Table of Contents

Crushing of mica prior to pneumatic processing technique were studied for concentrating coarse mica. Muscovite and phlogophite are the two major commercial mica minerals. However, this research was conducted exclusively with muscovite, and throughout this paper mica will mean muscovite. Two primary forms of commercial mica are (1) sheet mica and (2) scrap and flake mica.

Based on the quantity of visible inclusions and structural imperfections, the American Society for Testing and Materials (ASTM) has designated 12 quality groups for sheet mica. These designations range from black- and red- stained to perfectly clear. ASTM has also designated 12 grades of sheet mica based on the size of the maximum usable rectangle: sizes range from grade 6 (with 1 usable square inch) to grade OOEE special (with 100 usable square inches).

Scrap and flake mica is generally any mica of a quality and size that is not suitable for use as sheet mica. Most scrap and flake mica is recovered from schists, pegmatites, and, occasionally, as a secondary product from the beneficiation of feldspar and kaolin. Such mica is processed into ground mica for various end uses. Coarse, dry-ground mica of 5-mesh size is used in oil-well drilling mud to overcome lost circulation of the drilling fluid. Decorative finishes on concrete, stone, and brick are made with 16-mesh mica.

Twenty- and thirty-mesh mica is used to prevent sticking and for weatherproofing in the manufacture of roll roofing and shingles. Wallboard joint cements contain 100- and 200-mesh mica to eliminate cracking and reduce shrinking. Very fine mica is used in paints to improve exterior durability.

The United States is almost totally dependent on imports for its sheet mica. The high cost of skilled labor needed to mine and beneficiate sheet mica is prohibitive for many U.S. companies. The domestic supply of scrap and flake mica is reported to be adequate, although there is a short supply of high-quality scrap and flake mica for mica paper production. The Bureau of Mines investigated the pneumatic processing method as an alternative means to recover both sheet mica and coarse flake mica.

Current Beneficiation Methods

Sheet mica is selectively mined and beneficiated by hand. Scrap and flake mica can be recovered by several methods. The simplest method separates the mica from its host rock by differential crushing and screening in washer plants. Crushing, which has little effect on the size of the mica because of its platy, flexible characteristics, can effectively recover plus ¼-inch mica. A second method utilizes screens, classifiers, and Humphrey’s spirals to concentrate the mica from the ground ore, which permits the recovery of a finer size mica. Also, flotation methods can recover minus 20-mesh mica with recoveries ranging from 70 to 92 percent.

Pneumatic Concentration Methods

An alternative technique, designed by the Bureau of Mines, uses crushers, screens, and zigzag air classifiers to concentrate mica. Sheet or flake mica has two dimensions many times larger than the third dimension. After screening the ore into close size fractions, the mica sheets or flakes are significantly lighter than the gangue particles of the same size fraction.

Air classification separates the flat, light mica particles from the heavier gangue particles. Crushing and grinding of the ore is limited to the least amount necessary to liberate the mica from the host rock. The process is effective in treating mica-bearing ores down to approximately 65 mesh.

Equipment and Method

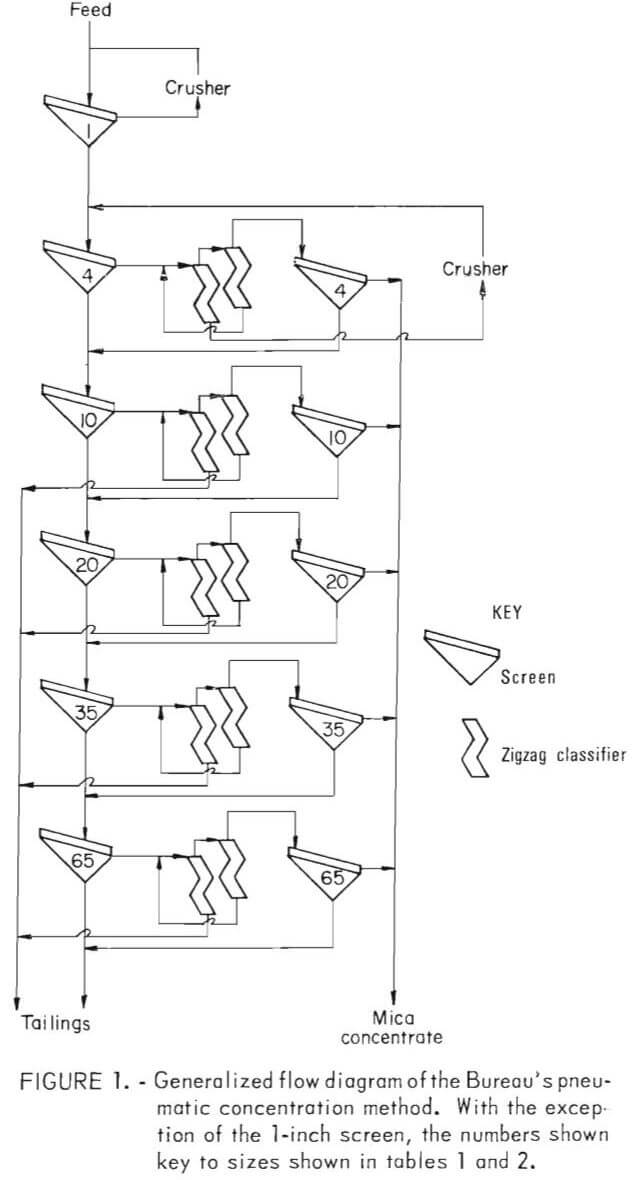

A generalized flow diagram of the Bureau’s pneumatic concentration method for mica recovery is shown in figure 1. For this study, three types of laboratory-size ore crushers were employed to liberate the mica: a standard jaw crusher, a roll crusher, and a hammer mill. Material too large to be fed to the crushers was broken with a sledge hammer to a usable size.

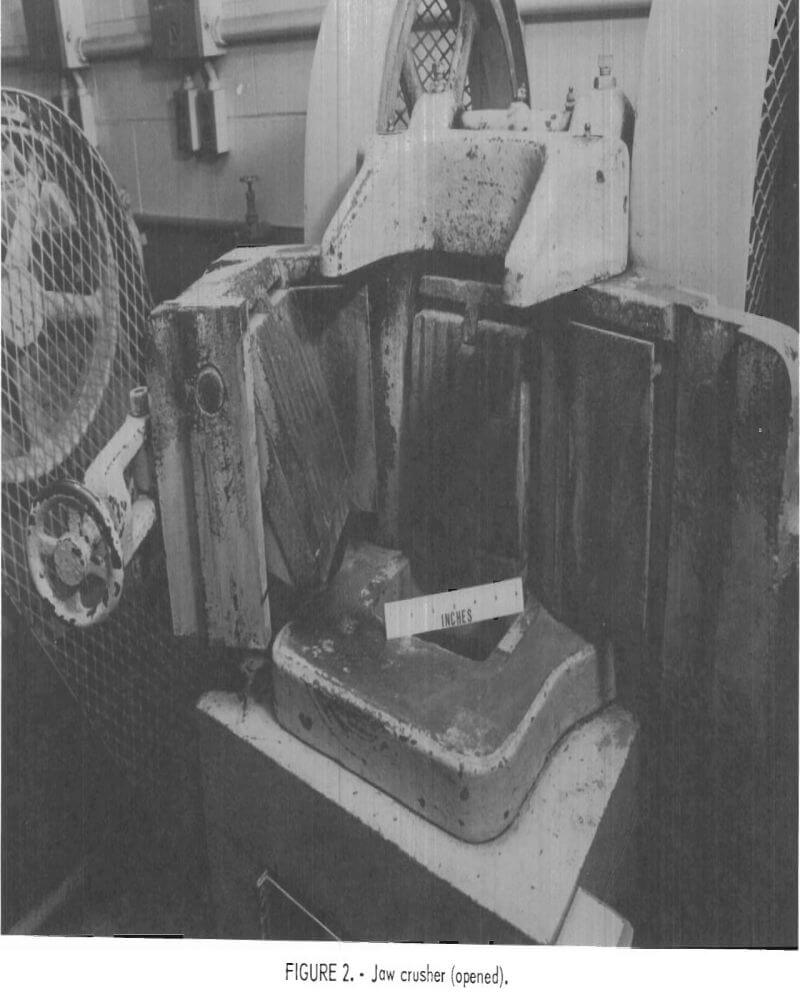

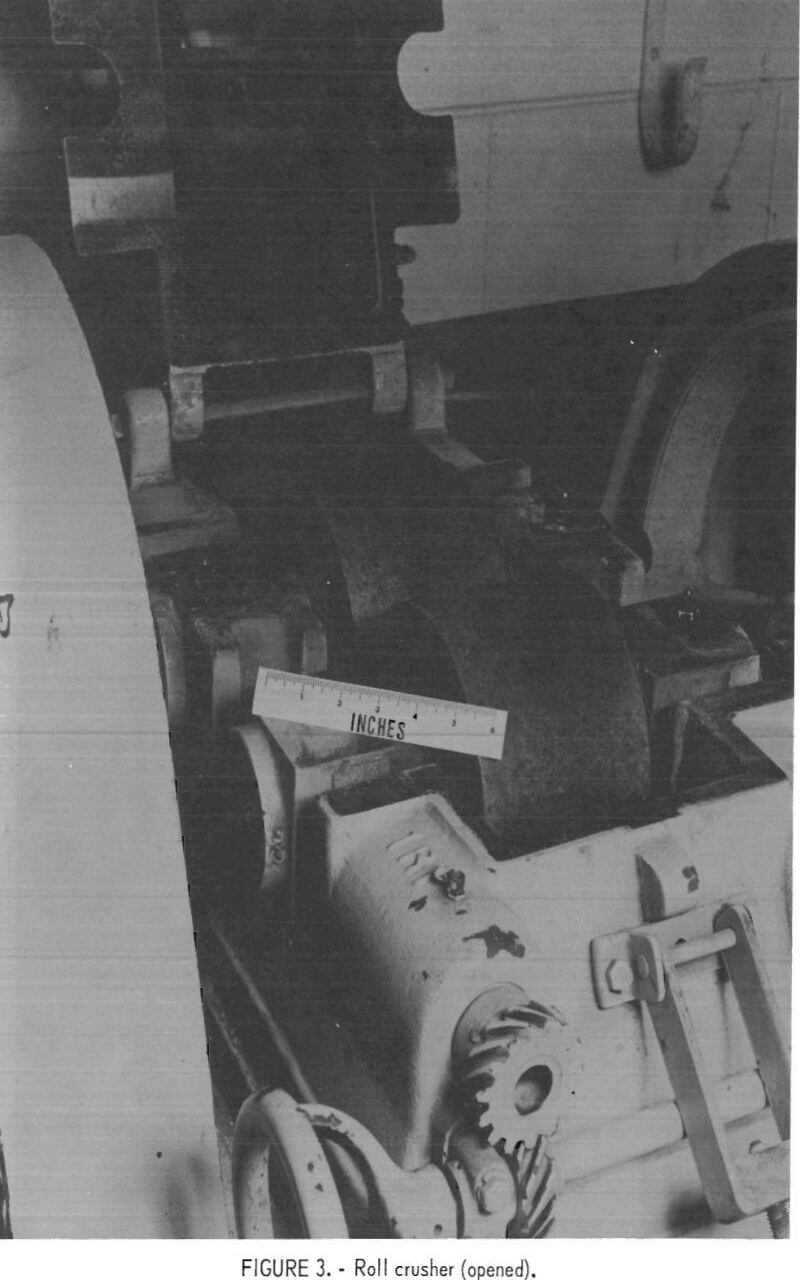

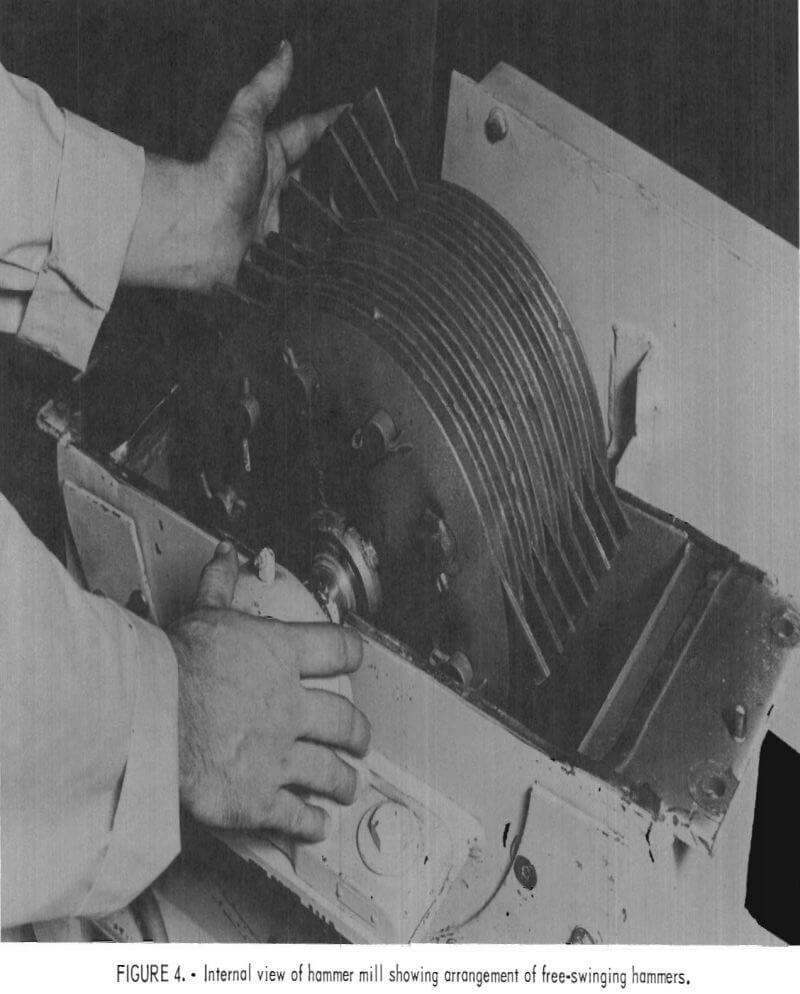

The jaw crusher had jaws measuring 5 inches wide by 8 inches high (fig. 2). Pieces of material up to 5 inches in diameter were crushed in this machine to minus 1-inch diameter for processing in the air classifier. The roll crusher (fig. 3) had two smooth rolls measuring 5 inches wide and 8 inches in diameter. Pieces of material up to 4 inches in diameter were fed to the crusher and crushed to minus 1 inch. The hammer mill (fig. 4) had a 12-inch-diameter rotating drum with free swinging hammers projecting 3 inches from the drum. The maximum feed size was approximately 8 inches.

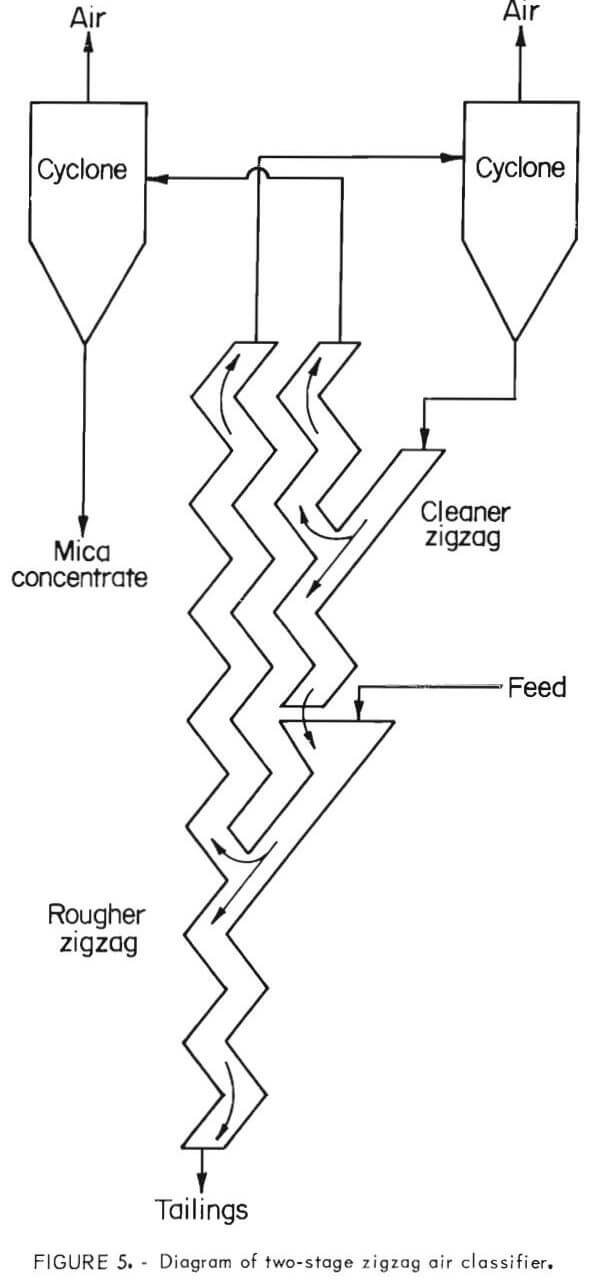

The Bureau’s pneumatic concentration method for mica recovery is designed to process closely sized particles of mica ore. Two screening units and a two-stage zigzag air classifier are used to process each individual size fraction. The oversize particles of the first screen pass through the air classifier to separate the liberated mica from the host rock. A diagram of the two-stage zigzag air classifier is shown in figure 5.

The ore enters the rougher zigzag section through a rotating air lock. Airflow through the classifier can be varied, depending upon the size of the particles being separated. The airflows used in this study ranged from approximately 30 cubic feet per minute for minus 35- plus 65-mesh material to approximately 160 cubic feet per minute for plus 4-mesh material. The heavier

gangue material falls through the airstream of the rougher zigzag section to be discarded as tailings. The light mica flakes are carried by the air-stream and are collected in the cyclone on the right side of the figure. This rougher concentrate is fed to the cleaner zigzag section through another rotating air lock. Again, the mica particles are carried by the airstream and are collected in the left cyclone. The cleaner concentrate leaves the cyclone through a third rotating air lock and is rescreened to remove undersize material that was missed by the first screening. The final product is generally a high-grade mica concentrate. Airflow through the cleaner zigzag section is set slightly lower than the rougher zigzag section to produce a purer product. Most of the gangue particles that are accidently carried in the air-stream of the rougher section fall through the cleaner section and are recycled to the rougher section. The screen undersize products are combined and feed the screens and zigzag classifier of the next smaller size fraction.

gangue material falls through the airstream of the rougher zigzag section to be discarded as tailings. The light mica flakes are carried by the air-stream and are collected in the cyclone on the right side of the figure. This rougher concentrate is fed to the cleaner zigzag section through another rotating air lock. Again, the mica particles are carried by the airstream and are collected in the left cyclone. The cleaner concentrate leaves the cyclone through a third rotating air lock and is rescreened to remove undersize material that was missed by the first screening. The final product is generally a high-grade mica concentrate. Airflow through the cleaner zigzag section is set slightly lower than the rougher zigzag section to produce a purer product. Most of the gangue particles that are accidently carried in the air-stream of the rougher section fall through the cleaner section and are recycled to the rougher section. The screen undersize products are combined and feed the screens and zigzag classifier of the next smaller size fraction.

Methods of Analysis

Industry has not established a standard method of analysis to determine the mica content of a sample. In this study, three methods were used individually and in combination to determine the mica content of the various products. These methods were (1) hand sorting, especially of coarse materials, (2) the inclined plane or cardboard method, and (3) separation in heavy liquids. Analyses were made by physically separating and weighing of the products. Analytical products were examined by binocular microscope to detect misplaced particles. The plus 10-mesh analyses were essentially 100-percent accurate, but were limited by sampling reproducibility. The precision of the analyses decreased as the particle size decreased. A statistical analysis indicated that the measured mica content of the concentrate had a confidence interval of 95 percent plus or minus 5 percent. The same confidence interval for the measured tailings analysis was plus or minus 2 percent. All of the analyses reported in this study should be understood to be within those boundaries of error.

Experimental Results

Tests were conducted on an ore sample from Arizona and two ore samples from Texas to determine the most effective crushing technique for use with the Bureau’s pneumatic concentration method.

Arizona Mica-Bearing Pegmatite

Description

A sample obtained from an Arizona mica-bearing pegmatite contained approximately 22 percent mica. The sample was split into three fractions to study the relative effects of the three types of crushers. Several mica sheets up to about 1.5 square inches of surface area were found in the sample, but most of the mica grains were smaller than 1 square inch of surface area. The sample was run-of-mine rock up to 12 inches in diameter, about 60 weight- percent of which was plus 8 inches. The large size of the pieces made representative samples difficult to obtain, which accounts for the discrepancy in the mica head analyses of the three samples given in tables 1, 2, and 4. The mica was liberated at 4 mesh. The mica contained in the plus 4-mesh material was locked with quartz, plagioclase, and minor amounts of microcline.

Procedure

Jaw Crusher

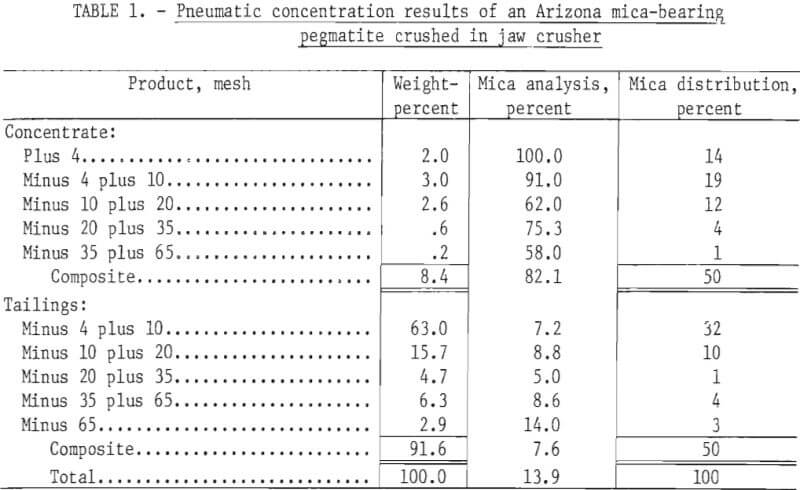

A sample of rock was fed to the jaw crusher and screened at 1 inch. The plus 1-inch material was recycled to the jaw crusher and was again screened. These steps were repeated until all material was minus 1 inch. The sample was then fed to the pneumatic concentration system as illustrated in figure 1. The tailings from the initial plus 4-mesh concentration were recycled to the jaw crusher to liberate additional mica and fed to the pneumatic concentrator. The cycle was repeated until no plus 4-mesh tailings remained. This system resulted in a composite concentrate containing 82.1 percent mica with total recovery of 50 percent of the mica in the sample (table 1). The jaw crusher produced a large number of thick, nondelaminated mica flakes that were not recovered during pneumatic concentration. Also, the jaw crusher produced a large number of flat gangue particles that were recovered in the pneumatic concentrator and lowered the grade of the mica concentrate.

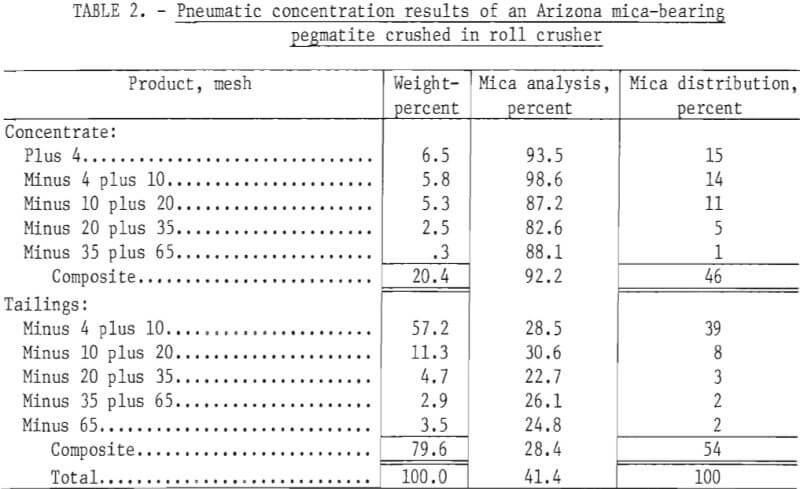

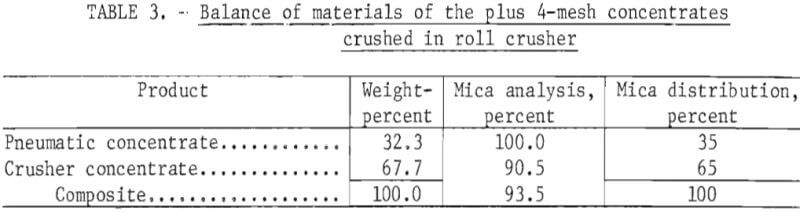

Roll Crusher

A sample of rock was run through the roll crusher prior to feeding to the same pneumatic system. This system produced a composite concentrate containing 92.2 weight-percent mica with recovery of 46 percent (table 2). The roll crusher failed to effectively delaminate the mica flakes, and much mica was left in the coarse tailings. In addition, during the initial treatment of the minus 1-inch, plus 4-mesh material, a small amount of mica was produced that would not respond to pneumatic concentration due to its laminated nature. Recycling this material to the roll crusher tended to cause the rolls to lock and stop running. Hence, this plus 4-mesh “book mica” was removed and recovered as a separate product. For calculation purposes, it was included in the minus 1-inch, plus 4-mesh concentrate and amounted to 67.7 weight-percent of this size concentrate (table 3).

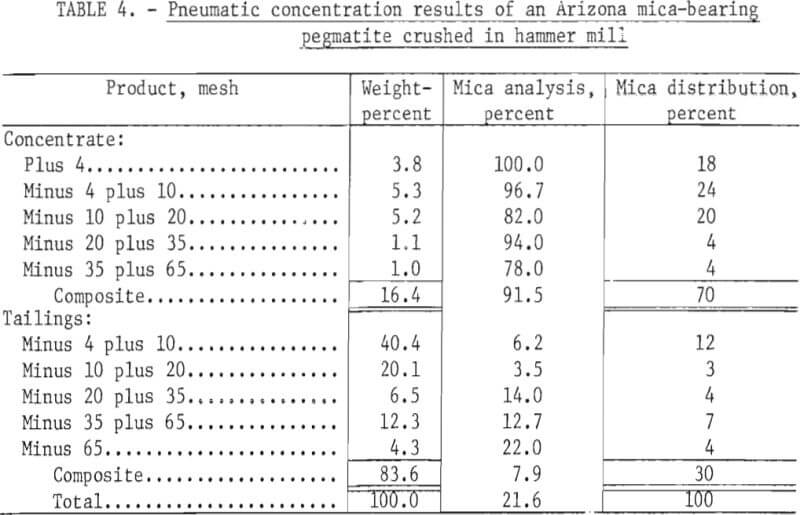

Hammer Mill

A sample was run through a hammer mill prior to separation in the same pneumatic system. The hammer mill overcrushed both the mica and gangue. Therefore, the hammer mill was modified by reducing the number of free-swinging hammers from the original 80 to 10, which were spaced about 3 inches apart. Also, the crushing screen or grate was removed so that a particle would receive a minimum number of impacts before leaving the unit. The use of the hammer mill resulted in a concentrate containing 91.5 percent mica with recovery of 70 percent (table 4). On this basis, the hammer mill was determined the best crusher for subsequent research.

Mica-Bearing Pegmatite

Description

A sample of mica-bearing pegmatite from west Texas was obtained for additional studies. The sample contained approximately 9 percent mica with the other constituents being primarily microcline with some quartz and plagioclase. The sample consisted of pieces 3 to 8 inches in diameter containing mica sheets with up to 1 square inch surfaces although most sheets were smaller. Complete liberation of the mica occurred at 4 mesh. The sample was crushed to minus 4 mesh in the modified hammer mill. The sample was then split into two fractions to determine the effects of the hammer mill modification.

Procedure

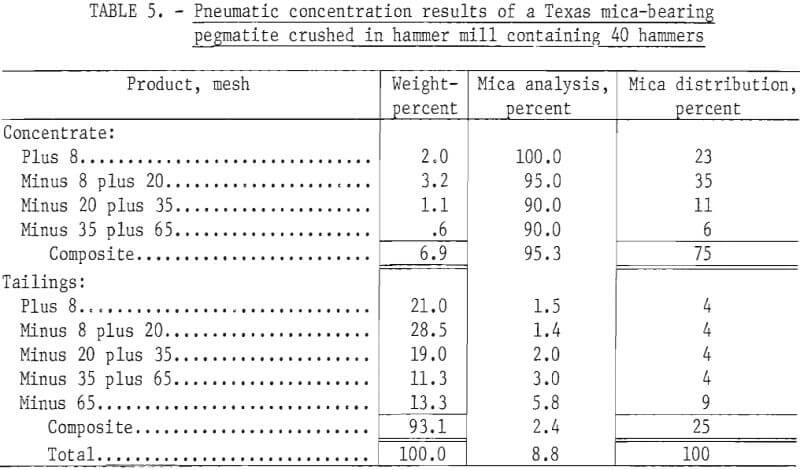

One sample was further crushed in an open hammer mill containing 40 hammers and concentrated. This system produced a concentrate containing 95.3 percent mica with a recovery of 75 percent (table 5). Approximately 9 percent of the mica was lost in the minus 65-mesh material.

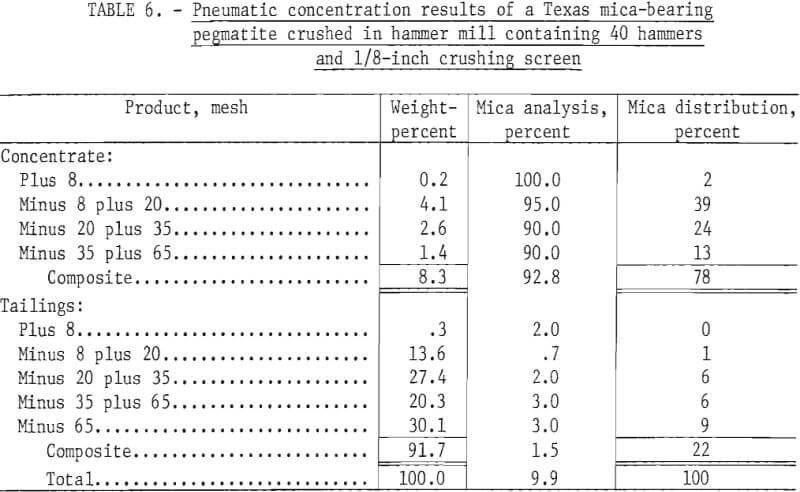

The second sample was further crushed in the hammer mill containing 40 hammers with a 1/8-inch crushing screen added. The crushing screen increased the residence time of the ore in the hammer and produced a finer mesh product. Because mica flakes are flexible, they were not broken as finely as the associated gangue, and no additional loss of mica to the minus 65 mesh occurred. This system produced a concentrate containing 92.8 percent mica with recovery of 78 percent (table 6).

Mica Schist

Description

A sample of mica schist from west Texas was obtained as part of a study to determine the performance of different types of ores. The sample contained approximately 28 percent muscovite and biotite micas. The other constituents were primarily quartz and plagioclase with minor amounts of microcline, zircon, and tourmaline. As received, the ore consisted of pieces 3 to 10 inches in diameter. Liberation and delamination of the mica was found to occur at 20 mesh.

Procedure

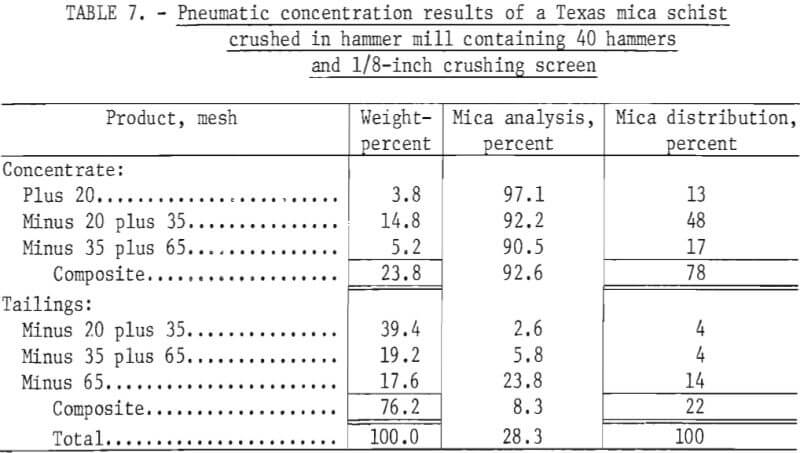

The schist was crushed in the hammer mill containing 40 hammers with the 1/8-inch crushing screen and then concentrated. This system produced a concentrate containing 92.6 percent mica with recovery of 78 percent (table 7).

General Discussion

Pneumatic concentration has been shown to be a successful method of concentrating mica. The process uses the ratio of surface area to mass to separate the mica from associated materials. The type of crusher used had a decisive influence on the delamination of the mica and greatly affected the results obtained using pneumatic concentration.

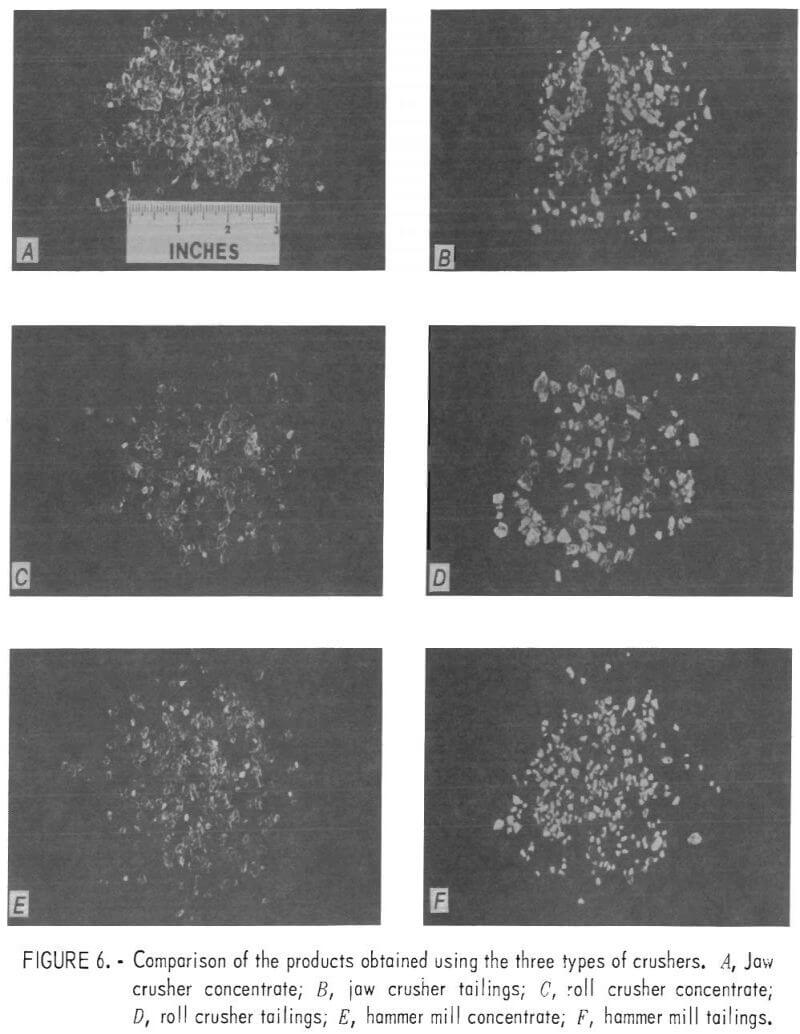

The three types of crushers investigated differed substantially in their effects on the pneumatic concentration of the ores. Figure 6 is a photograph comparing the pneumatic concentration products obtained using the three crushers.

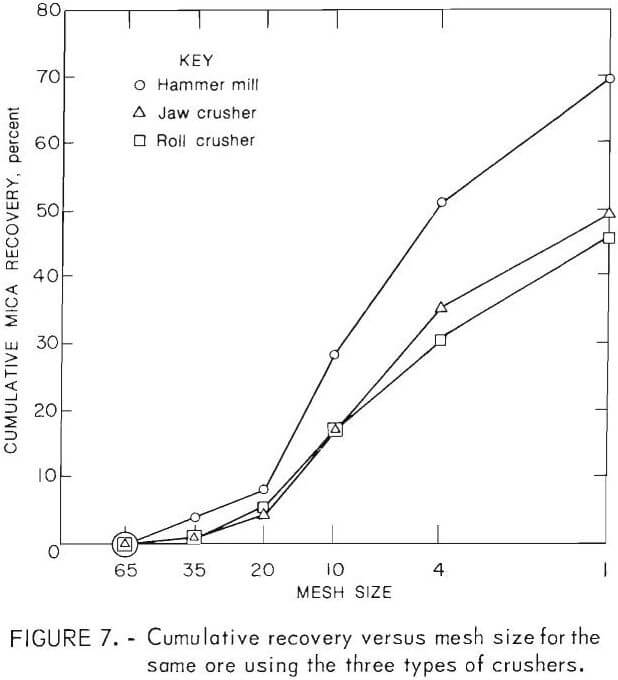

Jaw crushers proved to be inferior, producing a concentrate containing only 82.1 percent mica with recovery of only 50 percent. The jaw crusher also produced a large number of thick, nondelaminated mica flakes that did not respond to pneumatic concentration, resulting in a low recovery. In addition, the jaw crusher produced a large number of flat, platy gangue particles that concentrated with the mica flakes, lowering the grade of the concentrate.

The roll crusher produced a concentrate containing 92.2 percent mica with recovery of 46 percent. The roll crusher was not effective in delaminating  the mica, which lowered the recovery. The larger pieces of mica jammed the rolls of the crusher and stopped it. Some of the larger pieces of mica could not be delaminated enough to respond to pneumatic concentration. In a continuous system, this material would build up in the crushing circuit. In this study, the nondelaminated mica was removed as a separate product and considered to be a part of the plus 4-mesh concentrate.

the mica, which lowered the recovery. The larger pieces of mica jammed the rolls of the crusher and stopped it. Some of the larger pieces of mica could not be delaminated enough to respond to pneumatic concentration. In a continuous system, this material would build up in the crushing circuit. In this study, the nondelaminated mica was removed as a separate product and considered to be a part of the plus 4-mesh concentrate.

The hammer mill was the most acceptable crusher. The pneumatic concentrate contained 91.5 percent mica with recovery of 70 percent. The increased recovery attained by use of the hammer mill resulted from the delamination of the mica particles. Figure 7 is a graph comparing cumulative recovery and mesh size for the three crushers.

Further testing determined the most suitable hammer arrangement to use with the hammer mill. Preliminary testing showed that use of the hammer mill containing 80 hammers resulted in overcrushing of both the mica and gangue. Modifying the hammer mill by reducing the number of hammers to 40 produced a concentrate containing 95.3 percent mica with recovery of 75 percent. The minus 65-mesh fraction was 13.3 weight-percent and contained approximately 9 percent of the mica in the sample.

Placing a 1/8-inch screen in the hammer mill to increase the residence time of the ore produced a finer mesh product. This method of crushing produced a concentrate containing 92.8 percent mica with recovery of 78 percent. The minus 65-mesh fraction increased to 30.1 percent while the total loss of mica remained approximately 9 percent. Because of the flexible nature of the mica flakes, they were not as finely crushed as the associated gangue. The mica flakes were more delaminated with a resultant increase in recovery.

To determine its applicability, this crushing scheme and pneumatic separation was applied to a schist sample. Although a different rock type, with much finer grained material, the system performed equally well, producing a concentrate containing 92.6 percent mica with recovery of 78 percent.

Conclusions

The Bureau’s pneumatic concentration method for recovering mica was effective for coarse mica recovery. Liberated mica as large as 1 inch and down to plus 65 mesh was recovered. Since the minus 65-mesh mica is not recovered, the crushing circuit should be designed to minimize the amount of minus 65-mesh mica. The hammer mill delaminated the thick mica particles, thereby increasing the mica recovery by the zigzag air classifier. The pneumatic concentration method, with the modified hammer mill, performed equally well with the two types of ore (pegmatite and schist) tested. The mica concentrates contained over 90 percent mica, representing recovery of as much as 78 percent of the mica in the samples.