What is Metallurgy

Oh, please tell me what is metallurgy? There is no better way of paying tribute to the memory of a scientist than by developing and carrying forward those ideas which he has contributed to science and which are for us the very essence of his immortality. For a lecturer who has not had the great […]

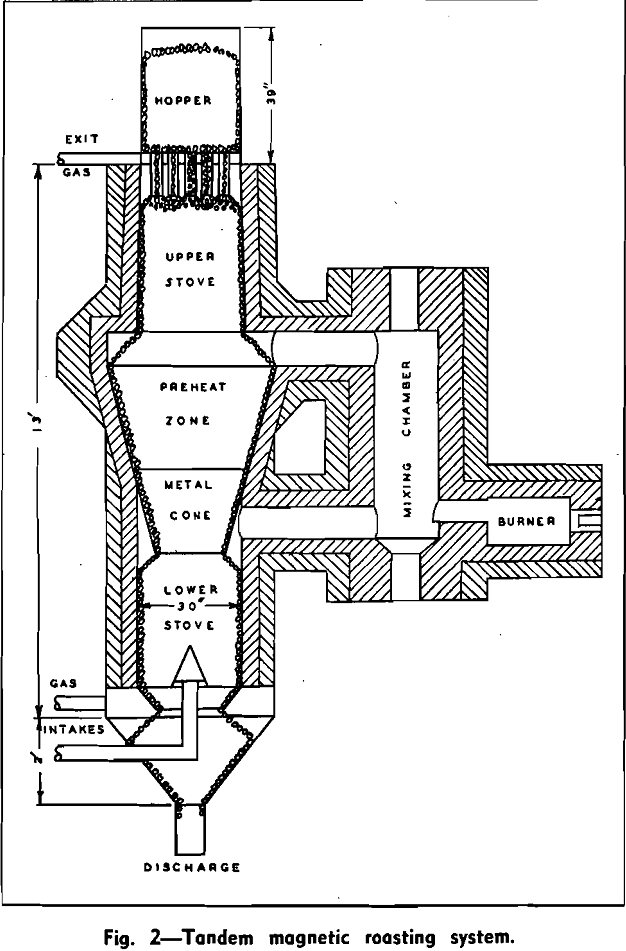

Magnetic Roasting of Lean Ores

During the past few years a radically new process for the magnetic roasting of iron ores has been investigated and developed by Pickands Mather & Co. and the Erie Mining Co. in the Erie laboratory at Hibbing, Minn. This process, originally devised by Dr. P. H. Royster of Washington, D. C., involves the use of […]

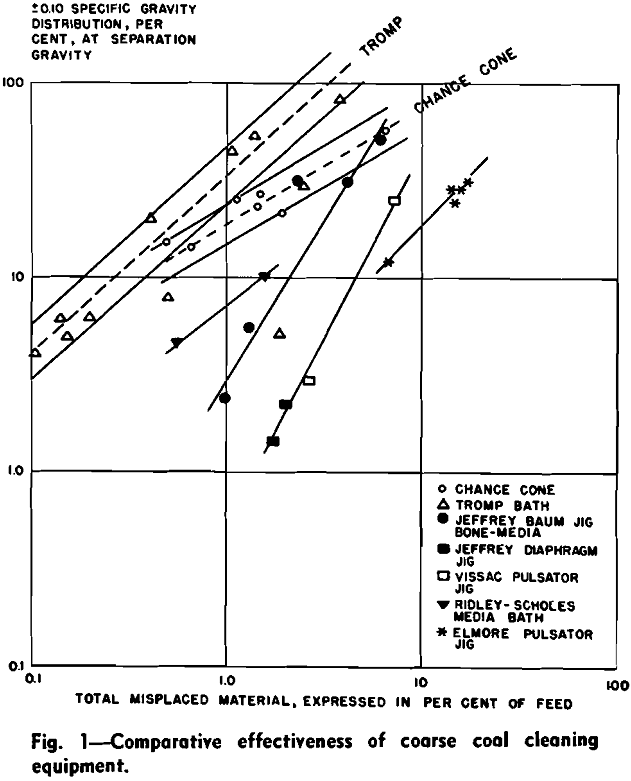

Coal Cleaning Equipment

The relative performance of coal washing equipment, or the effectiveness with which any type or make of equipment removes impurities from coal, has been most difficult to evaluate in the past. The most widely used yardstick is the Frazer and Yancey efficiency formula developed in 1922, but Yancey in a later article states that “washers […]

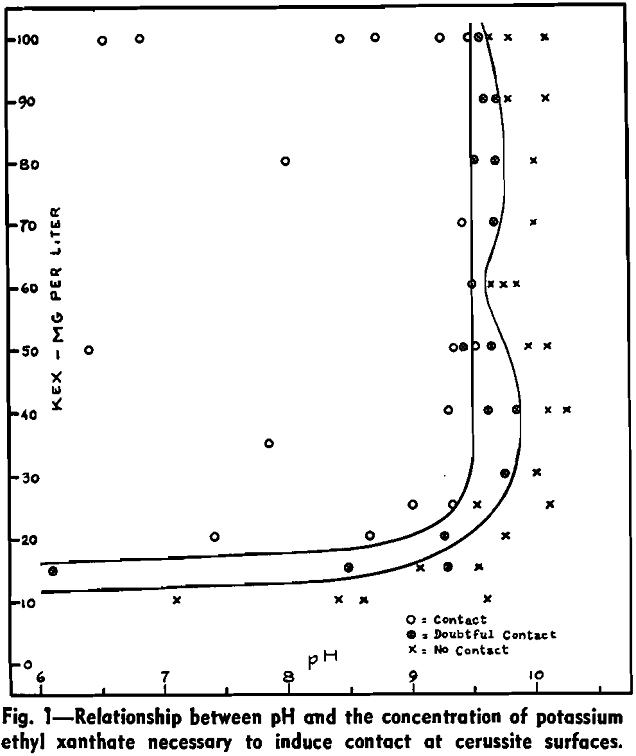

Effects of Alkalinity on Lead Flotation

Critical pH has been defined by Wark as that pH value below which a mineral will float and above which it will not float in solutions containing a given concentration of collector but free from other depressants or activators. The relationship between mineral, collector concentration, and pH is expressed in the form of a critical […]

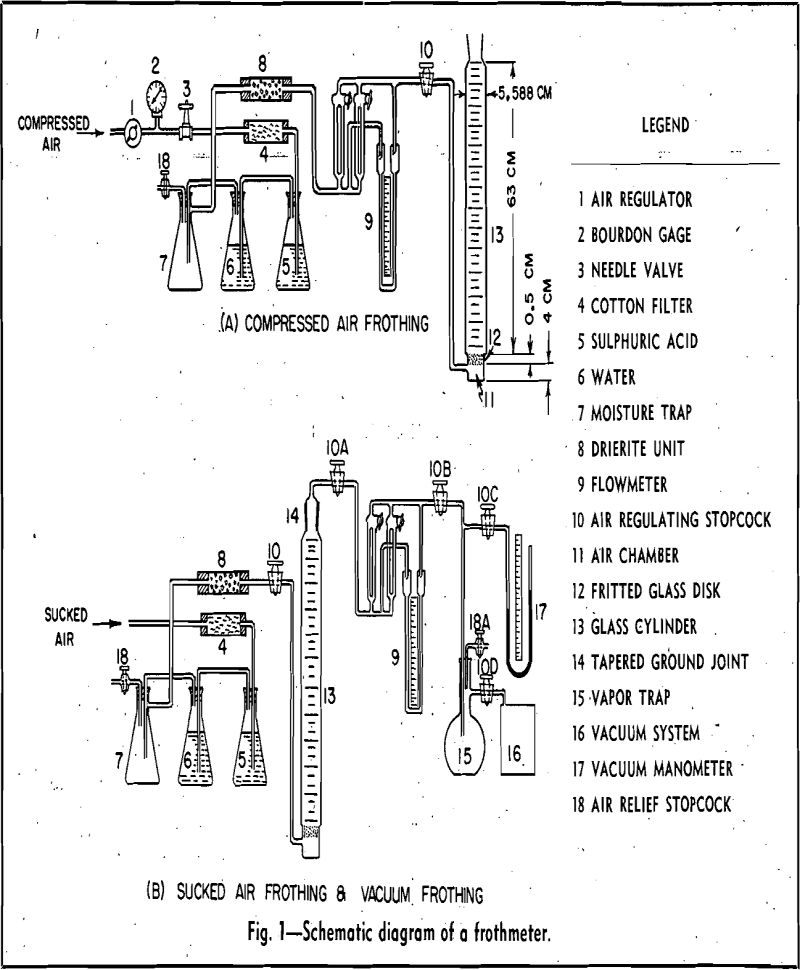

Pine Oil for Flotation Frother

This paper presents the design and operation of a frothmeter capable of measuring the frothing characteristics of pine oils and other frothing reagents. The experimental data show that the frothability of pine oil is governed by: 1—rate of aeration, 2—time of aeration, 3—height of liquid column, 4—chemical composition of pine oil, 5—pH value of solution, […]

Mining Face Preparation

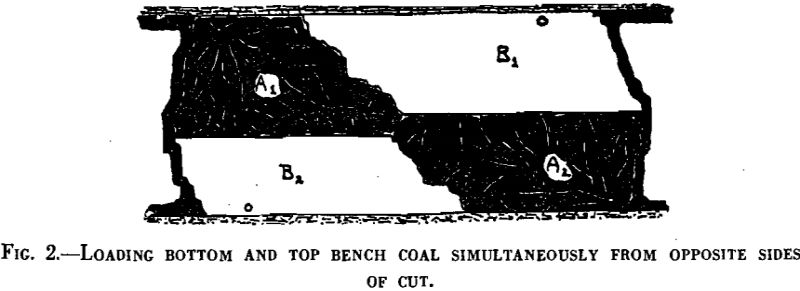

Anthracite Although the unmined anthracite will last for approximately 150 years, most of the thicker and cleaner coal beds have been almost entirely first-mined and pretty well robbed, leaving much of the present and future production to come from thin and dirtier beds. Herewith is a section of one of the dirty beds being mined […]

New Solvent Extraction Techniques for Uranium Purification

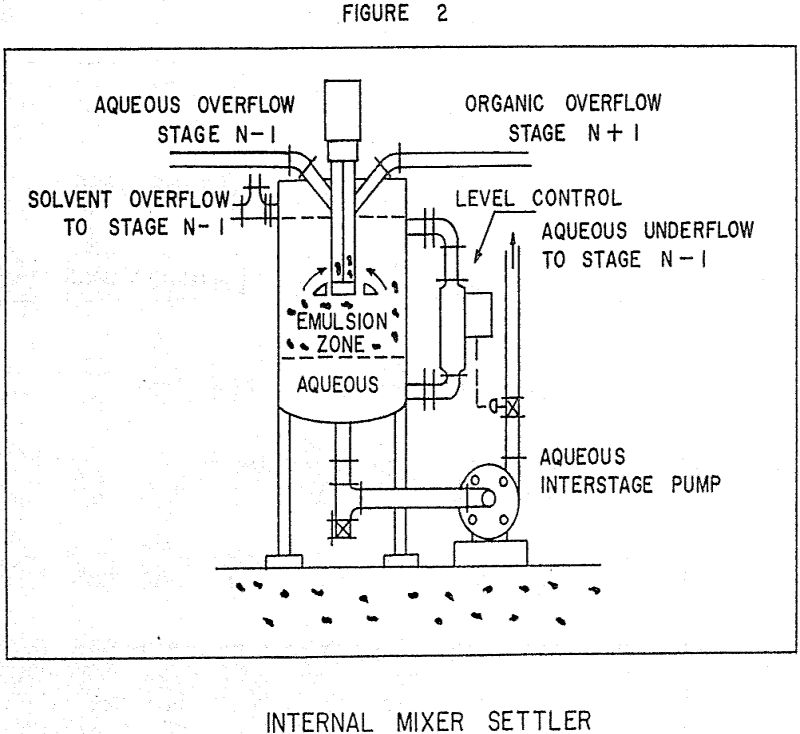

This paper reviews several new applications of solvent extraction developed in conjunction with a research project carried out under the AEC Raw Materials Division by the Dow Western Division laboratories during the last two years. Several methods for direct solvent leaching of ores have been investigated by AEC contractors. The method studied at this laboratory […]

How to Control Flotation Reagents

Reagent control in flotation is more an art than a science. Operators vary the amount of reagents used according to the metallurgy obtained. The amount of collector may be increased, for example, if tailings losses are high and decreased if concentrate grades are low. Often control decisions are based on only one assay, such as […]

Electric Furnace Melting of Copper

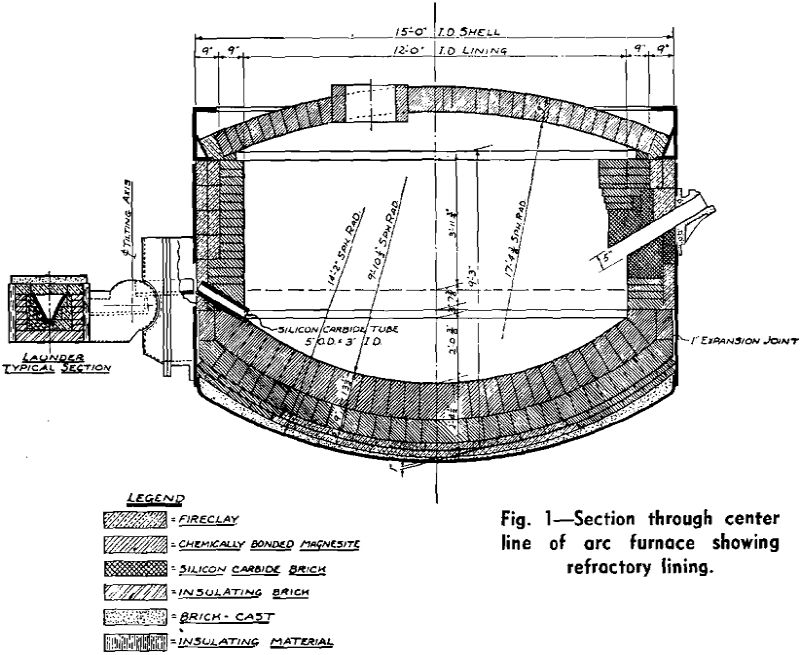

The final casting of refined copper has been restricted for generations by the following sequence of operations: Filling the reverberatory furnace, melting, skimming, blowing or flapping, and poling. The hoped-for 24 hr cycle, producing 300 tons or more, has been taken up largely with the necessary but time-consuming tasks of cleaning the bath, sulphur elimination, […]

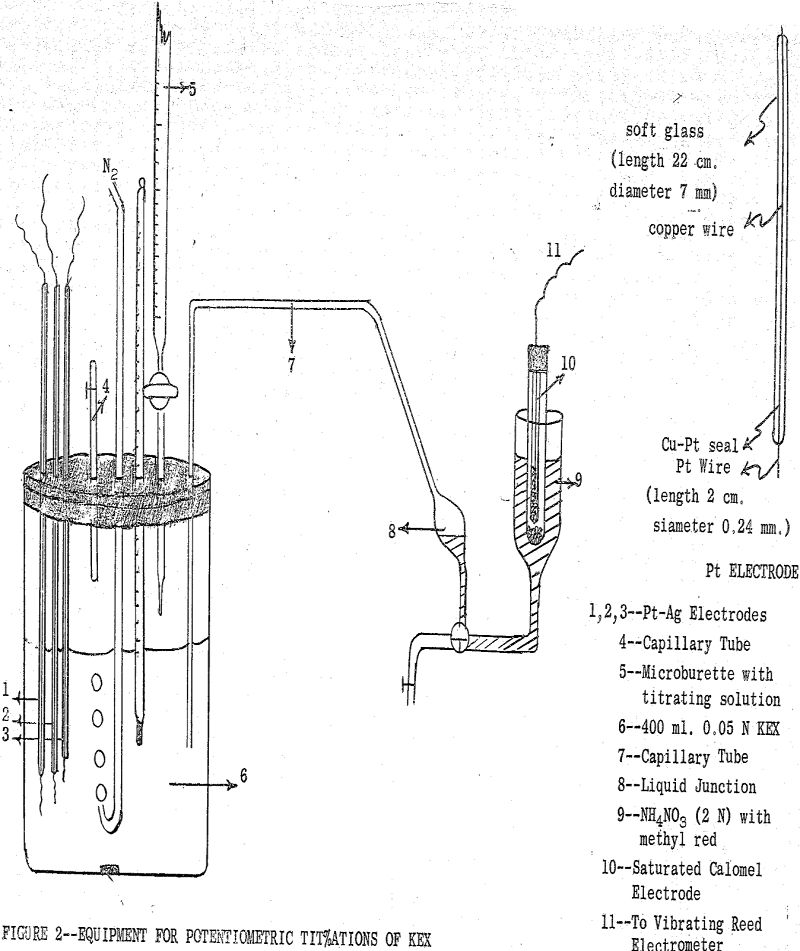

Metal Ethyl Xanthates Solubility

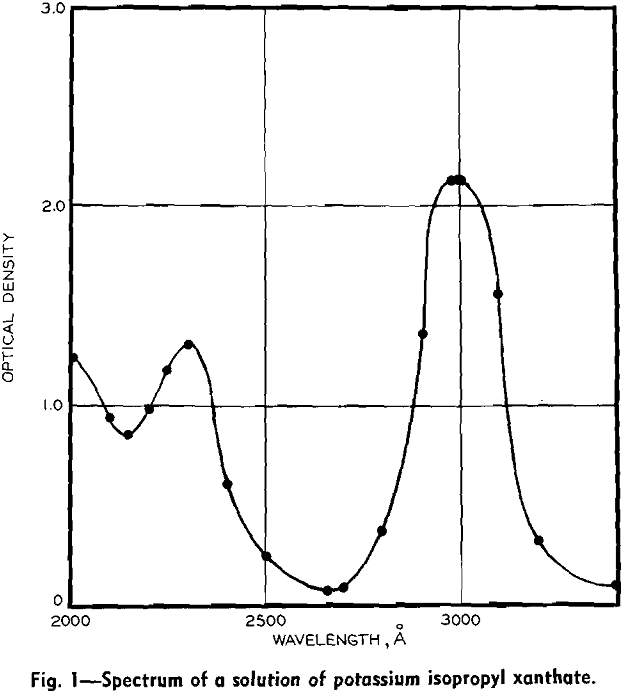

The flotation system is usually distinguished from other physical chemical systems by the importance of interactions at the solid-liquid and solid-gas interfaces. In recent years, numerous quantitative studies have been made of the distribution of common collectors between the solid and aqueous solution phase. Although in flotation the main emphasis is placed on the adsorption […]