Tailings Disposal and Liquefaction

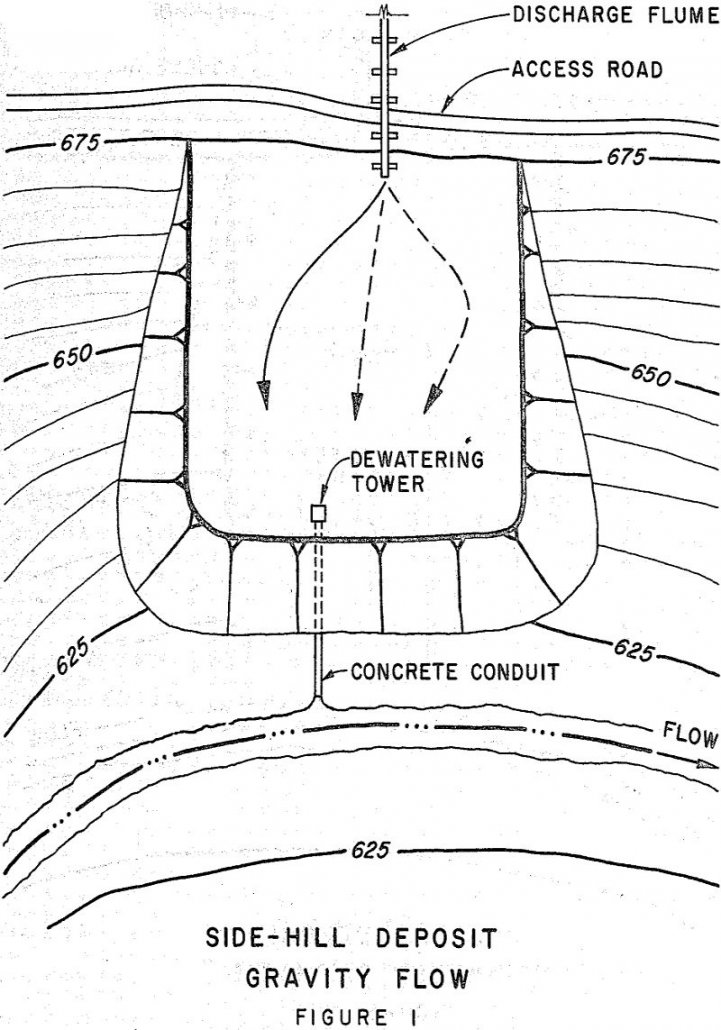

One of the many responsibilities of mining engineers and mill superintendents is to provide for the safe and economic disposal of wastes (or tailings) remaining after a mineral has been extracted from an ore. The cost of disposal of these tailings exerts a considerable influence on the minimum grade of ore extracted from the mine. […]

How to Recover Molybdenum in Oxidized Ore

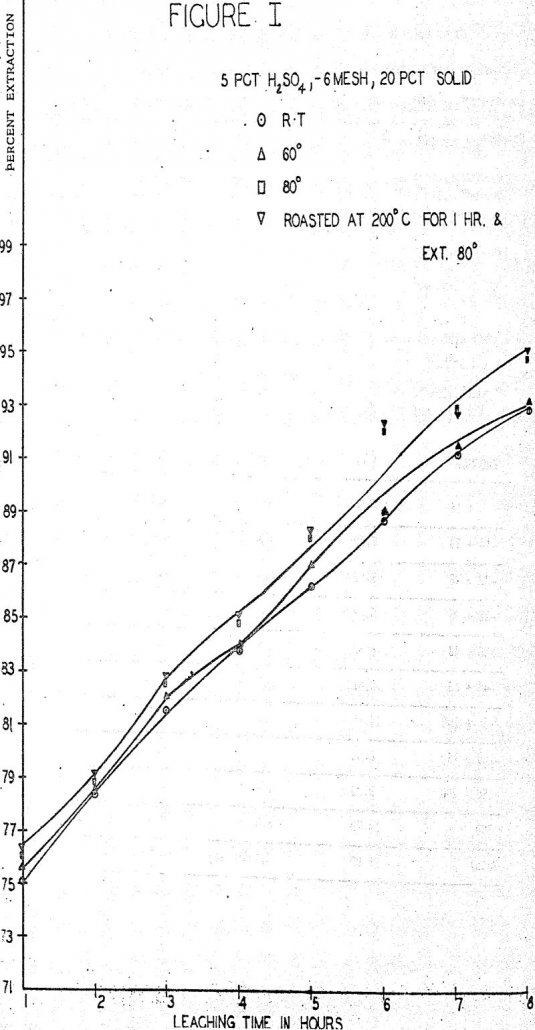

A study of some variables affecting the recovery of molybdenum from oxidized molybdenum minerals was made. The effects of variations in contact time, temperature, pulp density, particle size, and solvent concentration on the recovery of molybdenum using acid and alkaline solvents were investigated. Chemical analyses, screen analyses and microscopic examinations were made and the presence […]

Power Scale-Up for Agitating Slurries

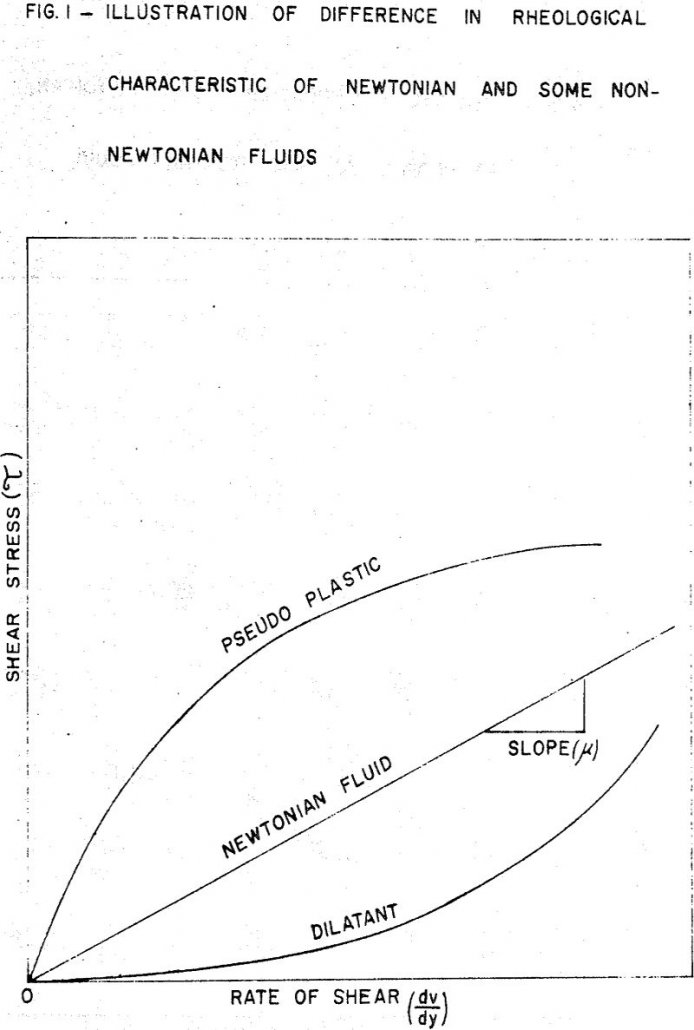

An interesting problem with which the senior author has been concerned with is the scale-up of power requirements for slurry agitators operating in the laminar region with pseudo-plastic materials. Pulps of shaly ores, after various chemical reactions in aqueous leaching systems, are often difficult to settle and filter if agitation is violent. In these cases […]

Tertiary Zeolite Ore Mineral Distribution in Size Fractions

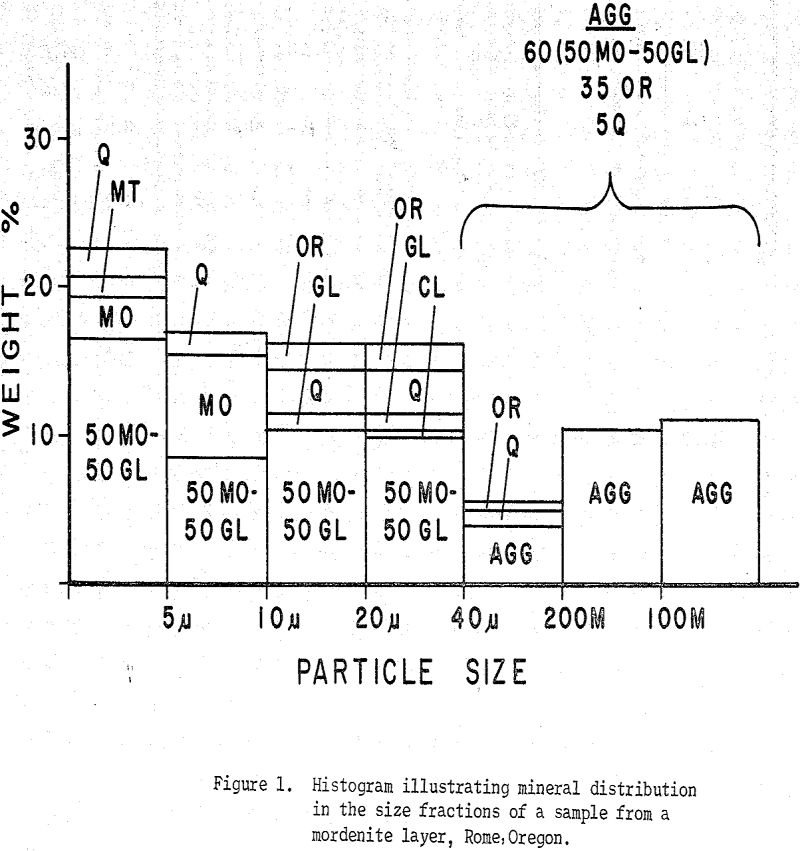

Zeolite ores and protores occur in extensive deposits in the western United States. A recent paper describes the general geology and mineralogy of these deposits and their geographical distribution. The zeolites are alkali- and silica-rich varieties of mordenite, erionite, chabazite, phillipsite, ferrierite, and clinoptilolite. The Tertiary zeolite ores consist of one or more zeolites (mordenite, […]

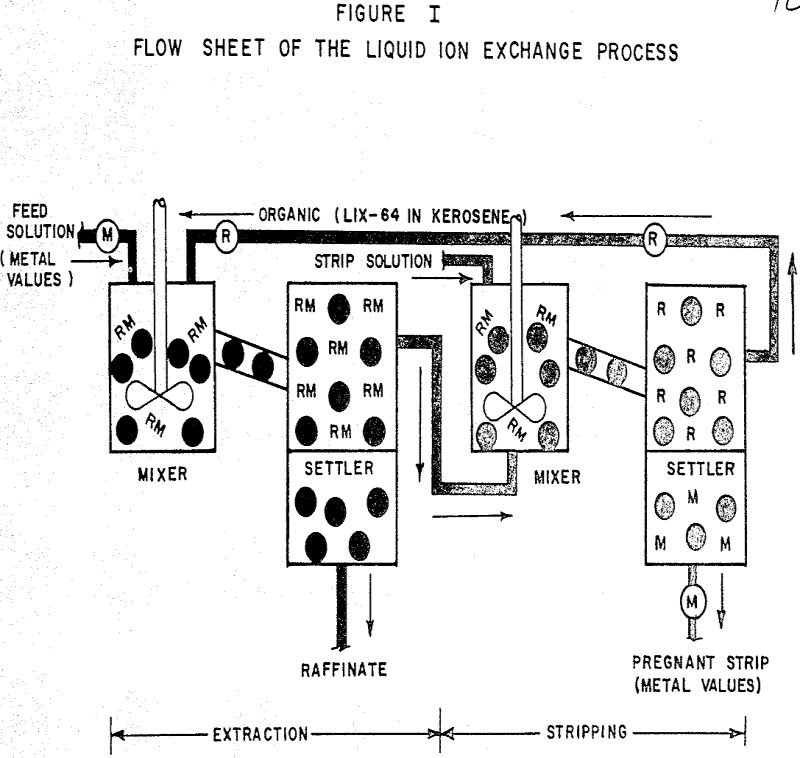

Use LIX-64 Extractant for Copper Pilot Plant Data

Design parameters for scale-up to commercial plants are presented and discussed along with a revised capital cost estimate. The future pilot program is discussed, including minor design changes and the effect of entrained organic on dump leaching efficiency. Description of The Liquid Ion Exchange Process In the extraction section, a water-immiscible organic solvent (normally kerosene) […]

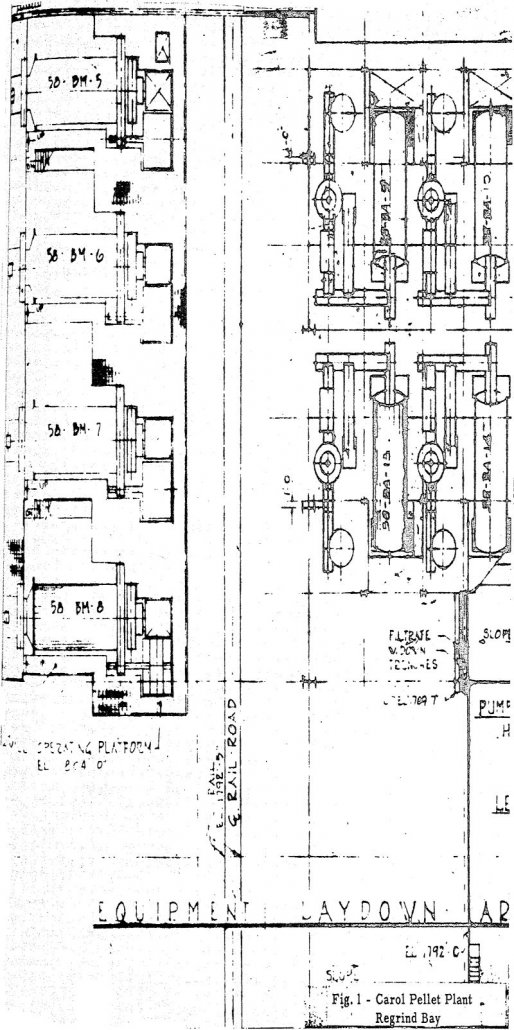

Designing a Mill for Maintenance

Its purpose is to highlight the things that have been accomplished by the mill designers to lighten the load for the maintenance superintendent and to reduce the overall costs for the plant operator. The complexity of plant design, the civil and structural engineering problems encountered when the satisfactory maintenance layout is accomplished are appreciated, and […]

Heap Leaching Copper Ore

Ranchers began its evaluation of the Bluebird Mine in late 1963. The property which included some 400 acres, adjoined one of the country’s leading producers – Inspiration Consolidated Copper Company. Such proximity led many to equate availability with undesirability. However, a relatively short period of exploration and metallurgical evaluation and a simultaneous assessment of other […]

Correlation Between Surface and Flotation in Silicates

Experimental studies on the flotation of silicate minerals go back at least thirty or forty years (Bull, 1929; Bull, Ellefson, and Tylor, 1934; Fuerstenau, 1962; and Gaudin, Glover, Hansen, and Orr, 1928). These investigations for the most part have been empirical and have failed to give detailed information on the nature of the silicate-solution interface. […]

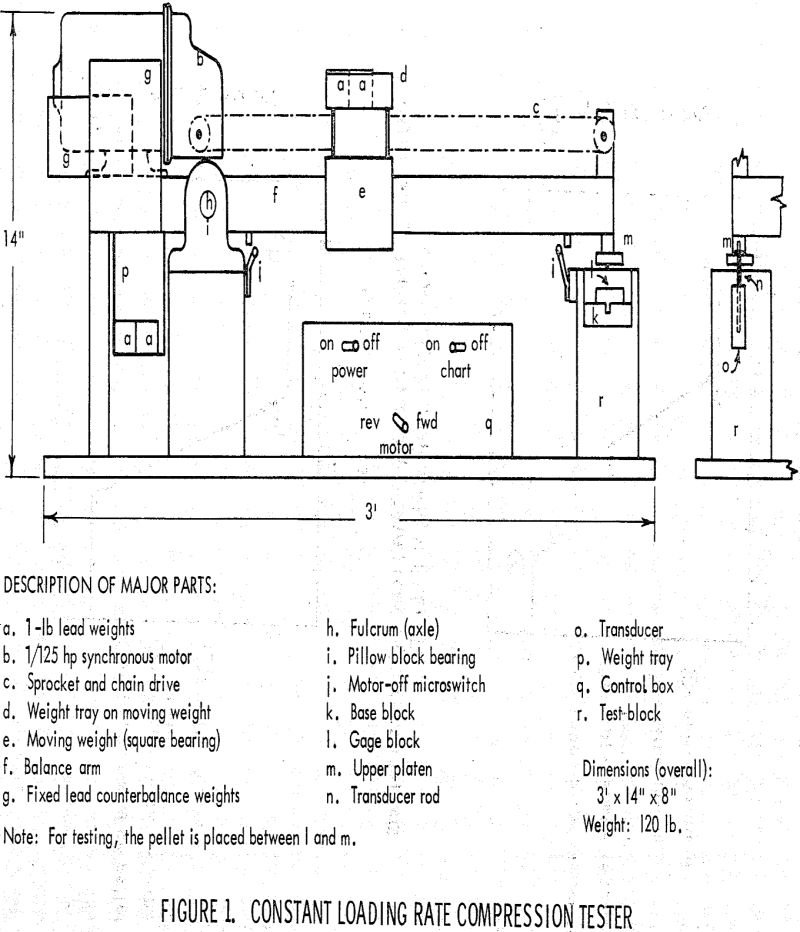

Compression Testing of Green and Dry Iron Ore Pellets

For many years the green and dry compressive strengths of pellets have been considered as possible criteria of pellet performance during induration. Although widely quoted throughout the industry, little attention has been given to standardizing the unfired pellet compressive strength test or to determining the characteristics of the test. Materials and Equipment Most testing machines […]

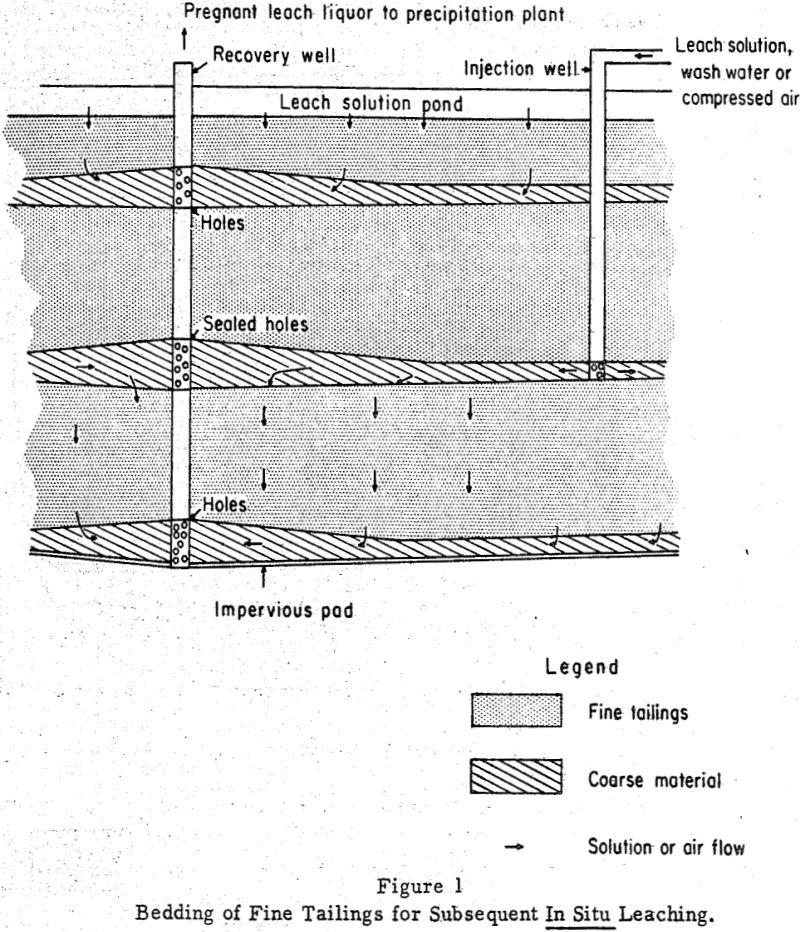

Chemical Mining

Chemical mining is the in situ extraction of metals from ores located within the confines of a mine (broken or fractured ore, stope fill, caved material, ores in permeable zones) or in dumps, prepared ore heaps, slag heaps, and tailing ponds on the surface. These materials represent an enormous, untapped, potential source of all types […]