In 1976 CVRD started the investigation of organic binders application for iron ore agglomeration. The ore was mixed in a Eirich Mixer with quantities of Peridur ranging from 0.1 to 0.4% and pellets were prepared in a laboratory disk. At first the results were not satisfactory at all. The wet and dry compressive strength and drop number increased with the increasing quantity of peridur added but the resistance against the thermal shock was deteriorated. When peridur was added in an amount of 0.4%, the pellets suffered thermal shock at 250°C. However, for these same pellets the dry compressive strength was very high up to 15 kg/pellets.

A second test serie was carried out using a lower dosage rate of Peridur.

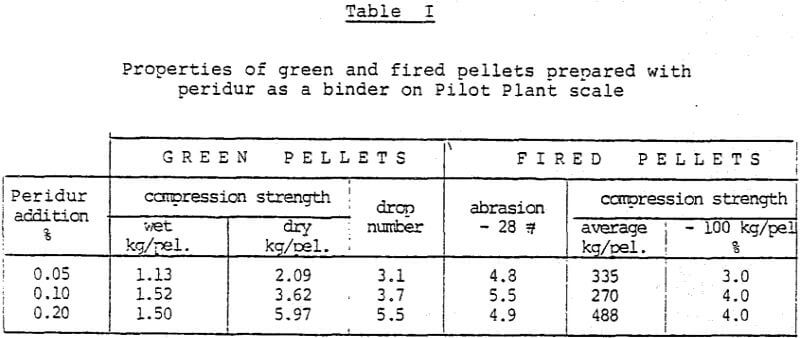

At a 0.05 – 0.1% addition level shock temperature was more than 950°C, whereas the other green pellet properties were above the requirement. See Table I . The pellets were fired in a pot furnace. The fired pellets properties were acceptable and the research program was aimed at a plant test.

From the outset there were problems anticipated with the mixing of such a low quantity of binder in the plant. It has been observed in the laboratory experiments that peridur added in small quantities up to 0.05% improves significantly the rate of filtration of magnetite slurries.

This should also provide an excellent distribution of the Peridur through the ore mass. Therefore some experiments were carried out to add peridur powder to the pulp just before filtration. However, this hematite ore responded differently wherein the filtercake became gelatinous hampering filtration at all.

Plant Test Preparation

Mixing experiments with tracer material

The mixing of binders is very important. If the binder is not dispersed, evenly optimal results can not be expected. This applies to bentonite as well as to an organic binder but in view of the smaller dosage of peridur – about 5 to 15% of the quantity of bentonite commonly added – mixing of an organic binder would appear to be more important. In order to determine the mixing efficiency of the mixer in use (Pekay), a special tracer material was prepared. The tracer material is based on cellulose upon which special ultra violet active

Conclusion

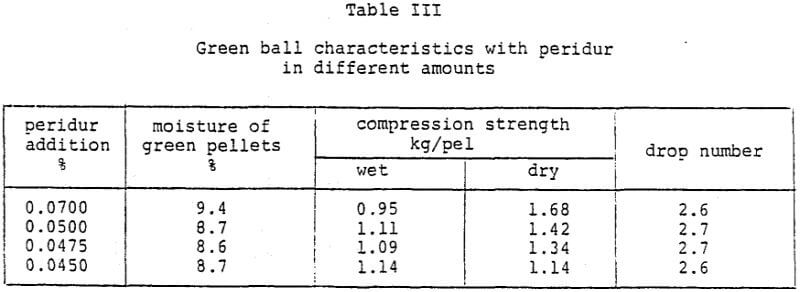

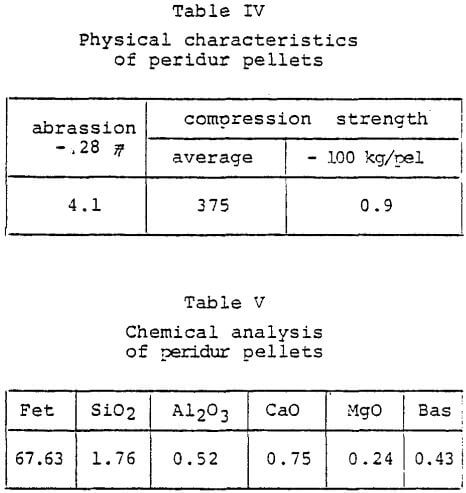

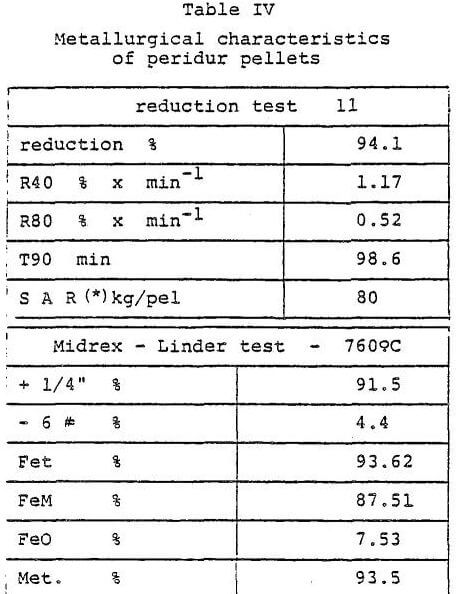

Peridur has proven to be an efficient binder for the production of pellets at CVRD. The plant was run satisfactory at a quantity of 0.045% peridur.

The pellets showed to have a better shape and a smooth surface.

In general the quality of the pellets did meet the requirements.

Due to the elimination of peridur during firing, its use is very suitable for the production of pellets for direct reduction.

As far as economics is concerned, peridur has a great potential to become an option for pellet production.