Through a cooperative agreement, the Carondolet Foundry Co. of St. Louis, Mo., supplied 1,000 pounds of 2-inch Ni-hard balls for comparison with balls of other composition. Ni-hard balls are said to contain 2.5 to 6 percent nickel and 0.5 to 1.5 percent chromium. They have a Brinell hardness of 548.

The company also furnished a stock of annealed, cast-iron balls. They were very soft, having a Brinell hardness of 150, much of the carbon being in a graphitic state.

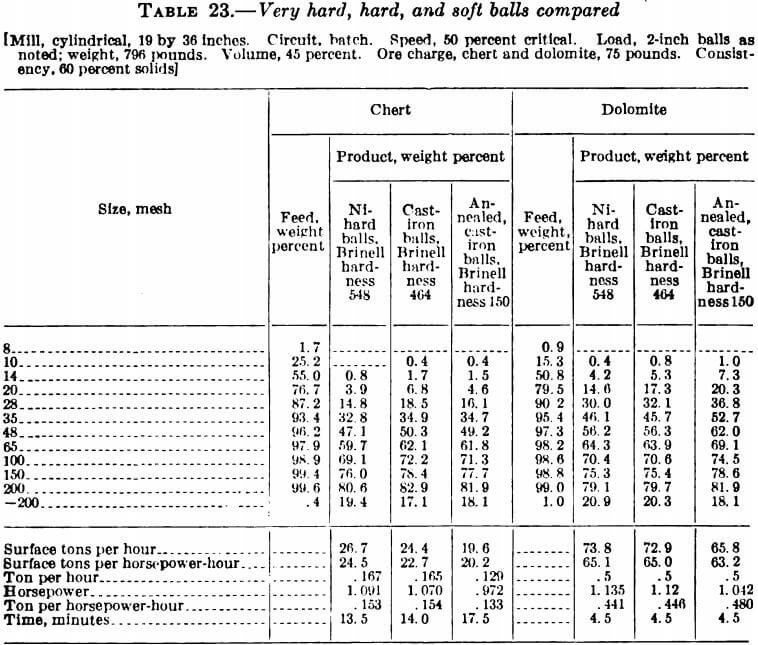

To the stock was added ordinary cast-iron balls for further comparisons. The three batches of balls were used for comparative grinding tests and the results are shown in table 23. The table is in two sections of three tests each. The left section is for chert and the right section is for dolomite. In the grinding of chert the Ni-hard balls were superior in every way, the order of decreasing effectiveness being Ni-hard, cast iron, and annealed cast iron. In the grinding of the dolomite the Ni-hard balls were superior, but the advantage was not so marked as with the chert.

Examination of the power readings showed that the annealed, cast- iron balls required about 10 percent less power than the Ni-hard balls. If they had required more power the possible imbedding of the ore particles into their surface to increase the nip would have been offered as an explanation; but since the power required by the soft cast-iron balls was less, the presence of graphite must explain this.

The surface of the annealed, cast-iron balls was about 8 percent graphite by volume. By acting as a lubricant, the graphite probably caused slipping of the load against the breast of the mill and slipping of the balls among themselves. This deportment would reduce the power requirement. The annealed balls would have been given the same amount of action as the Ni-hard balls if the mill loaded with the annealed balls had been run a little faster. The extra speed would have compensated for the loss in capacity but probably not for the loss in efficiency.

With very hard ore the Ni-hard balls showed an advantage that should be given consideration. With hard and moderately hard ores some of the energy of soft balls that should go into crushing goes into deformation of the balls. When the ore is soft, the soft balls are not handicapped so severely.