Laboratory Measurement of Relative Permeability

This paper presents the results of laboratory measurements of relative permeabilities to oil and gas on small core samples of reservoir rock by five methods, and describes the influences of such factors as boundary effect, hysteresis, and rate upon these measurements. The five methods used were the “Penn State,” the “single core dynamic,” the “gas […]

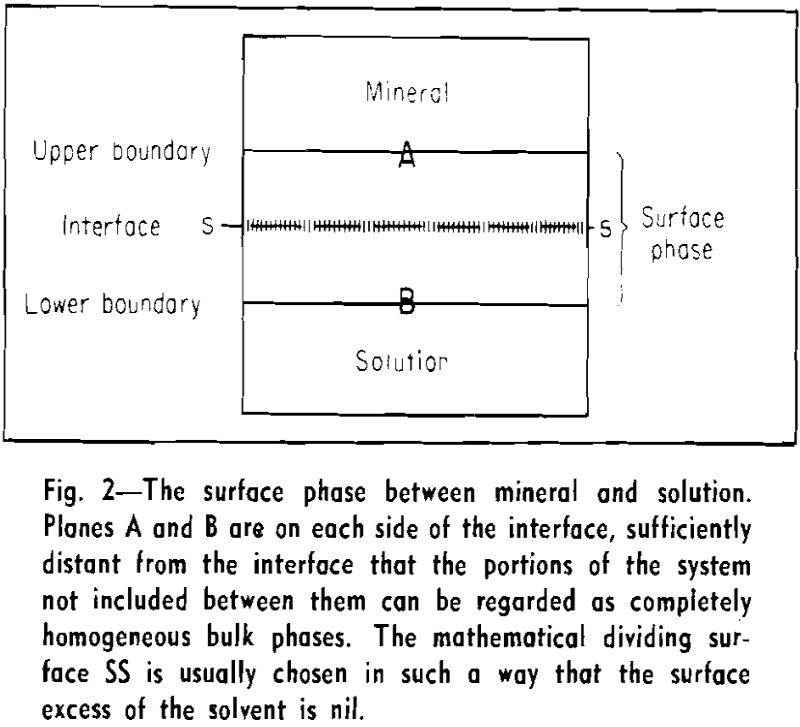

Flotation – Gibbs Adsorption Equation

The technique of concentrating valuable minerals from lean ores by flotation depends upon the creation of a finite contact angle at the three-phase contact, mineral-water-air. If the mineral is completely wetted by the water phase, contact angle zero, there is no tendency for air bubbles to attach themselves to the mineral. The contact angle is […]

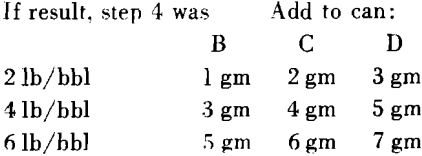

How to Determine Graphite in Drilling Mud

A field procedure for determining graphite in drilling mud is presented which is sensitive to 0.25 lbs/bbl and accurate to 20 per cent. The method, utilizing oil flotation principles, is suitable for use in all oil-free water base muds except those containing ligno-sulfonates, lignites, or surface active agents. Instructions for determining graphite in mud: Collect […]

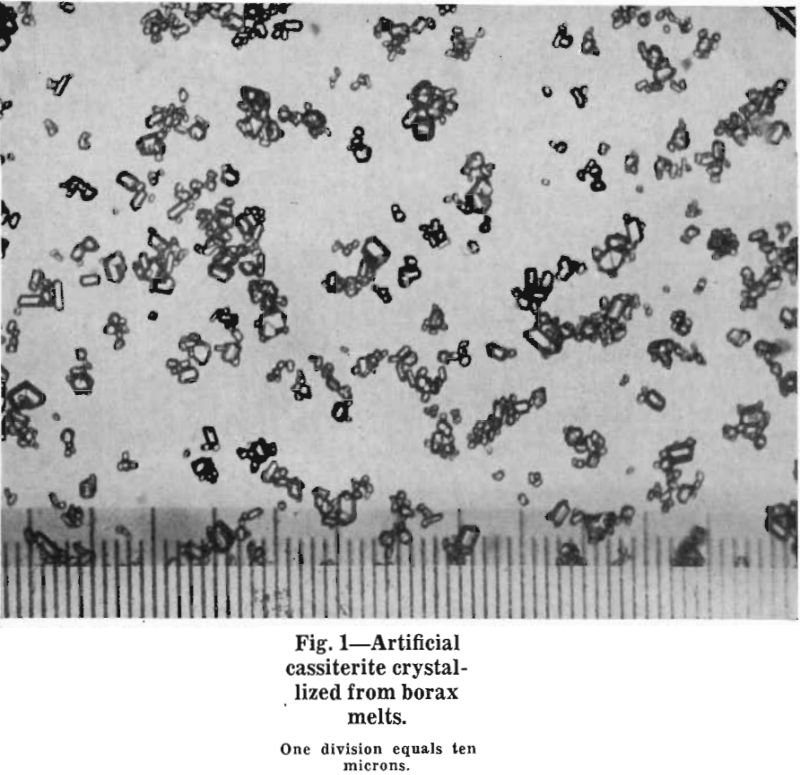

Soap Flotation

Flotation test work on Bolivian tin ores some years ago led to the development of several workable schemes of selective soap flotation, but left unanswered many questions of soap-flotation chemistry. Accordingly, the study of the activation and soap flotation of quartz just reported was undertaken as a start toward the elucidation of some of the […]

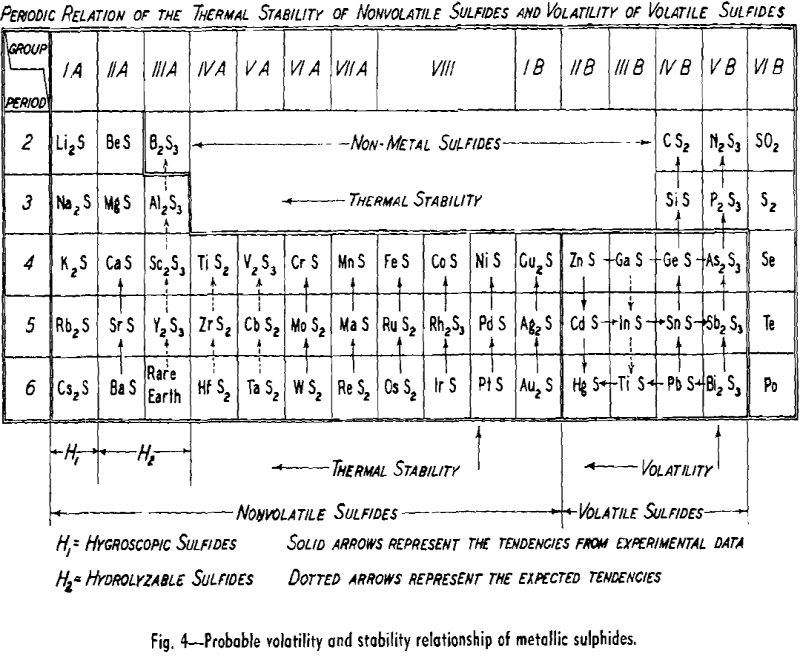

Volatility and Stability of Metallic Sulphides – Vapor Pressure

The direct reduction of metallic sulphides, as in the precipitation method for lead or antimony, is not a widely used process today. However, it might be employed for the production of a number of metals if the operation were carried out under reduced pressures. Two general procedures are possible; the reducing agent could form a […]

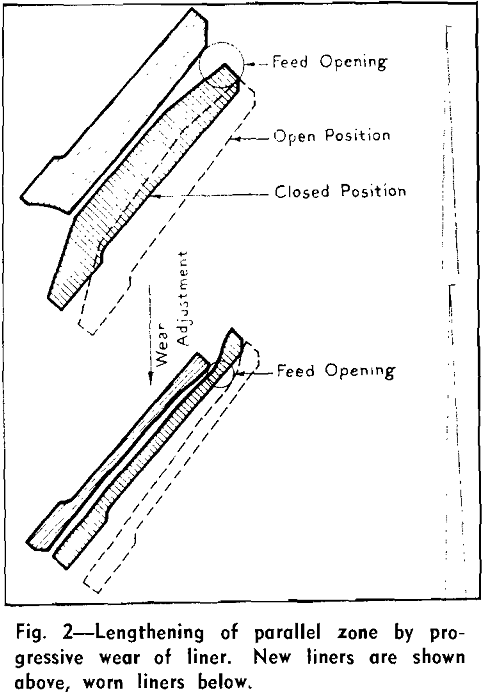

Crushing Cavity Design

In these times of rising labor and material costs, it has become more and more necessary that attention be paid to some operating details which, in their obscurity, may be the key to major economies. Liner wear in crushing cavities of secondary and tertiary crushers can become an appreciable cost item when the material to […]

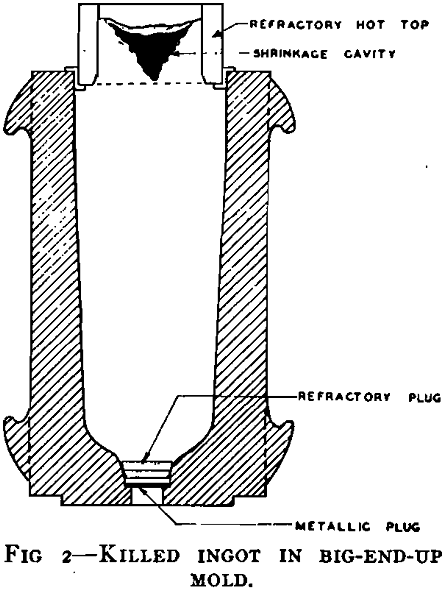

Steel Ingot Solidification

Steel has been chosen as the metal whose solidification will be used to tie in the principles discussed in the previous papers. Although steel is the most important practical example that could be chosen, its solidification is complicated by the presence of many elements added either intentionally or present as impurities. The liquid steel bath […]

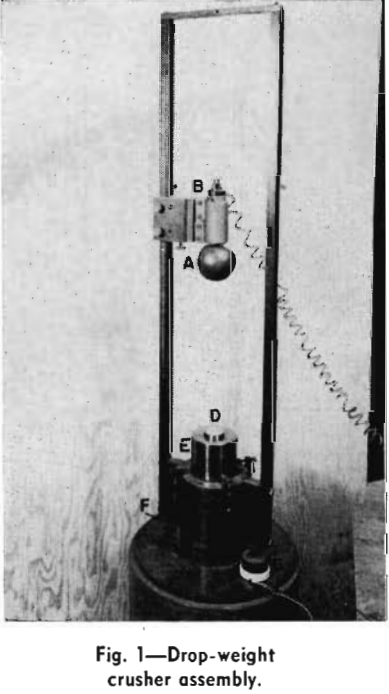

Laboratory Crushing Tests

Crushing has always been a major operation in the chemical and metallurgical industries, yet little is known about the theory of crushing, and today, the design of crushers is still based almost entirely on empirical knowledge and accumulated practical experience. In view of the increasing national need for the economic working of poorer grades of […]

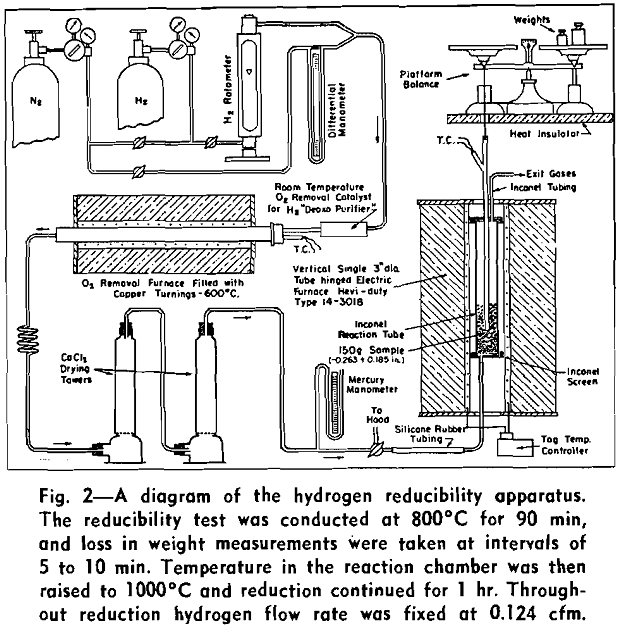

Sinter Testing

This report to the American iron and steel industry marks the completion of a 1949 survey of blast-furnace sinter practice sponsored by the Sub-committee on Agglomeration of Fines of the American Iron & Steel Institute. The use of sinter in blast furnaces, sinter properties, raw materials, and sinter plant operation have been reported recently. Each […]

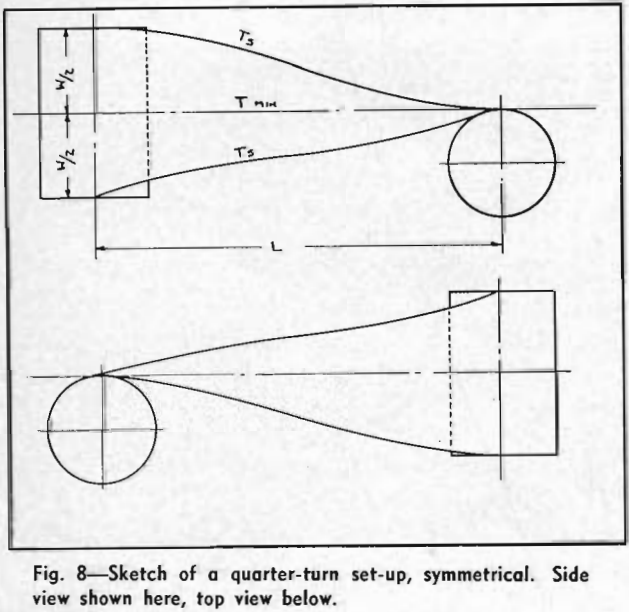

Two-Way Belt Conveyor Transportation

Since 1920 use of belt conveyor transportation has increased steadily, and capacity in tons per hour per unit has increased at about the same ratio. Belt conveyor systems for simultaneous two-way material transportation have been widely discussed, but heretofore have proved impractical for specific operations. The two-way belt conveyor for coal mine service is not […]