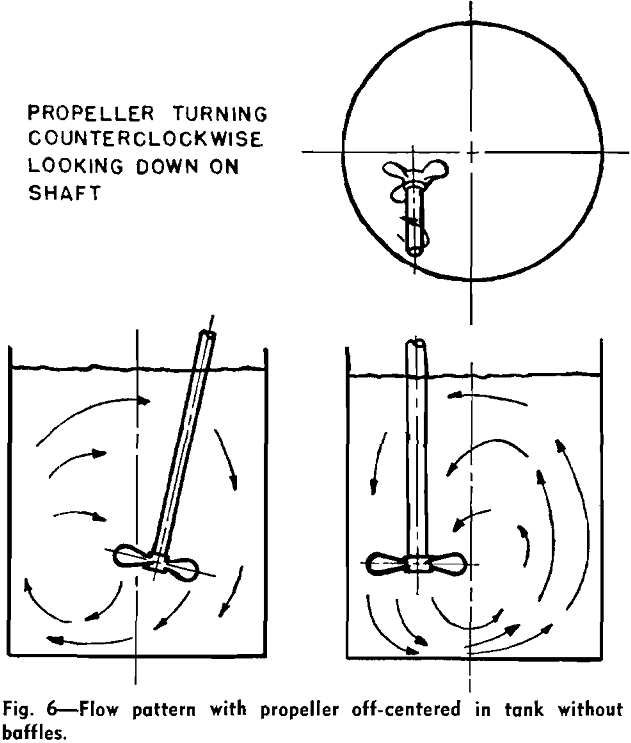

Fundamentals of Mixing and Agitation

Mixers are being applied with increasing frequency to problems in the metallurgical industries. The increase represents in part the modernization of mechanical equipment used through the application of unitized drives, modern electric motors and speed reducers, and recently developed materials of construction. Some applications have resulted from process changes and the use of techniques for […]

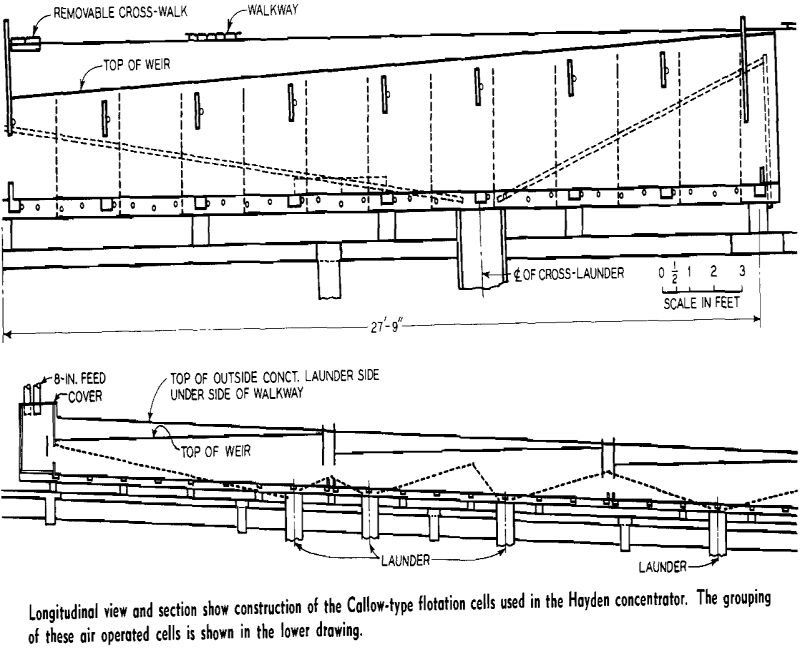

Callow Flotation Cells – Design and Operation

Callow-Type flotation cells, with various modifications, have been employed at the Hayden concentrator since 1917. Other flotation machines, such as matless-air and mechanically agitated types, which have been tested in competition, have failed to handle tonnages or give metallurgical results equal to the modified Callow-type cells on the Ray ores. While experimental work was conducted […]

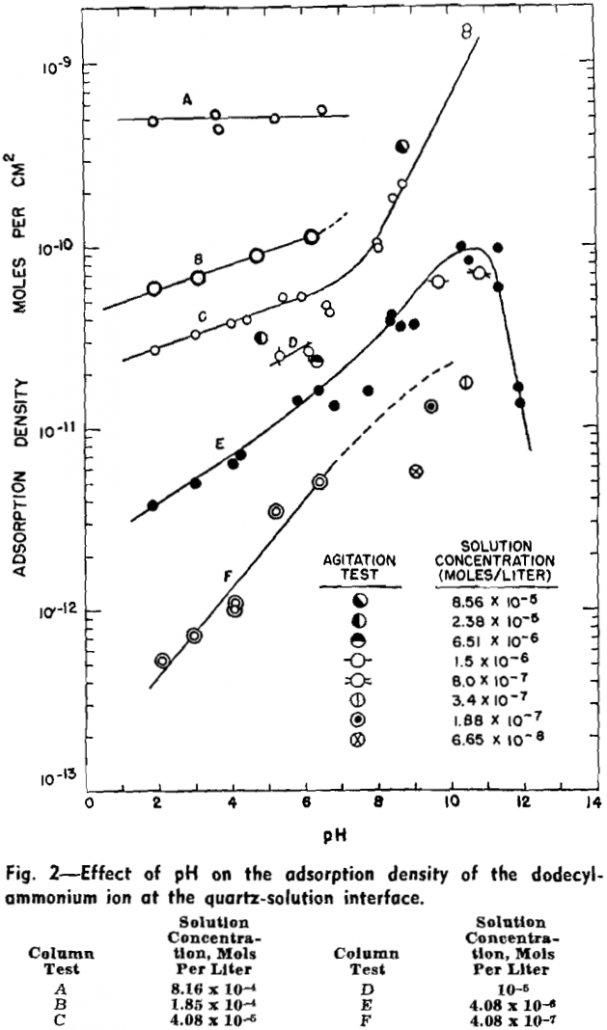

Cationic Collector for the Flotation of Quartz

The behavior of collectors at the mineral-solution interfaces is usually explained in terms of an ionic adsorption process. Through the distribution of collector ions between the solid surface and the co-existing solution phase the mineral is believed to acquire a water-repellent surface coating. Quartz A —100 mesh ground crystalline quartz was infrasized; the products of […]

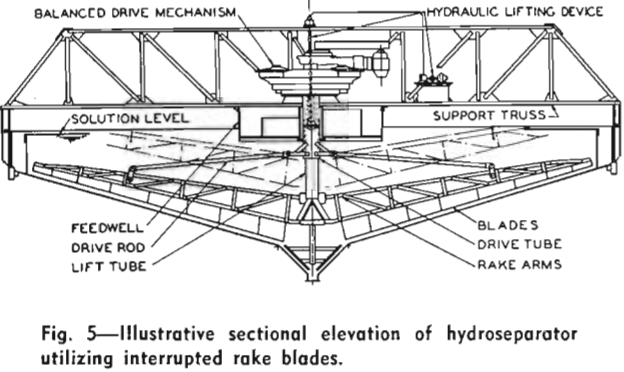

How to Select the Correct Classifier

Separating a mixture of particle sizes of material suspended in a liquid medium is by no means an exact science. Selecting machines for individual classifying operations is even more difficult. The plant operator’s own background is of course invaluable, and considerable help may be obtained from technical articles, talks with sales engineers, and handbooks on […]

Crushed Limestone Aggregates for Concrete

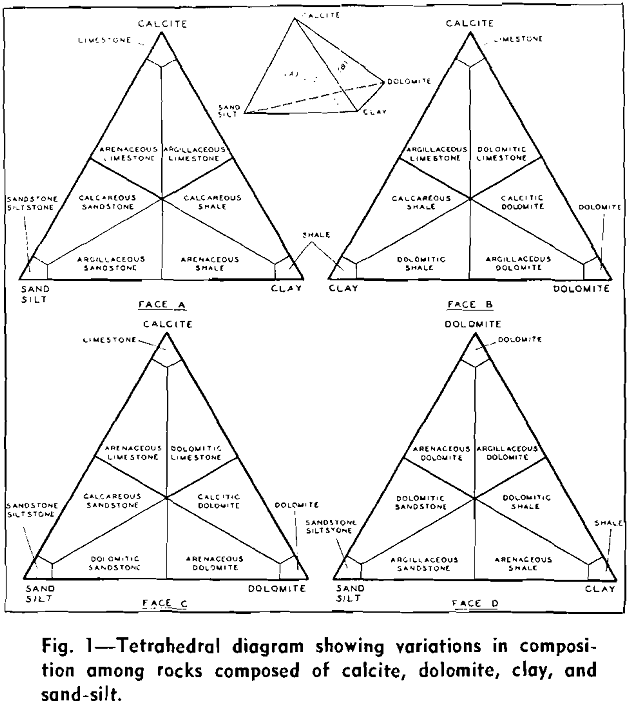

The problems encountered in efforts to explain the behavior of limestones, dolomites, and related rocks as concrete aggregate lie on the frontiers between the ignorance of the geologists and the ignorance of the engineers. The mineral composition and textures of the rocks have not been adequately explored and described, and the effects of mineral composition […]

Belts and Concrete Ore Passes

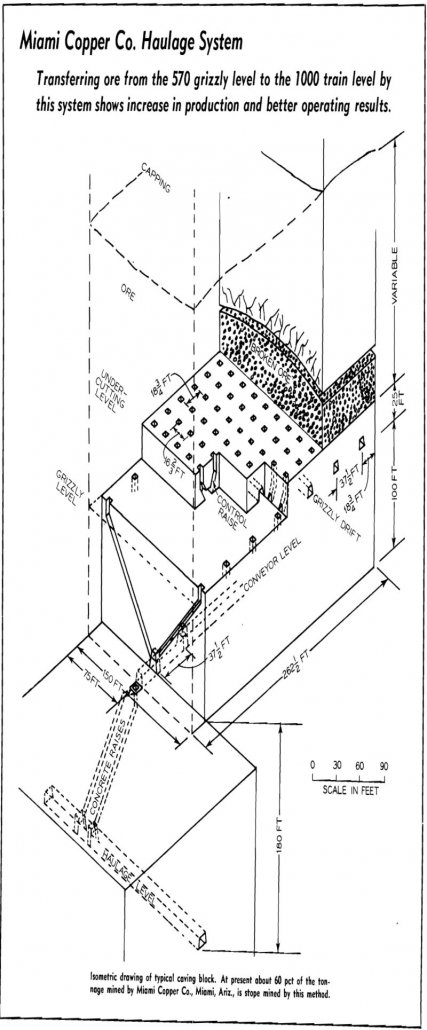

Conveyors were first used underground at Miami Copper Co., in the latter part of 1947. At that time some of the stoping area was too heavy and too close to the haulage level to use conventional haulage. To get the haulage drifts out from under the stoping area belt conveyors were used for the additional […]

Control Conveyor Belt Acceleration

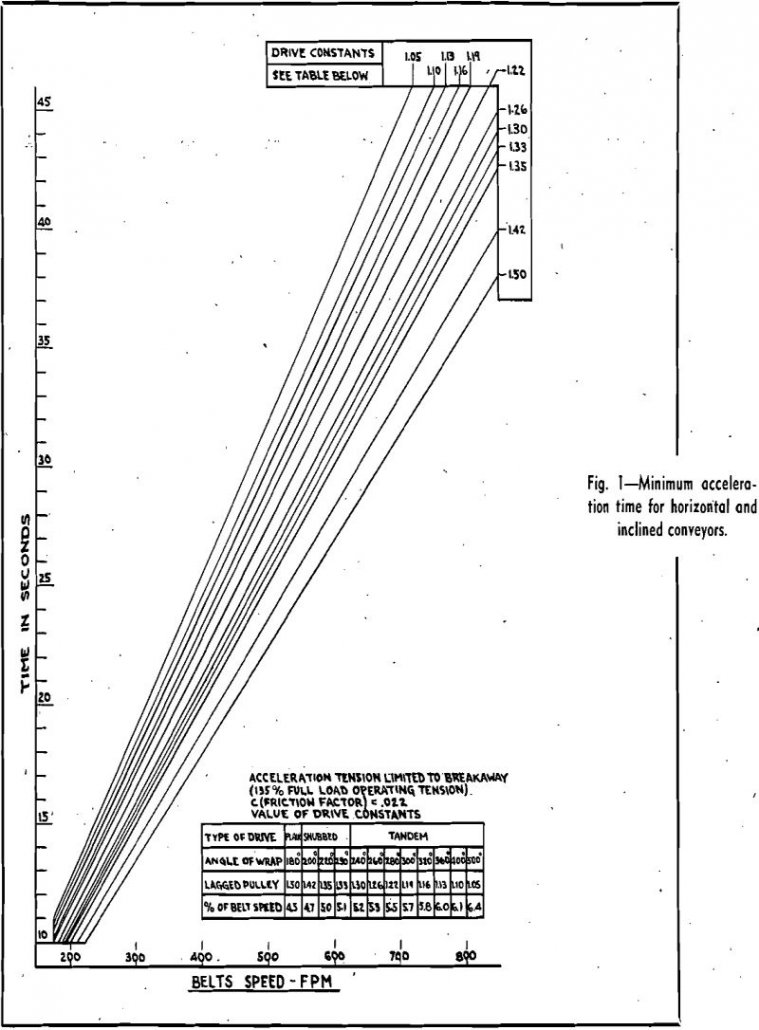

The part that acceleration plays in starting a belt conveyor and its effect on belt conveyor design are well understood in a general way. Its practical importance is easily overlooked, however, and under some conditions, it is absolutely necessary to give the problem of acceleration detailed study. Mathematical Analysis In working out the various problems […]

Dry Process Cement Plants

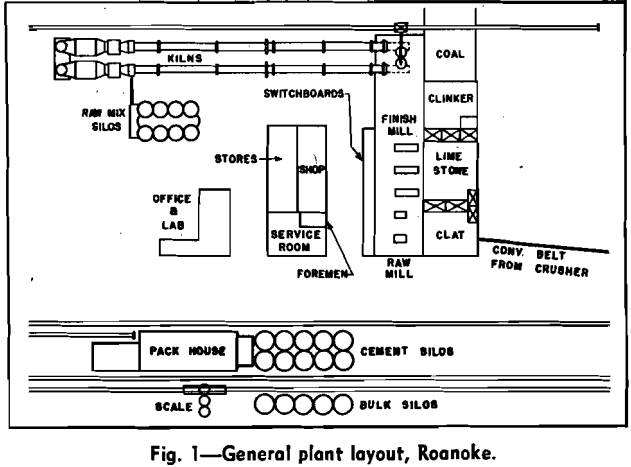

The heavy postwar demand for Portland Cement has created shortages that are gradually being overcome by increases in plant capacity. In the postwar period, the Lone Star Cement Corp. has expanded several of its existing 15 plants and has built 2 new plants, now in operation, with a third new plant under construction in Brazil, […]

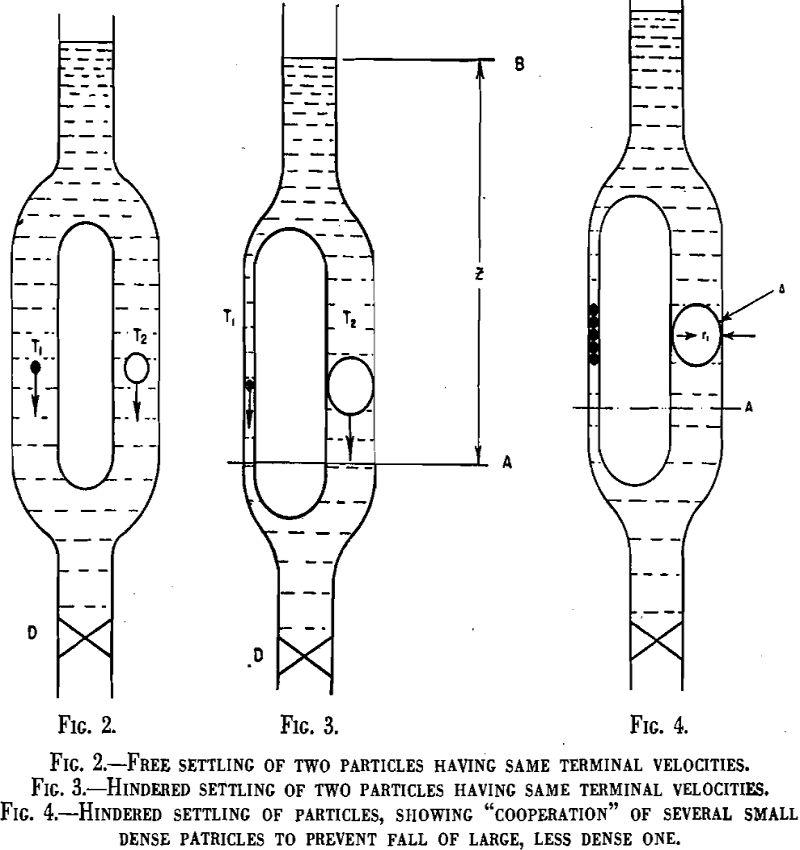

Principles of Gravity Concentration

Gravity concentration is a general term designating processes for separating and sorting granular material by means of forces that depend on the density, size and shape of the particles. When these forces are applied to the particles the latter are caused to move, those of a given density along one path and those of a […]

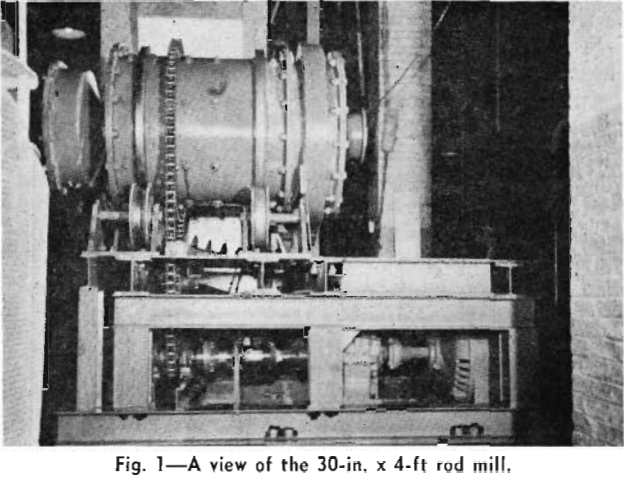

Rod Milling Variables

Several constructive and fundamental studies have been made in the analysis of data obtained from experiments carried on with batch ball and rod mills. The operating characteristics of ball milling in small continuous circuits have also been appraised. It is from these analyses that some of the theories of comminution have been developed. Data presented […]