Cathodic Protection

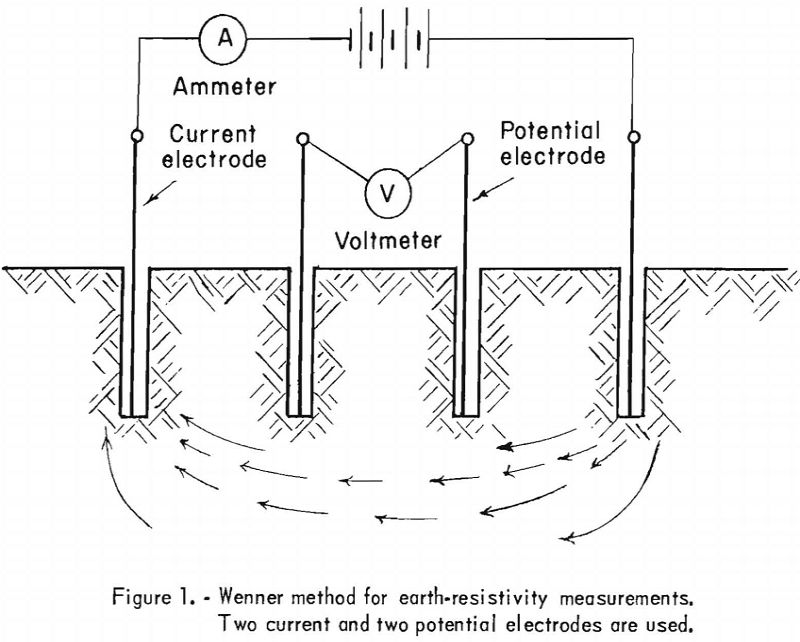

Loss of metal and damage to buried metal structures because of corrosive action is, to a large extent, determined by the soil resistivity in the immediate vicinity of the structure. The intensity of corrosive action is inversely proportional to the soil resistivity; that is, corrosive action will increase as the soil resistivity is lowered. Moisture […]

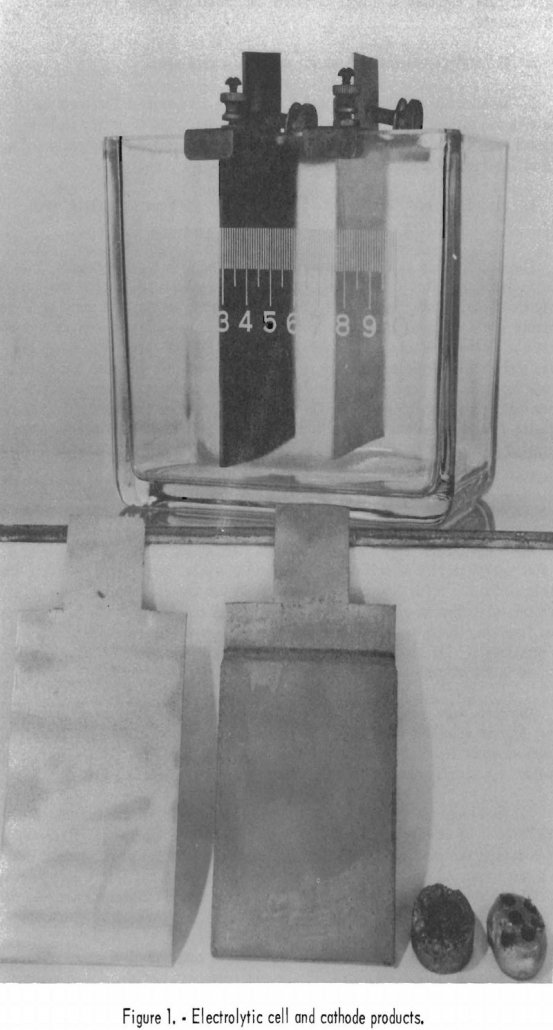

Titanium Electrorefining

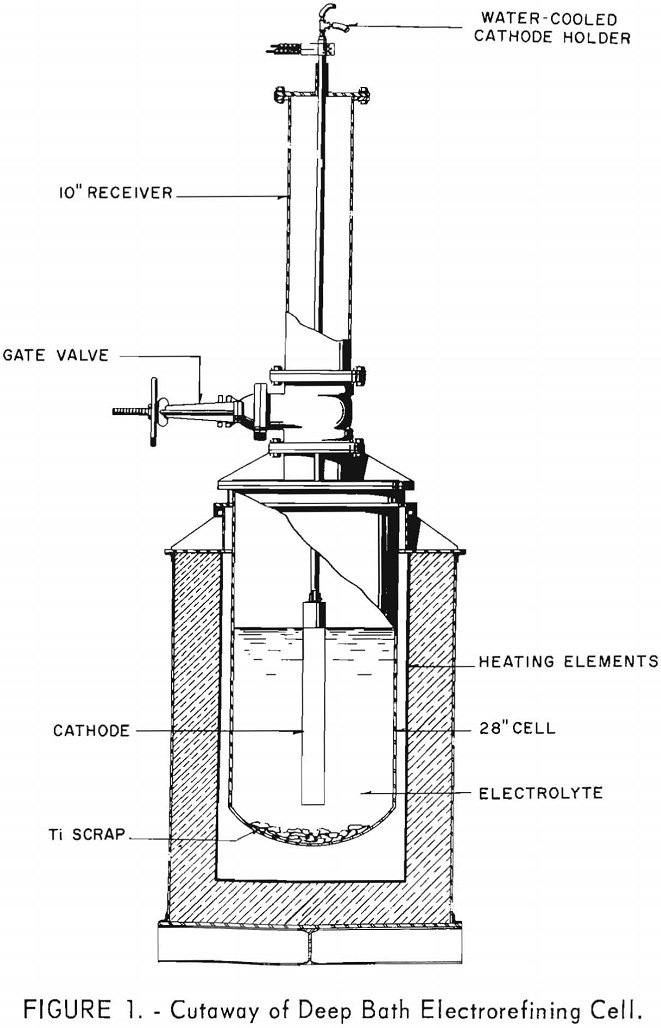

The development of a fused-salt Titanium Electrorefining technique to recover hyperpurity titanium from offgrade sponge and mill scrap, under investigation by the Federal Bureau of Mines Electrometallurgical Experimental Station at Boulder City, Nev., for several years has been described in many publications. This report describes the investigations to obtain greater capacity by increasing the depth […]

Volumetric Assay Determination of Uranium

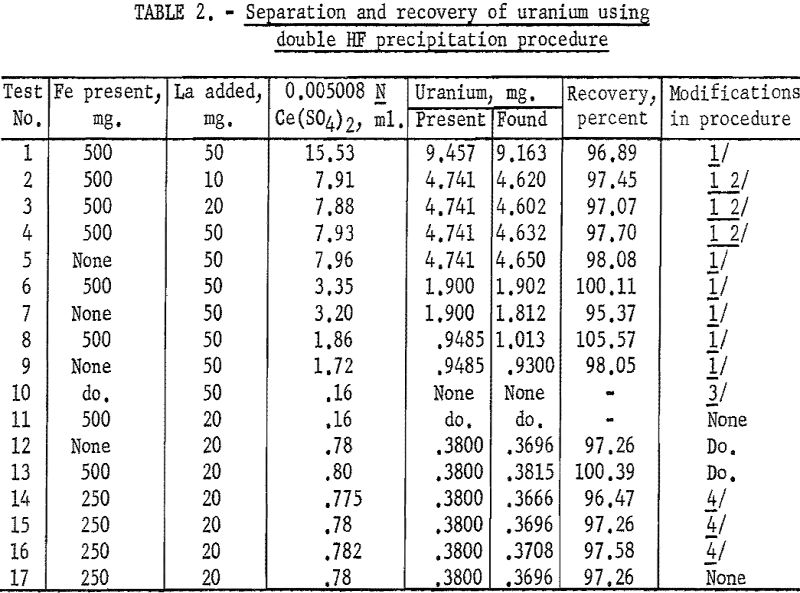

According to Katz and Rabinowitch, workers do not agree as to the solubility of uranium tetrafluoride. However, the conditions under which solubility data were obtained were not always the same. In any event, since both uranium (III) and uranium (IV) fluorides are generally regarded as insoluble in a carbonate-free, nonoxidizing acid solution, in which fluoride […]

Electrorefining Titanium Electrowinning

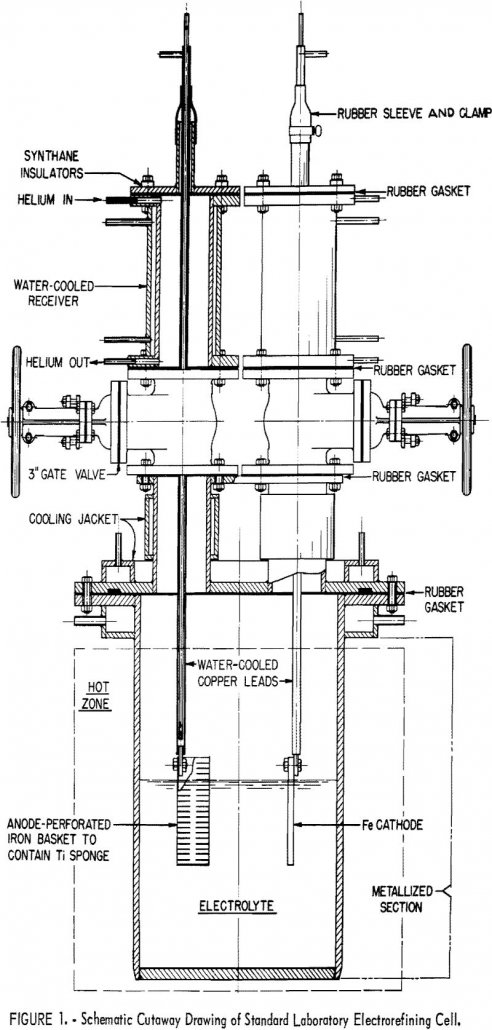

This series of investigations was exploratory in nature, as all variables that might influence alloy-element transfer were not examined. The test show, that, under the conditions described, titanium can be refined almost completely from molybdenum, tin, and zirconium; that refining from aluminum and chromium is only slightly less successful; and that refining from vanadium and […]

Nickel and Cobalt Electrolytic Separation

Preliminary work on electrolytes of neutral sulfate, neutral chloride, ammoniacal sulfate, and ammoniacal chloride solutions offered little promise for separating cobalt from nickel by the anodic deposition of cobalt peroxide. Electrolytes composed of synthetic Nicaro liquor, dichromates, cyanides, and phosphates offered little or no promise. An ammonium sulfate electrolyte showed separation of cobalt from nickel […]

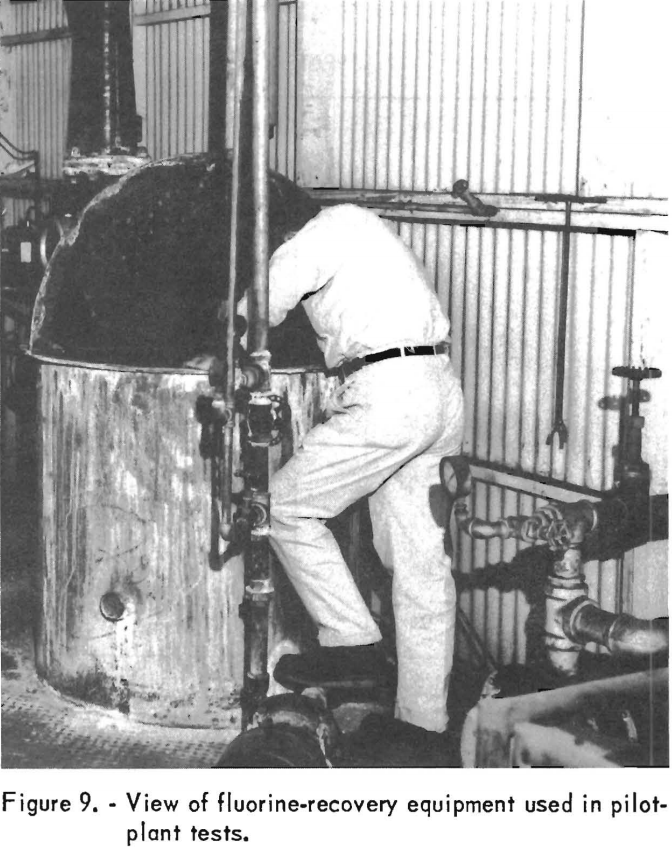

Phosphate Rock Fluorine Removal

Numerous patents and references may be found that relate to studies of phosphate-rock defluorination processes. Most of these require sulfuric acid and heat, phosphoric acid and heat, or water vapor and heat for the defluorination reaction. One of the most thorough studies was made by K. D. Jacob and coworkers at the United States Department […]

Copper Gold Sulfide Ore – Flotation & Cyanidation Tests

Grinding the ore to minus 100-mesh gave satisfactory liberation of the minerals. Standard flotation procedure with potassium ethyl xanthate, cresylic acid, and lime produced good-grade copper concentrates with over 85 percent recovery of copper and about 60 percent recoveries of gold and silver. This stop was employed in two methods of treatment developed during laboratory testing. […]

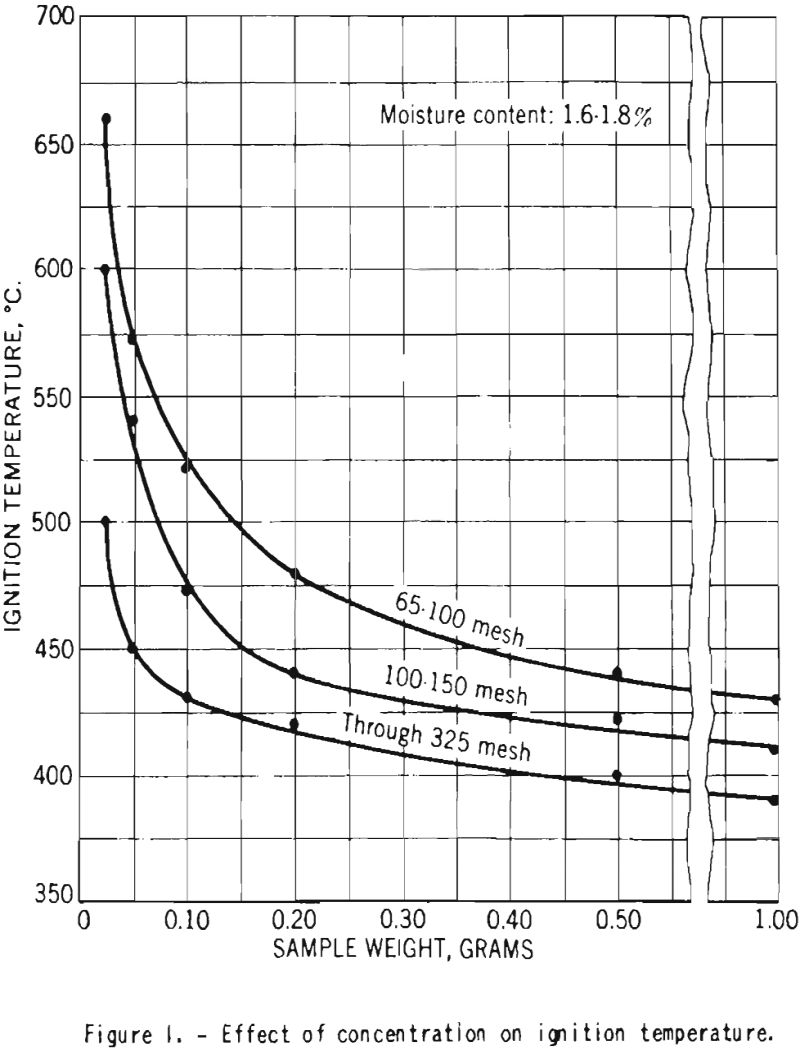

Cornstarch Explosibility

Laboratory experiments were conducted with cornstarch to study the effects of duet concentration, moisture, particle size, treatment with oil, and admixture of calcium carbonate on the dust-explosion hazard. One series of tests were made on five size fractions of starch and on samples with four different moisture contents, all prepared from a single batch. Within […]

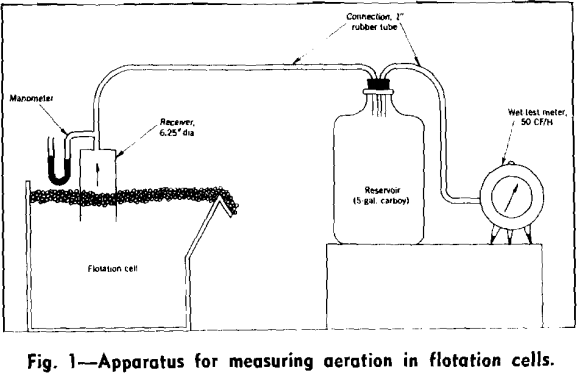

How to Measure Flotation Cell Aeration

Present flotation processes depend almost entirely on the buoyant properties of air bubbles to effect separations of mineral and gangue, but there is no convenient method for measuring aeration in flotation cells. Consequently the relation between aeration and cell performance has not been definitely established. In connection with a comparative study of kerosene and froth […]

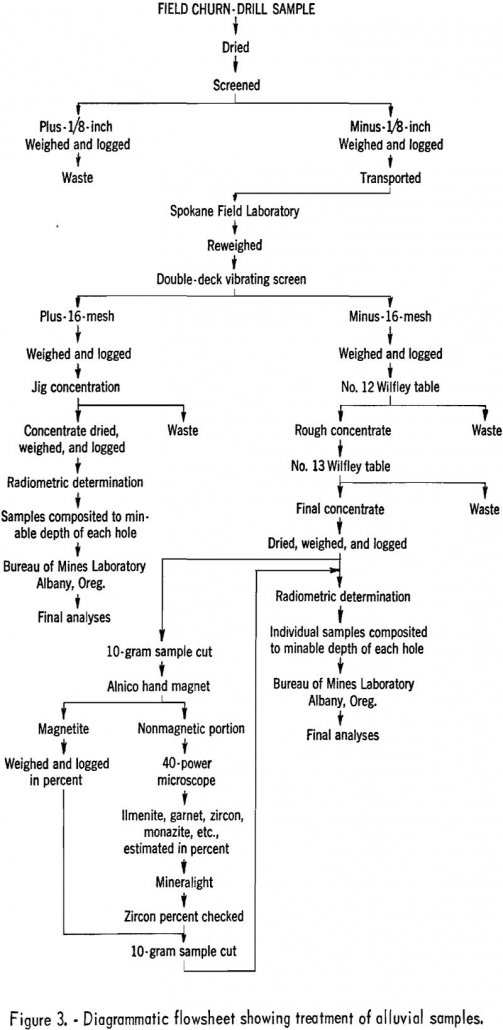

Black Sand Minerals in Gold Placer Deposit

This report describes work done as part of a Bureau of Mines program to appraise the titanium-mineral resources of Idaho. The work included both field reconnaissance and a spot churn-drilling program. Much general information was available, as a result of earlier work done under the Western Radioactive Minerals Exploration Program conducted between 1950 and 1954 […]