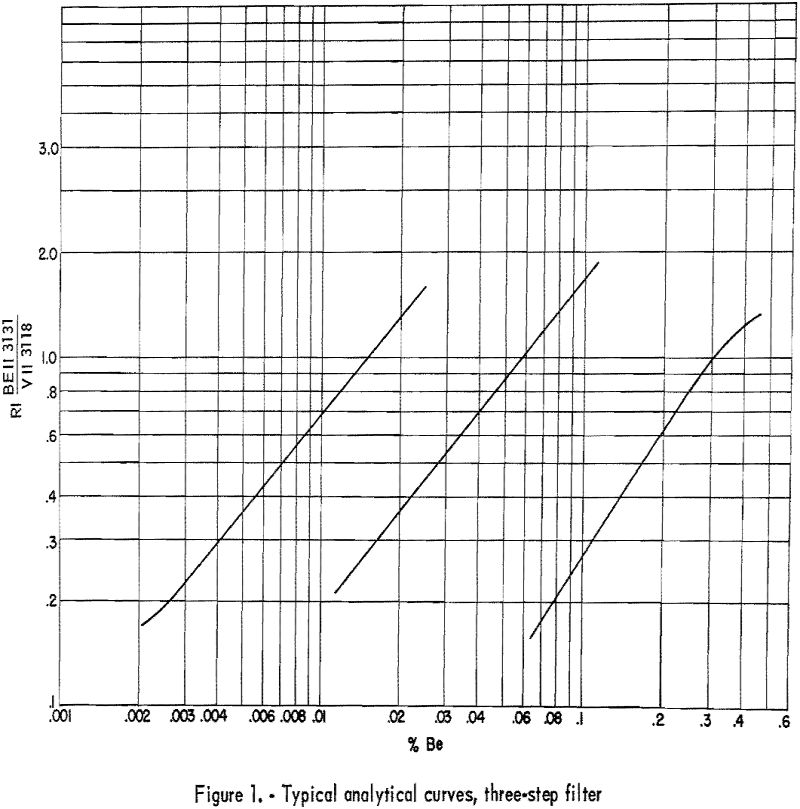

Beryllium Determination

The main source of beryllium in pegmatite is the mineral, beryl. Many of the conventional methods for the determination of beryllium in beryl are not suitable for control purposes because of lack of speed and accuracy, especially in the range below a few tenths percent. Beryl resists the usual chemical attack and can be lost […]

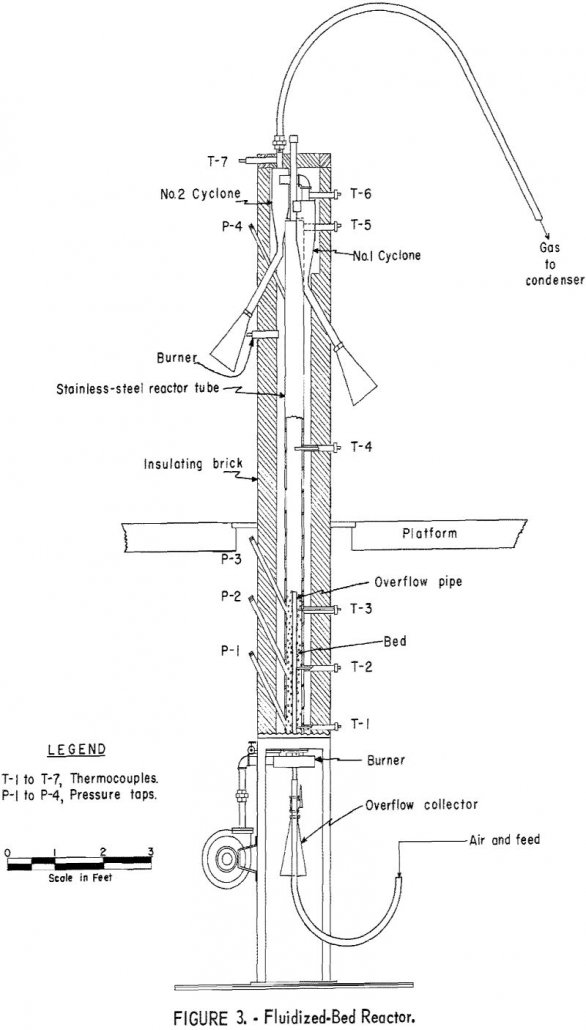

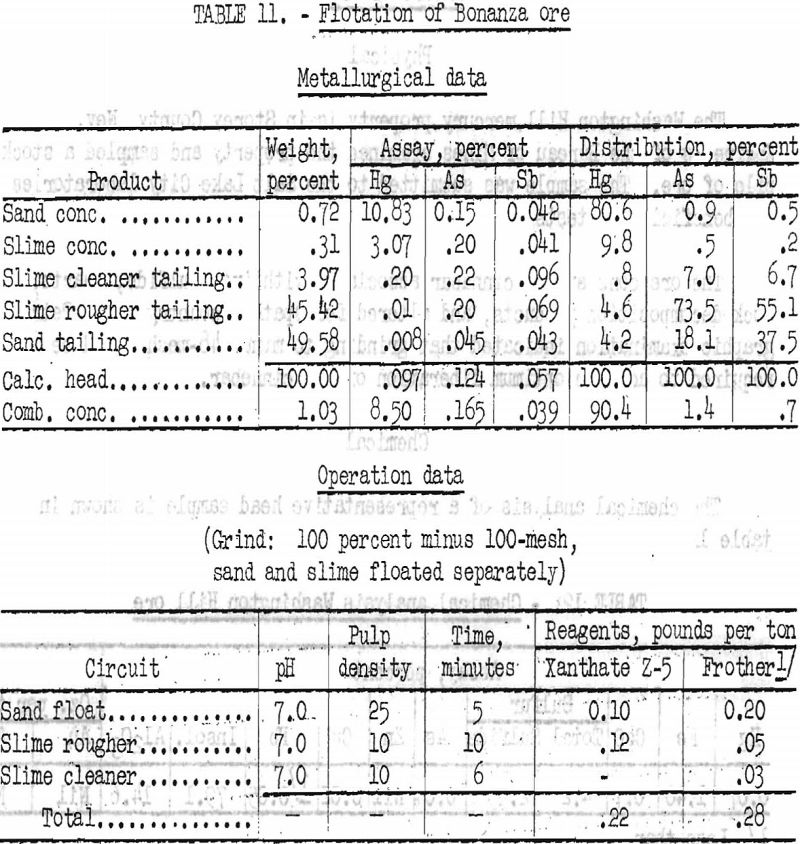

How to Recover Mercury from Cinnabar Stibnite Ore

Generalized conclusions cannot be drawn from the laboratory studies about the economic feasibility of extracting mercury by a combined flotation and fluidized-bed roasting process. The 94 percent mercury recovery indicated in the laboratory compares favorably with the 90 to 95 percent recoveries usually reported by mercury-plant operators. Grinding the entire ore to liberation size, plus […]

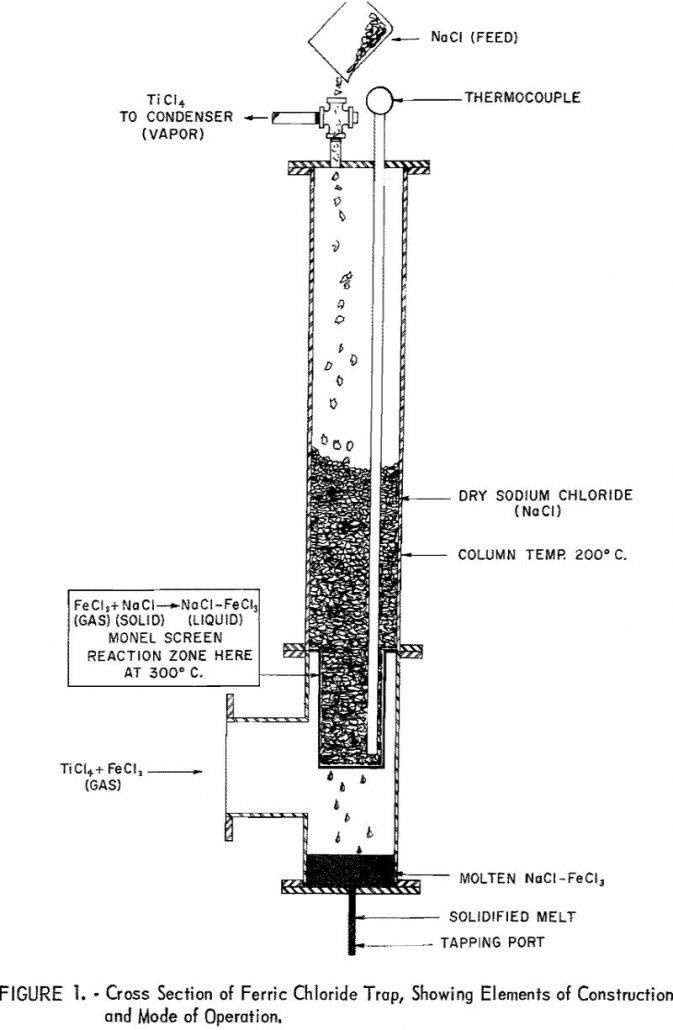

Ferric Chloride Trap

This paper discusses the design and use of the ferric chloride trap. The operation is simple and self-adjusting. The rock-salt column is self-cleaning and will remove ferric chloride, other impurity chlorides, and dust from gaseous titanium tetrachloride. The losses of titanium are low, and the molten mixture is easy to handle. The trap is placed […]

Crushing Granite

The quarry is located in the western part of the Piedmont Plateau. Geologically, this province is described by Watson as an area of highly metamorphosed sedimentary and igneous rocks of Paleozoic and pre-Paleozoic age. The Piedmont region of South Carolina has extensive areas of granite and gneiss that are suitable for aggregate. The gneisses have […]

How to Concentrate Mercury

Most mercury ores are directly roasted or retorted for recovery of metallic mercury without preliminary concentration. Recoveries are high, often approaching 100 percent; the cost is nominal. The tenor of domestic mercury ores, however, has been dropping steadily, so that the estimated average heads are now about 0.35 percent Hg or 7 pounds per ton […]

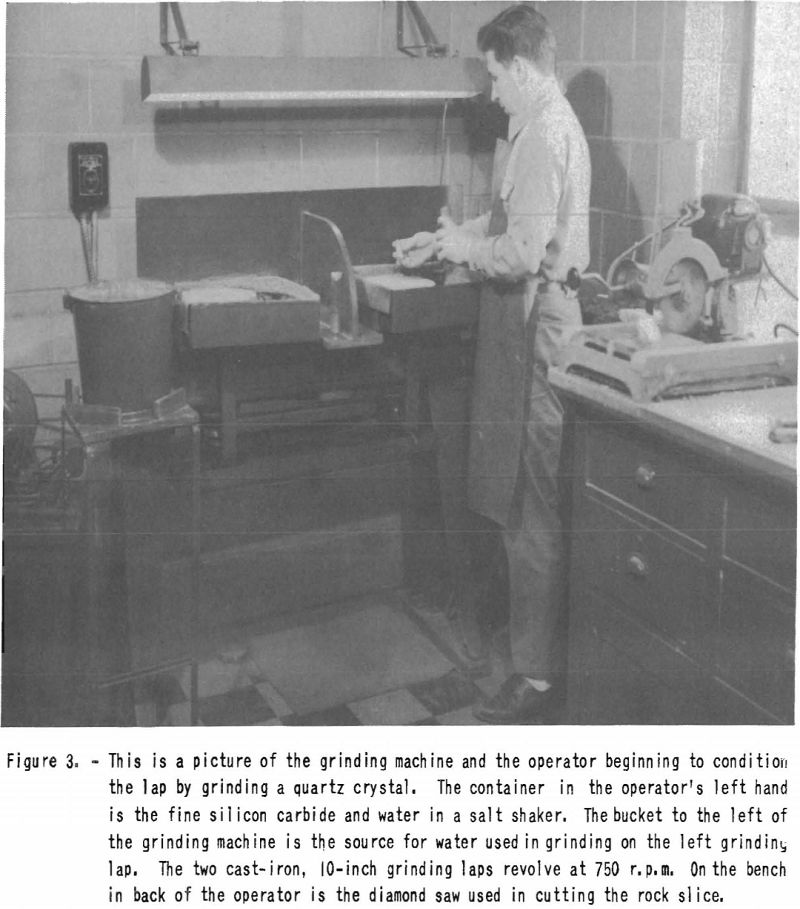

How to Prepare Thin Rock Sections

In this recommended method of preparing a thin section the operator begins by obtaining a rock slice approximately 1 inch in diameter and 1/8 inch thick. The rock slice is ground on the coarse and fine grinding laps until a flat surface without visible pits is produced on one side. An important step in the […]

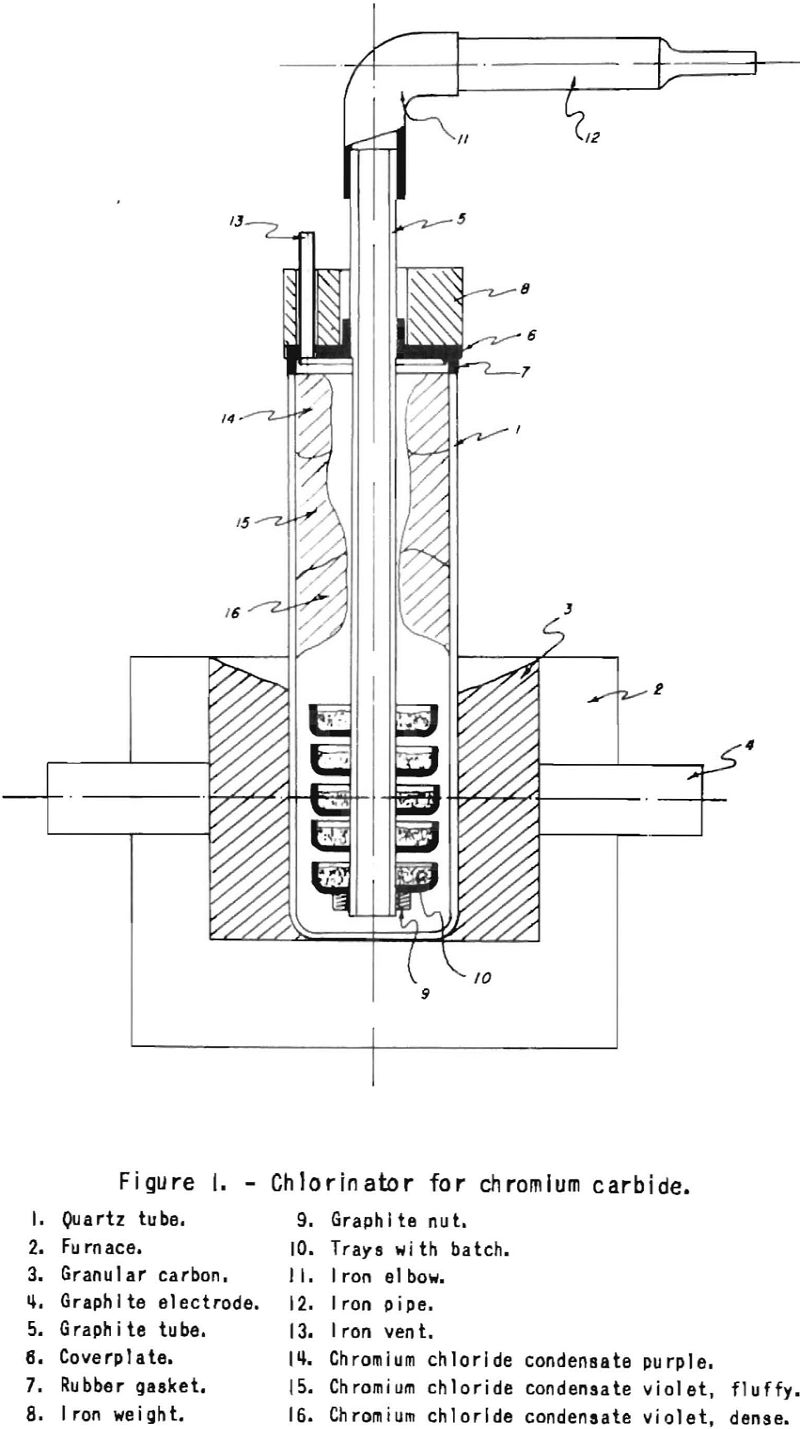

How to Make Chromium Metal – Metallurgy

Aluminothermic or silicothermic processes used for the metallurgical production of chromium metal from chromium oxide yield a metal that may contain more than 99 percent chromium. A metal of this purity apparently meets all the requirements of the alloy industry, but the price is about three times that of chromium in the form of low-carbon […]

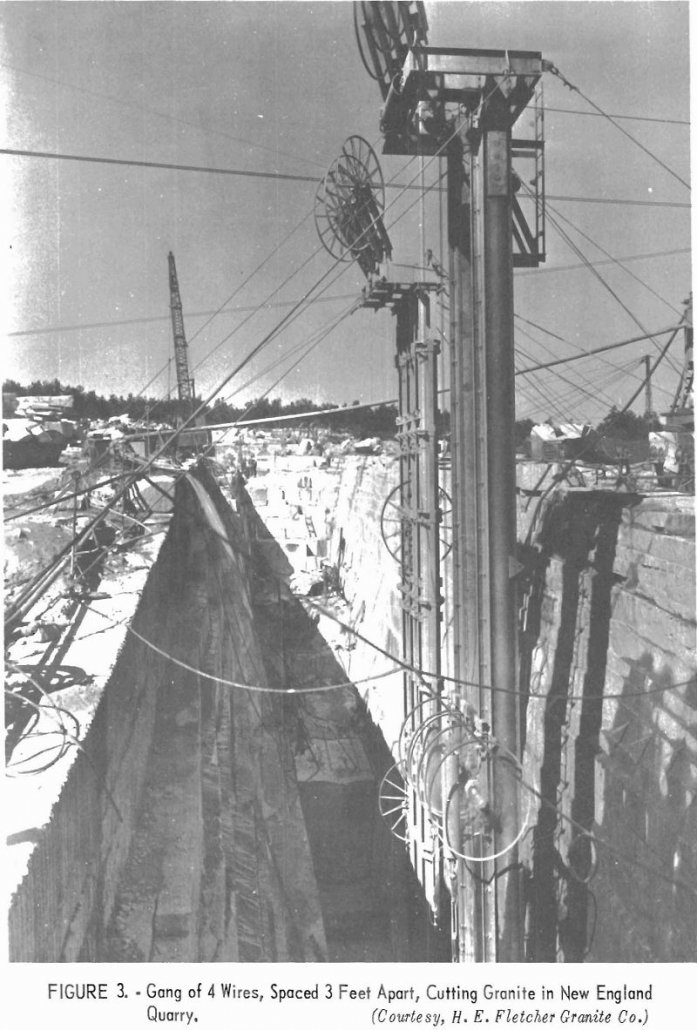

Stone Cutting and Polishing

The mining and fabrication of structural and ornamental stones is a wide-spread industry involving the use of such rocks as granite, limestone, marble, sandstone, and slate. Granite is a medium- to coarse-grained igneous rock comprising chiefly quartz, feldspar, and either mica or hornblende. Limestone is classed as a sedimentary rock consisting essentially of calcium carbonate. […]

Fluorspar Beneficiation Process Plant

The Fluorspar Beneficiation Problem Acid grade fluorspar which is in great demand by the chemical and aluminum industries, must contain at least 97.5% CaF2 with not more than 1.5% SiO2 and 0.5% Fe2O3. Often the Silica is limited to 1.2% with penalties starting at 1.0% SiO2. These limitations on grade and impurities require extremely close […]

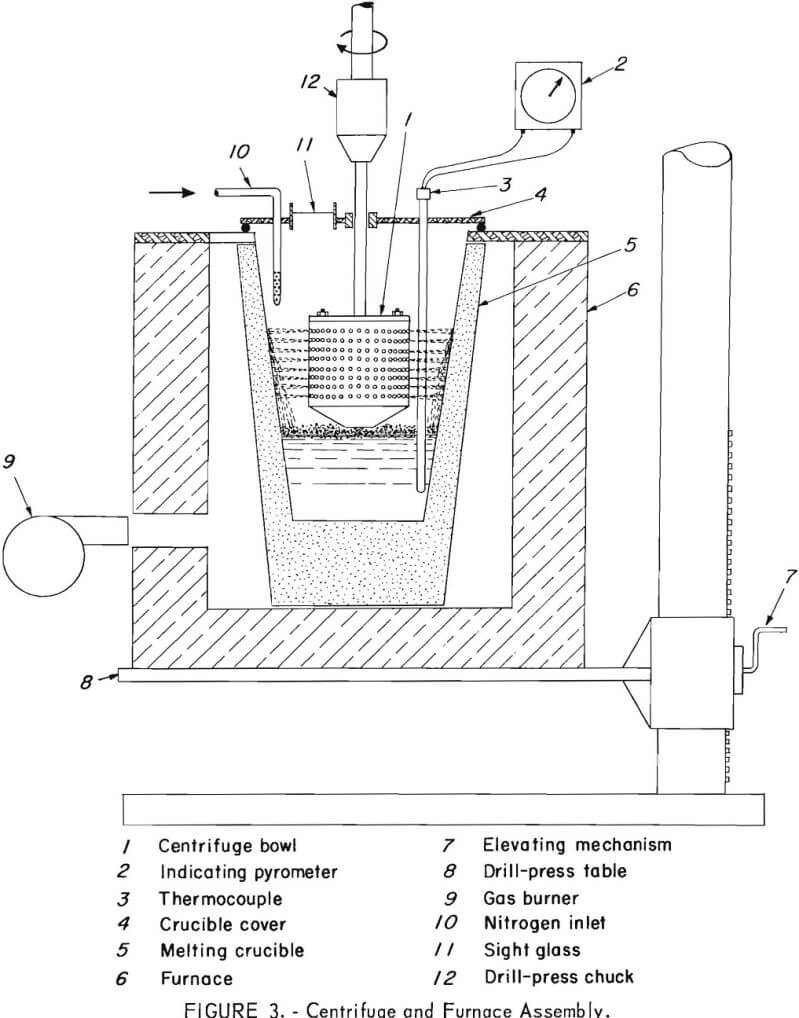

Refine Zinc from Iron Impurity

A process was developed in which iron-contaminated zinc was refined to readily acceptable purity. Aluminum added to the molten impure metal reacted with the iron, forming a solid intermetallic compound, Fe2Al5, which floated to the surface of the melt. Small amounts of residual aluminum were eliminated from the product easily by fluxing with zinc chloride. […]