Factors Affecting the Angle of Slope in Open-Cast Mines

The problems of slope stability in open-cast mines are examined. A criterion, the instantaneous stripping ratio, is suggested for use in the design of pit slopes and as an index of control at all stages of the exploitation of the ore body. This criterion may also be related to safety and to the maximizing of […]

Low Alkali Portland Cement

The concurrent observation of the phenomena of alkali-aggregate reaction and development of efficient dust collection systems on rotary-kilns made mandatory the process modifications to produce low alkali cements. Such low alkali cements as were available prior to these recent changes were either the rare result of low alkali raw materials, the loss of alkalies, with […]

Cultured Quartz

The technique of growing crystals from the melt, such as KI, NaBr, was already commercially in use. Quartz could not be so grown, since its utility depends on the form stable below 573° C, and, even if it could be grown from an extraordinarily viscous melt, the higher form passing through this transition becomes twinned. […]

Clinkering Process in Portland Cement Manufacturing

In portland cement manufacturing, the raw materials are changed to clinker in the burning operation. Generally the rotary kiln is used for this purpose and involves many processes including pelletizing and nodulizing. This transformation is called clinkering and is analyzed as now generally practiced in cement making from the raw material to the resulting clinker. […]

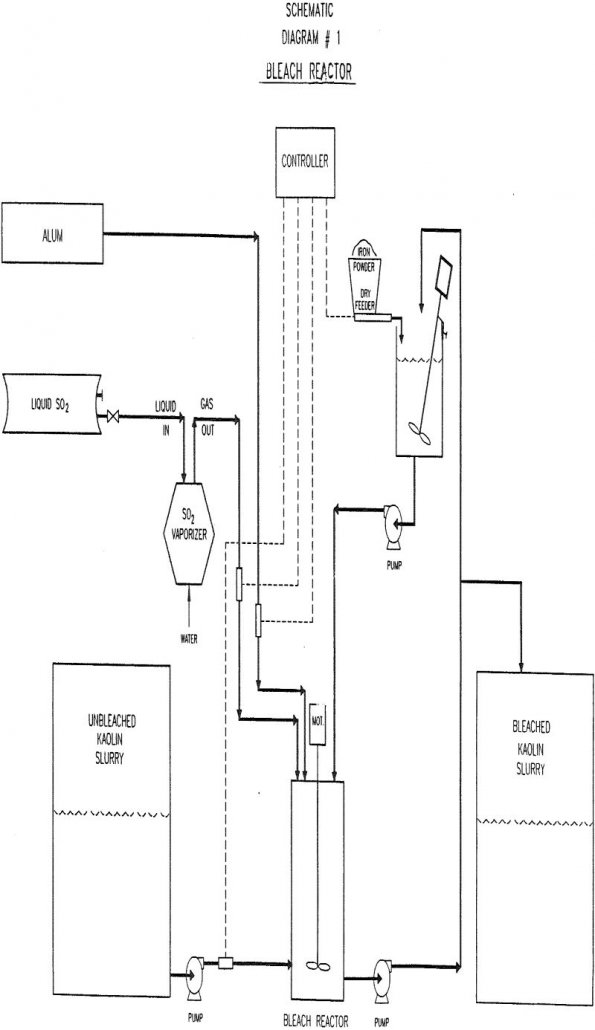

Kaolin Bleaching Process

A process for producing reductive bleach in-situ in kaolin slurries has been developed. The bleach is formed by mixing an iron sponge powder (-325M) with slurry treated with SO2. The process has been successfully demonstrated in production, and applied to several grades. The color, brightness, and viscosity of the bleached product is equivalent to or […]

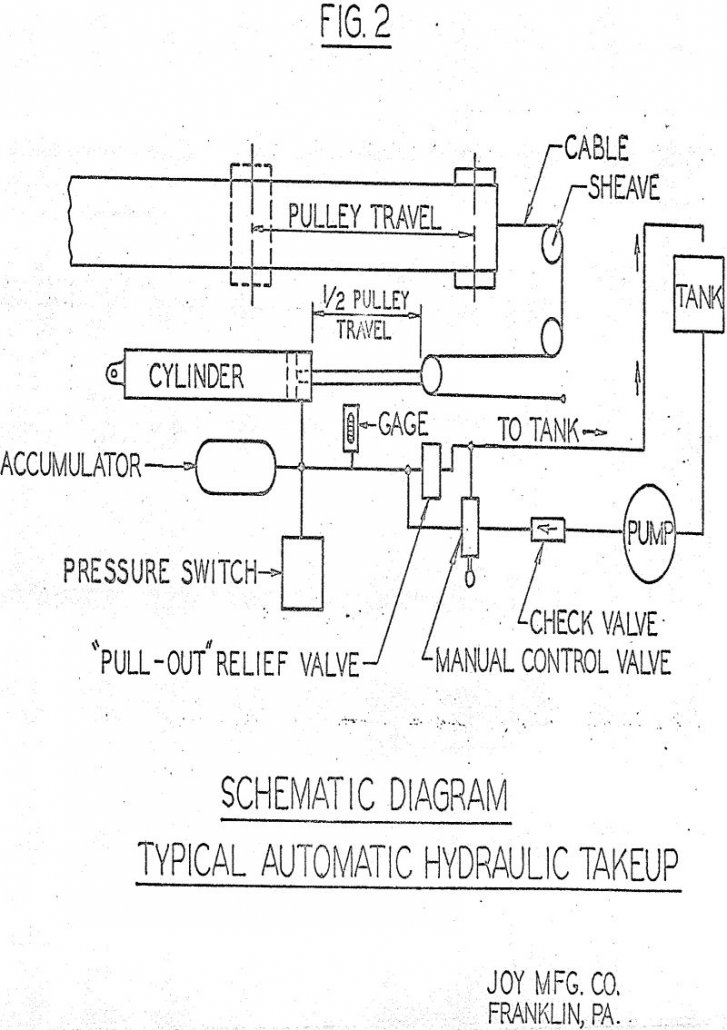

Automatic Hydraulic Takeups for Belt Conveyors

Since the majority of mines were then using direct current power systems, we were able to use controllers with 3 or more steps of starting resistance. The slow belt speeds coupled with relatively long starting cycles kept the rate of acceleration low and gave us smooth, easy starts. The conveyor belts in common use were […]

Ammonium Nitrate Blasting Agents

The situation of The Consolidated Mining and Smelting Company of Canada Limited, or Cominco, may be somewhat unique in that the Company is not only a manufacturer of ammonium nitrate, but as a mining company is a major user of its own product. This situation has resulted in highly successful application of ammonium nitrate-oil explosives. […]

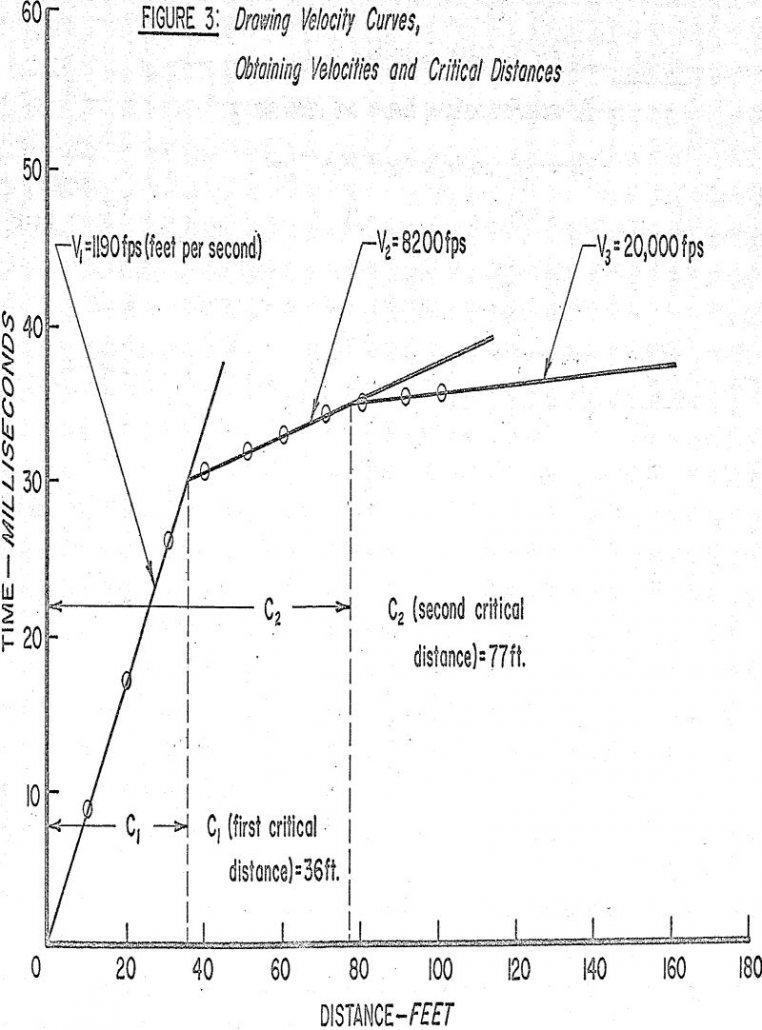

Seismic Refraction Equipment

Within recent years portable seismic refraction units have found their place in the industry for shallow investigations. Completely portable, relatively inexpensive and of proven accuracy, the portable refraction seismograph is an electronic tool in an electronic age. The seismic refraction theory is based on the ability of various materials to transfer shock waves at different […]

Remote Control of Longwall Operations

It is truly remarkable how the image of longwall as a method of mining has changed. Today the world looks on longwall in the hope that it can produce the next really big break through in productivity. Three correlated machinery developments have made this possible, but it is not only the machinery developments, interesting though […]

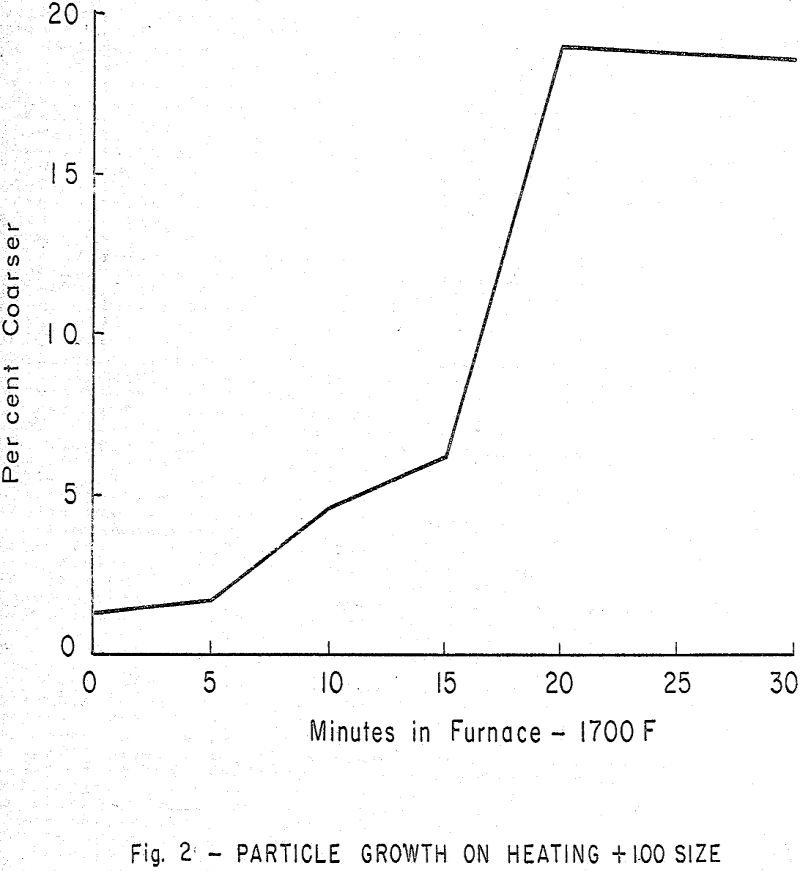

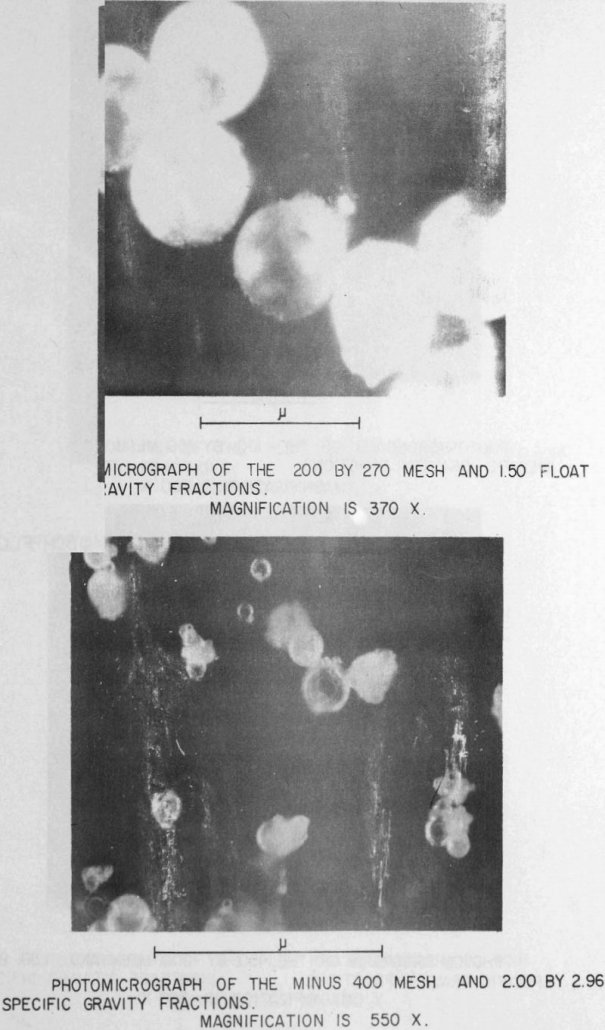

Fly Ash Properties and Beneficiation Methods

Fly ash is extremely variable and heterogeneous in all respects except its fine size. Because of its production in huge quantities, it becomes significant as a potential raw material. Fly ash is a finely-divided, widely variable, heterogeneous material most of which is formed by the solidification of molten droplets of inorganic substances in the cooler […]