How to Remove Bismuth from Lead

The Betts electrolytic process was for many years the only method available for debismuthizing lead Kroll suggested the use of calcium to form a high-melting-point Ca-Bi intermetallic compound that could be separated from molten lead. This process, however, was not used industrially. About a decade later, Betterton developed a commercially feasible process using a combination […]

Hydrochloric Acid Leaching Trisodium Phosphate, Zinc

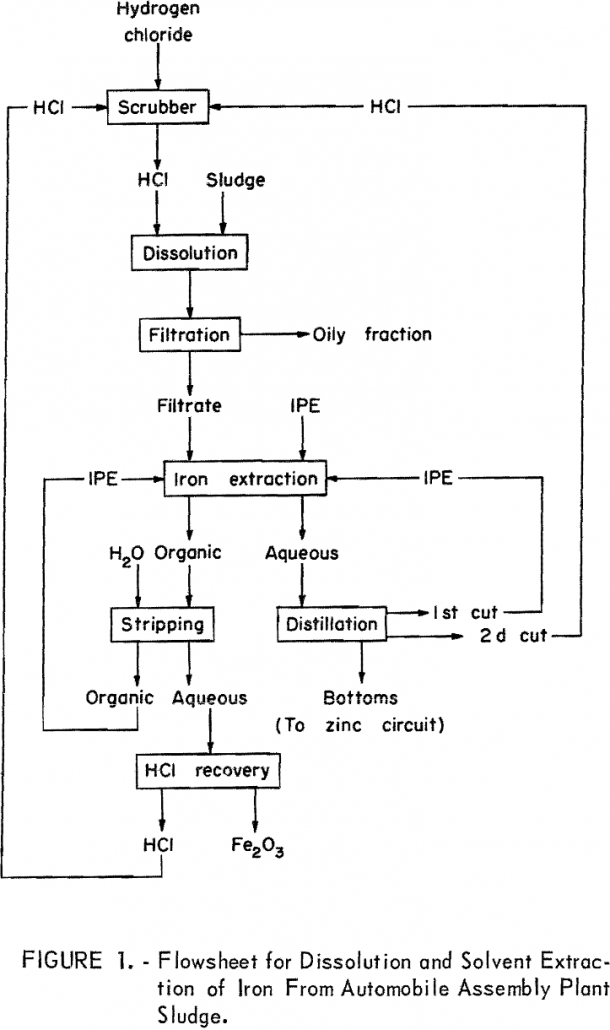

As part of its solid-waste research, the Bureau of Mines is engaged in a broad program to develop low-cost processes for recovering and recycling metals and minerals from a variety of industrial wastes. One benefit is the alleviation of pollution associated with many of these wastes. The phosphate coating of metals is widely used in […]

How to Reduce Surface Hot Shortness of Copper Bearing Steels

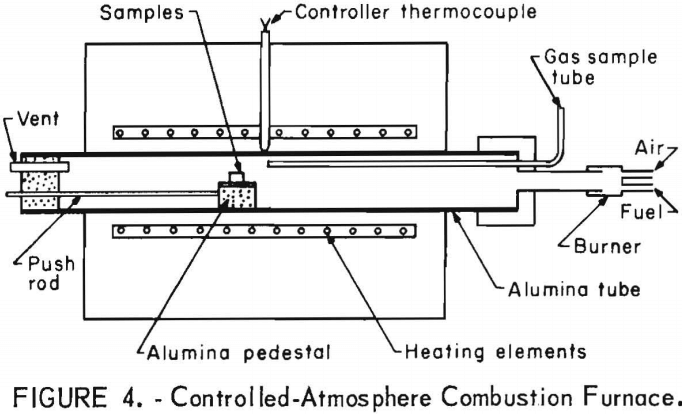

The use of controlled steel silicon content or the application of borax coatings showed promise in preventing molten copper from forming on the surface of steels containing up to 1 pct Cu when these steels were heated to 2,370° F (1,300° C) , a common temperature for rolling. By preventing copper formation during heating, surface […]

How to Recover Aluminum & Precious Metals from Electronic Scrap

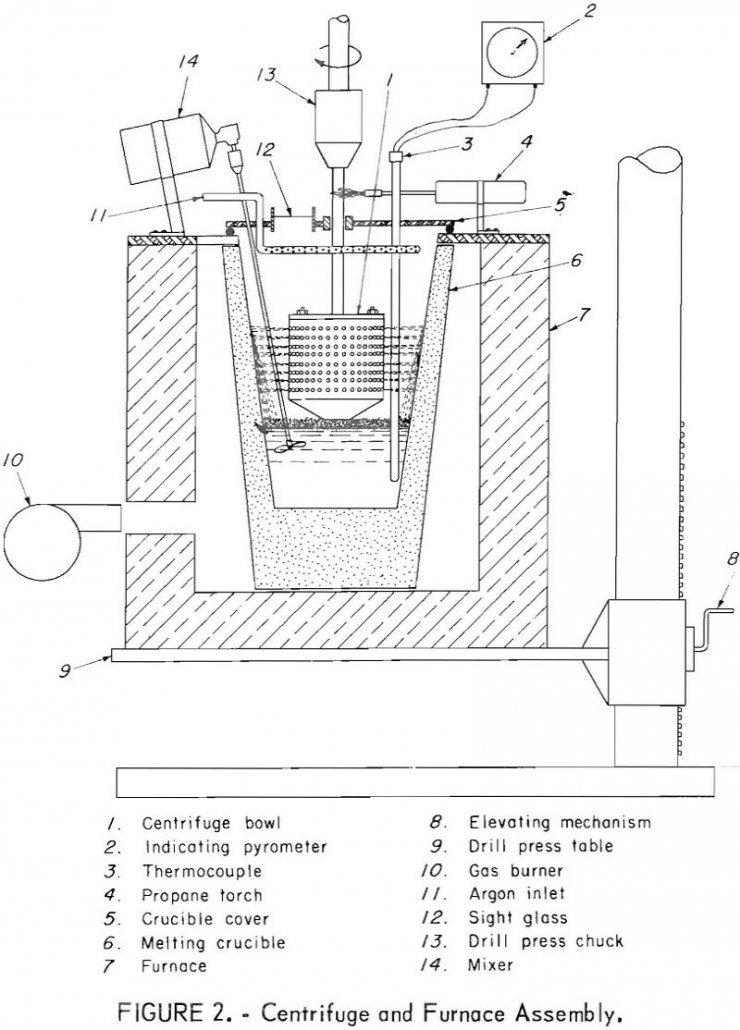

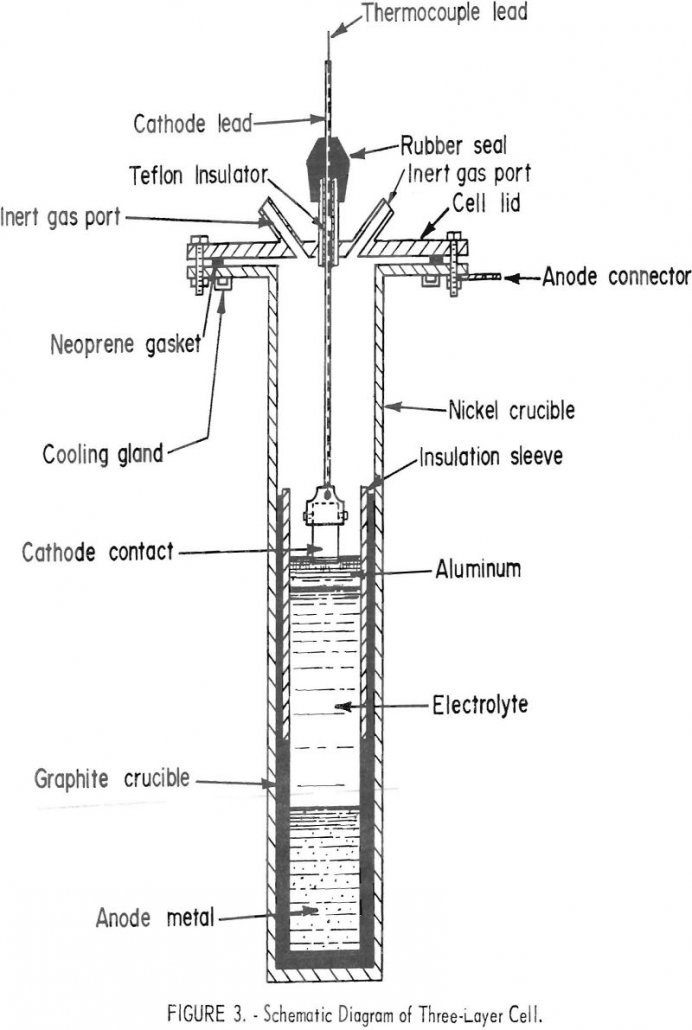

Our Solid Waste Program is directed toward three main areas of research: (1) Extraction of mineral, metal, and energy values from urban refuse; (2) recovery of mineral and metal values from wastes generated in the industrial utilization of raw materials and mineral-base products; and (3) upgrading and utilization of automotive scrap. The objective of this […]

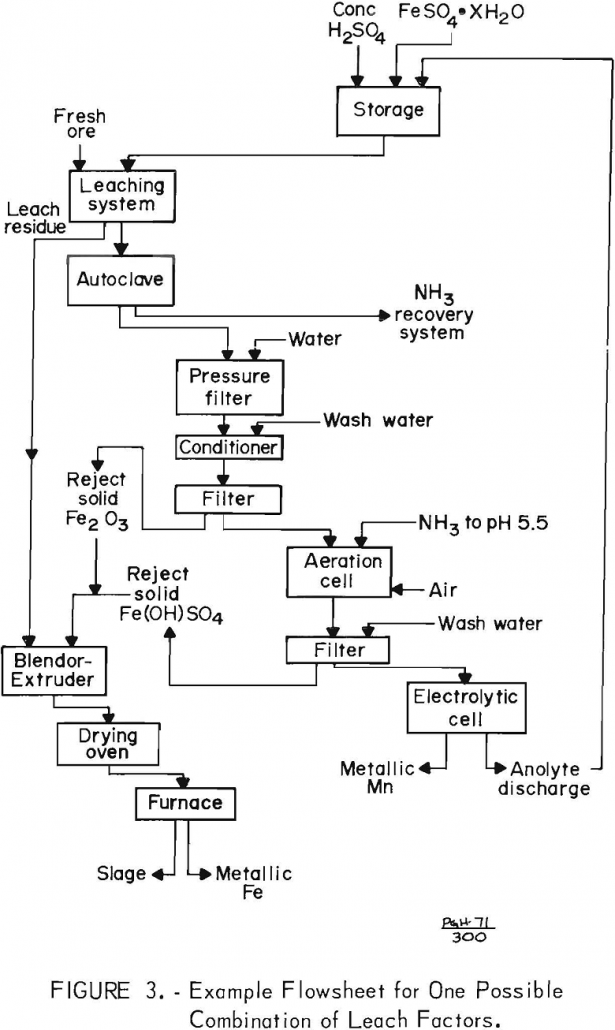

Extraction of Manganese by Leaching

Demand for manganese continues to grow, but essentially all manganese used in the United States is imported. Although large deposits of low-grade manganese minerals are located in this country, domestic manganese producers have been unable to compete with the foreign ore except when subsidized by the Government. Desiring a degree of independence, both Government and […]

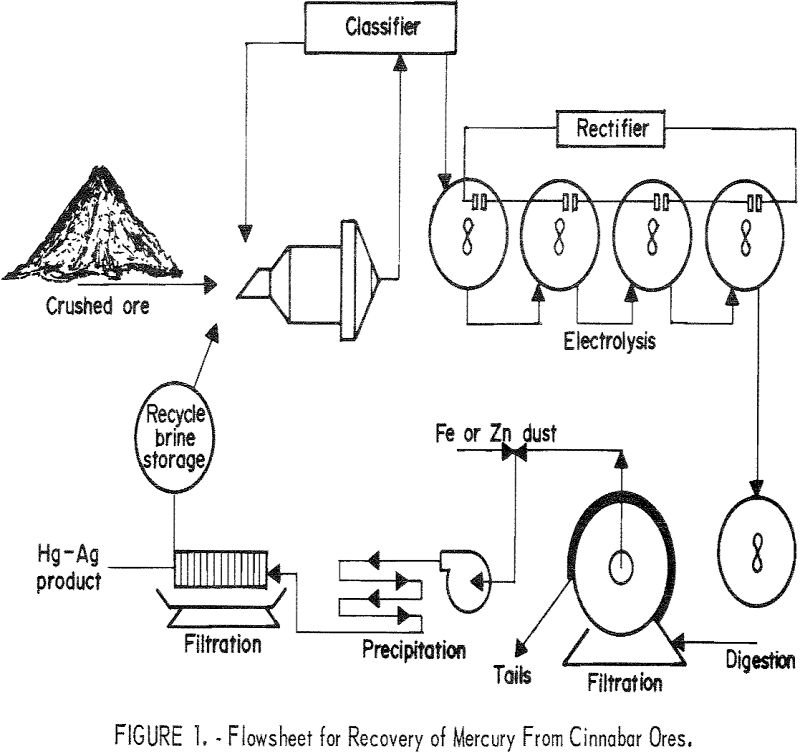

Recovery of Silver and Mercury by Electrolytic Oxidation

Silver was one of the first metals known to man, and metallurgical processes for the recovery of silver from ores date back into antiquity. Mercury amalgamation and retorting to recover metallic silver from slags, mine tailings, and scrap were in common use by the end of the 15th century. In 1557, the Patio process was […]

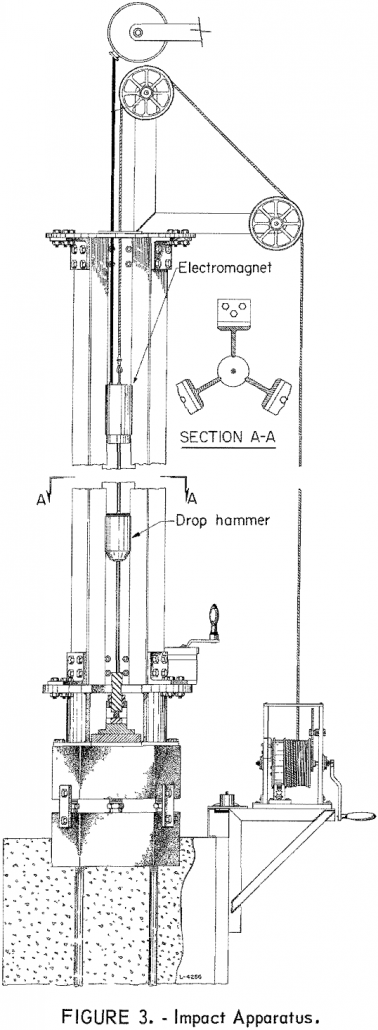

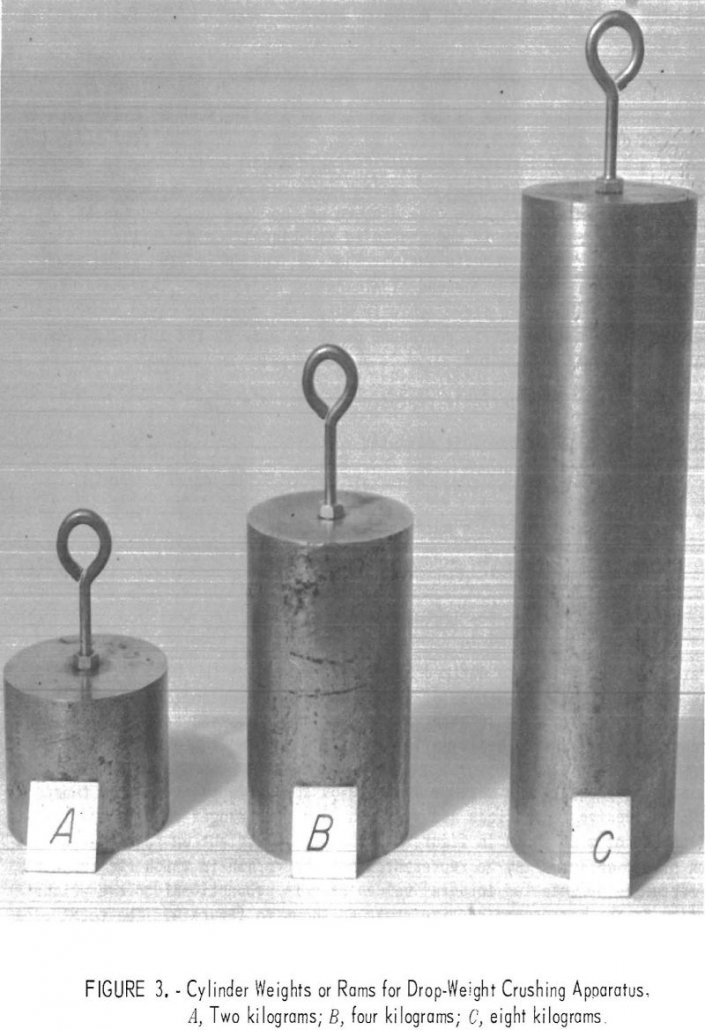

Drop Weight Impact Tester

For many years, the impact test has been one of several techniques used to determine explosive sensitivity. This test has provided a useful index having practical value; however, it provides only an ordering of the sensitivities of a series of materials and, because of a lack of standardization in apparatus design and test conditions, comparison […]

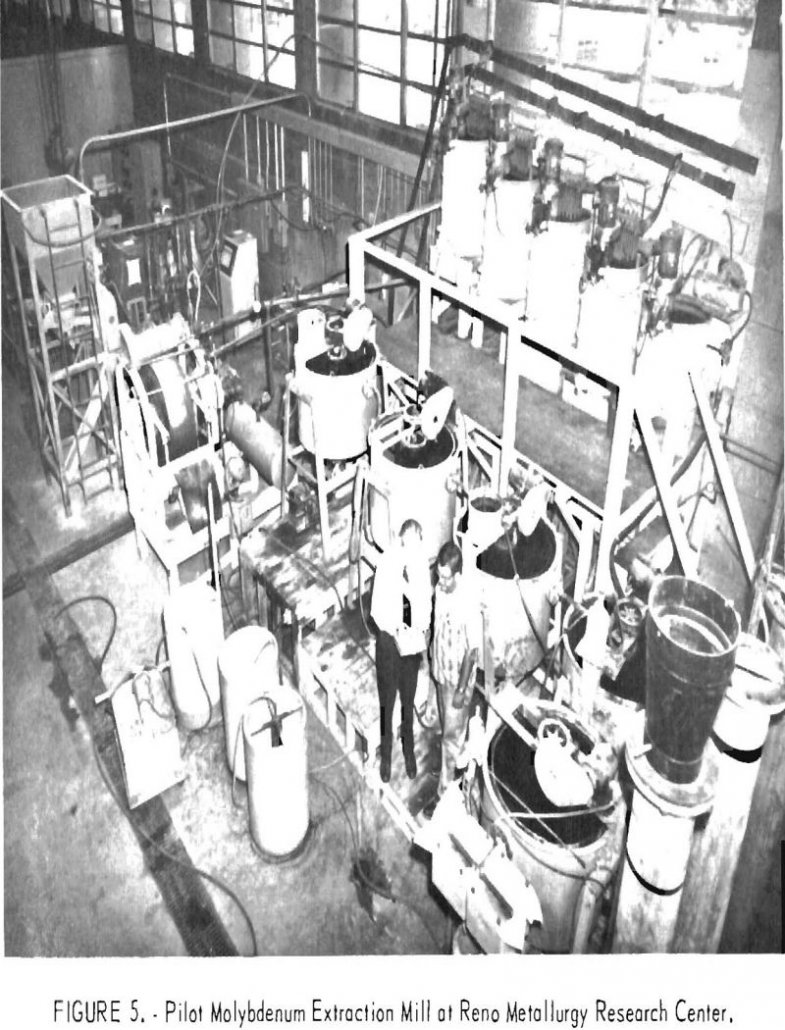

Electrically Leach Molybdenum by Oxidation

Classic flotation and roasting procedures for recovering molybdenum oxide from molybdenum source materials frequently result in low recovery of molybdenum. This is particularly true in molybdenum flotation from porphyry copper ores where difficulties can he encountered in refloating molybdenite which has been recycled to rougher and cleaner flotation sequences. Because copper-molybdenum separation may be less […]

Impact Crushing Size Distribution

Although the comminution process has undergone much experimental study, there is not yet an adequate theoretical basis for predicting the mean size and size distribution of the product from a comminution machine. This lack is hardly surprising, since most of the considerable body of knowledge concerning the deformation of solids becomes inapplicable when the stresses […]

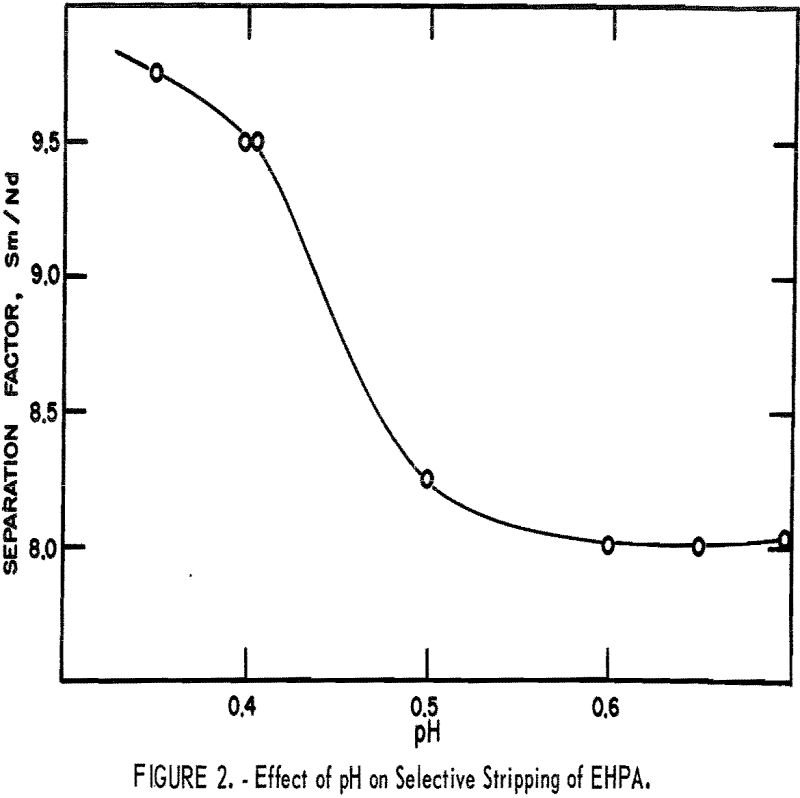

Extraction Process Sm2O3 Samarium Leaching

The growth in demand for certain lanthanides has resulted in the development of industrial processes for their separation and purification from source materials. These operations have resulted in the availability of substantial quantities of a byproduct mixture of rare-earth elements that contain mostly samarium and neodymium, and lesser amounts of praseodymium, cerium, and lanthanum. Potential […]