High Pressure Grinding Rolls

High-pressure grinding rolls (HPGRs) have struggled for acceptance into the hard-rock mining sector. CRITICAL HPGR PARAMETERS HPGR roll diameters typically range from 0.5 m to 2.8 m, depending on the supplies, and roll widths vary from 0.2 m to 1.8 m. The aspect ratio of the rolls also varies as a function of manufacturer. Typical […]

Homemade Rock Crusher DIY

The 911JAC12K MINI Rock Crusher is our smallest rock crusher, designed for those on a tight budget. It includes all the high-quality, precision-machined parts that are pre-cut and ready to weld, making it a compact version of a small jaw crusher. It is a Do-it-yourself version of on Mini Crusher. You will need to supply […]

NON Chemical Gold Recovery

Setup an iCON i150 IGR100 Gravity Gold Plant and get some NON Chemical Gold Recovery. Here we’ll be guiding you step by step in putting together and operating an IGR100 Plant. The IGR100 Plant is a modular self-contained gold recovery system. It uses classification and enhanced gravity to assure recovery of the finest gold material and […]

Kiln Temperature Controller Guide

You wonder how to enter the burn off program in our programmable kiln temperature controller, so today we’re going to show you an Example of exactly how to do that. With your kiln all set up and plugged in it will flash showing ambient temperature; STOP or HOLD. You will access the program setting to […]

Step Up Converter Voltage Transformer

Amazon Radio Shack

iCon Shipping Cost

Eddy Current Aluminium Separation

The eddy-current separator was initially developed to recover non-ferrous metals from shredded automobile scrap or municipal solid waste. In these applications the metallic fraction consists of relatively large items such as various crushed automobile engine components or aluminum beverage cans resulting in excellent separation efficencies. The repulsion of aluminum beverage cans from a rotating permanent […]

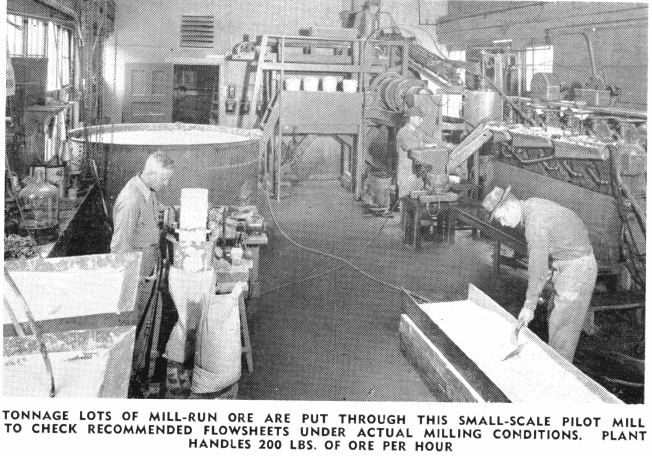

Metallurgical Pilot Plant

The Metallurgical pilot concentration plant is completely equipped with gravity and flotation units sufficient to provide for practically any flowsheet employing these methods of concentration. All equipment for the pilot concentration plant is set for continuous operation. Due to movable launders, pumps, and flow pipes, extreme flexibility is available. Crushing: Ore is prepared in the crushing, […]

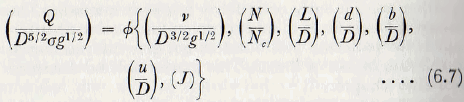

Slurry Flow Rate Through a Mill

The factors upon which the rate of flow of the pulp through a mill depends appear not to have received extensive investigation. In an article by Anselm translated by Pearson a method for the calculation of the time of passage of cement through a ball mill was given. The basis of the method is that the […]

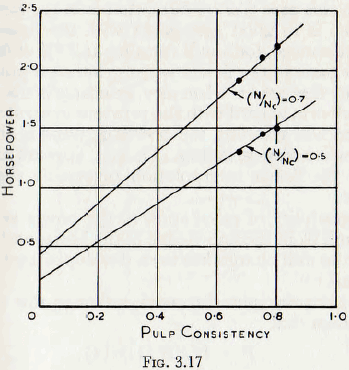

Effect of Pulp Rheology on Grinding Mill Power

The dependence of the power demand of a mill on the nature of the pulp does not appear to have received a great deal of study, and, in general, observations on this matter take the form of general statements. For example, Taggart states that, other things being equal, wet milling requires 60-90 % of the power […]