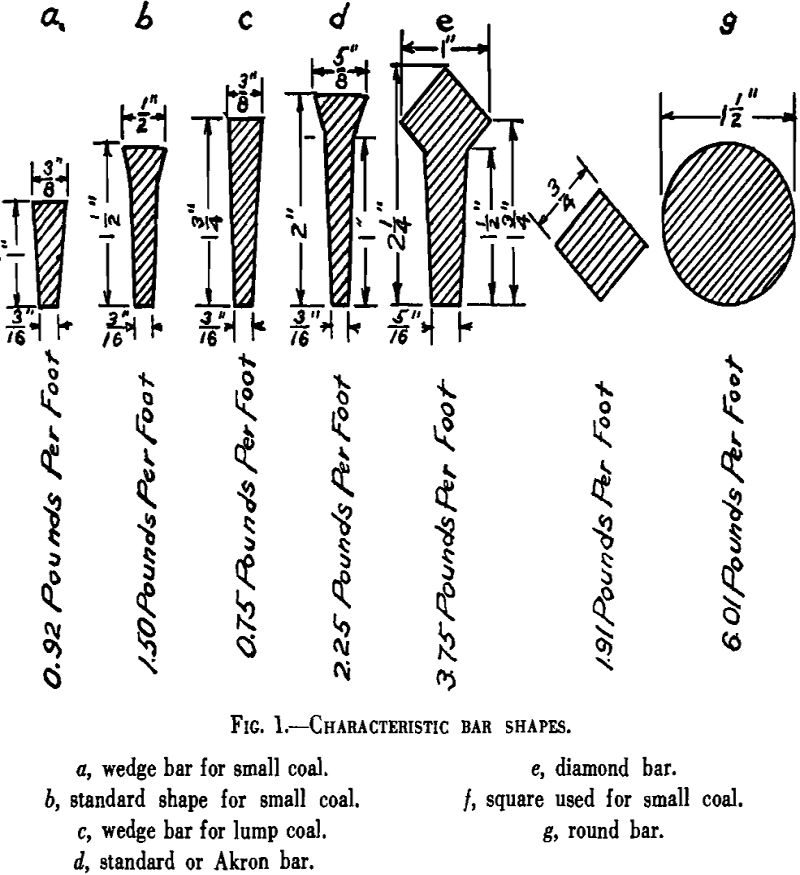

Screening Equipment

Sizing is the process of separating mixed particles into groups of particles all of the same size, or into groups in which all particles range between certain definite maximum and minimum sizes. In coal preparation, sizing is generally accomplished by passing the coal over screens. Separation by differential settling in air or water currents has […]

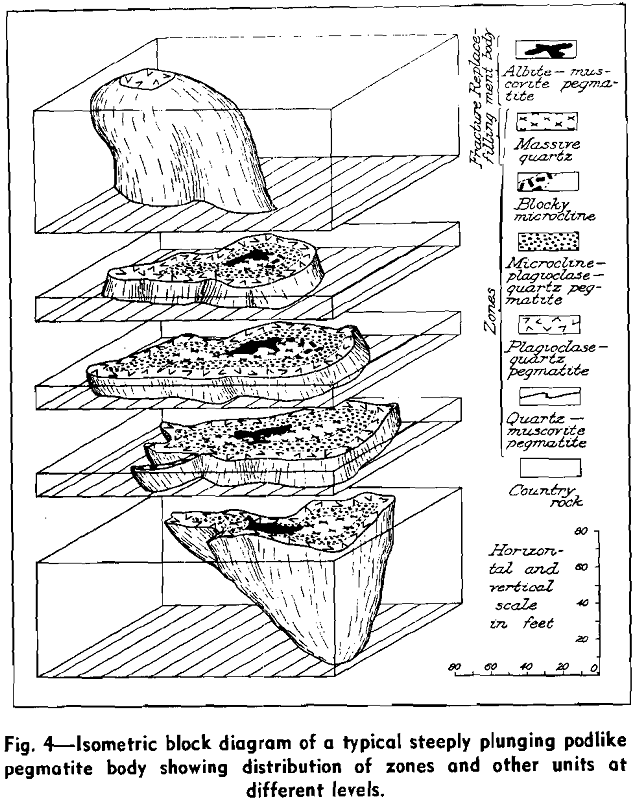

Pegmatites Geology

Granitic pegmatite deposits are the chief source of commercial feldspar, sheet mica, beryllium, tantalum-columbium, and lithium minerals, and certain types of kaolin. They also have yielded significant quantities of cassiterite, gems, scrap mica, molybdenite, tungsten minerals, uranium-thorium and rare-earth minerals, and zircon, either directly or as the sources of placer deposits. The output from […]

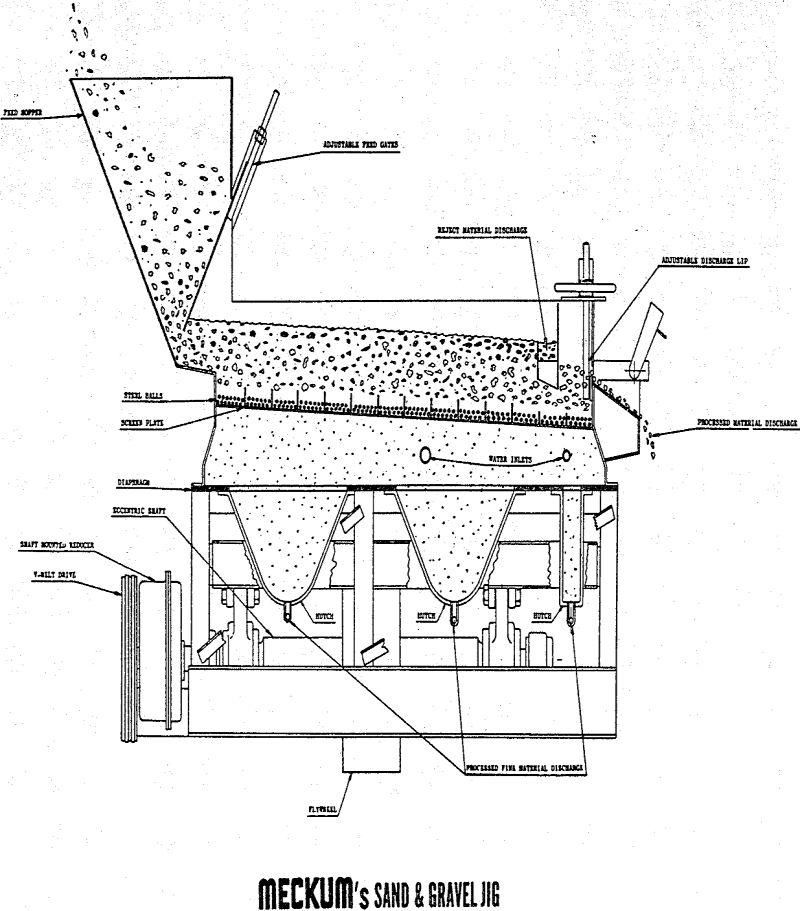

Sand and Gravel Jig

In general, the beneficiation of sand and gravel consists of the removal of certain low specific gravity deleterious particles from the sand and gravel. These particles are coal, lignite, ochre, chert, sandstone, wood, clay, shale, and chalk. These deleterious materials almost always have an apparent specific gravity which is less than 2.35 while good sand […]

Lightweight Aggregates

Lightweight aggregates have been in use for many years in the United States but are now receiving more and more attention by manufacturers and users of concrete shapes. These shapes comprise building blocks, special forms, such as door sills, lintels, floor slabs, and beams. Lightweight aggregate also is adapted for monolithic construction. The increased building […]

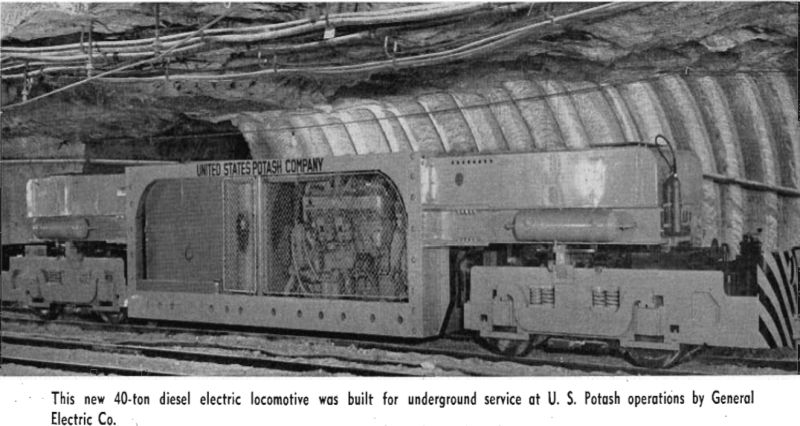

Potash Mining Methods

Commercial beds of sylvite ore were discovered by the Snowden & McSweeney Co. while drilling a wildcat oil well some 25 miles northeast of Carlsbad, N. M., in 1925. After a preliminary core drilling program the U. S. Potash Co. sank a 1060-ft shaft within 4 miles of the original discovery. This shaft was in […]

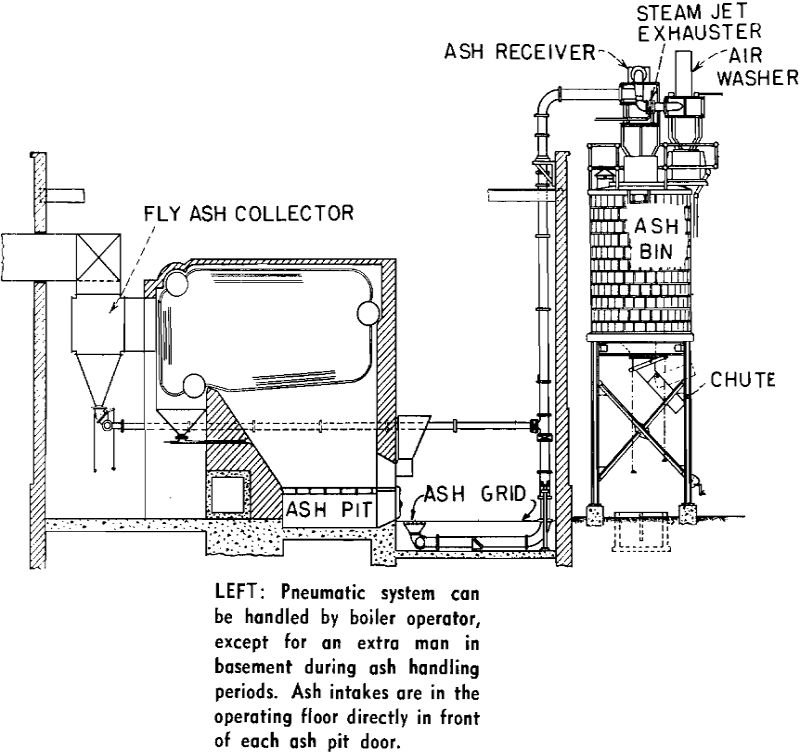

Small Coal Burning Boiler Plant

How much can the mine operator afford to spend on his coal burning boiler plant? The usual answer is as little as possible and still get the job done. Thus, attention must be focused on the spot where excessive costs are most likely to arise —the materials handling end of the job. Silo System for […]

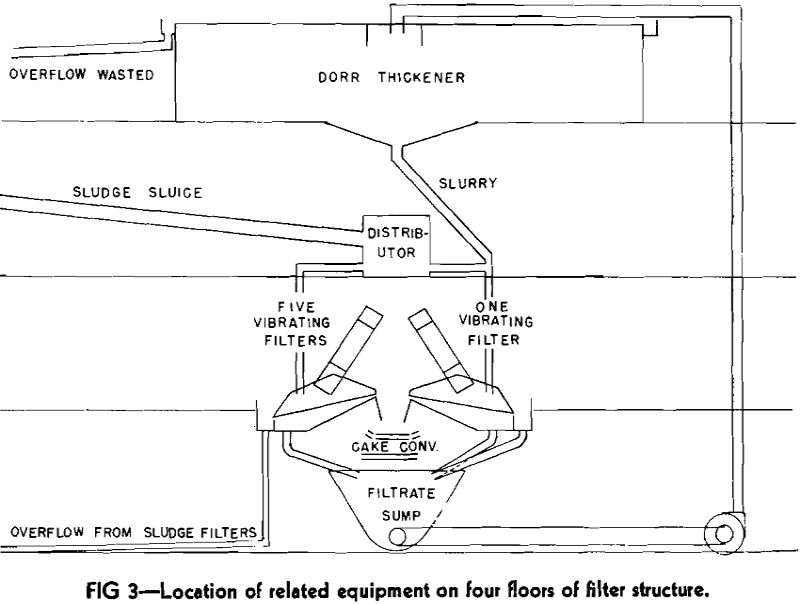

The Rupp-Frantz Vibrating Filter

One of the chief difficulties with which the operator of a coal washing plant has been forced to contend is the handling of the very fine coal. First he has the problem of separating the fine coal from washery water. This is usually accomplished by the use of settling cones or Dorr thickeners: in either […]

How to Produce Graded Glass Sand by Grinding and Classification

The problem of producing a uniform, medium-fine sand for glass-furnace feed has been of interest to the glass-container industry for many years. In the present investigation of the problem, conducted by the Bureau of Mines in cooperation with the Owens-Illinois Glass Co., Alton, Ill., a satisfactory method of producing such sand was developed. The investigation […]

How to Produce Ammonium Sulphate and Manganese Oxides

Manganese Products, Inc. has developed a sulphurous-sulphuric acid leaching process for the recovery of manganese from low-grade, intermediate manganese ores. By the term “intermediate manganese ores” is meant those ores in which the manganese in the form of manganese oxides is found to have two different valences, usually two and four, as is probable in […]

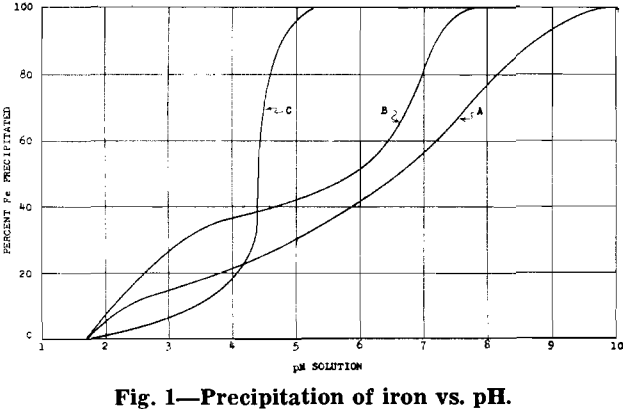

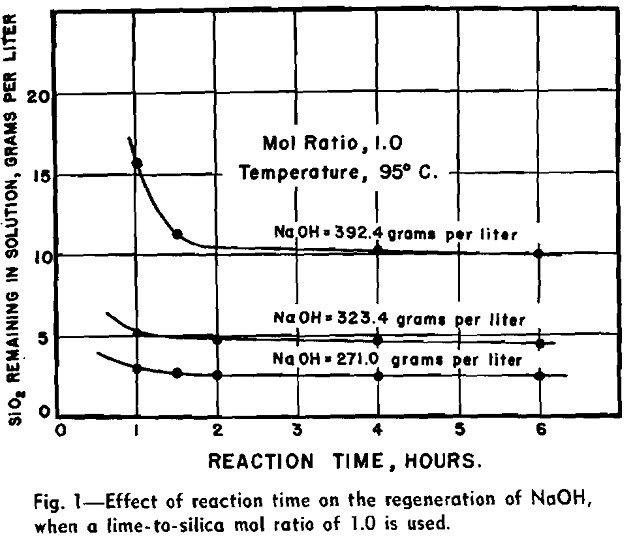

Leaching Manganese Ore with Caustic Soda

All of our larger domestic deposits of manganese are very low grade, but estimated tonnages in these deposits are large enough to constitute a potential strategic reserve of manganese for emergency periods, provided these ores can be upgraded sufficiently to meet industrial specifications. Many types of processes have been suggested for upgrading these ores, several […]