How Impurities Affect Titanium Properties

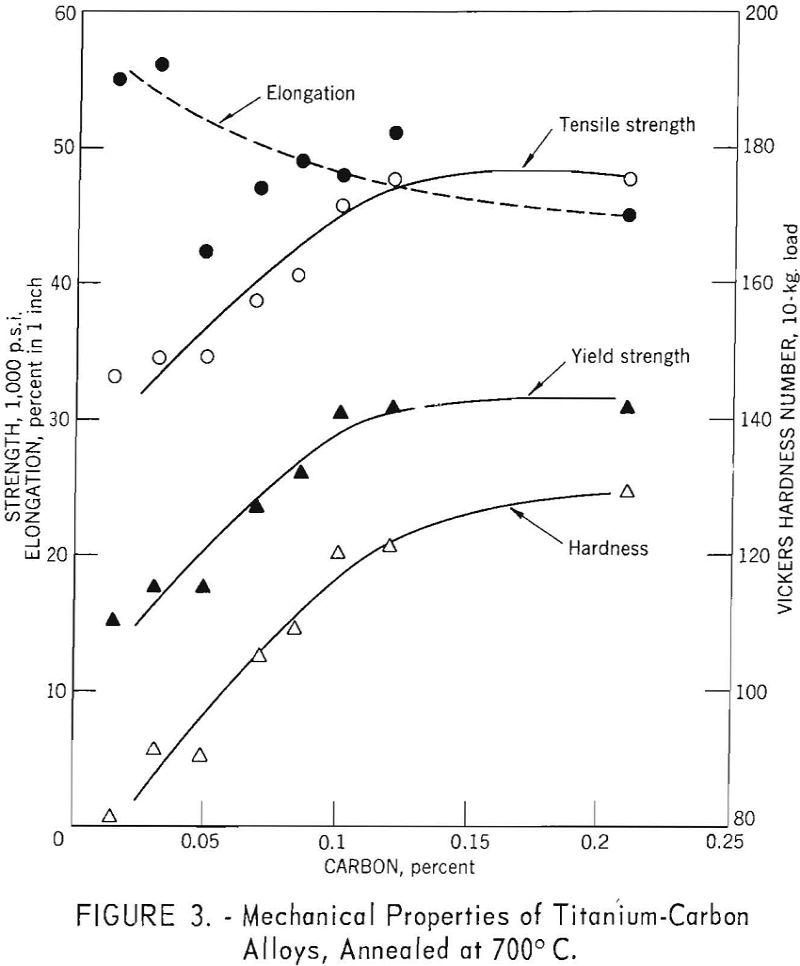

The purpose of this investigation was to determine the effects of the impurities, oxygen, nitrogen, carbon, and iron (in low percentages) on the mechanical properties of electrolytic titanium. The strength and hardness of binary Ti-O, Ti-N, and Ti-C alloys are linear functions of alloy content in the composition range investigated. Compared to oxygen and carbon, […]

How to Increase Tensile Strength Titanium

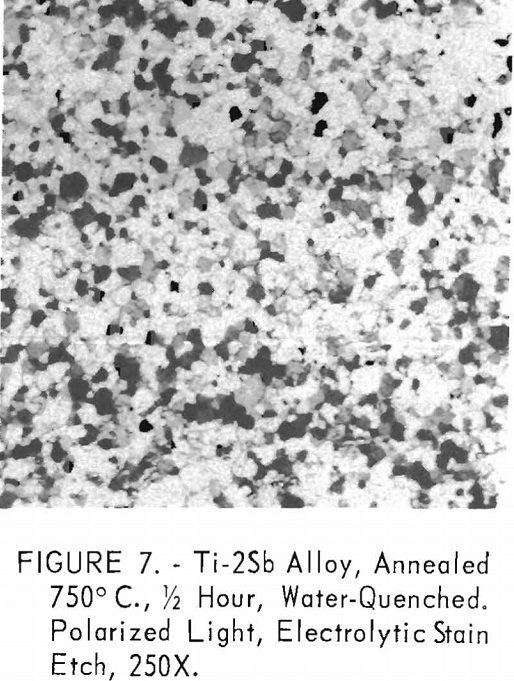

Antimony up to 10 percent increases the strength of titanium by solid-solution hardening. The general relationship of hardness, strength, and elongation in these alloys is similar to that found in several grades of high-purity and commercial titanium. Tensile strength (annealed condition) appeared to be a linear function of Vickers hardness regardless of composition. For equivalent […]

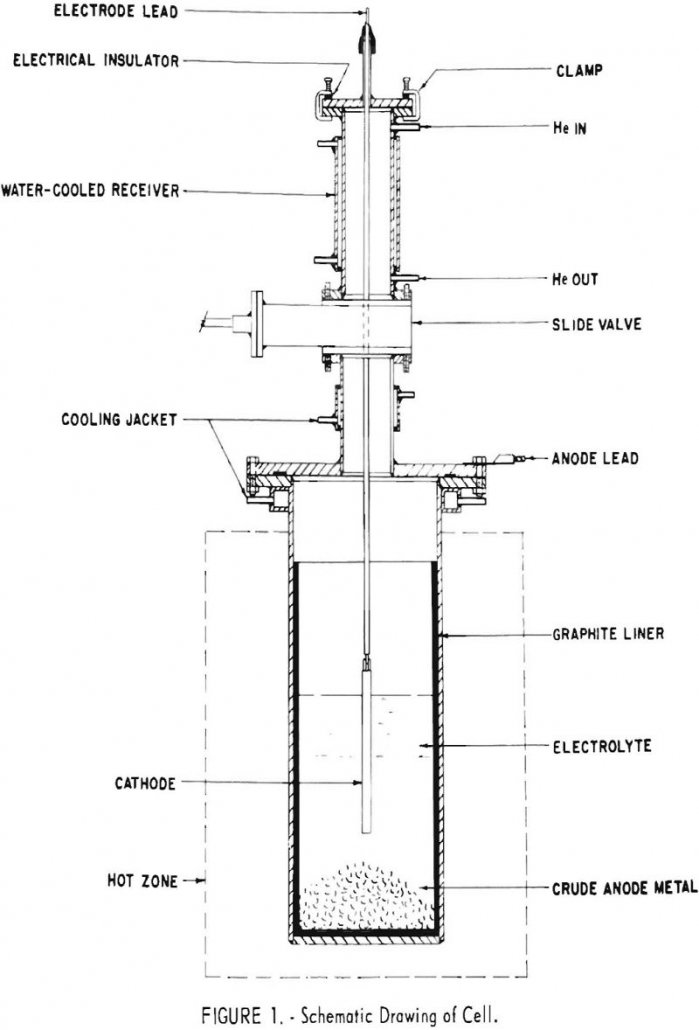

Electrorefining Beryllium

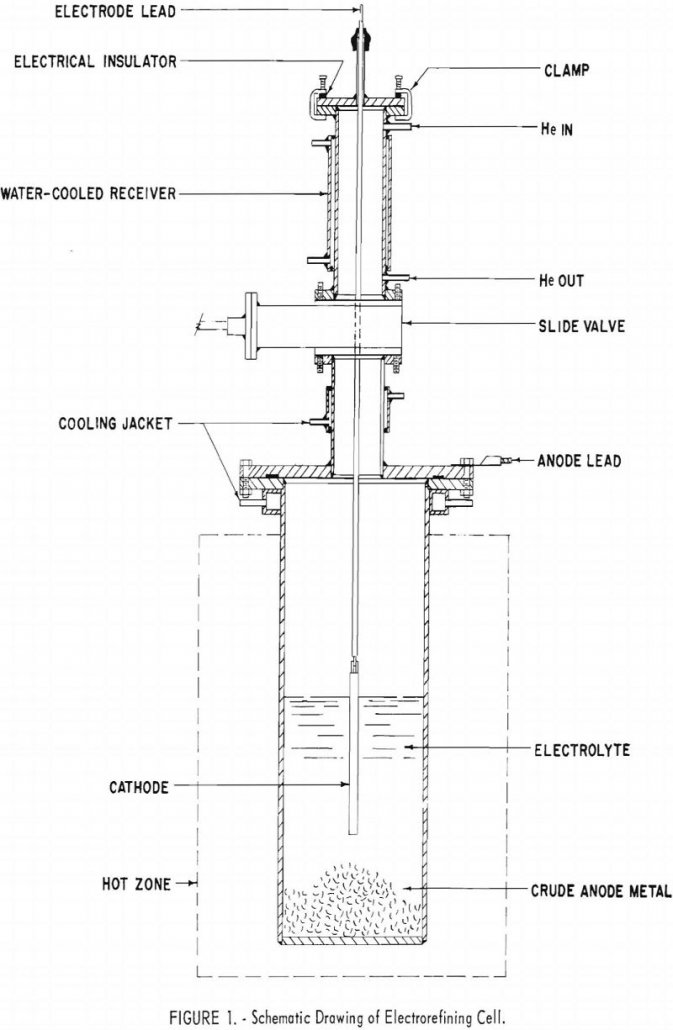

Results of the preliminary tests have demonstrated the possibility of electrorefining beryllium in KCl-LiCl-BeCl2 baths. Qualitative spectrograph analyses of the starting material and the products indicate the following estimated percentages of reduction of metallic impurities: Magnesium was reduced by at least 50 percent. Iron, copper, silicon, and manganese were reduced by at least a slight […]

Fine Screening using Sieve Bend

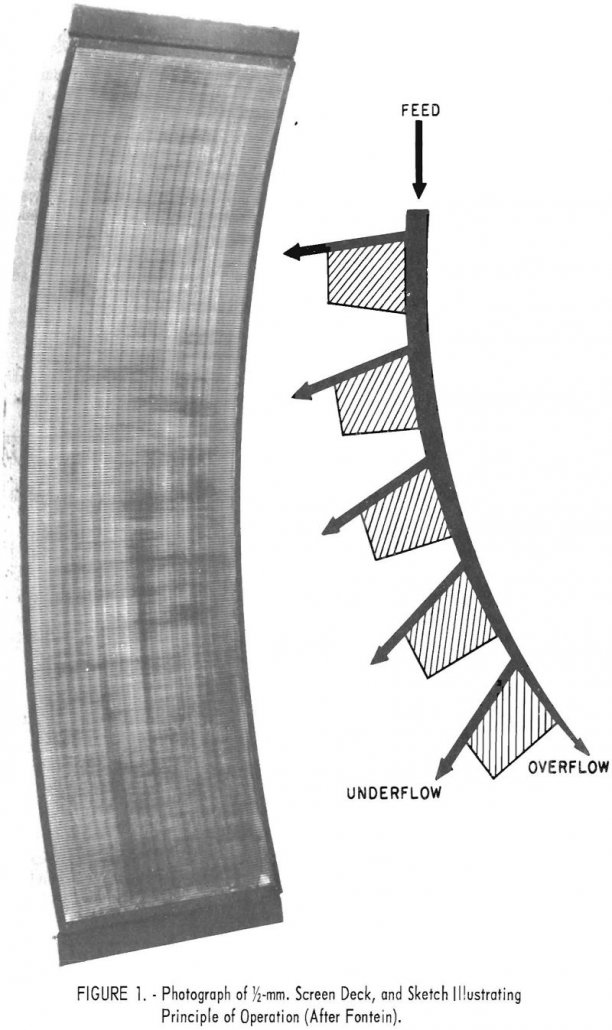

The cleaning of fine coal, particularly for metallurgical use, is receiving greater attention. An increase in the proportion of fine coal in the run-of-mine product has been created by changes in mining practice, and a concurrent deterioration in the quality of the fines has occurred because of more widespread full-seam mining. These two factors, augmented […]

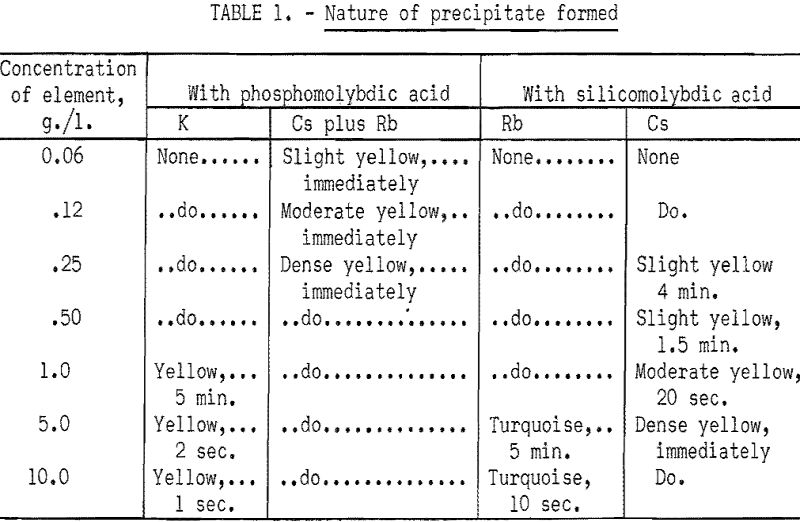

Detecting Rubidium and Cesium

A semi-quantitative test for the presence and identification of cesium and rubidium in rocks, clays, and mineral waters has been developed by the Bureau of Mines. The test can be used in the field, as a guide for the prospector, geologist, or mining engineer engaged in location or development work. It comprises two simple spot […]

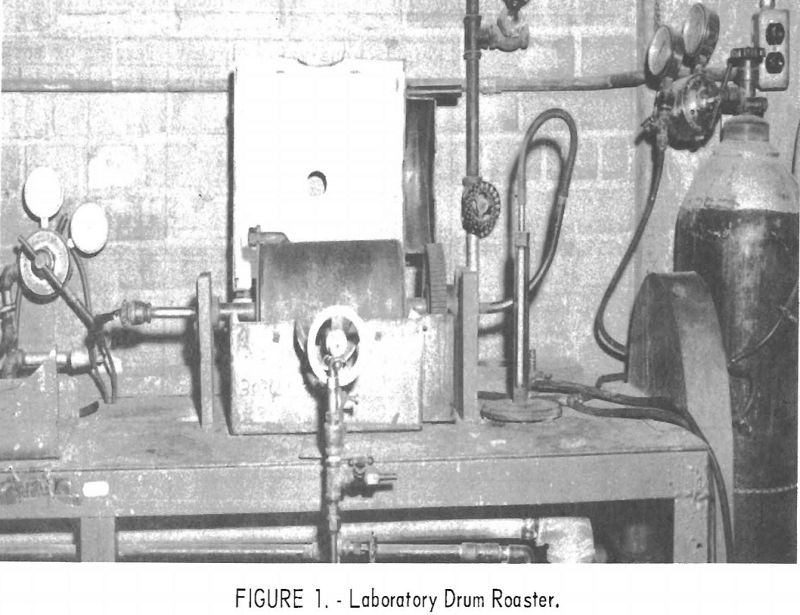

Limonite Siderite Iron Ore Beneficiation

A laboratory mineral-dressing investigation was conducted by the Federal Bureau of Mines on four limonitic and four sideritic iron ores from the North Basin of the east Texas iron-ore district. The samples, composited from drill cores, were considered representative of the iron-ore reserves of the area. The objectives of this research were twofold: (1) To […]

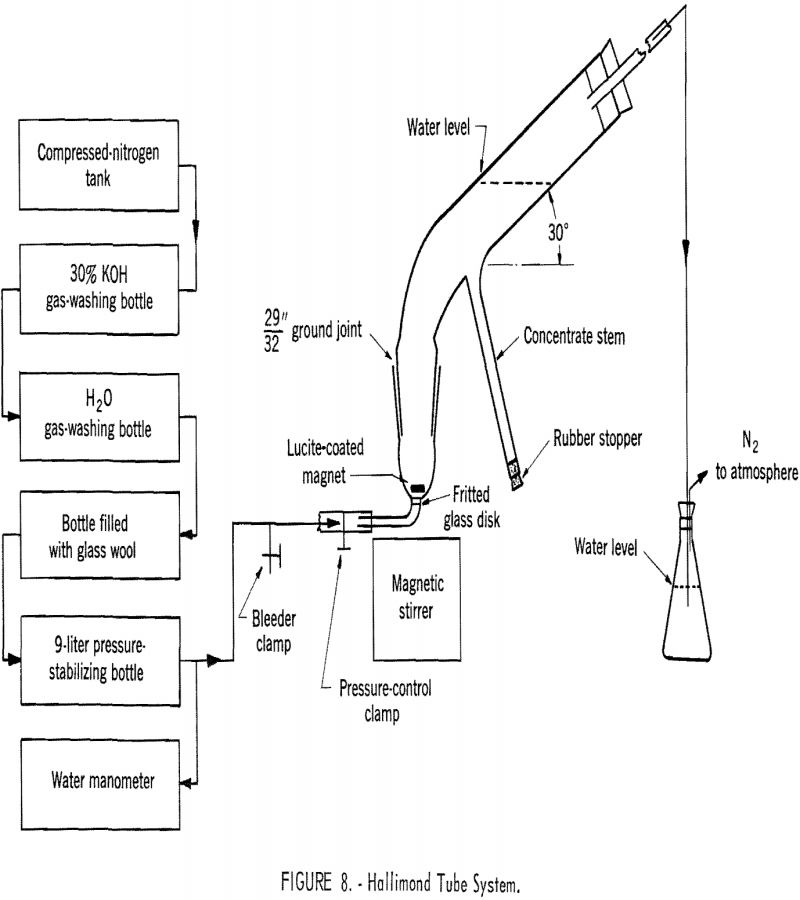

Goethite Flotation

The basic flotation characteristics of goethite were determined by using vacuum flotation, contact angle measurement, and Hallimond tube flotation, and the results have been correlated with information on the electrical condition existing at the goethite-aqueous solution interface. The results have also been used to interpret the batch flotation tests made on an artificial mixture of […]

Electrorefining Chromium

The Federal Bureau of Mines refined chromium from an aqueous electrolytic process in molten sodium chloride-chromium chloride electrolytes. Oxygen and nitrogen contents were reduced by a factor of 10 to 40, but most other impurities were little changed. The product usually contained a little more iron than the feed. Since iron was entering the bath […]

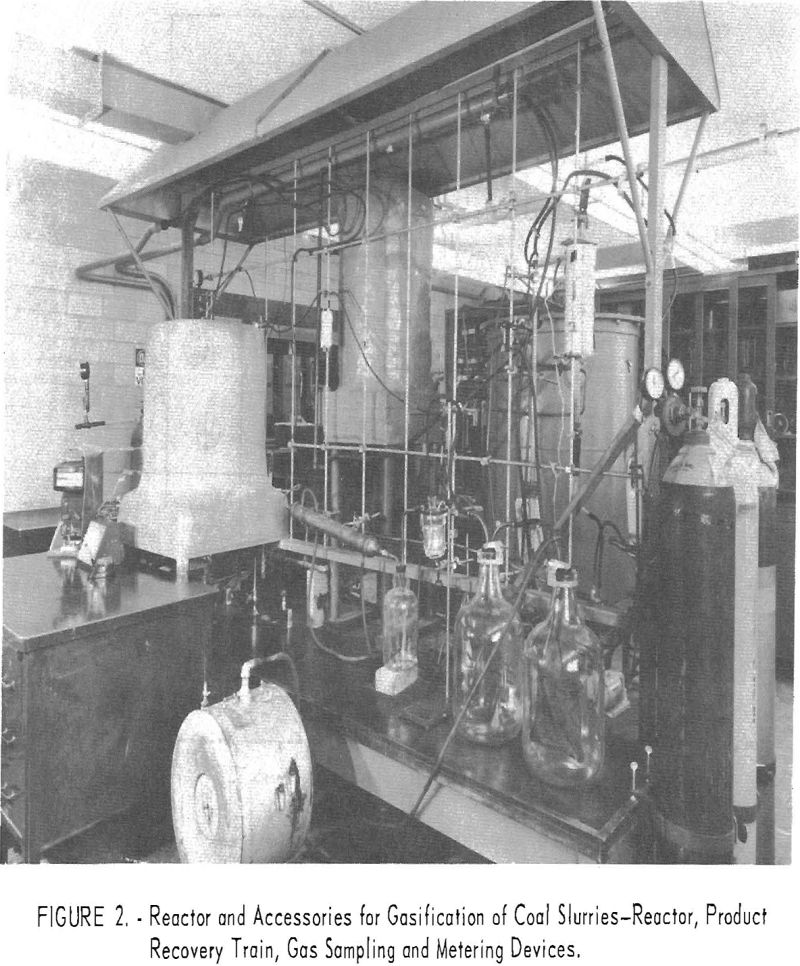

Gasification of Coal Water Slurry

The results were surprisingly reproducible in view of the complex reactions, and the scatter of data was small. Rank of coal exerted the greatest effect on gasification. Tests with only three ranks of coals do not permit firm conclusions about the effect of rank. However, work in progress reveals the same trend for other ranks […]

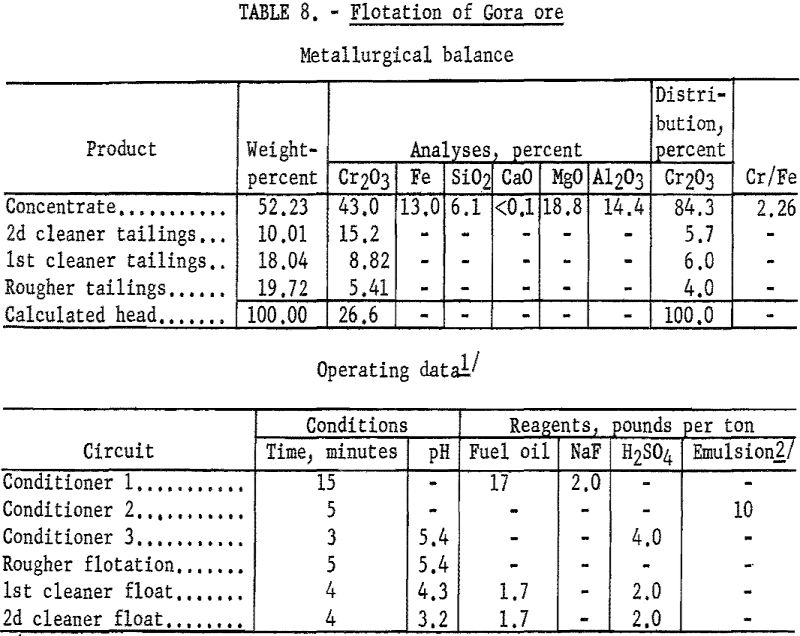

Recover Chromite by Flotation

This report describes an investigation by the Bureau of Mines of flotation techniques for the recovery of chromite from fine-grained disseminated ores. Reported work on the concentration of chromiferous materials shows that flotation has been applied almost exclusively to slime-free pulps. Therefore, chromium recoveries that could be obtained by flotation were related to the amount […]