How to Recover Lead from Lead Chloride by Electrolysis

The earliest known specimen of lead, dating from 2000 B.C., is a figurine found near the Dardanelles at the site of the ancient city of Abydos. Since that time, the method for producing lead from its most abundant mineral, galena, has changed very little. Basically, a lead concentrate is mixed with fluxing agents, roasted to […]

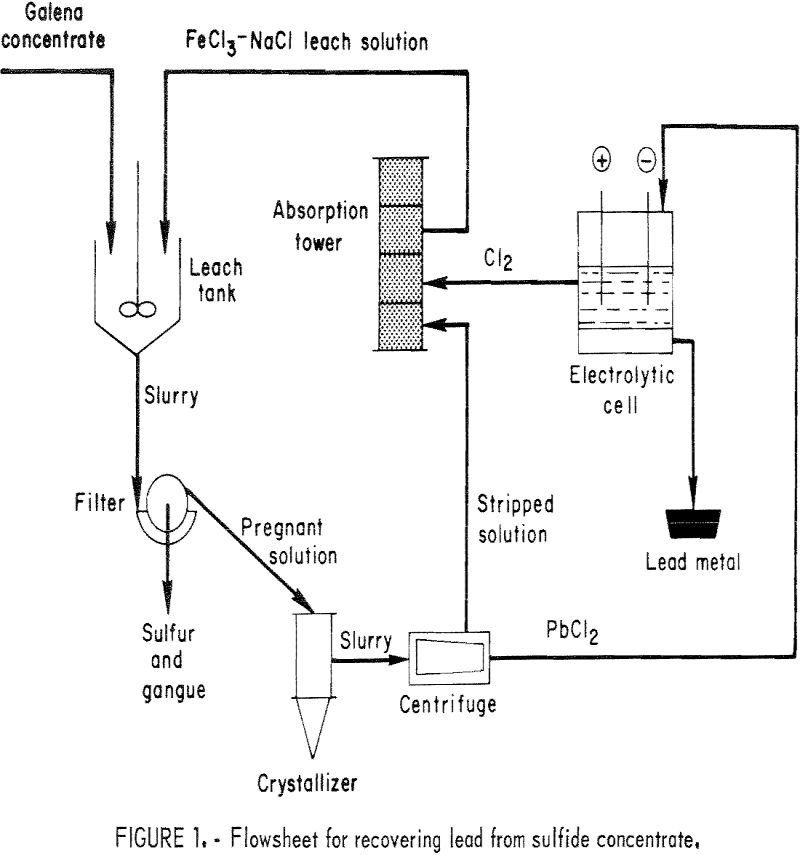

Lead Chloride Electrolysis

During electrolysis, metal was produced from solid lead chloride in contact with the cathode rather than from lead in solution. Relatively high current densities—up to 300 amp/ft²-were possible when operating in this way. Primary lead is now usually produced from sulfide concentrate by a smelting process that involves sintering, blast furnace reduction with carbon, and […]

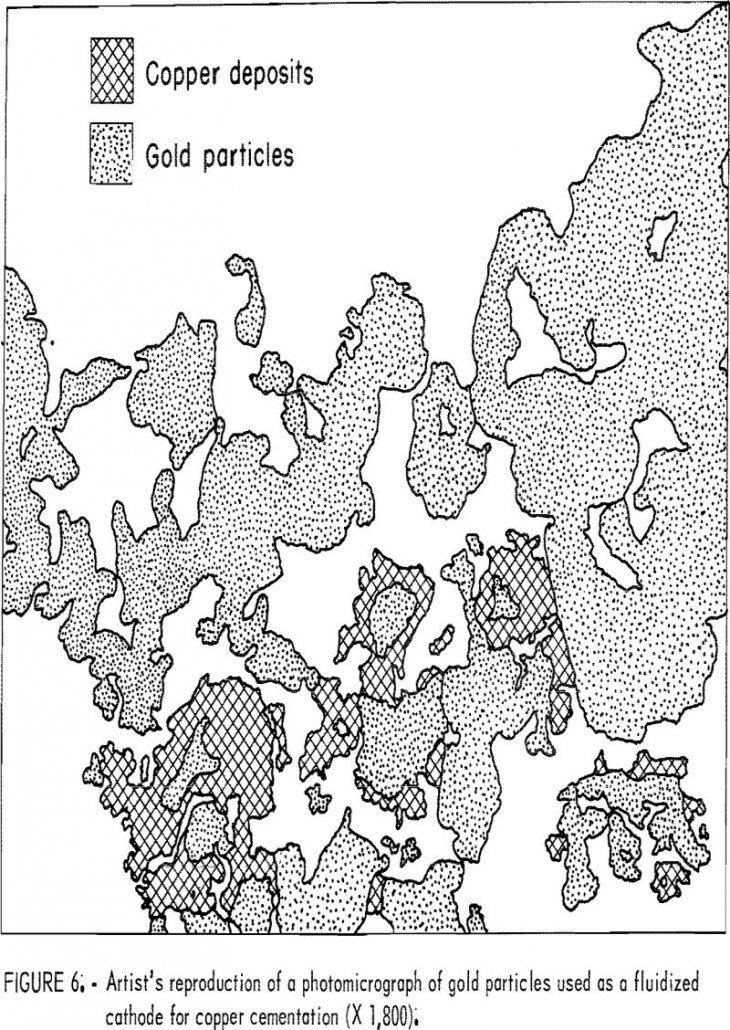

Copper Cementation Kinetics – Revolving Drum Reactor

A kinetic investigation of copper cementation on iron was made to study the effects of deposited copper on the reaction rate. Both the copper deposit attached to the iron and slurried copper particles were considered. The revolving-drum reactor used in this study allowed some of the copper to remain attached to the iron and provided […]

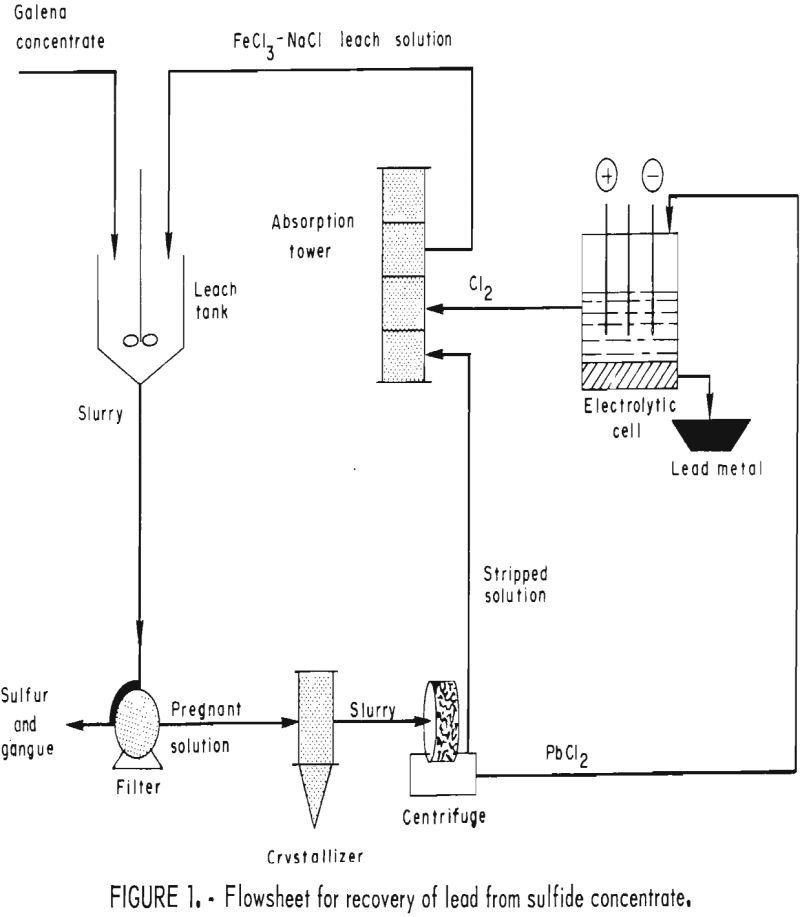

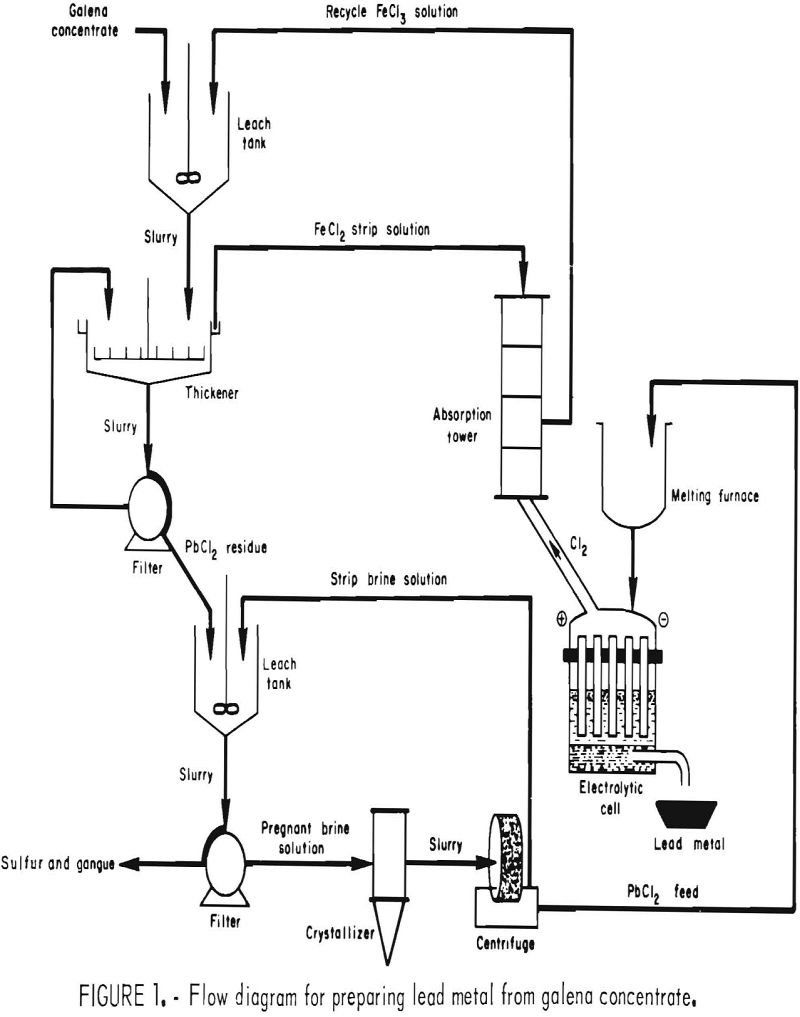

Ferric Chloride Brine Leaching of Galena Lead Concentrate

Domestically produced primary lead is won from lead sulfide concentrates by a smelting process consisting of sintering, blast furnace reduction with carbon and refining. Unfortunately, this pyrometallurgical practice creates gaseous sulfur oxides and particulate lead, which must be controlled to prevent air pollution. For some smelters, meeting environmental regulations requires production curtailment at times, and […]

Conveyor Design for Mining Machines

It does not appear likely that this conveyor-system function requirement can be avoided. The emphasis on the continuous miner performance is necessarily such that the conveyor system must be required to handle any material that is provided by the cutting head. Hence, a slowing down in the rate of advance of the miner to produce […]

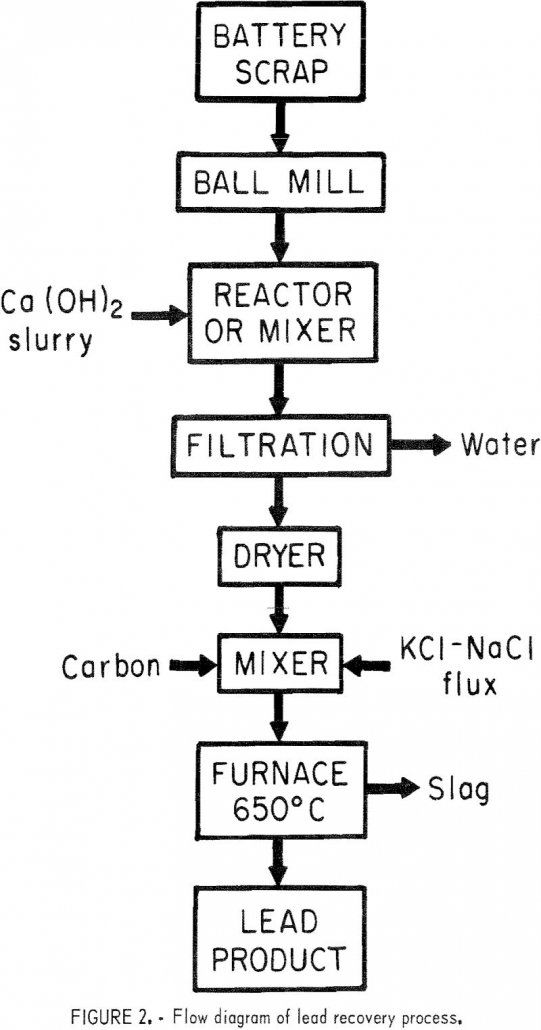

How to Recover Lead from Battery Scrap

Demand for lead for transportation uses (1) has continued to grow as requirements for batteries have increased. The quantity of lead used in battery manufacturing has reached a record high, and the recycling and recovery of lead from lead battery scrap represented 56 percent of the total secondary lead recycled in 1972. The two methods […]

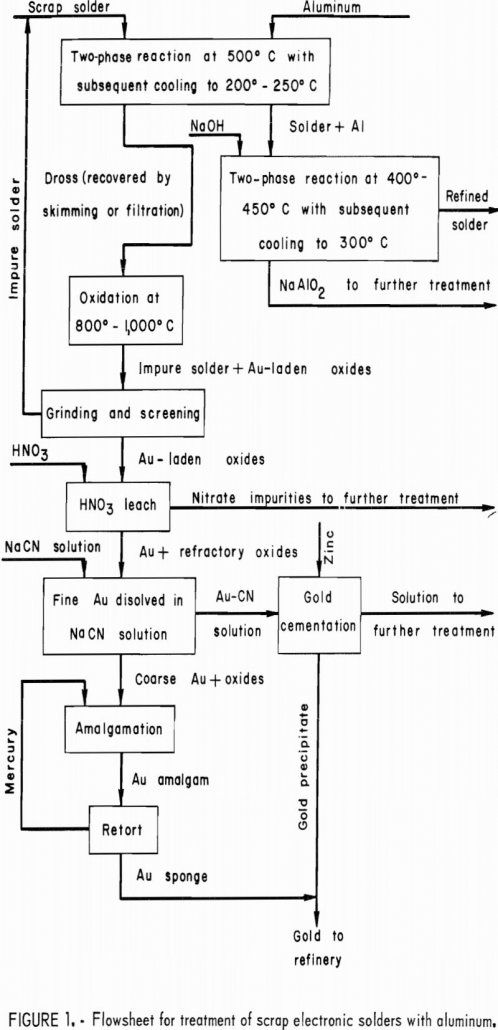

Recovering Gold from Scrap Electronic Solders by Drossing

For several years, the Bureau of Mines has been actively involved in developing techniques for recovering and recycling metals and alloys from industrial scrap, including waste materials generated by the electronics industry. Among the latter materials is tin-lead solder that has become contaminated with gold and other impurities to a point where it no longer […]

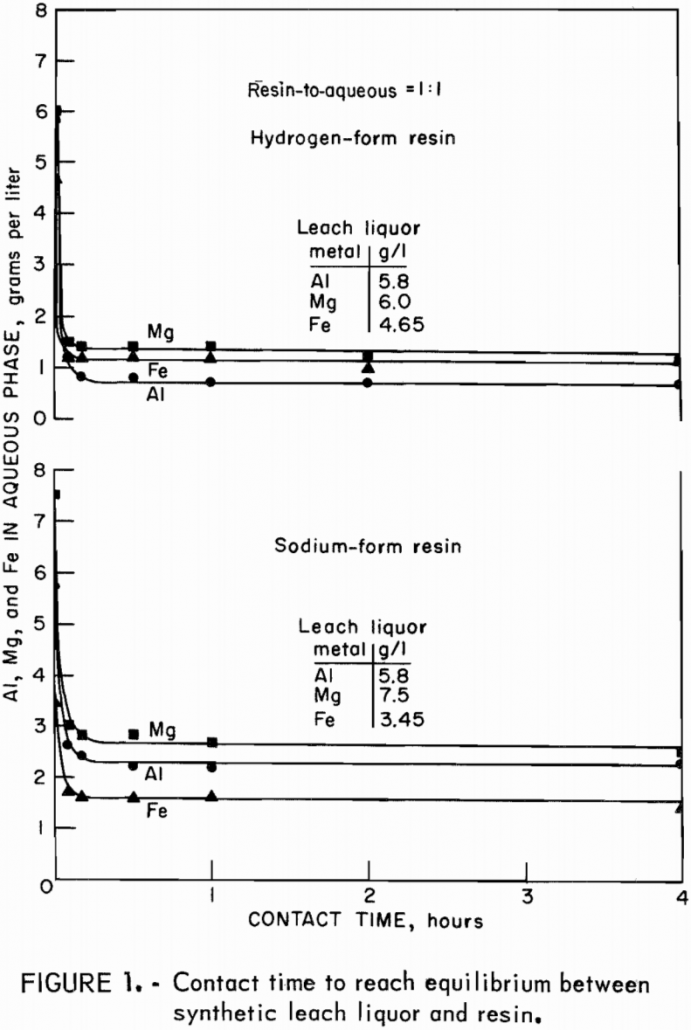

Recovering Aluminum from Copper Leach Liquor by Ion Exchange

The leaching solutions circulated at copper dumps in the United States contain an appreciable concentration of aluminum-as much as 5 to 10 grams Al2O3 per liter in some solutions. This aluminum passes through the copper-recovery operations and recirculates to the leach dump. The aluminum concentration in the leach liquor appears to be in an equilibrium […]

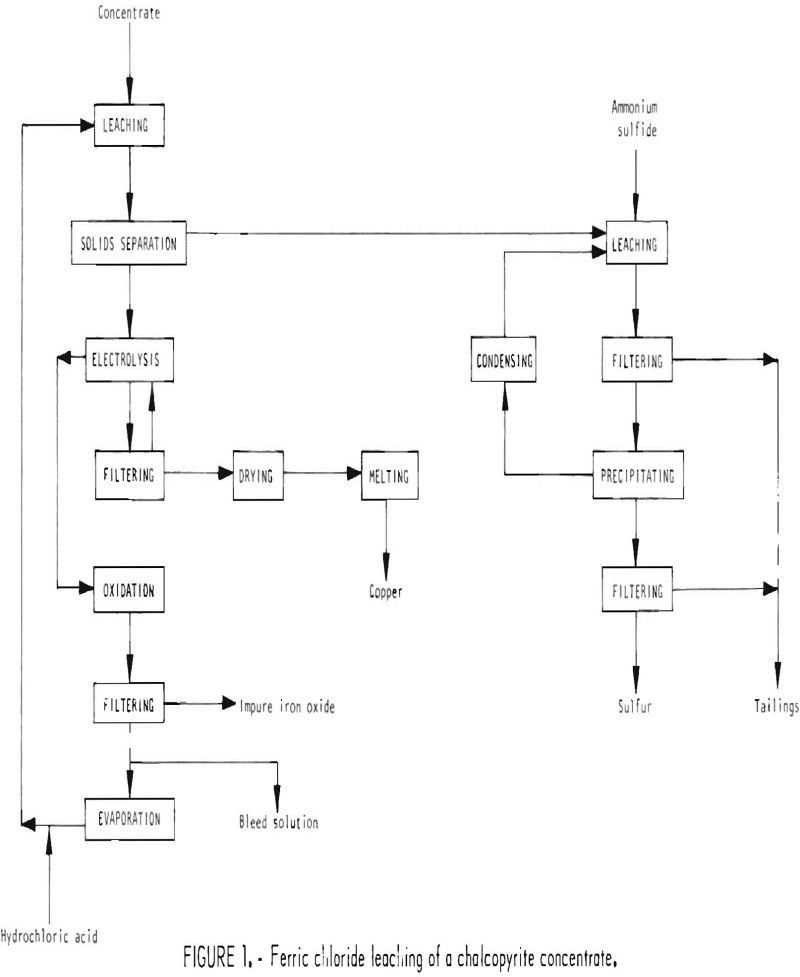

Ferric Chloride Leaching of Chalcopyrite Concentrate

Most copper is produced from chalcopyrite concentrates by smelting. While smelting is both simple and efficient, it converts the sulfur in the feed concentrate to sulfur dioxide. To meet the ambient standards for this pollutant, as established by the Clean Air Act, the Federal Environmental Protection Agency (EPA) has established a goal for smelters to […]

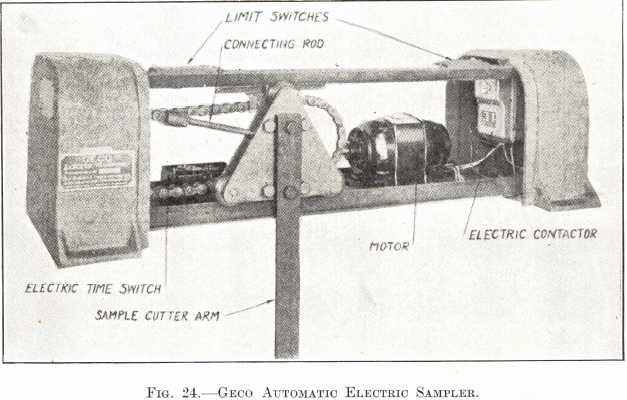

Metallurgical Plant Sampling Techniques

Concentrator Slurry Sampling In milling operations sampling is essential to proper control. This can only be based on the results obtained through sampling the various materials throughout a plant. Sampling of the feed, concentrates, tailings and other products give data indicating the effectiveness of the entire operation. Often these results are desired for comparative purposes for each […]