Solving Industrial Mineral Flotation Problems

Flotation was practiced by this and succeeding engineers to concentrate many of the non-metallic minerals available from Canadian resources. Experimentation, and some extensive experimentation. A number are still under investigation. A few have evolved into producing plants. The results obtained for some have been used to increase efficiencies in existing plants. Results for others have […]

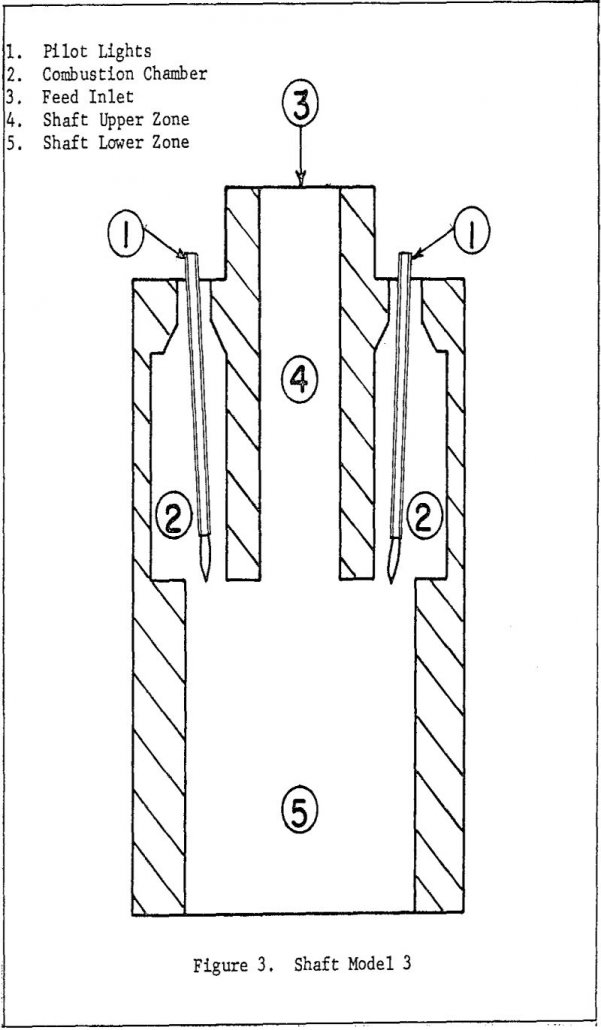

A Shaft-Electric Furnace for Melting and Smelting

The electric arc furnace has characteristics which make it attractive for a number of metallurgical applications. Some of these characteristics are: high thermal efficiency, the possibility of attaining very high temperatures, low off-gas volume compared to fuel-fired furnaces, no impurities are introduced by the heat source, and impurities in only minor amounts are introduced by […]

Slurry Pulp Distributor

The practical and effective pulp distributor here presented is believed to be of a completely new and innovative design. It was developed at the San Nicolas Plant of the Marcona Mining Company in Peru, where it has been thoroughly plant tested using iron ore slurries of a particularly abrasive nature. As indicated, the motivation for […]

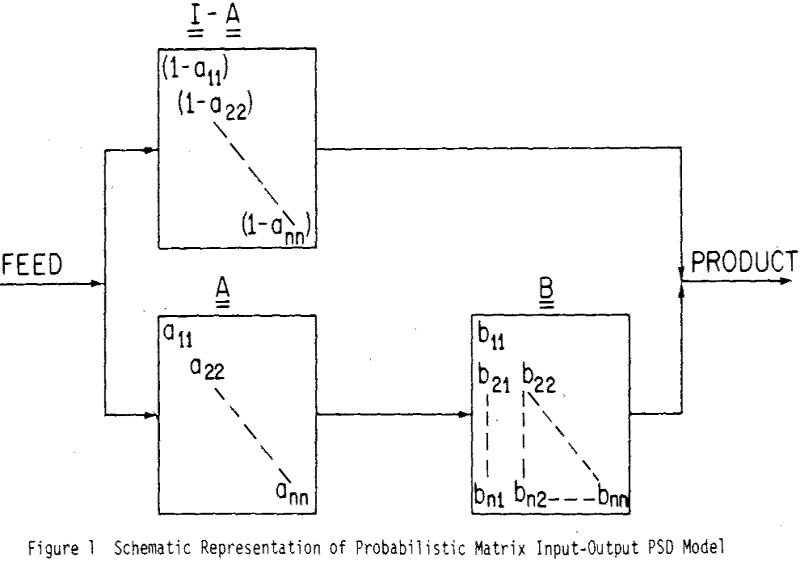

Population Balance Models for Predicting Grinding Mill Performance

Comminution represents one of the major costs.of mineral recovery from low- grade ores. Efficient mineral recovery in a typical low-grade ore grinding-flotation process depends on grinding the ore small enough to liberate mineralization without producing excessive slimes, which would result in higher power and flotation reagent costs. Size criteria for efficient grinding should be stated […]

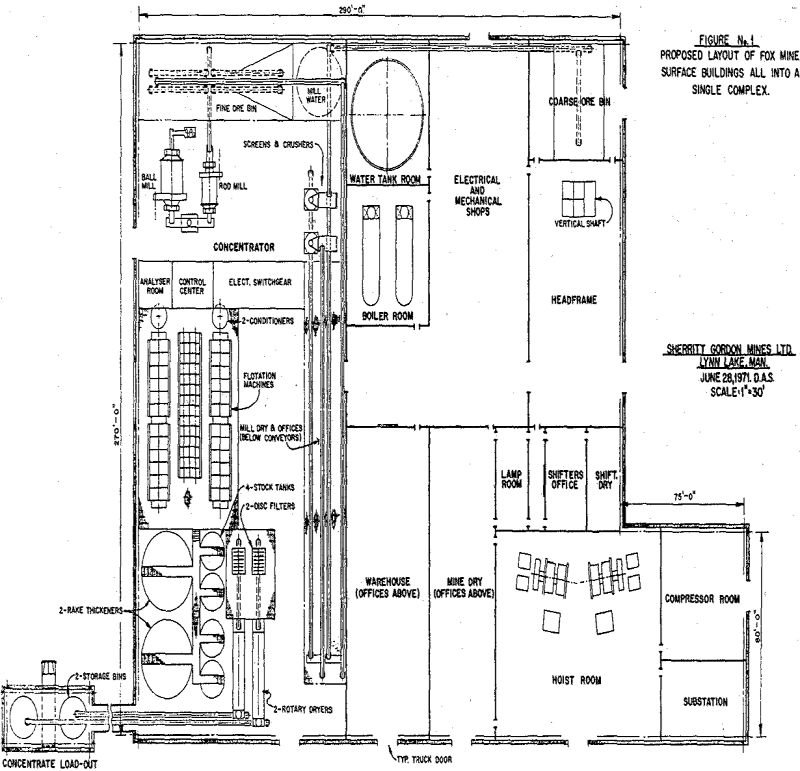

Plant Layout – Cold and Remote Areas

Basic things to remember in plant design for cold and remote areas are, everything in these areas is more expensive due to long and difficult supply lines. Fuel is expensive and would be a major cost item even if it were not expensive, due to the extended periods of low temperatures. Building volumes should therefore […]

Pelletizing of Iron Ore Concentrates

The program of study of pellet binder materials was begun by the ORF in 1963 to examine various Canadian materials as substitutes for bentonite which is imported in large tonnages (199,270 tons in 1969) from the U.S.A. for Canadian pellet plant operations. Most of the raw bentonite used in Canada originates in Wyoming, North Dakota […]

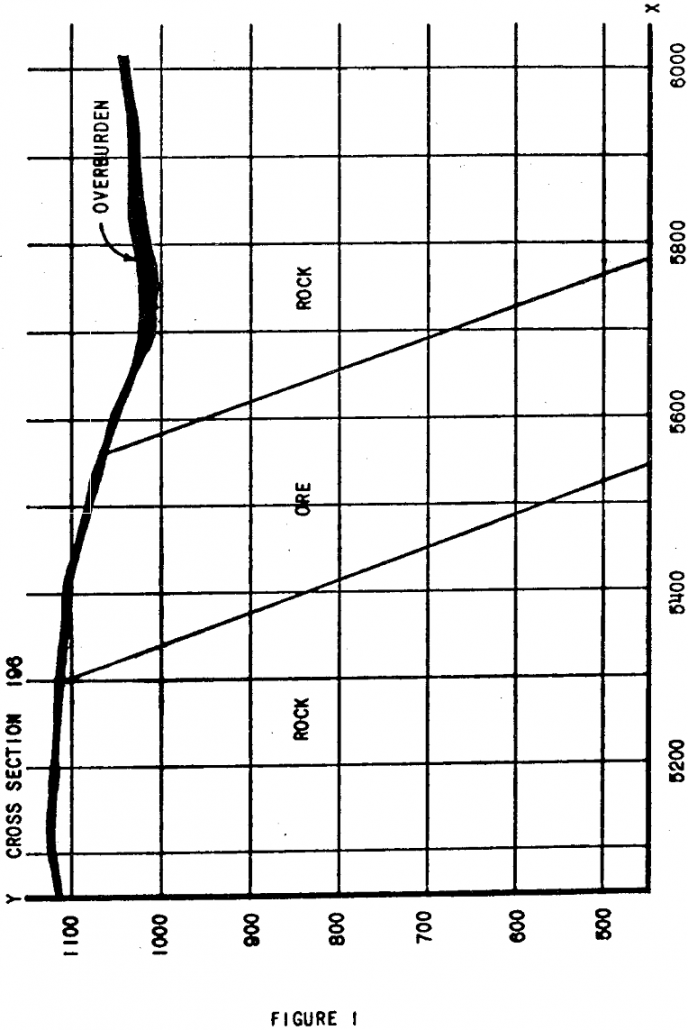

Functional Optimization of Open Pit Mine Design

In the development of the ultimate pit limits for a narrow ore body, parameters necessary in the design of a functional, or working, pit become highly sensitive factors in the determination of ore reserve levels and their associated waste to ore stripping ratios. Through the use of geologic cross sections, ore reserves can be roughly […]

Separation of Solids and Fluids by Magnetic Flocculation

Flocculation, the process of coagulation or coalescence of finely divided particles, is commonly used in separating fine solids from fluids. Forces disposing of the particles to flocculate include: ionic forces of attraction, secondary entropic forces, and magnetism. Magnetic flocculation is due to a physical magnetizing process which affects suspended ferromagnetic particles. Such particles, after exposure […]

Gypsum Tailings Pond Design

Tailings disposal has been a problem for the mining engineer since the beginning of the metal milling process. Disposal systems in common use have evolved as the most economic method for the disposal of an unwanted waste material within the disposal restrictions in force at the time of construction. As restrictions are constantly being expanded, […]

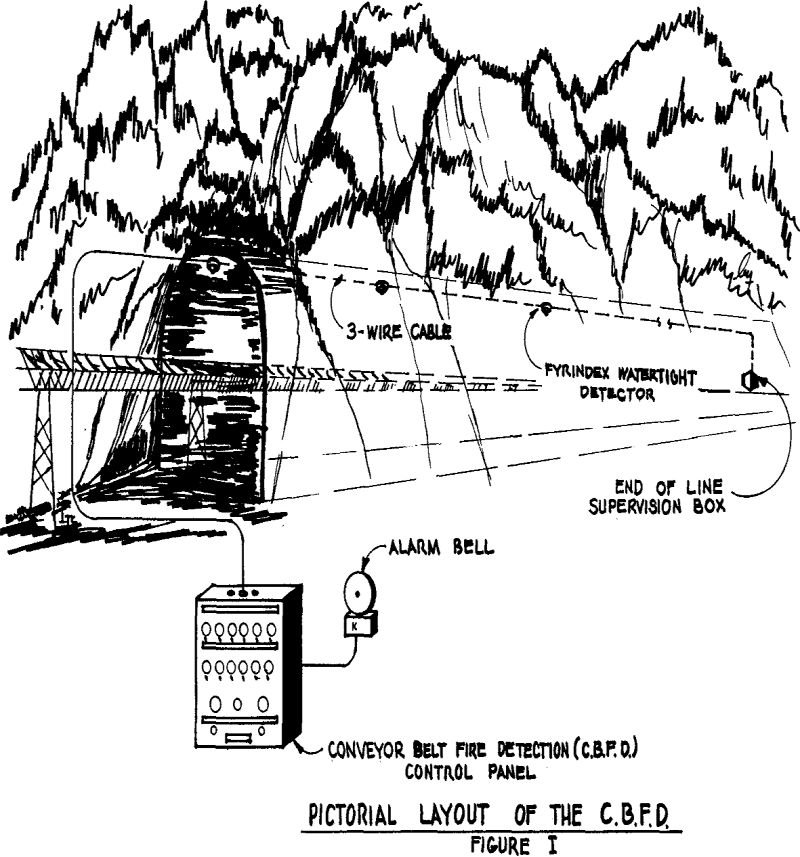

Fire Protection for Belt Conveyors

For more than fifty years Walter Kidde & Company, Inc. has engaged in the development and manufacturing of both fire suppression and detection equipment. Our initial work for the mining industry centered around dry chemical extinguishing equipment for mine haulage cars. To fulfill this need, Kidde engineered and developed a manually activated dry chemical system […]