How to Reduce Steel Consumption in Grinding Mills

The fact that over 25% of the original weight of steel liners and balls is discarded as waste is probably one of the factors that has not been considered often. This is particularly true for mill liners, “Mill liners are finished metal products of some precision, they cost two to four times the basic cost […]

Grinding Circuit Modelling

Grinding Circuits Fine grinding is carried out in five primary circuits, six secondary circuits and one regrind circuit which grinds copper scavenger concentrates and copper cleaner tailings. A diagram of the primary and secondary grinding circuits showing sample points and their identification is given in Fig. 1. Mechanical details of the ball mills are listed […]

Flotaire Flotation Cell

The Flotaire Cell can be constructed in many configurations, but presently, we prefer a round tank that is 2 to 4 m in diameter with an overall depth of about 5 m. Simplicity of design, and operation, is a principle attraction of the Cell and can be best understood by reference to Figures 1A and […]

Total Cyanide Determination by Reflux Distillation

The determination of aqueous cyanide is accomplished by either detection in the sample as collected or by removal of the cyanide of the collected sample, followed by detection. The direct determination of the cyanide content of a solution can only be used in the simplest of systems, since many interferences can result in errors. Thus […]

Gangue Depressant in Molybdenum Flotation

Sodium cyanide and Nokes reagent are commonly used depressants to reject iron, copper, and lead sulfide minerals for the flotation recovery and upgrading of molybdenite concentrate. With the ever increasing cost of reagents and more stringent regulations, it is necessary that these depressants are used as efficiently and effectively as possible. Therefore, a study was […]

How to Control a SAG Grinding Mill Circuit

Autogenous and semi-autogenous grinding have experienced renewed interest as efforts to reduce operating and capital costs have increased. As a result, the mill operator is faced with new equipment perhaps ten times as large as was common in the sixties and new circuit designs with different operating characteristics. No longer can he grab a handful […]

Placer Gold Mining

The location of a prospect usually results from some physical evidence of the presence of gold and/or past mining activity. Any earlier activity that may have produced gold from the prospect, should be investigated before making the trip. The initial reconnaissance should attempt to verify a near-surface presence and then make observations concerning the geomorphic […]

Mineral Processing Plant Sample Equipment

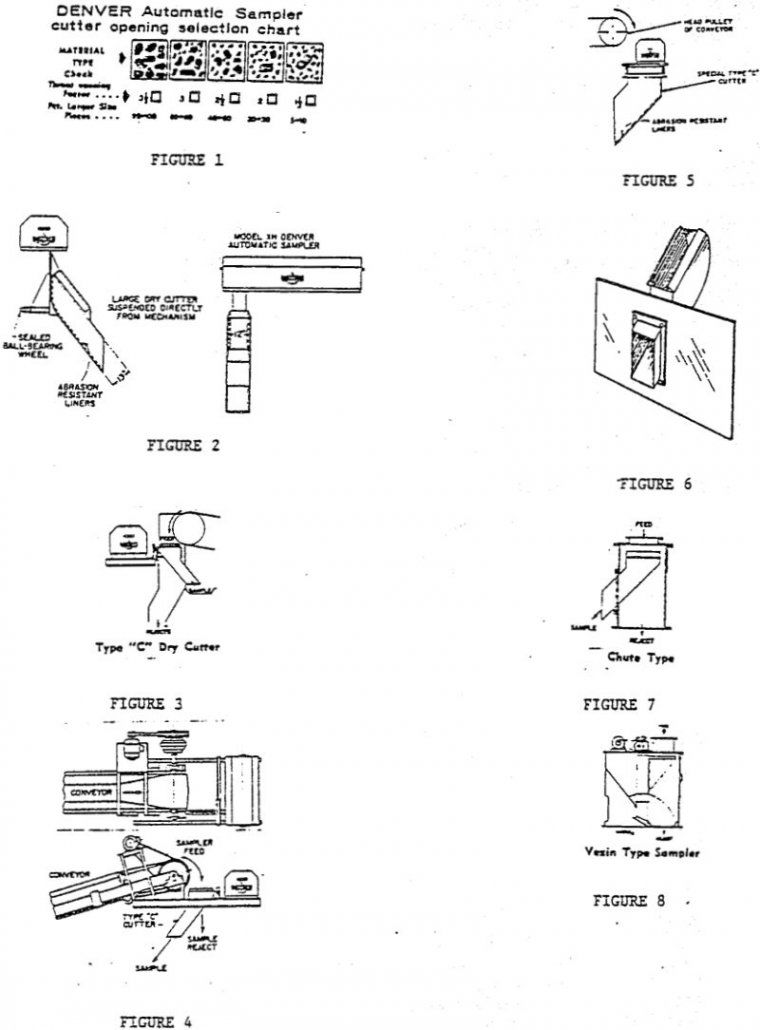

Coarse-ore dry sampling of the type found in primary and secondary crushing systems prior to processing, often requires sampling large flow rates containing 2″ to 6″ particles. The cutter width must be adjustable, with the minimum opening being 2½ to 3 times wider than the largest particle (Figure 1). The cutter blades should enter the […]

Cone Crusher Operating Variables

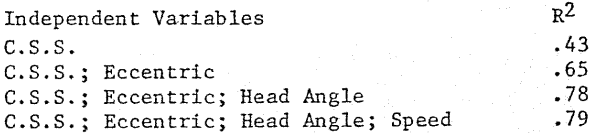

Although past investigations have been conducted to determine crushing relationships, no program which covered a broad range of crushing conditions had been conducted. The previous studies appear to concentrate on small segments of the overall picture and did not fullfill our desired information objectives. Due to the broad range of variables utilized in a production […]

Zinc Roasting Furnaces

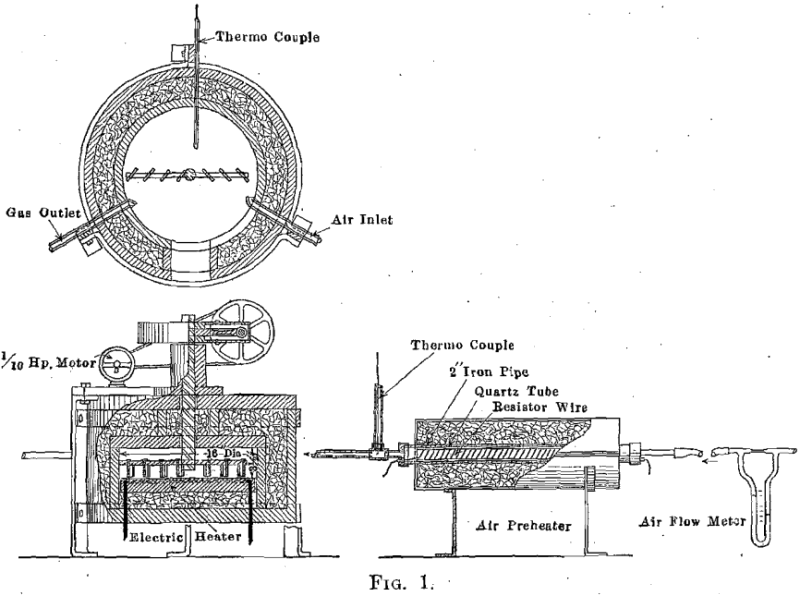

Roasting Ferruginous Zinc Sulfide Ores Mr. J. B. Keating was developing an electrolytic-zinc process for application to the ores of the Bully Hill mines of the General Electric Co. These ores consist of blende and pyrite so finely crystallized and so intimately mixed that no mechanical separation of the individual minerals had been found possible. […]