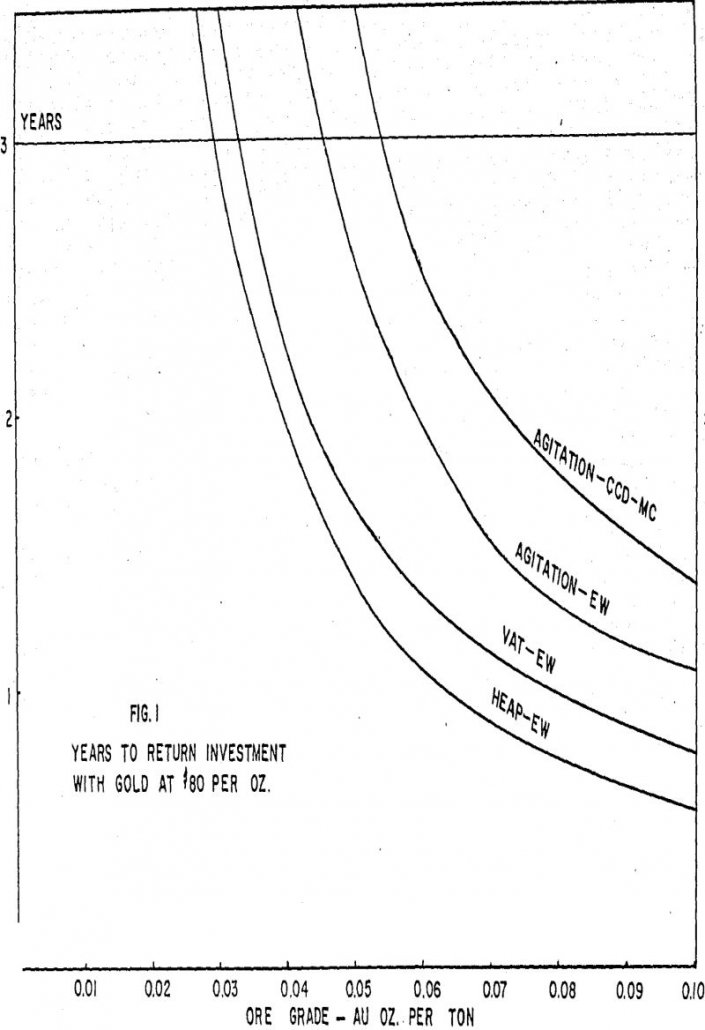

Leaching of Low Grade Gold Ores Economic Evaluation

The treatment methods applicable to comparatively higher grade ore averaging better than 0.2 ounce gold per ton and having a cutoff grade of about 0.07 ounce gold per ton, include gravity concentration, amalgamation, flotation, cyanidation or direct smelting. Such processes involve high capital investments as well as high operating costs. A conventional cyanidation plant used […]

Continuous Countercurrent Decantation and Filtration

In extractive metallurgy, separation of insoluble solids from solutions is an important economic factor in almost all flowsheets. This separation step can employ sedimentation, filtration (vacuum and pressure), or centrifugation. Since practically all systems require a relatively complete separation, multiple unit, countercurrent thickeners or vacuum filters are generally used. Continuous Countercurrent Decantation In its simplest […]

Concentrate Slurry Pumping System

Exploration on Bougainville for copper by Conzinc Riotinto of Australia (CRA) began in 1963 and by 1968, through geophysical, geochemical and diamond drilling methods, an orehody containing nearly one billion tons of ore grading approximately 0.48% Cu. and some gold had been outlined. Bougainville Copper Ltd., the company operating the mine, is 53.6% owned by […]