Grinding Circuit Control Strategy

Figure 4 is a schematic diagram of a ball mill/cyclone control system. This diagram shows the instrumentation and the calculated variables used in the control strategies. The prior detailed process analysis study produced two major conclusions: Reduce mill feed size Reduce ball charge size The reduction of the mill feed size could be reduced by […]

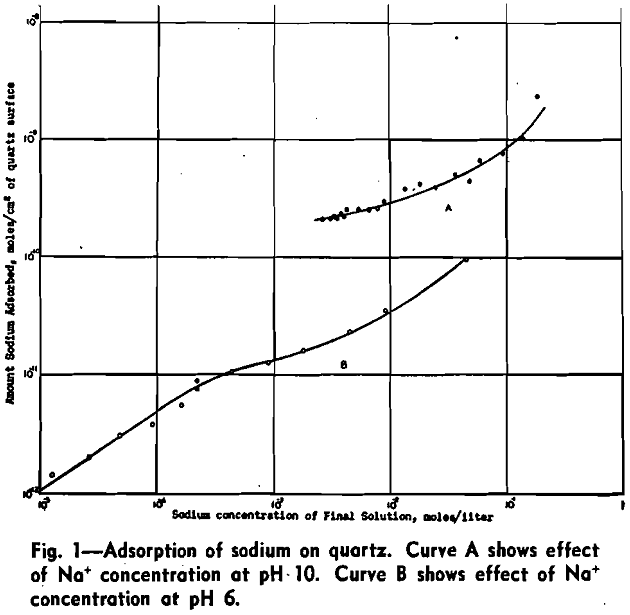

Adsorption of Sodium Ion on Quartz

When a mineral particle is fractured, bonds between the atoms are broken. The unsatisfied forces that appear at the newly formed surface are considered to be responsible for the adsorption of ions at the mineral surface. A knowledge of the mechanism and extent of ion sorption from solution onto a mineral surface is of interest […]

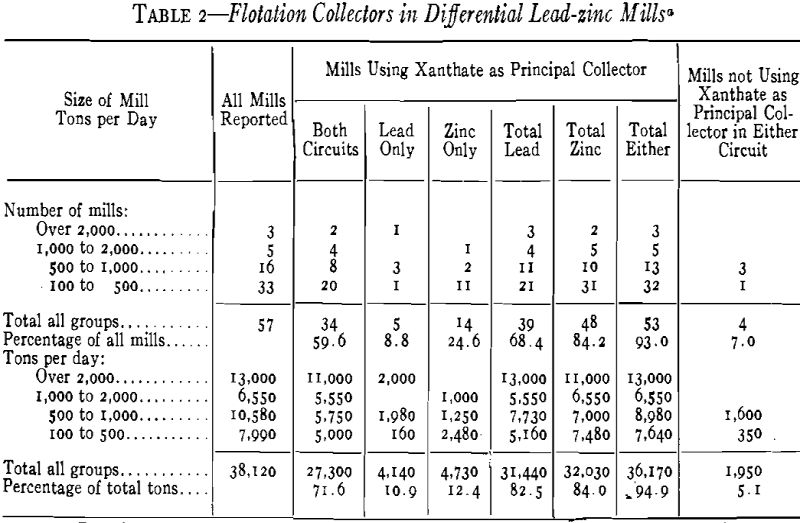

What are the Applications of Xanthates to Flotation

Most papers on xanthate have dealt with principles rather than practice. On the assumption that many millmen are interested in knowing where and in what manner the xanthates are being used in mills other than their own, this paper will summarize the results of a recent survey of North American plants. A brief background story […]

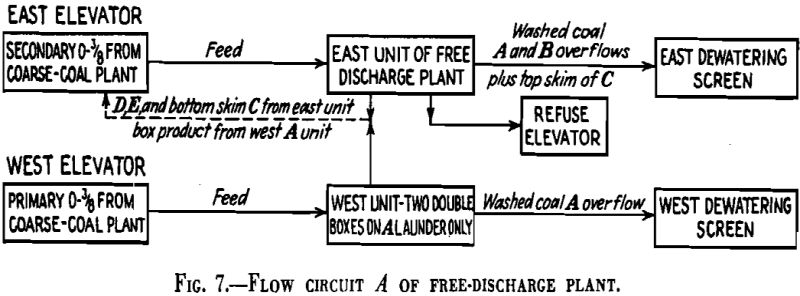

Launder Washers

Trough washers were among the earliest methods used for concentrating ores; they are referred to by Agricola about the middle of the sixteenth century as already being used while the hand-operated jigging sieve had only recently come into use. For cleaning coal the trough washer apparently was first used in France and Belgium about 1841. […]

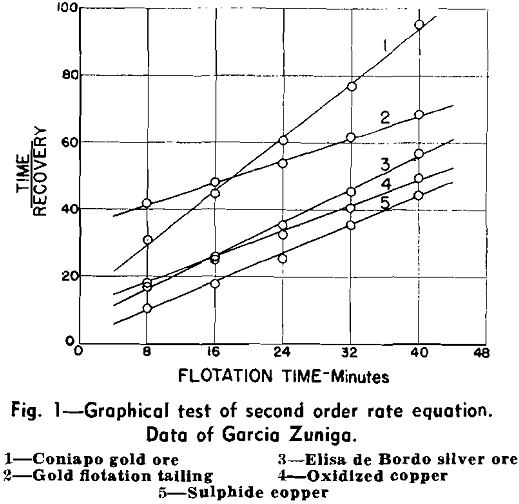

Flotation Rates and Flotation Efficiency

The separation of minerals by flotation can be regarded as a rate process, with the extraction of any one mineral determined by its flotation rate, and the grade of concentrate by the relative rates for all the minerals. So regarded, the significant variables for the process are those that control the rates. These variables are […]

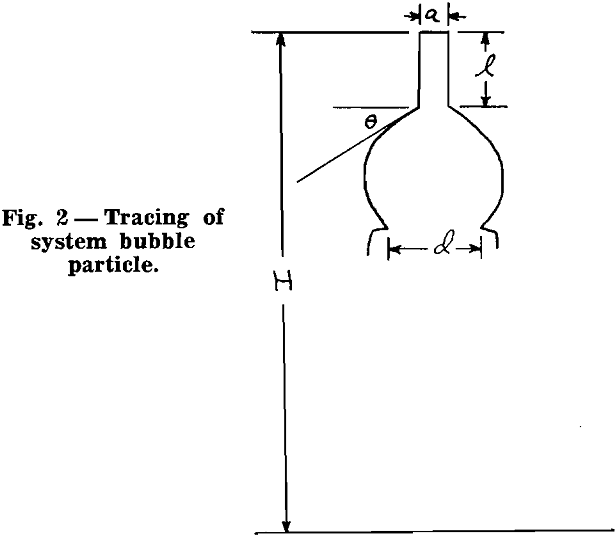

Effect of Flotation Air Bubble Size

A search of the literature reveals that no measurements have been made of the forces acting between a small solid particle whose surface is hydrophobic, and an air bubble to which the solid adheres, both immersed in water. Analyses have been made of the forces acting to support a greased solid on the surface of […]

Physical Metallurgists

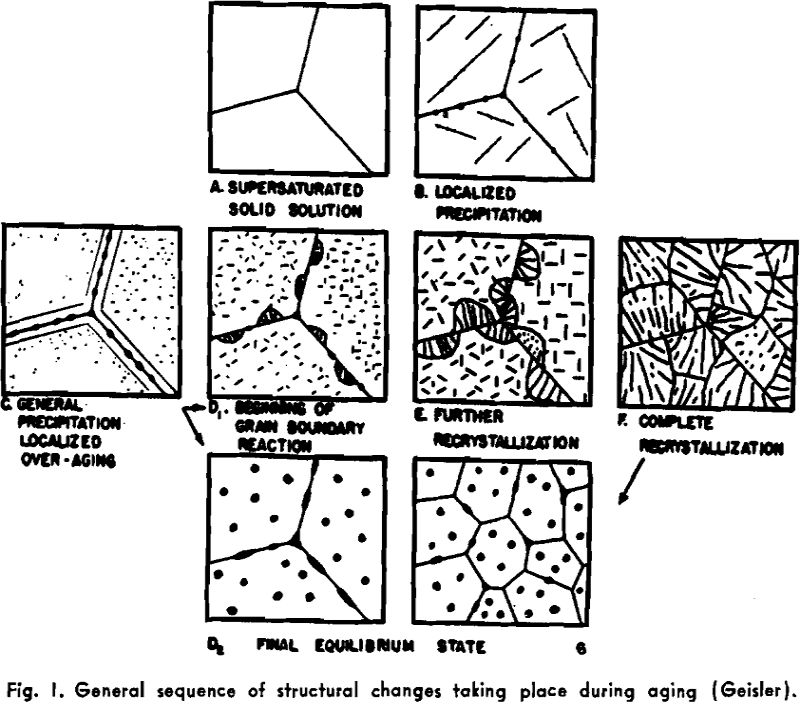

During the past year there have been a number of significant investigations that have furnished evidence on the driving forces governing grain growth and on the role played by boundary impurities. Thus Burke has shown that in high-purity alpha brass the rate of grain growth in the earliest stages is approximately inversely proportional to the […]

Precipitation in Copper-Beryllium Alloys

The nature of the atomic rearrangement involved in the precipitation of the compound γ-Cu-Be from supersaturated solid solutions of the copper-base alloys has been the subject of two extensive investigations. The precipitate in this alloy system has a rather simple structure; at equilibrium it has a body-centered cubic unit cell with copper atoms on the […]

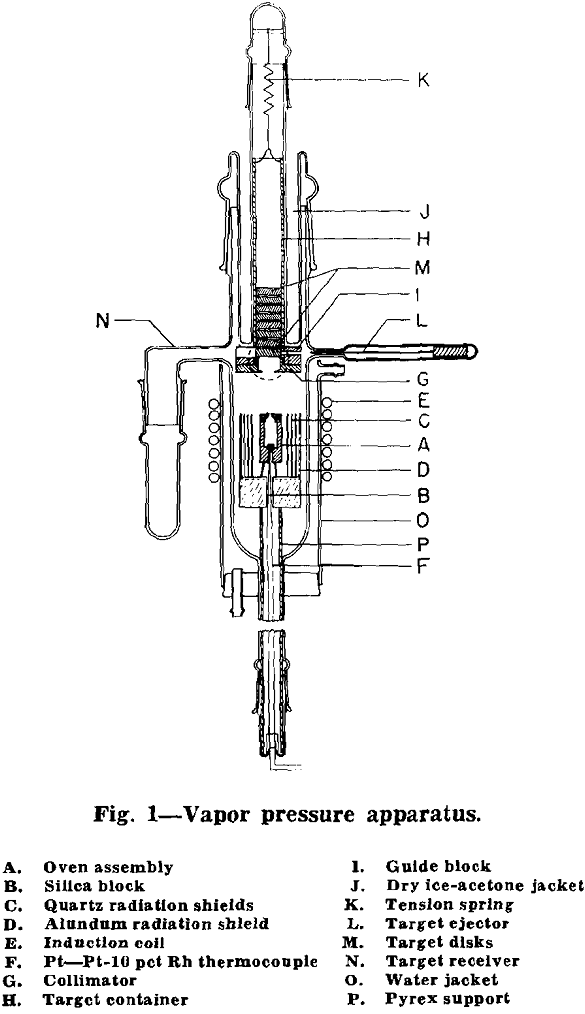

Vapor Pressure of Silver

The purpose of this study was to measure the vapor pressure of silver as the first step in the determination of activities in silver alloys and to test the limitations of the method adopted. In order to work at low pressures, below 2×10-² mm of mercury, the orifice effusion technique was employed. To shorten the […]

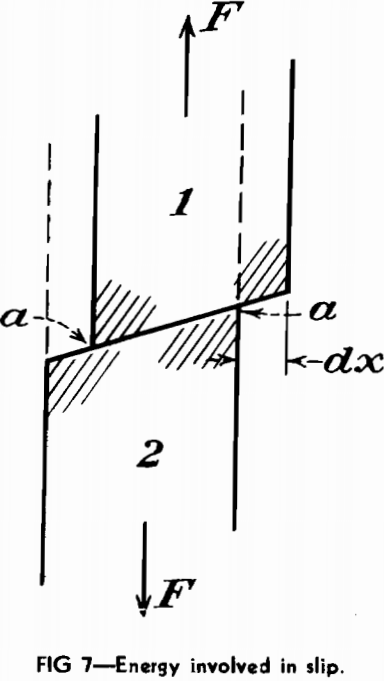

Solid Copper Surface Tension

G. Kuczynski and B. H. Alexander—This paper represents a most noteworthy attempt to evaluate experimentally the surface tension of a solid metal. Because of the great importance of such measurements, any proposed method should receive the closest scrutiny before the results can be considered reliable. The writers think, however, that the experimental results are fairly […]