Neutron Activation Analysis for Silver

Gold values in the surveyed sulfide-poor rock units proved to be generally even lower than those in sulfidic sandstone. As a further check on this survey of mineralization, silver values began to be measured by NAA on the silver-gold beads. Radioactivity induced in silver by neutron bombardment is long-lived. The half-life of 110mAg is 253 […]

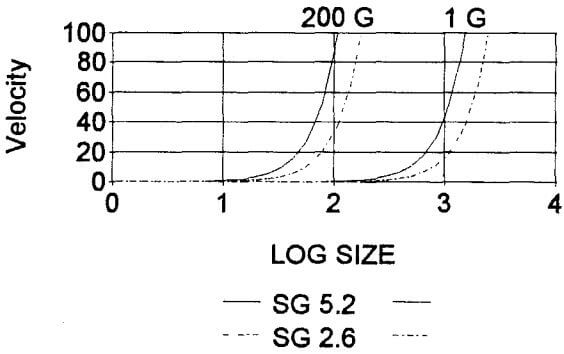

Falcon Enhanced Gravity Separator

Enhanced gravity separation devices (centrifuges) have been patented for over a century but were impractical until recently. The physical laws behind the concept were well understood but engineering had to catch up with the science. This included the development of abrasion resistant materials, the improved design of rotating equipment that allowed higher RPM, and a […]

Compression Tests Iron Pellets

A number of compressive tests were conducted on iron ore pellets obtained from the Samarco pelletizing plant located at Ponta Ubu, Brazil. These pellets are formed by disk pelletizing of a mixture consisting of hematite iron ore, (particle size less than 50 µm) water, and lime; they are hardened in a traveling-grate furnace and the […]

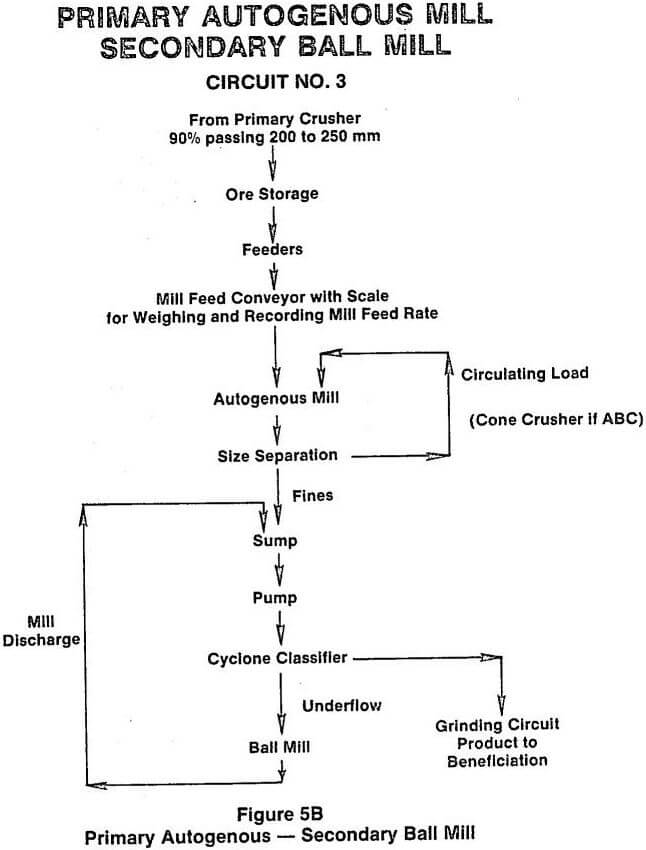

Autogenous and Semi-Autogenous Grinding Mill Testing

Ff the drill cores indicate that the ore could contain sufficient lumps in the sizes needed for ore media in autogenous and semi-autogenous grinding, then bulk samples (750 kg) of mine run or primary crushed ore, with an even distribution by quantity in the size fractions between 100 mm and 200 mm, should be obtained […]

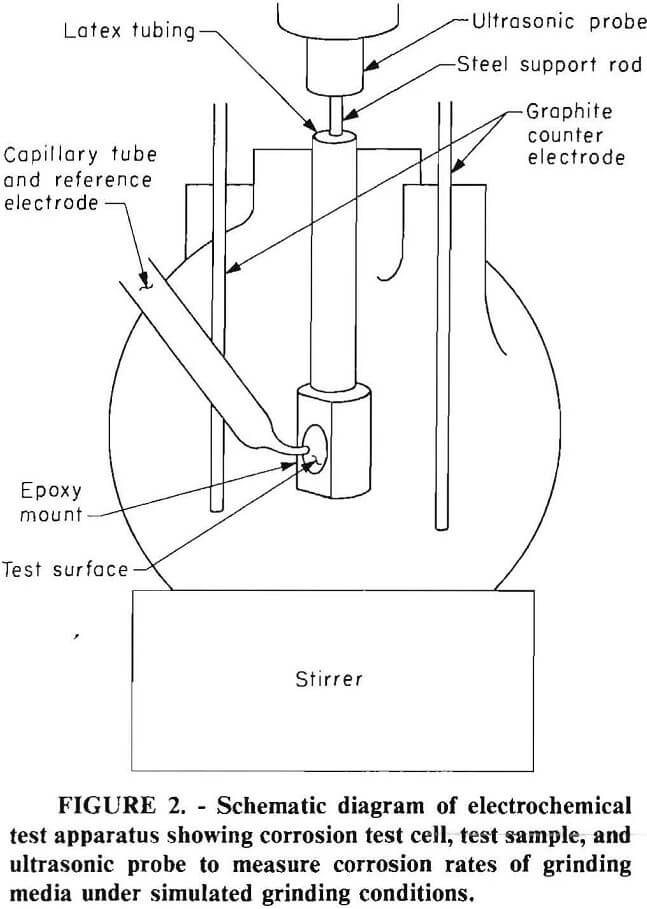

Grinding Media Corrosion Rate

While grinding is unavoidable in nearly all mineral processing, it is an inefficient and costly step. As an example, the National Academy of Sciences (NAS) estimates that the copper industry consumed 205,000 tons of grinding media in 1978. A typical copper producer processing 100,000 tons of ore per day may spend approximately $25,000 daily to […]

DSM Wood Chip Removal Screen

One of the minor but occasionally troublesome problems in the Creede plant is related to the clayey nature of some of the ore from the mine. At times the thickener underflow is so clayey that it forms a rope which can almost be carried around without a bucket. As described in the previous report: ” […]

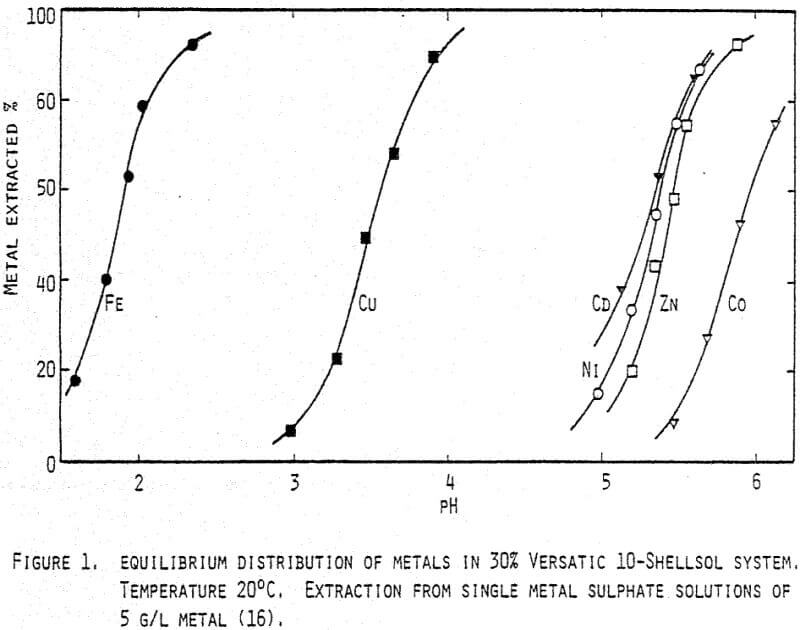

Zinc Hydrometallurgy Solvent Extraction

Part of Zinc Hydrometallurgy and Zinc Solvent Extraction includes the zinc and iron sulphate solution from the hot acid leach will typically contain 80-100 g/l Zn, 20-30 g/l Fe, mostly in the ferric state, and 40-60 g/l free sulphuric acid. The sulphuric acid concentrations will depend upon the leaching techniques used, and the composition of […]

Alunite Crystal Chemistry

Alunite has been described both by the chemical formula [KAl3(SO4)2(OH)6] and by the chemical formula [K2SO4·Al2(SO4)3·2Al2O3·6H2O]. The latter gives an erroneous impression that water is structurally associated with the mineral. The former representation is therefore, to be preferred. It is more in conformity with the crystal structure of alunite. The structure of alunite is similar […]

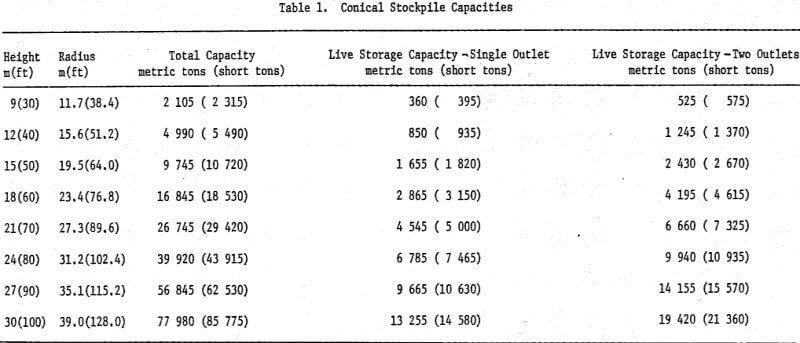

Calculating Stockpile Capacity

Calculating Stockpile Capacity: Once the minimum storage capacities which will assure maximum mill output are known, the appropriate stockpile configuration must be determined. Stockpiles fall into two general categories: conical and elongated. Conical Stockpiles The conical stockpile is the simplest and easiest to analyze. The total stockpile capacity is given by: 3.14 (Tan A)R³ D/3000 = […]

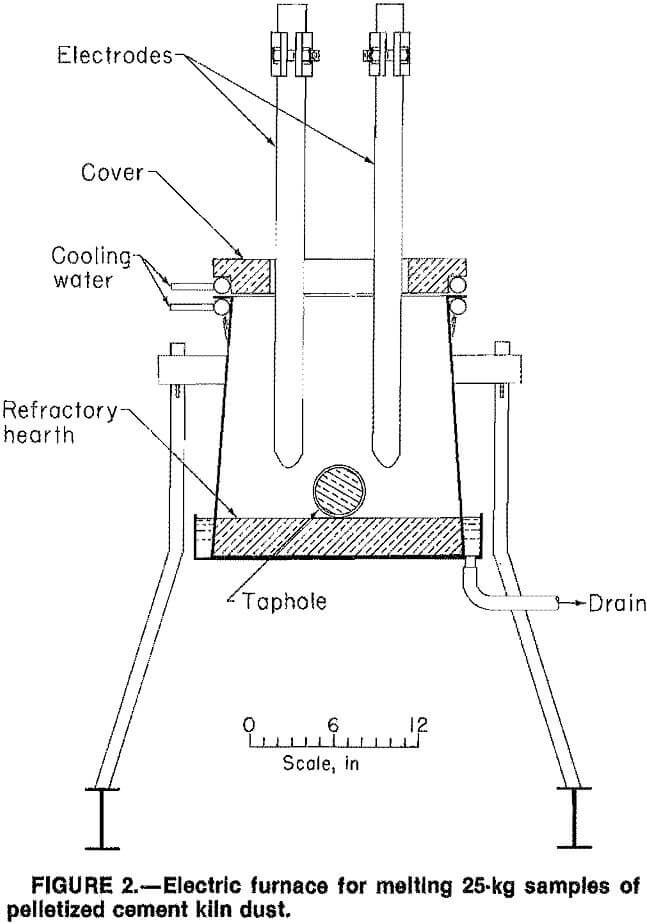

Portland Cement Kiln Dust Reprocessing

From 10 to 12 million tons of cement kiln dust accumulate annually at domestic cement plants. This finely divided dust is emitted from cement kilns to prevent the buildup of excessive salts in the cement product. The alkali salts in the dust are derived from the clay raw materials, which include potassium and sodium feldspars. […]