Dry Grinding VS Wet Grinding

The choice between wet and dry milling is, in general, unimportant in small-scale milling but is a major technical problem when large-scale milling in the metallurgical industries is involved. On purely mechanical grounds it is difficult to see any great difference in fundamental principles between wet and dry milling, since dry milling may be regarded […]

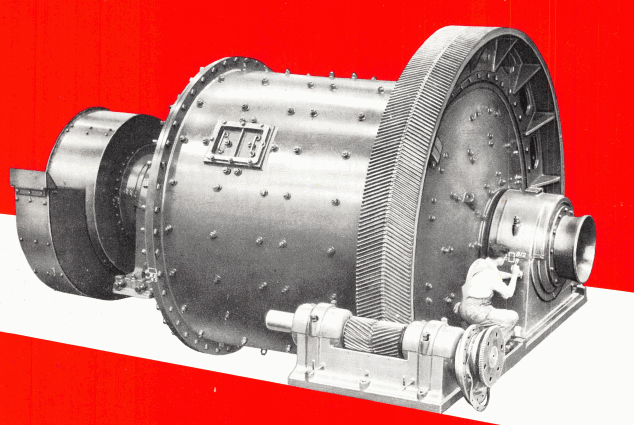

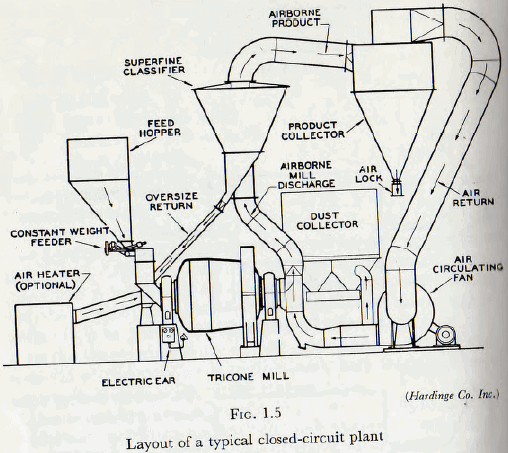

Air Swept Mill

In an air-swept mill, the body of which does not differ significantly in general design from a trunnion overflow mill, a powerful stream of air is passed through the mill and removes the finer particles produced by the grinding process. This stream of powder-laden air is then passed through the classifier and the “oversize” material, […]

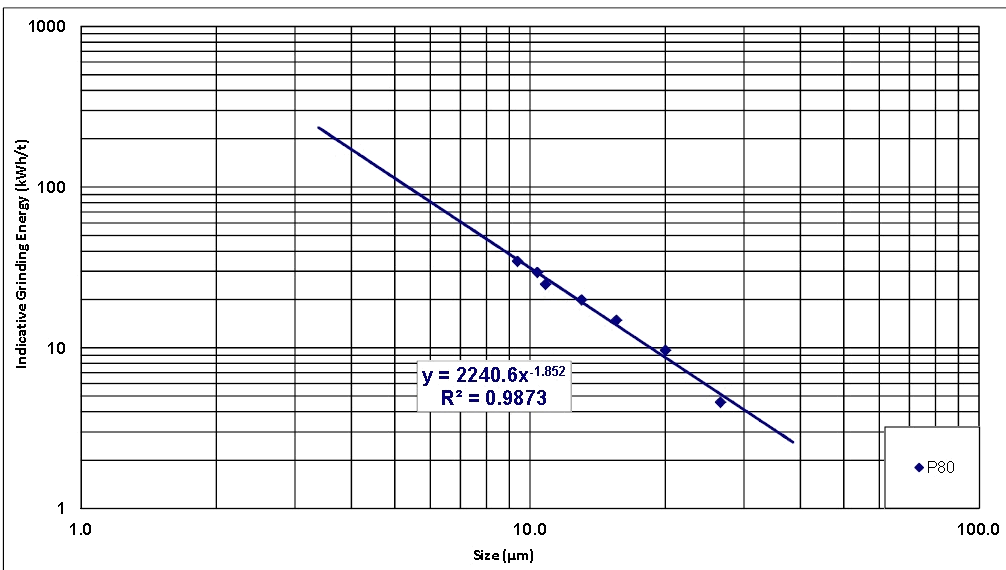

Signature Plot

General Procedure for IsaMil Signature Plot The relationship between product size and energy input remains constant during scale-up of IsaMill™ technology. As the diameter of a particle is halved, the surface area of its progeny is doubled. Within reasonable reduction ratios, the log of size plotted against the log of energy produces a straight line. […]