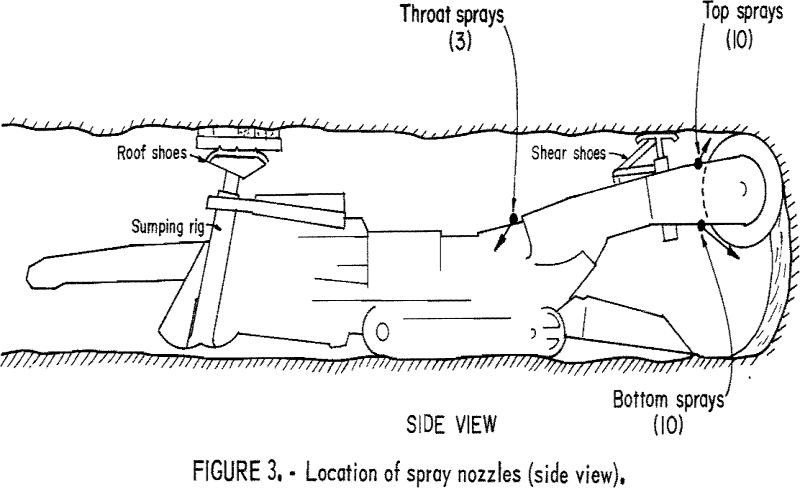

Water Sprays Affects Dust Suppression

The Federal Coal Mine Health and Safety Act of 1969 specified that the average respirable dust level to which a miner is exposed during the work shift must be 2.0 mg/m³ or less as of January 1, 1973. In response, the Bureau of Mines initiated a program to develop new and improved methods of technology […]

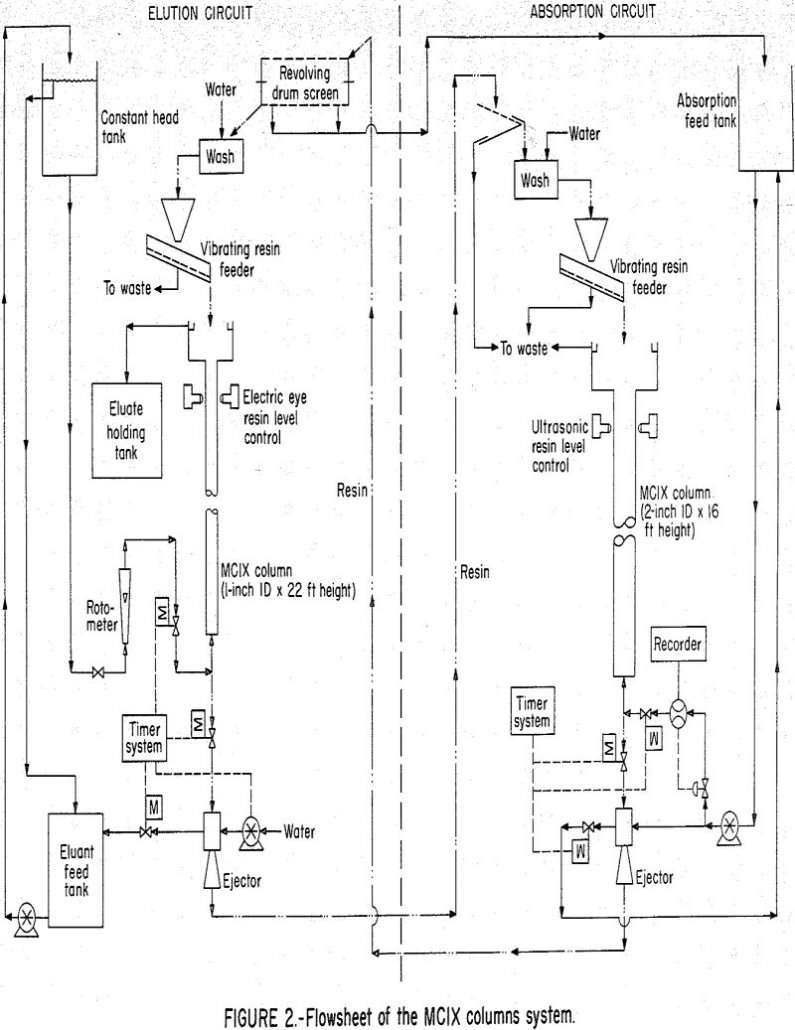

How to Design Uranium Ion Exchange

The Bureau of Mines has developed and tested countercurrent fluidized bed, multiple-compartment ion-exchange columns (MCIX) to recover uranium from mine water, clear solutions, and slime slurries. A 14-inch-diameter MCIX absorption column and a 4-inch-diameter fixed-bed upflow elution column were field tested on uranium-bearing mine water at Bingham Canyon, Utah, and Grants, N. Mex. The same […]

Rock Sample Nondestructive Evaluation

As part of a program on mine safety directed by the U.S. Bureau of Mines, the Oak Ridge National Laboratory (ORNL) studied radiographic techniques on specimens of stressed rock. This phase of the program on mine safety is related to the structural integrity of the roof of the mine. A common practice for roof support […]

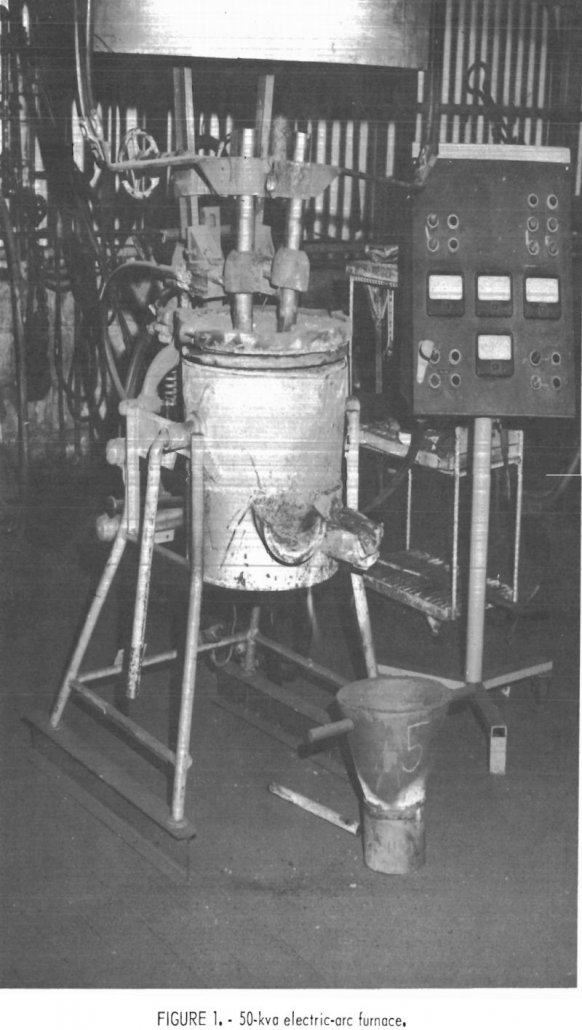

Smelting Nickel Electric Furnace

This Bureau of Mines report results from a study on prereduced nickel concentrate from the FENI project in Yugoslavia; this study was conducted in cooperation with McKee Overseas Corp., Western Knapp Division. The Bureau was particularly interested in establishing the chemical relationships between pre-reduction of low-grade nickel ore and the ferronickel produced by smelting the […]

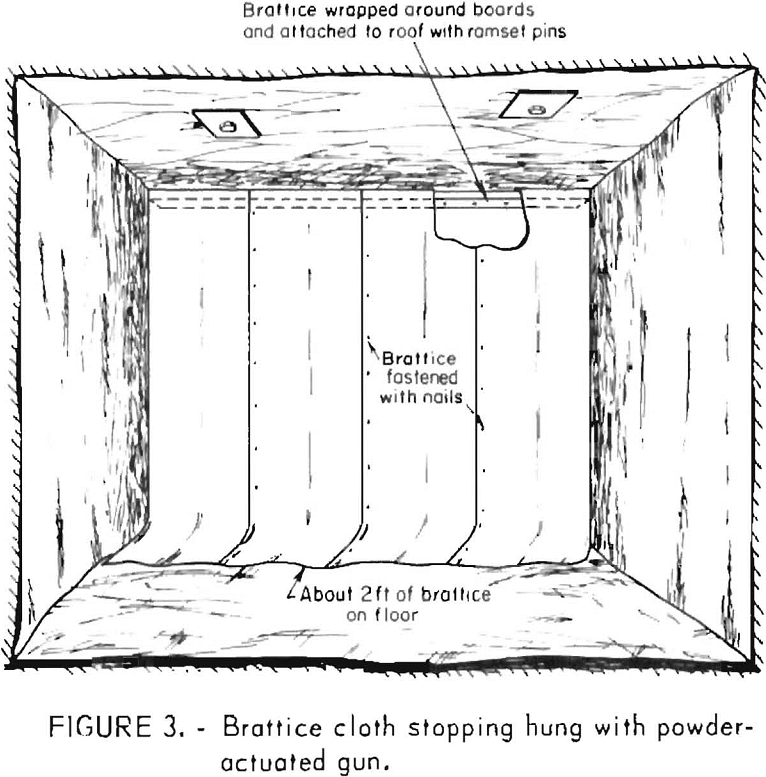

Mine Stoppings

Most of the mines with large openings in the United States today are salt and limestone mines. Some potash and trona mines also have moderately large openings. Moreover, it is expected that in the near future numerous underground oil shale mines will be developed in the oil shale regions of Colorado, Utah, and Wyoming. These […]

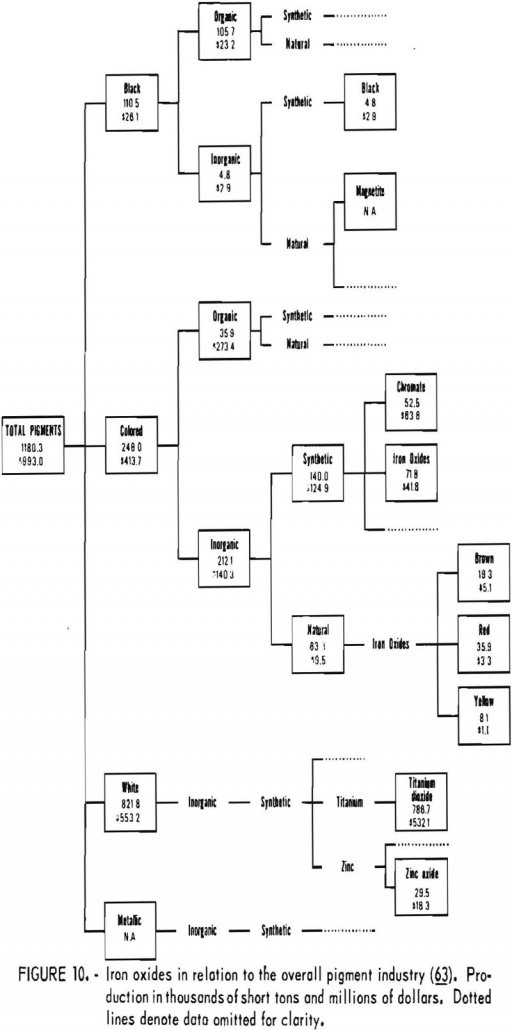

Iron Oxide Pigments

Until the late 19th century iron oxide pigments were obtained wholly from natural materials, generally with little alteration other than physical purification. In some cases roasting or calcination was also carried out. However, beginning in the first part of the 20th century, chemical methods were developed for synthetic production of commercial iron oxides. Synthetic production […]

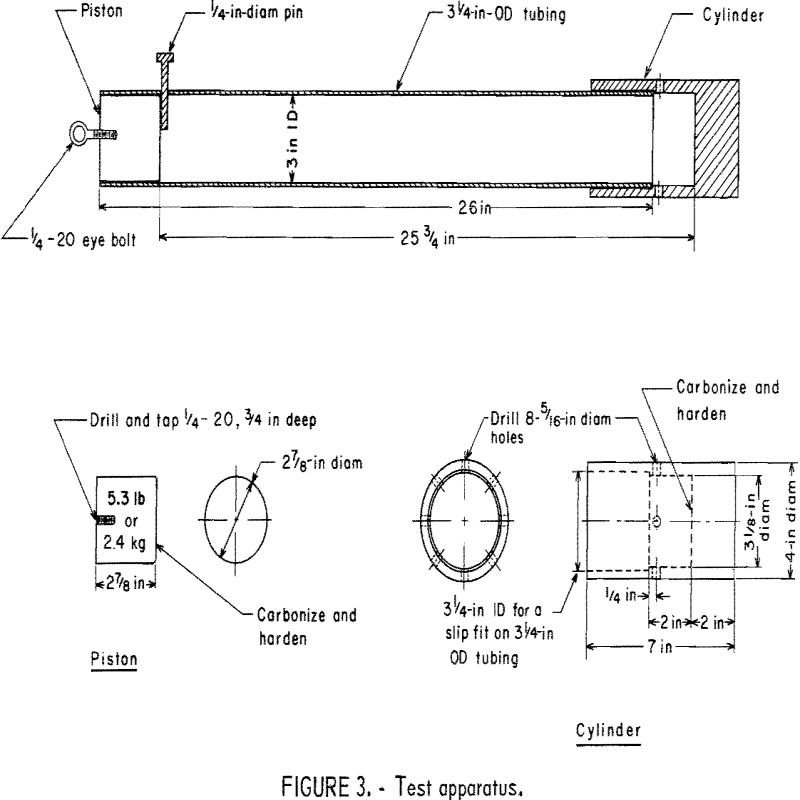

Drillability Index

Cost is a major criterion in decision making for selecting operational methods in mining. Knowledge of the operating cost, therefore, provides a sound basis for evaluating the feasibility of plans and for selecting alternative operational procedures. In production drilling, the choice of a drilling method is primarily based on several factors such as working condition, […]

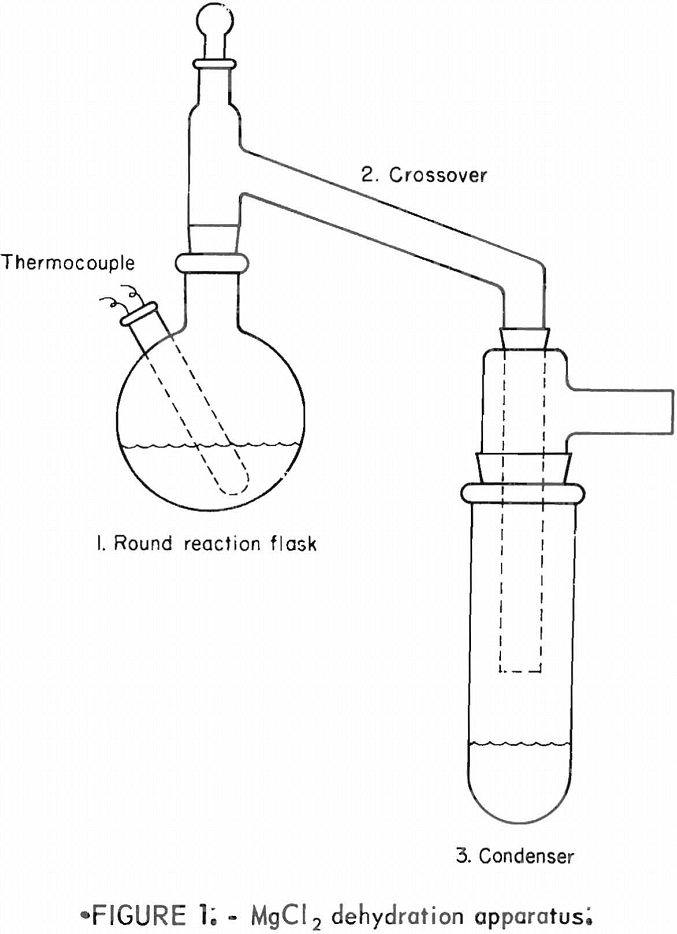

How to Dehydrate Magnesium Chloride

The United States has almost limitless supplies of magnesium chloride available for the production of magnesium metal in the form of hydrated salts or brines from seawater, wells, and the Great Salt Lake. Anhydrous magnesium chloride has certain advantages for metal production but cannot be made from the hydrate or brines by simple drying. In […]

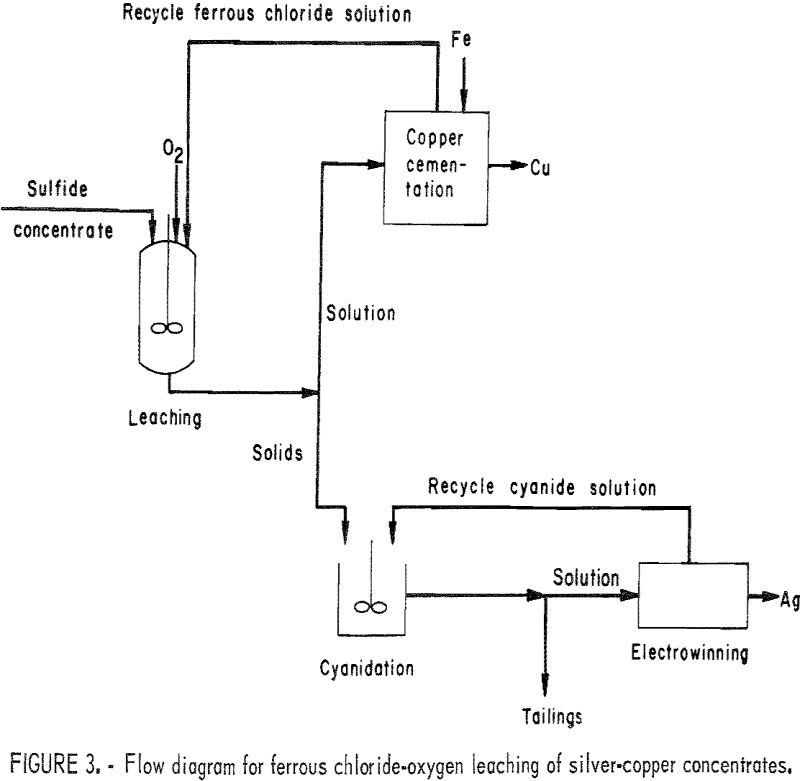

How to Recover Copper & Silver Sulfide Concentrate

One of the goals of the Bureau of Mines is to insure that an adequate supply of minerals is available to meet national, economic, and strategic needs. To help reach this goal, the Bureau is conducting research to advance minerals processing technology, which includes investigations for recovering metals from complex sulfide ores and concentrates. Marketing […]

Remove Cobalt and Nickel from Zinc Sulfate Electrolyte

The Bureau of Mines strives continually toward its goals of maximizing minerals and metals recovery from primary and secondary domestic resources, and reducing energy requirements of mining and mineral processing. This investigation to improve zinc electrolysis by separating and recovering the currently discarded cobalt and nickel found in Missouri zinc concentrates is among the Bureau’s […]