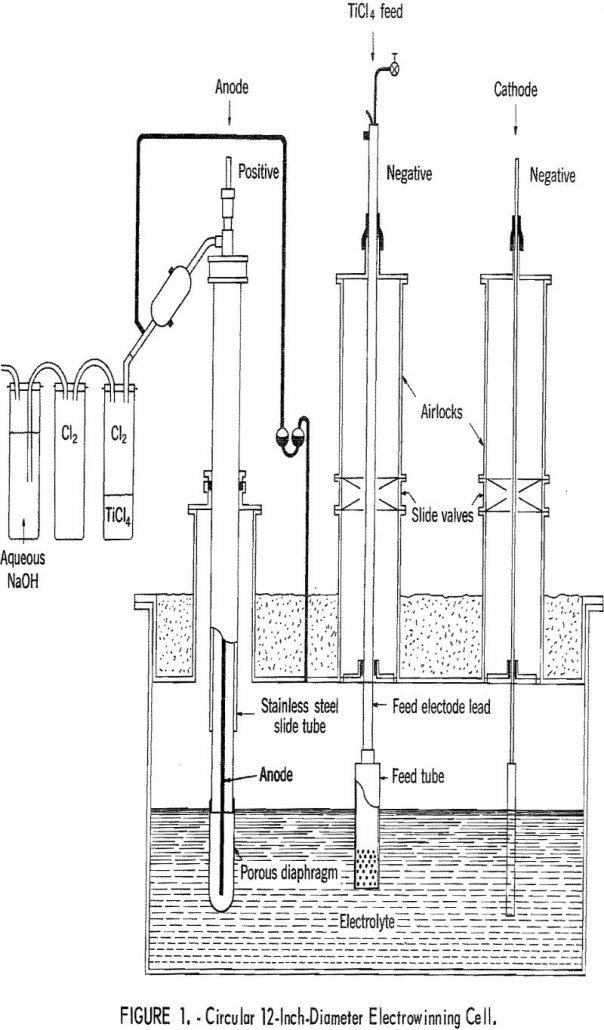

Electrowinning of Titanium

Composite diaphragms were constructed and used for the electrowinning of Ti from TiCl4 to eliminate some of the problems associated with diaphragm failure. High-purity titanium (Ti) was previously electrowon from titanium tetrachloride (TiCl4) fed into a molten electrolyte (520° C) composed of lithium chloride, potassium chloride, and titanium dichloride (LiCl-KCl-TiCl2). Two papers describing the work […]

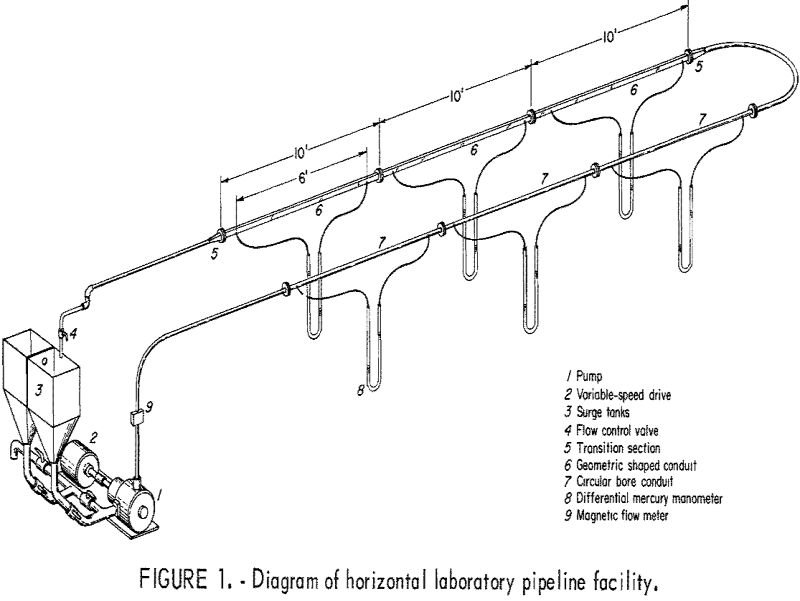

How Pipe Geometry Affects Flow Velocity & Head Loss

Transporting solids in pipelines generally is considered economical in the mining industry as well as in other industries. For example, the procedure has been used successfully in the iron ore slurry pipeline of the Savage River mines and the coal slurry pipeline of the Black Mesa mines. Even under conditions in which this mode of […]

Leach Gold by Sodium Hypochlorite / Chlorine

The extraction of gold from ores that contain carbon and organic compounds has presented a problem to the cyanide mill operator ever since the widespread adoption of this classical dissolution technique in the late 1800’s. The problem was studied in 1924 by Leaver and Woolf. More recently, Hedley and Tabachnick indicated that a general solution […]

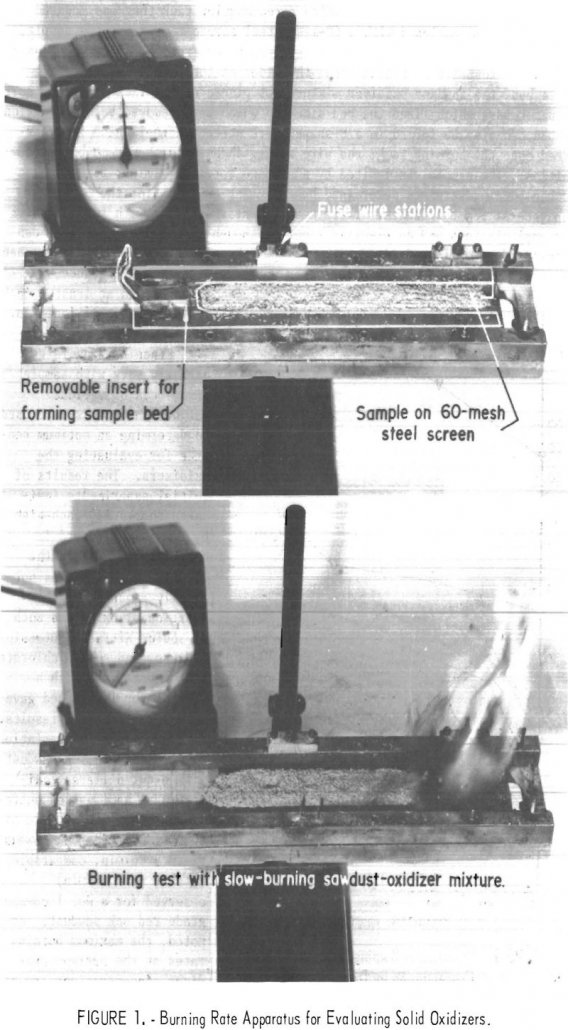

Classification Solid and Liquid Oxidizers

We recently prepared recommendations on methods of evaluating and classifying flammable liquids and solids for use in government transportation regulations. This report is the third in this series and describes the classification of oxidizing materials which are defined in the transportation regulations as substances that can yield oxygen readily to stimulate the combustion of organic […]

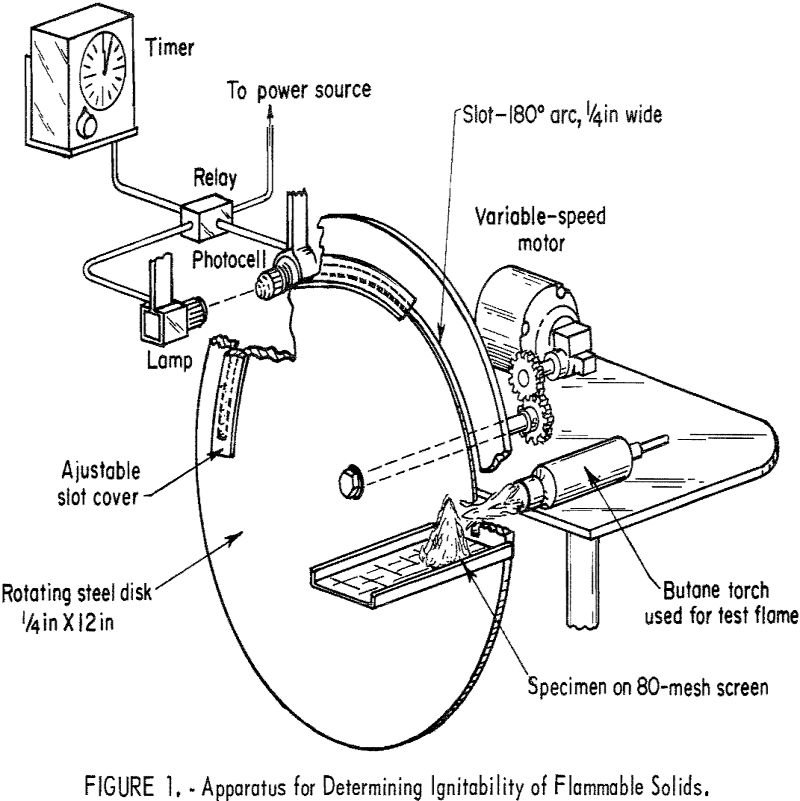

Classification Flammable Solids

The Bureau of Mines research programs are partly directed to developing safety guidelines for the reduction of fires and explosions in industries that produce, transport, or utilize mineral fuels and their products. As a result of a request by the Department of Transportation, the Bureau is evaluating test methods for classifying hazardous materials and developing […]

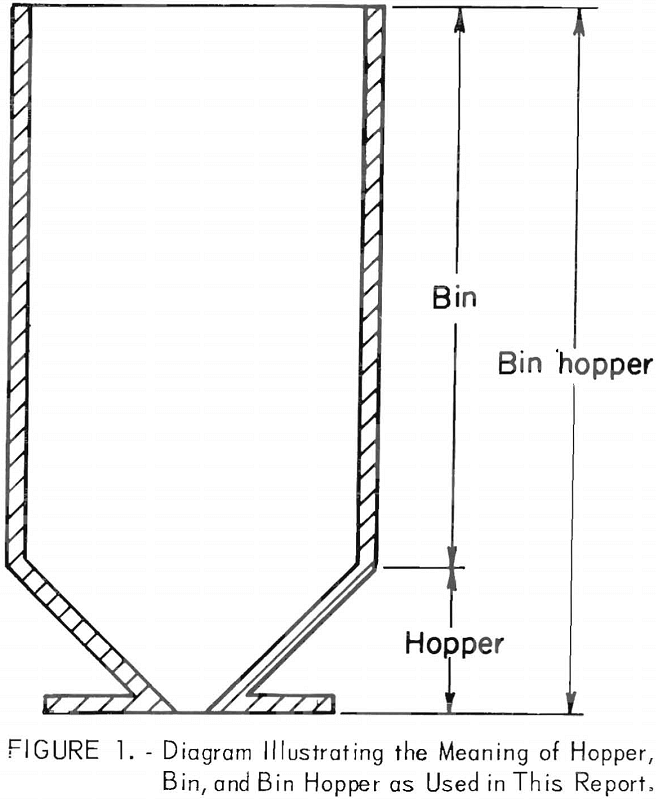

Bin Hopper Flow Design & Engineering

A detailed Bin Hopper Flow Design & Engineering Study: The mining industry in the United States alone produces nearly 4 billion tons of new bulk materials annually that has a mine-mouth value in excess of 20 billion dollars. The potential for realizing substantial savings in mining and processing costs through improved materials handling systems design […]

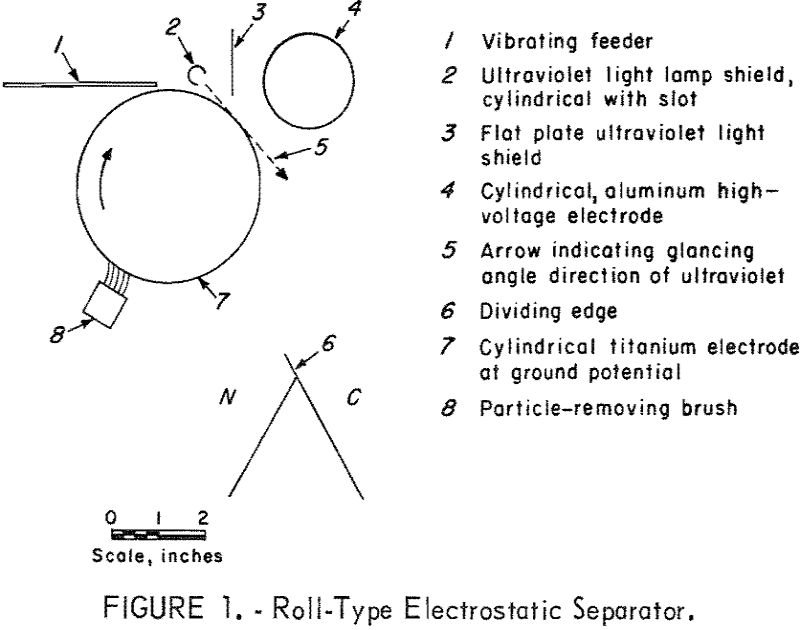

Photoelectric Charging & Electrostatic Separation

Electrostatic separation is used when froth flotation fails, such as with oxidized ores, or where there are similarities in response with magnetic and gravitational methods, or when the use of water is to be avoided. Theoretically, for fine-size particles the electric field has an advantage over the magnetic field in that the viscosity-limited particle velocity […]

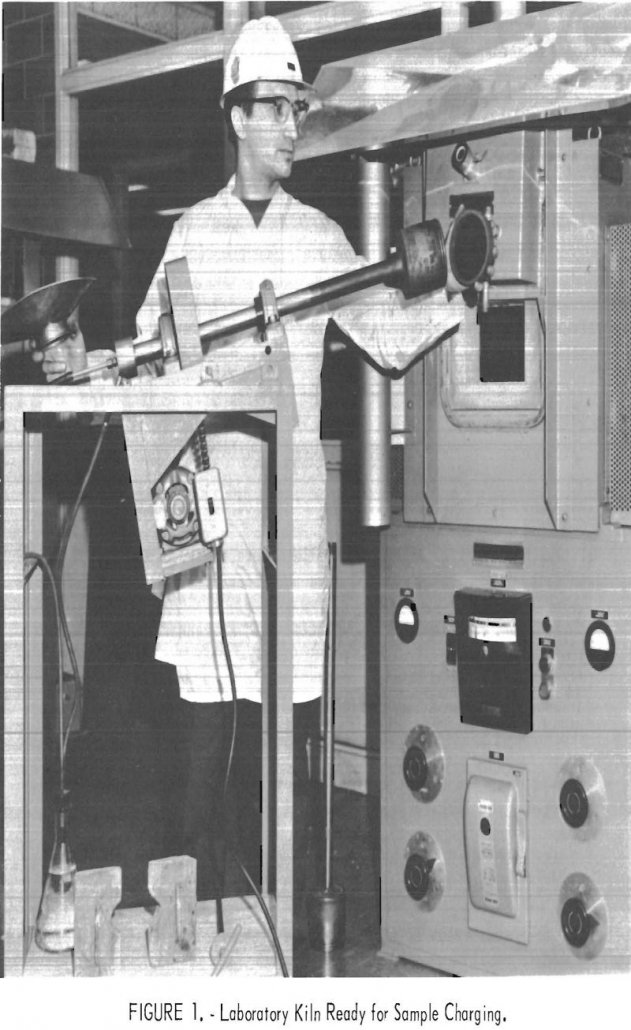

Effect of Preheating Iron Ore Pellets

The production of pre-reduced iron ore pellets involves the expenditure of considerable capital and energy. Both prereduced and oxide pellets can be produced in similar equipment by using reducing and oxidizing processes, respectively. However, the throughput for a 5-m-ID by 50-m-long kiln with a preheating grate is 425,000 metric tons per year of ore, according […]

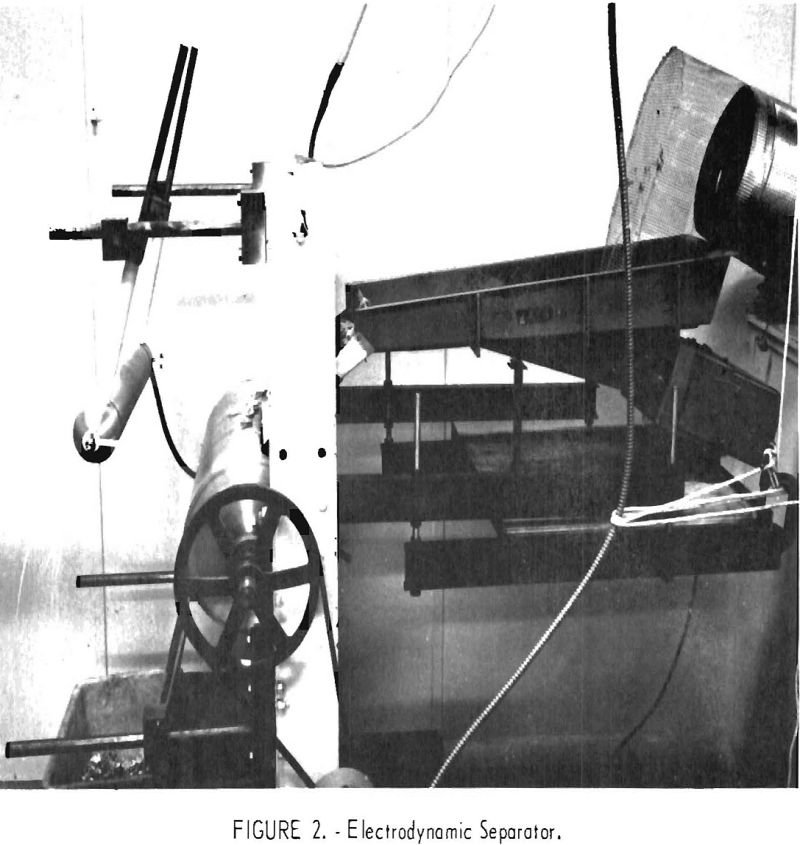

Electrodynamic Separator

Several years ago, the Bureau of Mines initiated a program to develop effective methods for reclaiming and recycling metal and mineral values contained in urban solid waste. The Bureau’s initial work at its College Park (Md.) Metallurgy Research Center dealt with establishing reliable methods for sampling and characterizing the residues left from the incineration of […]

Applied Mining Geology

The geologic notes are taken as soon as possible after the ground is broken so that any mistake in the mining may be corrected at once, or any particularly advantageous procedure may be suggested before any useless work is done. Taking the notes underground is a comparatively simple matter, but a few necessary precautions may […]