Hydraulic Backfill Support

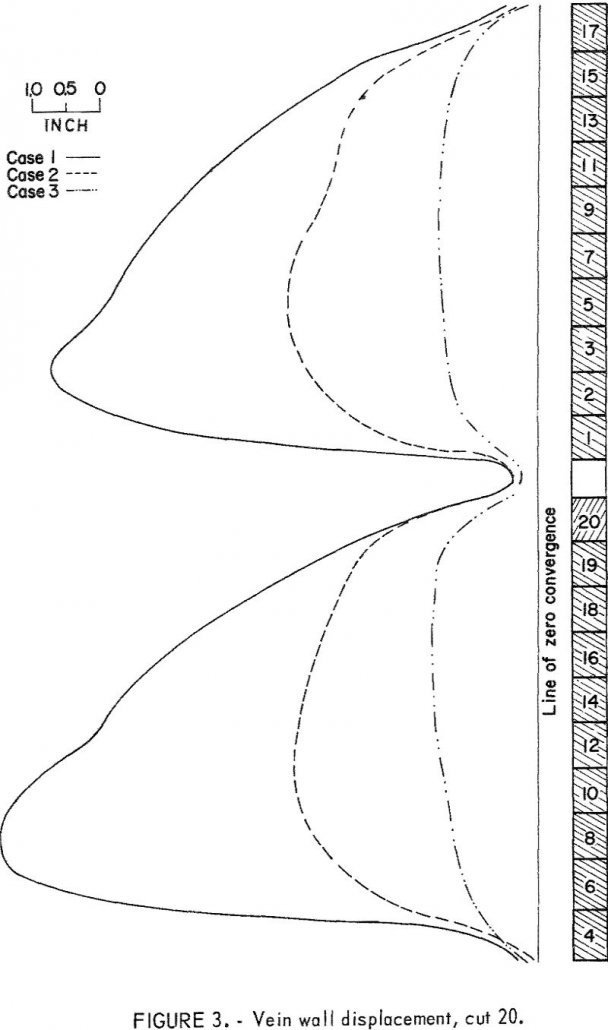

Mining companies have been confronted with a multitude of production problems in their endeavors to extract maximum quantities of ore at minimal costs. These problems are further compounded by the harsh mining conditions of deep vein operations, such as those found in the Coeur d’ Alene mining district of Idaho. One of the major obstacles […]

Underground Mine Design

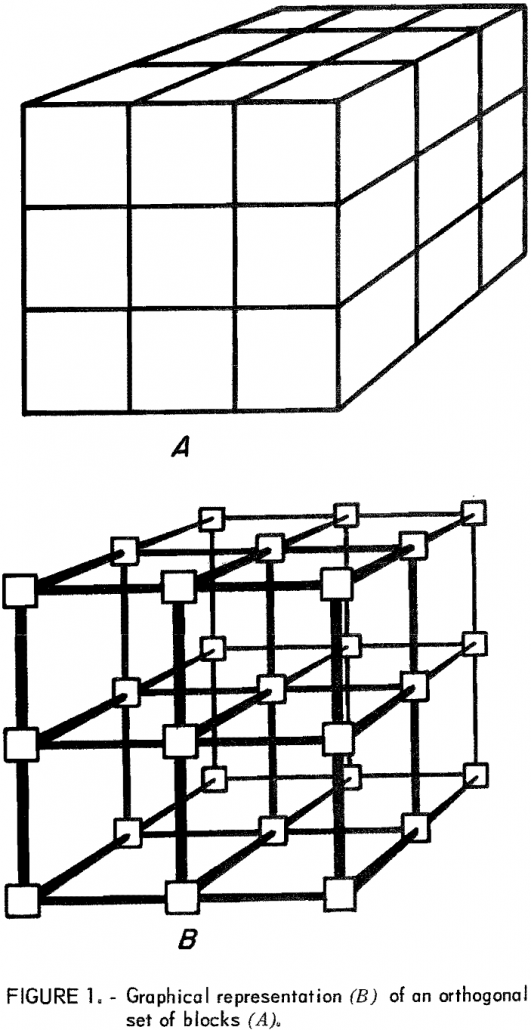

The minerals industry in the field of Underground Mine Design is presently faced with the problem of meeting a rapidly increasing domestic and foreign demand for its mineral resources. This increased demand has added to the problems already plaguing the industry increased land, labor, and material costs; increased foreign competition; more rigid Federal and State […]

Mill Tailings Dam Stability

The reconnaissance-level investigations were carried out to gather supplemental data to the in-depth studies of Kennecott’ s Magna and Phelps Dodge’s Morenci tailings deposits and Kennecott’s Chino leaching dump. The data were obtained by personnel of W. A. Wahler and Associates to determine to what extent the disposal systems and techniques used at the three […]

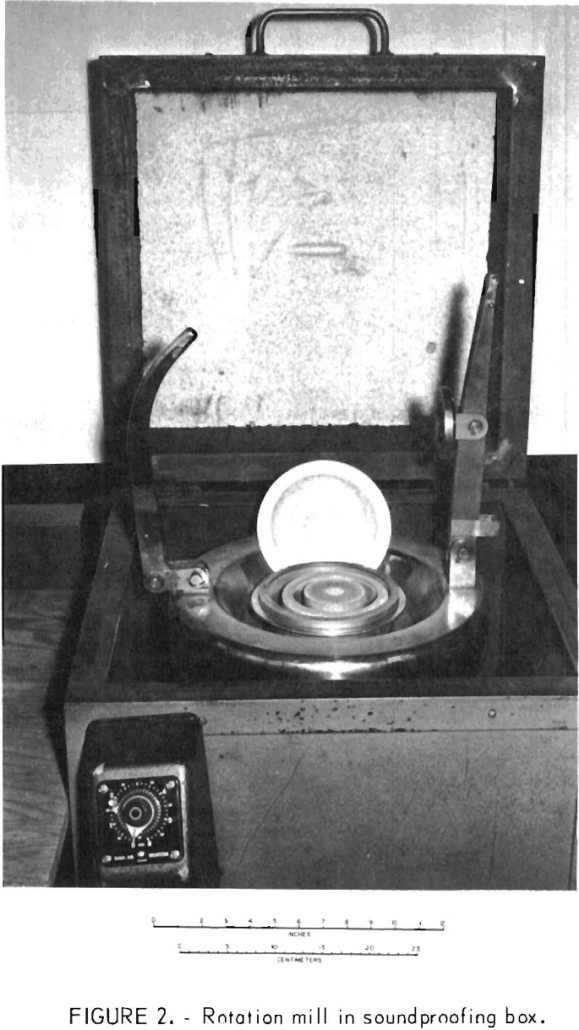

Rapid Particle Hydrosizing Size Analysis

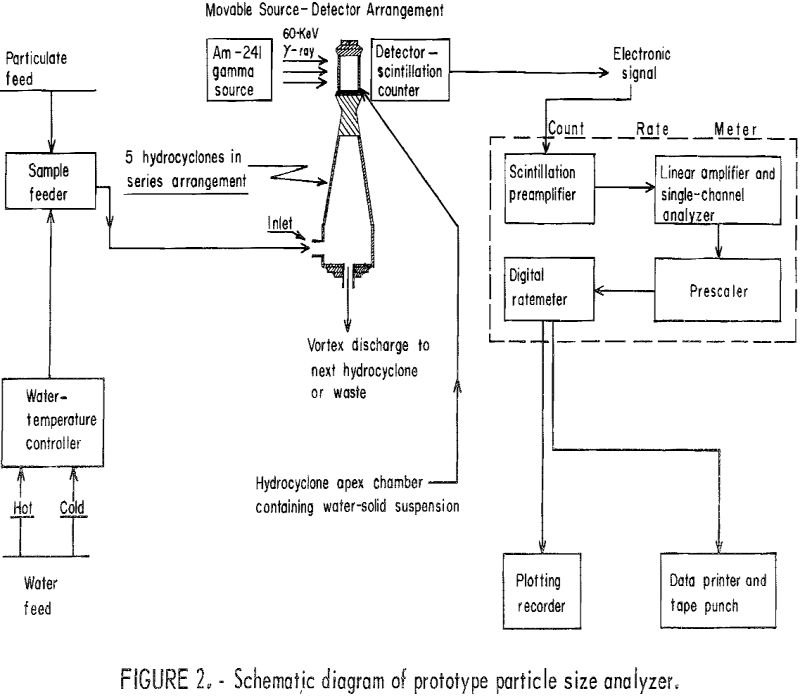

The knowledge of particle size distributions is a critical factor in the monitoring, control and optimization of many processes. This is particularly true of the mineral beneficiation industry, where comminution, the reduction of particle size, accounts for a major source of the processing costs. As an example, it is not uncommon in current taconite operations […]

How to Analyse Blast Furnace Slag

From May 1951 to March 1967, the Bureau of Mines, as part of its iron and steelmaking research program, operated a series of experimental blast furnaces. The first furnaces were located in Pittsburgh; later furnaces were constructed and operated at the Bruceton, Pa., facility just outside of Pittsburgh. With these furnaces, because of the shorter […]

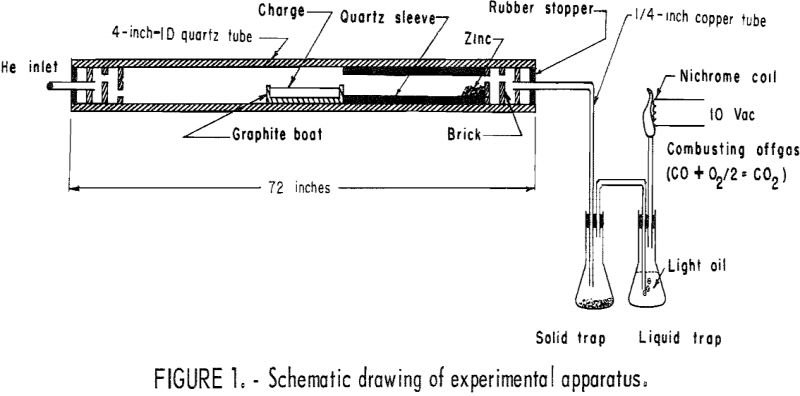

How to Recover Zinc & Lead from Brass Smelter Dust

The recovery and recycling of metals from process wastes is a major research effort of the Bureau of Mines. The present work was undertaken by the Rolla Metallurgy Research Center to develop data that could be used in a pyrometallurgical process to recover zinc and lead from the flue dust generated in the secondary smelting […]

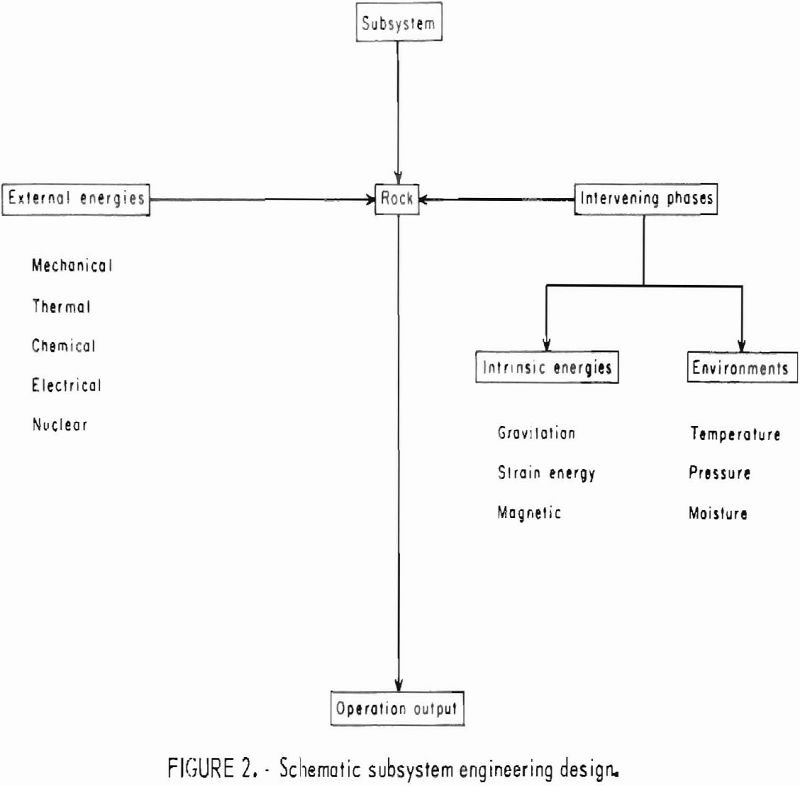

Rock Testing Procedure

Design engineers involved with mine or tunnel construction require knowledge of rock behavior in order to assure economic excavation of rock and stability of underground openings. For many applications, the behavior of a rock is determined from an engineering approach involving rather empirical experiments. A greater emphasis is now being placed on the use of […]

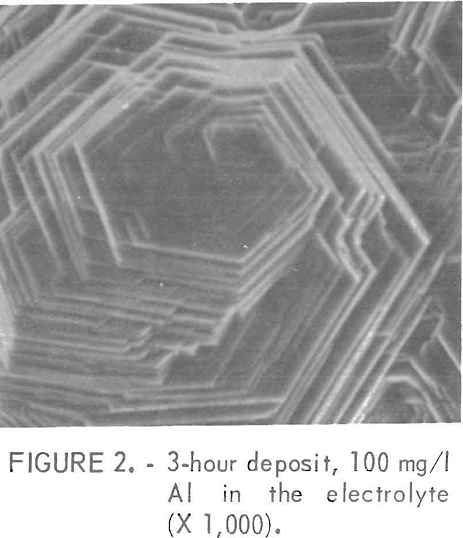

Zinc Electrowinning & Impurities

In the commercial electrowinning of zinc, zinc oxide is leached from the roasted calcine with an aqueous acid sulfate electrolyte. The zinc-rich solution is purified and then passed into an electrolytic cell where a fraction of the metal is cathodically deposited. The spent electrolyte is pumped from the cell to readjust the zinc concentration by […]

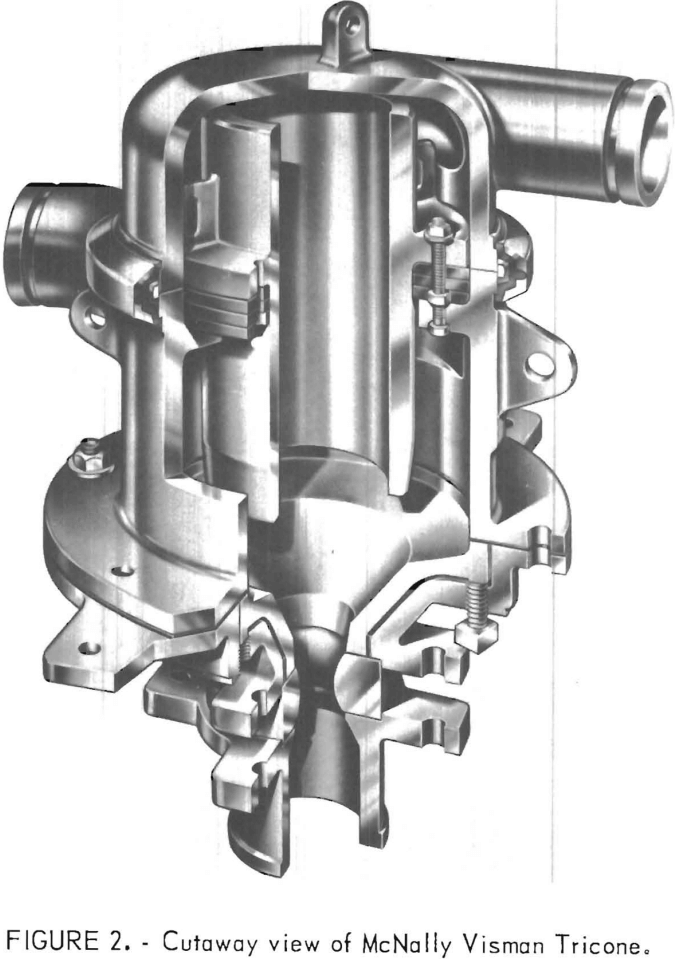

Hydrocyclone for Coal-Washing Equipment

The profitable operation of a coal preparation plant under today’s stringent product standards and ever-rising labor, material, energy, and equipment costs requires that the preparation engineer continually strive for maximum recovery of salable coal. Good performance data are a prerequisite to the design of a new plant or to the expansion of existing facilities, and […]

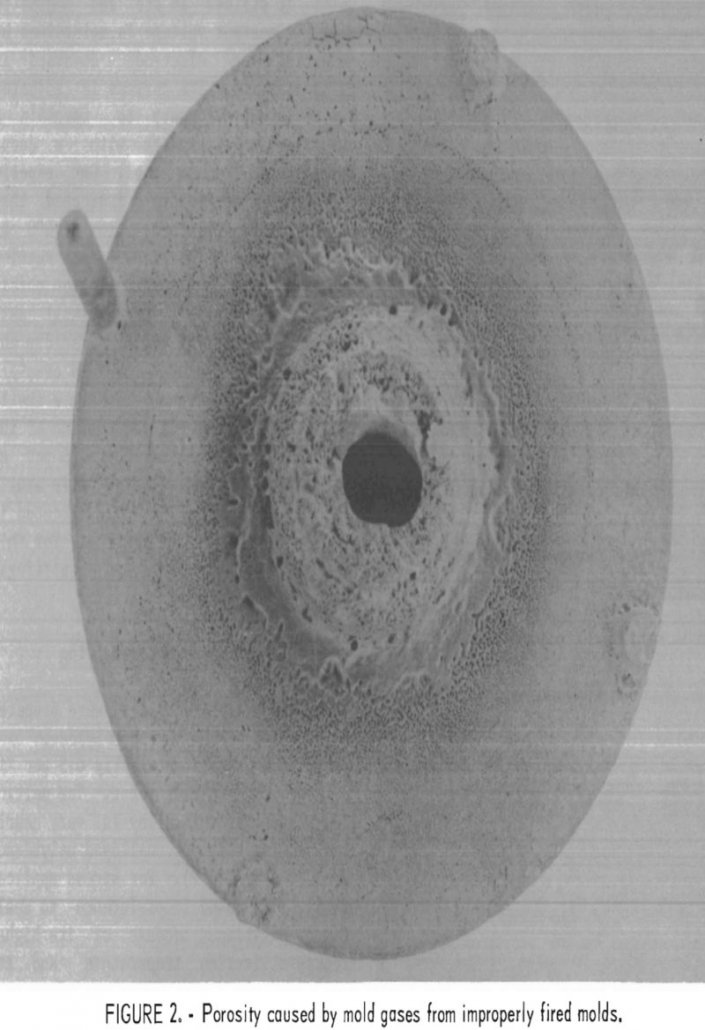

Zirconium Oxide Molds for Molybdenum

One of the goals is to minimize the requirements for critical and strategic mineral commodities through conservation and substitution. As a part of this effort, the Bureau conducted research to develop molybdenum as a potential substitute for alloys containing the critical and strategic metals nickel, chromium, or cobalt. As expressed in Iron Age, this Nation […]