Aluminum Extraction by HCl and Fluoride Leaching

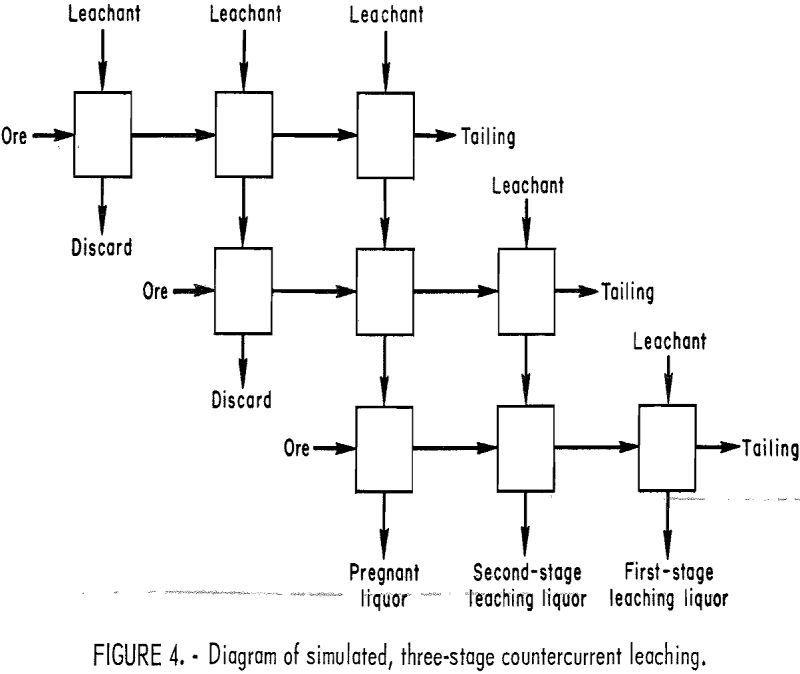

The United States depends on imports of bauxite and alumina for most of its aluminum requirements. To reduce this dependence, the Bureau of Mines conceived a raw materials-process technologies matrix as a means of systematically investigating the technology options available for processing domestic aluminum resources. In 1973, a research program was initiated based on this […]

Chemically Bonded Refractories

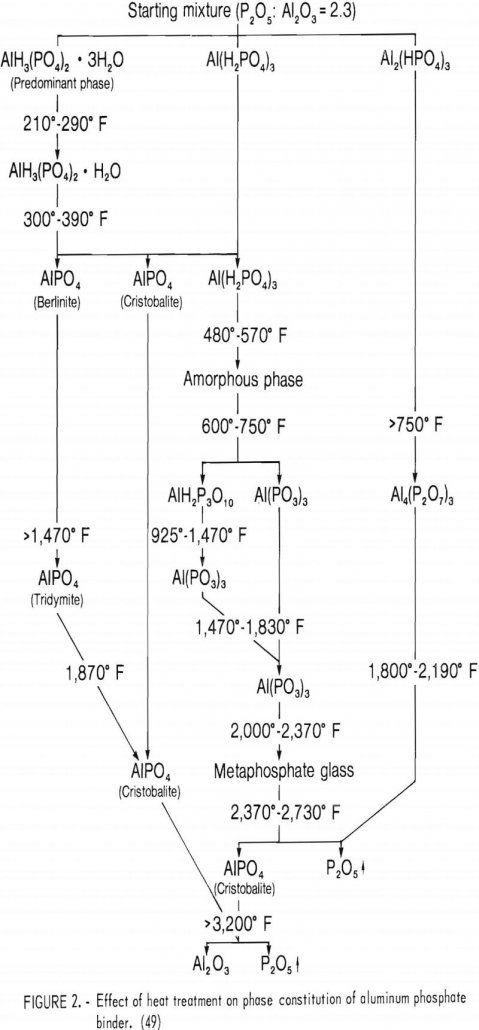

Improved ceramic materials are in constant demand for processes involving severe chemical, corrosive, and thermal environments, especially at high pressures. During the past decade, demand for higher quality ceramic materials has significantly increased. This is true, for example, in the steel industry where oxygen steelmaking has increased production rates and operating temperatures, thereby compounding the […]

Effect of Sodium Chloride Leach on Copper Chalcopyrite

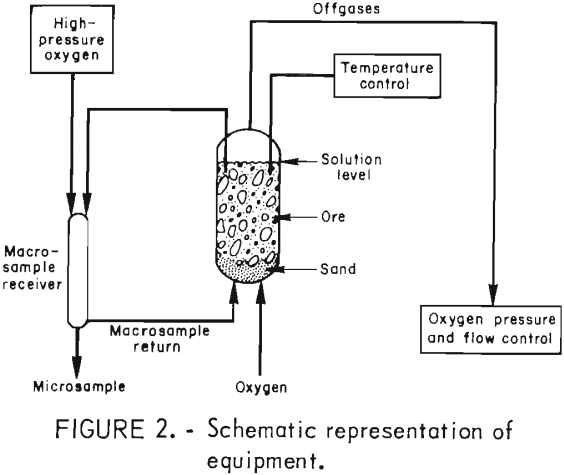

As part of the mission of the U.S. Department of the Interior’s Bureau of Mines to help insure the continued viability of the domestic minerals and materials economy, and to help maintain an adequate minerals base, research was conducted to investigate in situ leach techniques for extraction of copper from a chalcopyrite ore. Successful application […]

Recover PGM by Matte Smelting and Leaching

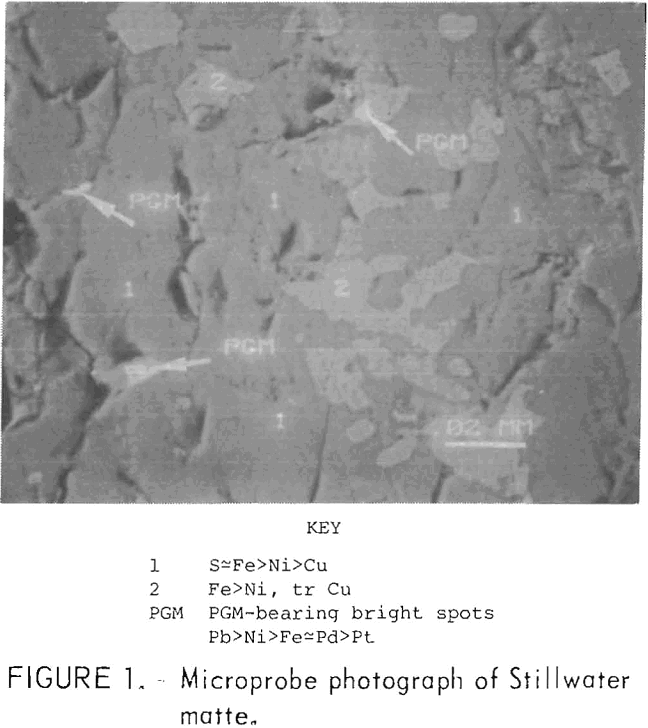

An important objective of Bureau of Mines research efforts is to investigate alternative technologies that may be applicable to domestic mineral resources. In addition, the Bureau seeks to avoid some of the difficulties or problem areas associated with conventional processing methods. In this regard, the Bureau has studied flotation concentration and extraction of platinum-group metals […]

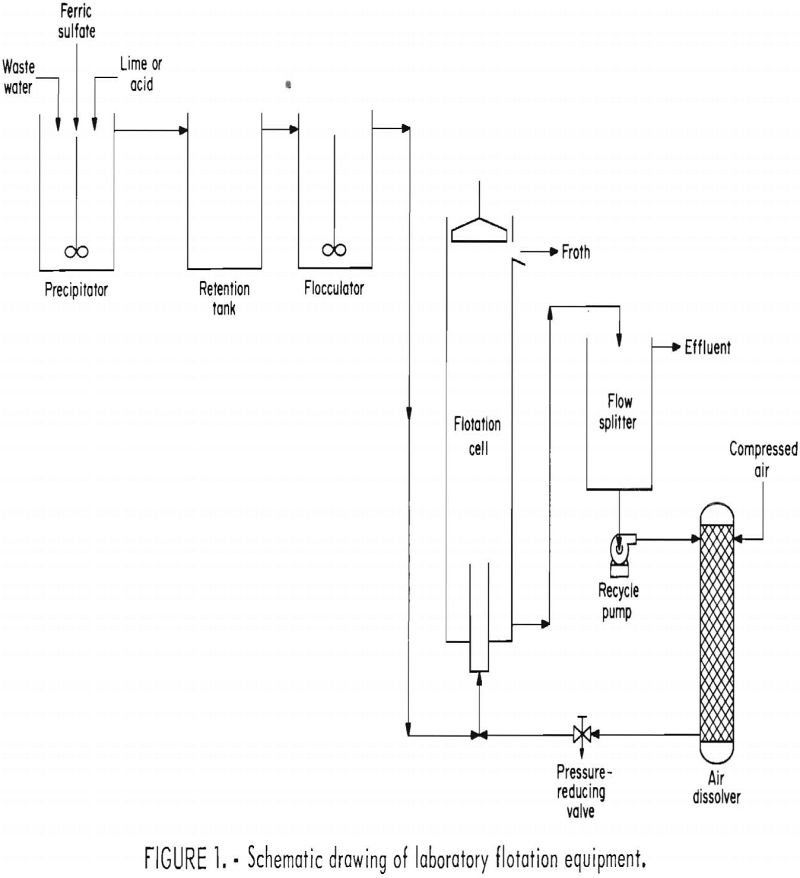

How to Remove Molybdenum Process Plant Water

The minerals industry uses large volumes of water in many of its operations. Because of the rapidly decreasing availability of water in many areas and the need to control pollution, efficient and economical processes for purifying mineral waste waters are urgently needed. As part of a continuing program to devise technology for abating pollution caused […]

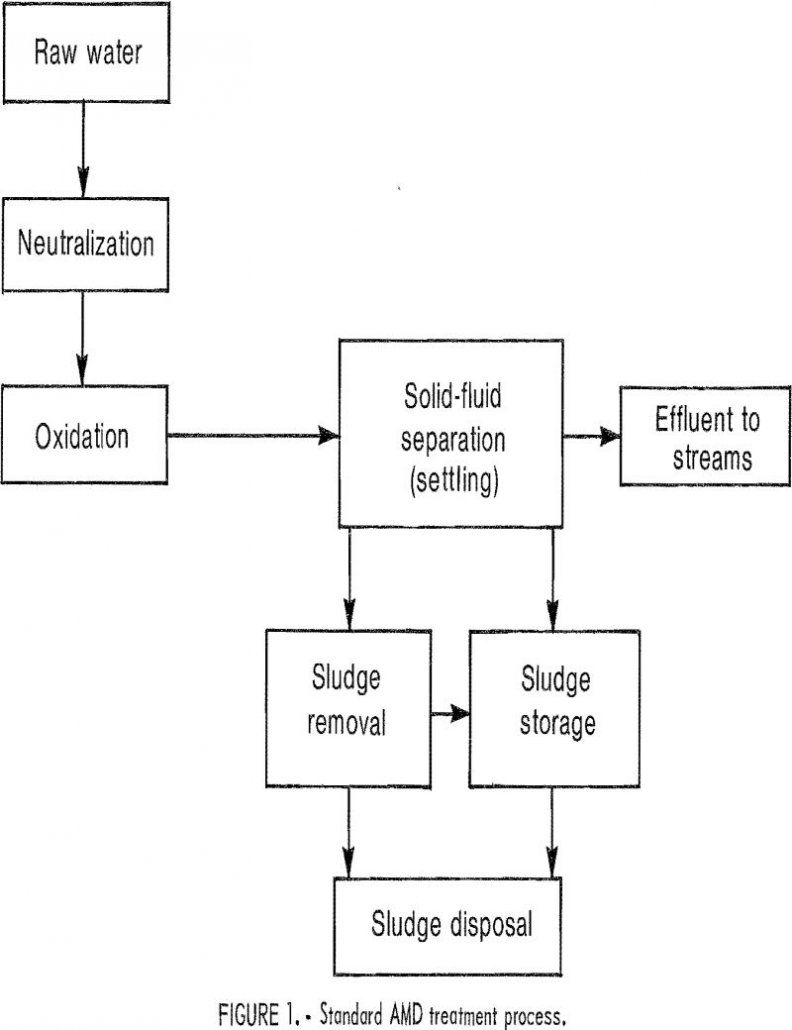

Acid Mine Drainage Treatment & Sludge Disposal

The technology of acid mine drainage (AMD) treatment has improved since the mid-sixties, and water pollution from active coal mining operations has been reduced considerably. Present treatment processes are designed to raise the pH of the effluent to within the range of 6.0 to 9.0 and reduce the total iron concentrations to less than 7 […]

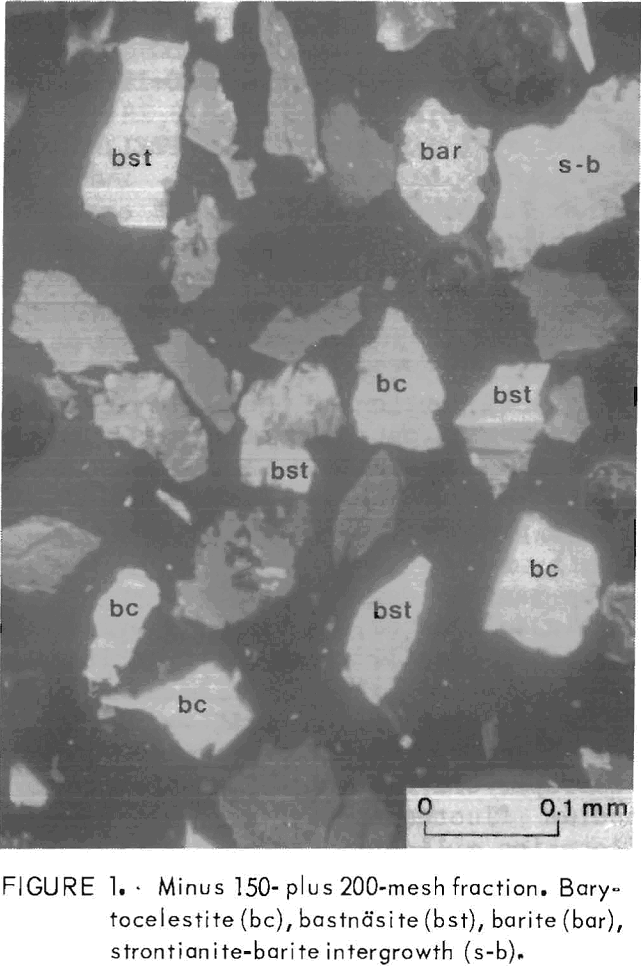

Flotation of Rare Earths from Bastnasite Ore

A large bastnasite deposit was discovered at Mountain Pass, Calif. Subsequent development of the deposit made the United States the world’s largest source of rare-earth minerals. Since then, bastnasite, a fluocarbonate of the cerium-group metals, REFCO3, has replaced monazite as the principal source of rare earths; in 1978 it accounted for more than half of […]

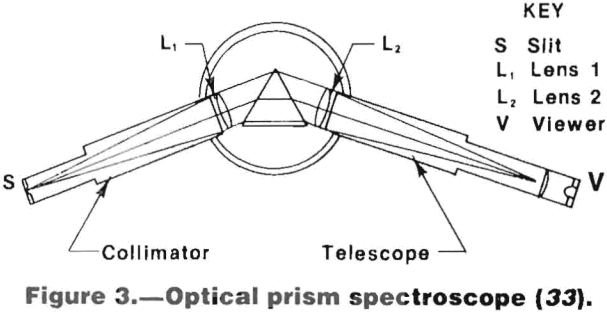

How to Identify Scrap Metals

Large quantities of scrap metals are discarded each year by industry and householders; recycling of these materials results in conservation of dwindling domestic resources and helps ease U.S. dependence on imports. Substantial energy savings are also achieved by increased use of recycled material. In order for these scrap metals to be returned to those operations […]

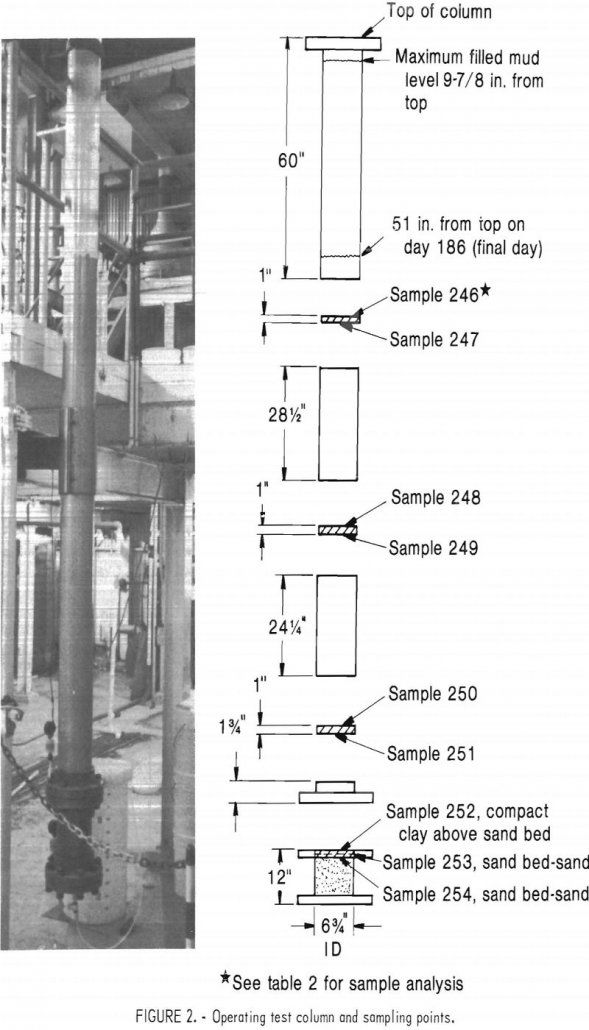

Sand Bed Dewatering

In 1979, as part of its minerals environmental technology research, the Bureau of Mines began a study of mine waste tailings disposal. Part of the investigation focused on evaluating the effectiveness of the sand bed dewatering technique on alumina miniplant tailings. Alumina wastes result from the hydrochloric acid extraction of alumina from nonbauxitic ores. These […]

Mineral Wool Furnace Refractories

A slag formulation conforming to that used by a commercial mineral wool producer was used throughout testing. The composition of the test slag was as follows, in weight-percent: 9 copper-smelter slag, 41 lead-smelter slag, and 50 iron blast-furnace slag. Each component slag was crushed through 20 mesh, and a weighed amount of each was blended […]