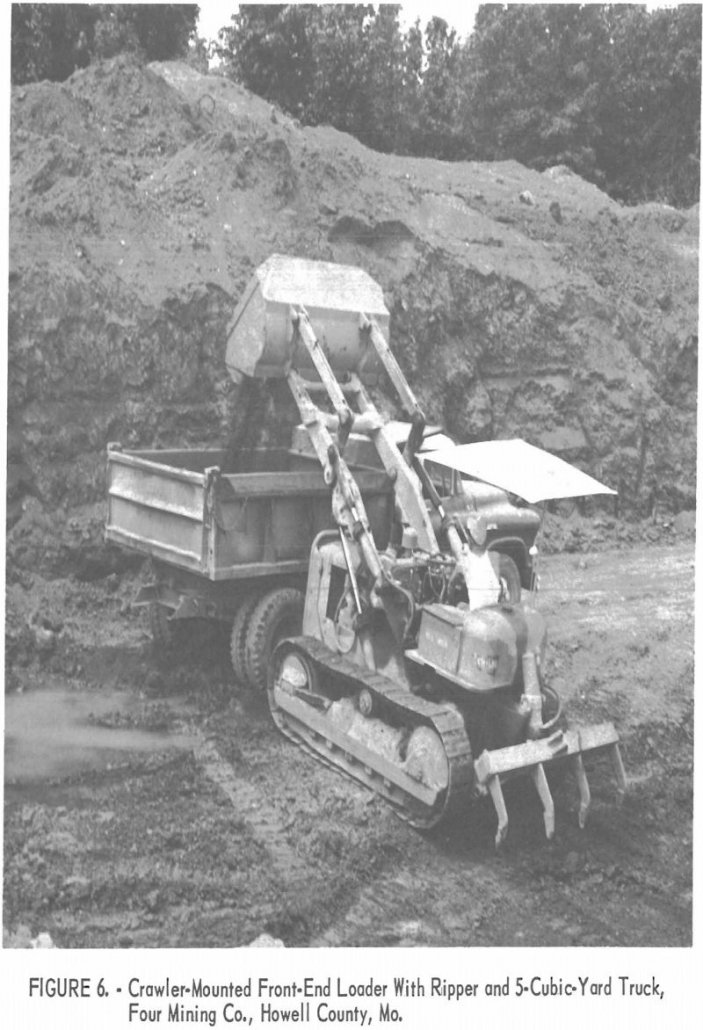

Brown Iron Ore Mining

Most brown-iron deposits of southern Missouri occur in residual materials resting on Jefferson City dolomite, Roubidoux sandstone, or Gasconade dolomite, all of the Ordovician system (see table 1). The residual materials, which consist mainly of clay, chert, and iron oxides, are products of weathering of sedimentary rocks younger than the Jefferson City dolomite. Deposits of […]

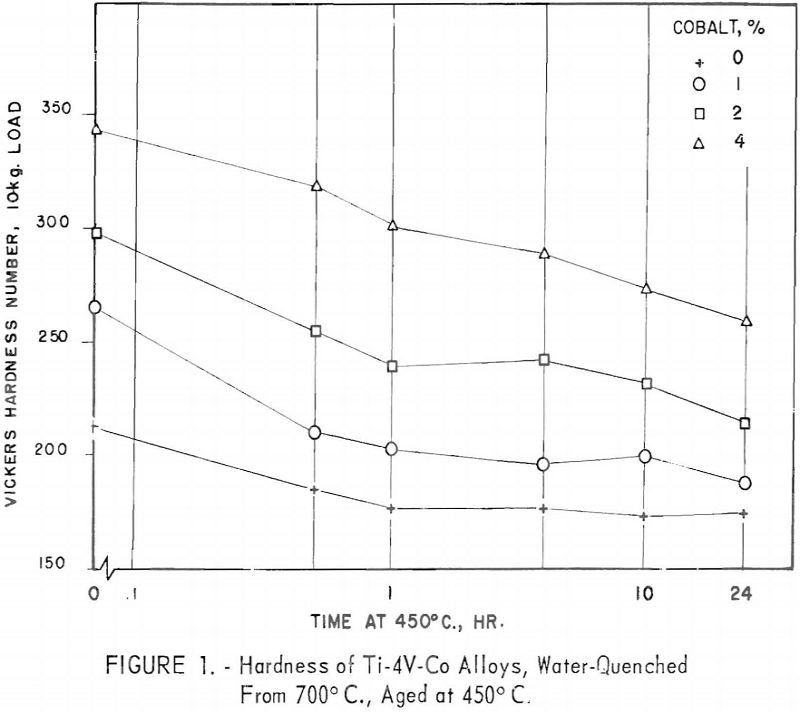

Titanium Vanadium Cobalt Alloys

Results of the study of titanium binary and ternary alloys containing vanadium and cobalt show that: Vanadium additions up to 16 weight-percent were insufficient to completely retain beta on water-quenching. Cobalt additions up to 4 weight-percent do not affect retention of the beta phase on water quenching Ti-V-Co alloys containing up to 16 weight-percent vanadium. […]

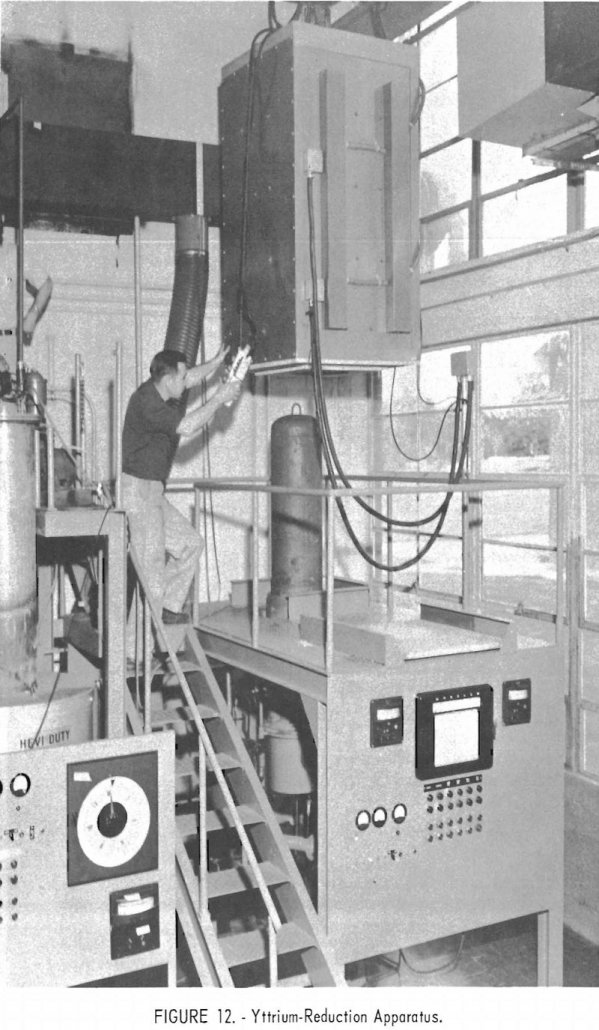

How to Prepare High Purity Yttrium

This report does not constitute a finished investigation. Its purpose is to report on the status of current reduction studies and to demonstrate that high-purity ductile yttrium metal can be prepared by metallic reduction of yttrium chloride. Although both lithium and sodium have proved to be effective reductants, no conclusions can be reached on which […]

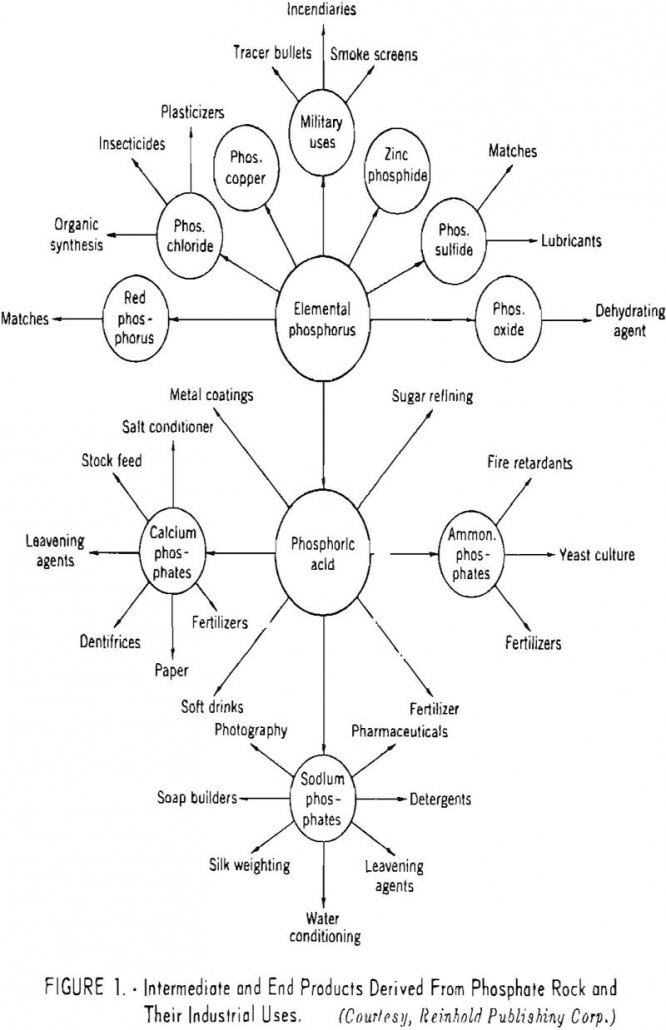

Phosphate Rock Properties

Three fundamental methods are employed in decomposing phosphate rock: Reduction by carbon at high temperature. Treatment with one or more acids. Calcination or fusion with silica, sodium salts, magnesium minerals, or small quantities of phosphoric acid. The products derived from phosphate rock by these treatment methods may be divided into the following live broad groups: […]

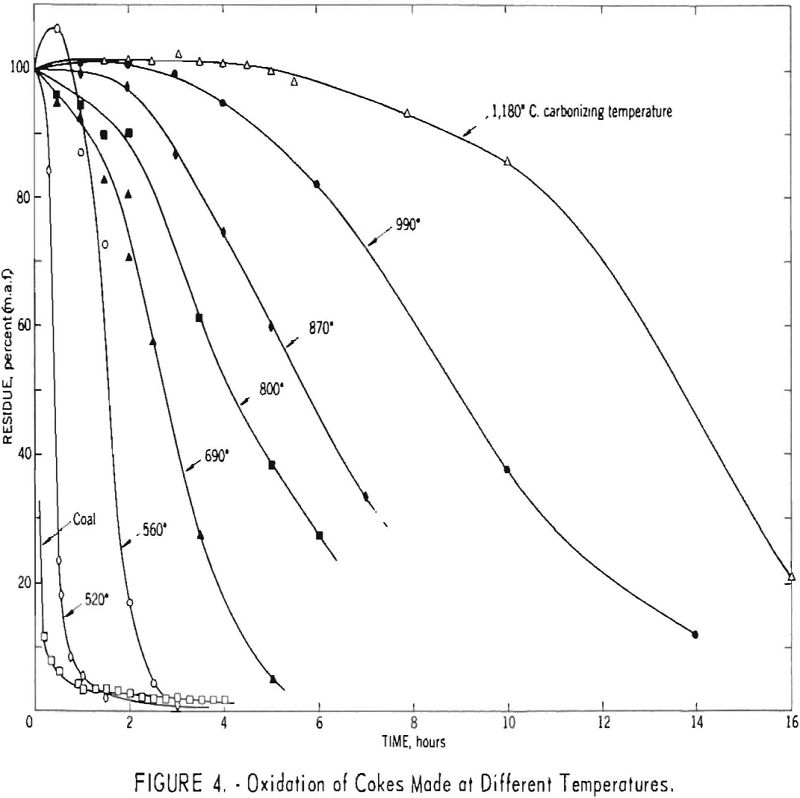

Nitric Acid Oxidation Rates of Coal

Coals ranging in rank from lignite to anthracite, cokes carbonized at temperatures ranging from 520° to 1,180° C., and synthetic polymers have been oxidized by the standard method, that is, by boiling in 8-normal nitric acid. Some of these materials were also oxidized by one or two modifications of the standard method. Although the fusain […]

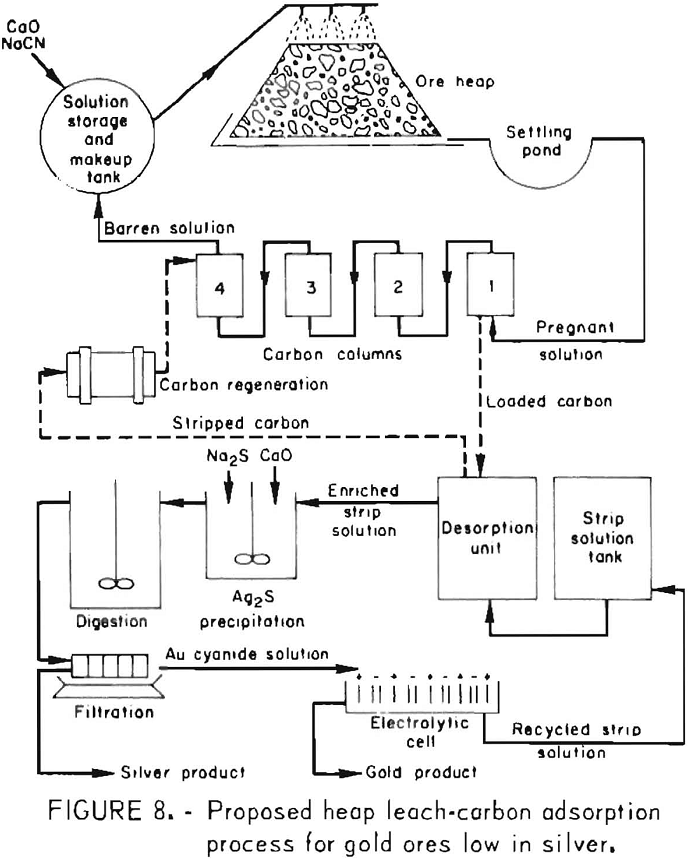

How to Process Gold Ores by Heap Leaching & Carbon Adsorption Methods

The heap leach cyanidation carbon adsorption electrowinning process developed has proved to be an economical method for exploiting low-grade gold ores and small isolated deposits not suitable for treatment by conventional cyanidation procedures. Heap leaching may be the most profitable method for processing selected gold and silver ores that do not require fine grinding and […]

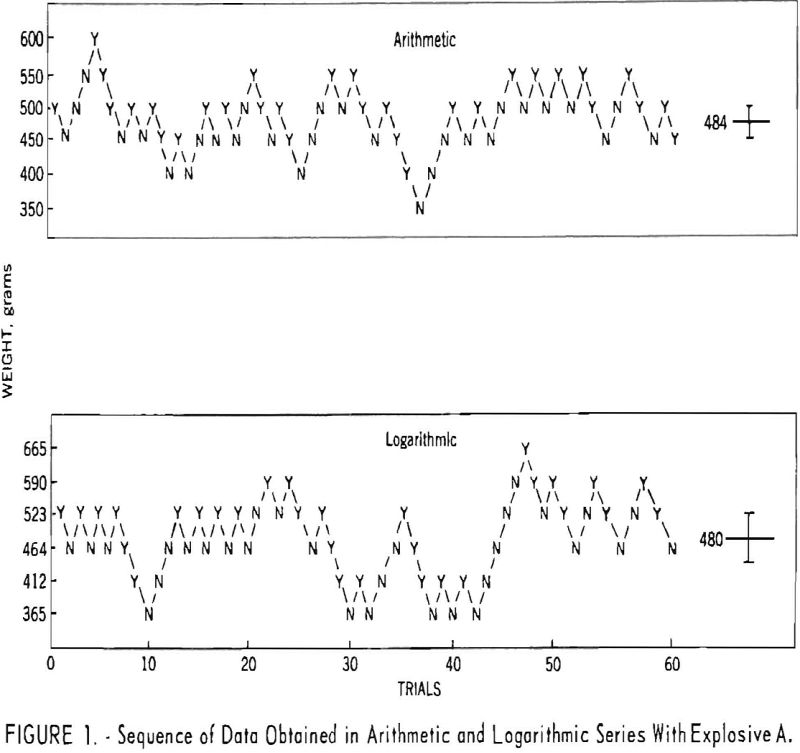

Sodium Chloride in Explosives

Based on the analysis of the W50 values of 65 permissible-type formulations, with and without added sodium chloride of various particle sizes, it was concluded that: The addition of sodium chloride to an explosive has a highly significant effect in reducing its probability of igniting firedamp. Addition of small amounts of sodium chloride (about 3 […]

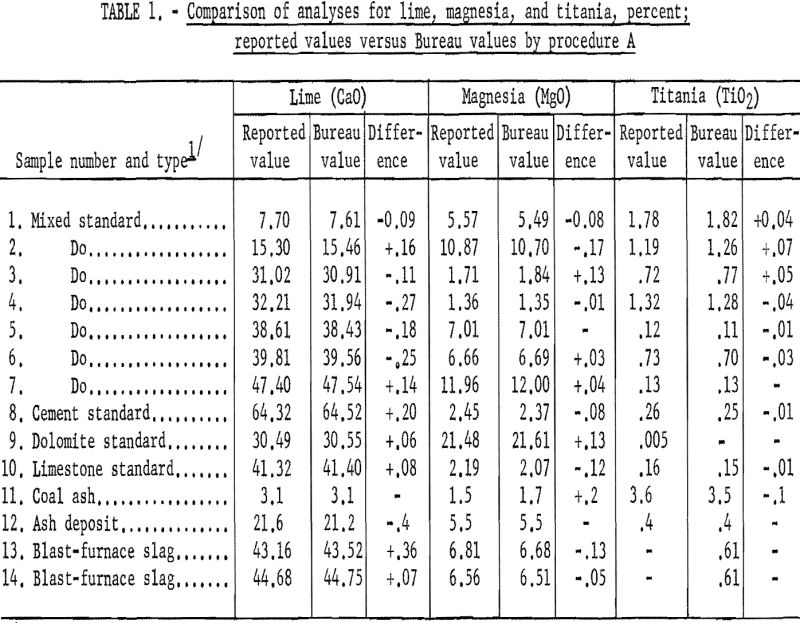

Determining Lime Magnesia and Titania in Slags

Standard methods of analysis for calcium and magnesium are involved and time consuming and generally require considerable analytical skill. Investigation of possible alternatives more suitable for rapid routine application led to a procedure developed for the rapid determination of calcium, magnesium, and iron in limestone, in which these cations are determined by a series of […]

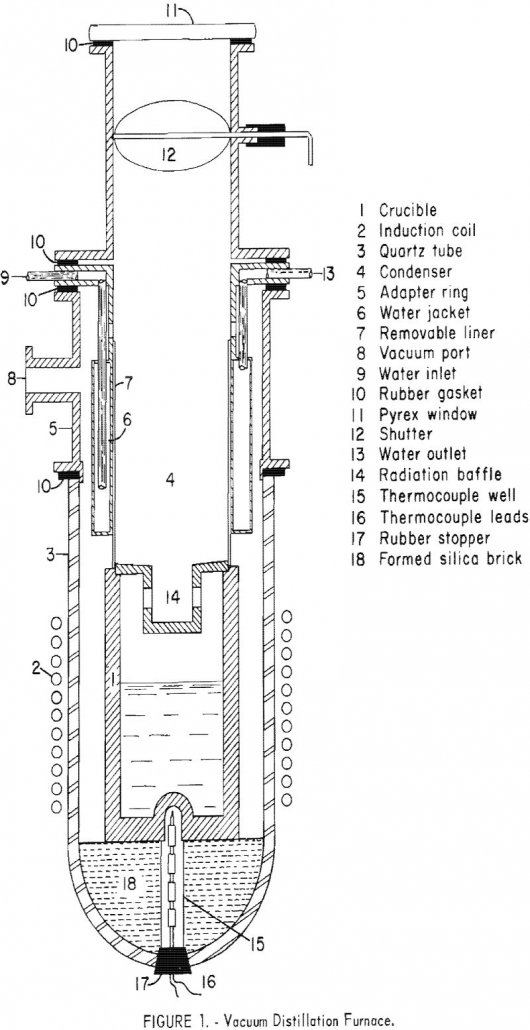

Vacuum Distillation – Remove Volatile Metals

The rate of evaporation of a volatile metal from a metallic solution containing less volatile metals is determined by its partial pressure and its diffusivity. The concentration of a volatile metal will be less at the surface than in the interior of the metal; it will adjust itself to keep the rate of diffusion and […]

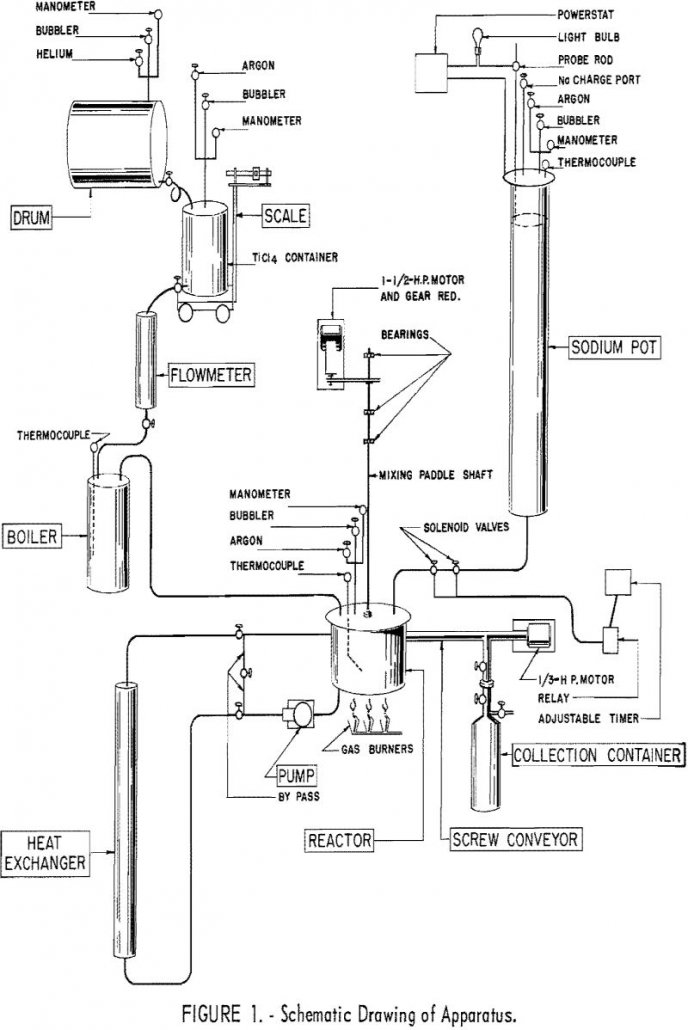

How to Reduce Titanium Tetrachloride

This investigation has demonstrated that finely divided titanium metal, titanium lower chlorides, or a mixture thereof can be produced at a temperature between 105° and 205° C. in a continuous operation. The relative quantities of metallic titanium and lower chlorides produced by the reaction are dependent upon the ratio of the feed materials used. For […]