Table of Contents

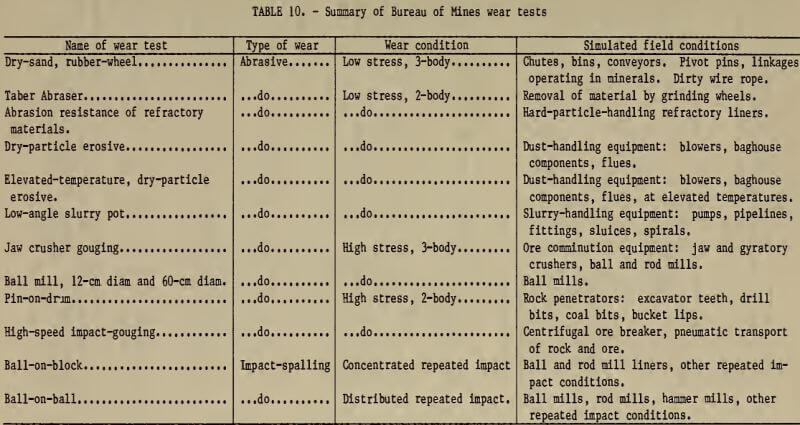

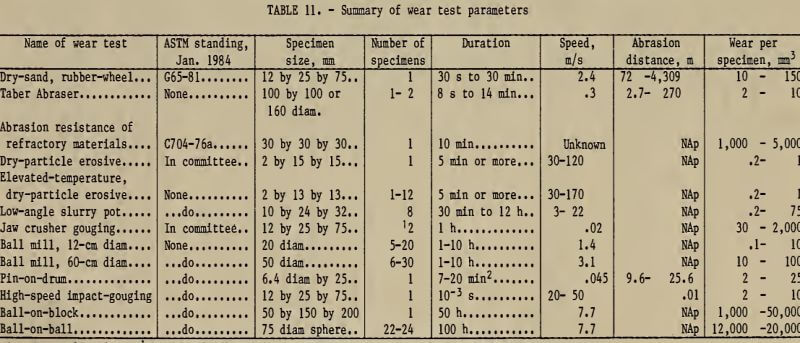

The laboratory wear testing capabilities are described. Wear tests are used to support the group’s research efforts toward reducing the wear of equipment used for mining and minerals processing and any wear involving a loss of strategic or critical materials. The emphasis is on abrasive wear because it accounts for most of the wear losses that occur in mining and minerals processing equipment. Spalling wear, caused by repetitive impact in grinding equipment, also is included. Ten abrasive wear tests, including high-stress and low-stress and two-body and three-body conditions, are described: dry-sand, rubber-wheel abrasive wear; Taber Abraser; abrasion resistance of refractory materials; dry-particle erosive wear; elevated-temperature, dry-particle erosive wear; low-angle slurry pot; jaw crusher gouging wear; ball mill wear; pin-on-drum abrasive wear; and high-speed impact gouging. Two repetitive impact tests are described: ball-on-block impact-spalling and ball-on-ball impact-spalling. Test equipment, procedures, and specimens are described, and typical test results are presented and discussed.

Wear is a major problem in the mining industry and occurs on a wide variety of items, such as excavator teeth, rock drill bits, crushers, slushers, ball mills and rod mills, chutes, slurry pumps, and cyclones. Wear results in a significant cost to the mining industry in terms of direct replacement costs, downtime, and maintenance. The Bureau of Mines is conducting research on various types of wear processes and materials. Wear mechanisms and the effects of variables such as alloy composition and heat treatment are being studied with the ultimate aim of devising alloy systems that reduce wear and significantly reduce the loss of critical and strategic metals. In order to support this research, a variety of laboratory test equipment has been purchased or constructed.

Although numerous types of wear tests have been reported, most are beset by lack of reproducibility or are too specialized to be of general interest. Only eight wear test practices have been published by the American Society for Testing and Materials (ASTM), although others are in process. The G.2 committee of ASTM, which is concerned with all types of wear, is devoting considerable effort toward developing wear test standard practices and procedures. The Bureau is working with the G.2 committee in this effort. The ASTM has published an evaluation of wear testing and, more recently, a volume describing a wide range of types of wear tests. Borik compared several abrasion tests on a variety of abrasion-resistant materials.

An ideal laboratory wear test would be small in scale, produce highly reproducible data quickly, and simulate a wide range of field conditions. The test results should predict the wear of a material in actual service. Such a test is difficult to achieve because wear processes are dependent on a number of variables that are affected by time and scale. Some of these factors are frictional heating (lowering the flow stress), work hardening rate, size and nature of wear debris, nature of abrasive particles, microstructure of the material, and environmental interactions.

Consequently, hundreds of wear tests have been devised, each an attempt by an investigator to closely simulate a given wear situation while producing significant wear in a short time. There is a need to standardize and minimize the types of wear tests in order to make interlaboratory comparisons and to reduce the number of tests and types of test specimens required. At the same time, there is a need for the tests to more closely simulate a broader range of field conditions.

It is hoped that the following description of wear tests used by the Bureau will be helpful to other organizations involved in wear testing and wear research. The comparison of test parameters such as specimen size, duration of test, surface speed, etc. may be particularly useful to those attempting to select a suitable wear test. Also, this report may stimulate further ideas in wear testing and wear research that will eventually help reduce the tremendous losses in materials that result from equipment wear in mining and minerals processing in the United States as well as other countries.

Description of Tests and Equipment

We have a total of 12 types of wear test units in use. Ten of these units are located at the Albany (OR) Research Center, where considerable research is being conducted on wear. The other two units are at the Rolla (MO) and Tuscaloosa (AL) Research Centers. Most of the Bureau’s tests are related to abrasive wear, including erosive wear and slurry wear, because most wear problems in mining and minerals processing are caused by abrasive materials. Two tests involve impact-spalling wear—a major wear problem in crushing and grinding equipment. Other types of wear, such as adhesive wear and lubricated wear, are not being addressed. One study of wear between quartz and steel was conducted in 1976 at the Twin Cities (MN) Research Center, but the pin-wear test equipment that was used no longer exists. Similar pin-wear test equipment belonging to the University of Maryland was recently used at the Avondale (MD) Research Center for evaluating molybdenum diboride coatings.

Among the wear tests described, the dry-sand, rubber-wheel abrasion test is an ASTM standard practice and the abrasion resistance of refractory materials is an ASTM standard test method. Two of the tests, the jaw crusher gouging abrasion test and the dry-particle erosion standard practice, were recently published by the ASTM. Of the remaining eight tests, three are novel tests devised by the Bureau, namely, the ball-on- ball impact-spalling test, the high-speed impact-gouging wear test, and the low- angle slurry pot test. The other five types of tests described are not ASTM standards but have been reported by other laboratories. In several cases, the Bureau has modified or improved the earlier tests.

Not included in this report are the frictional ignition tests at the Twin Cities, Albany, Avondale, and Pittsburgh (PA) Research Centers and the Los Angeles abrasion machine at Tuscaloosa Research Center. Although wear is inherent in the frictional ignition of methane-air mixtures, the frictional ignition equipment is not used at present to study wear processes or wear mechanisms although it may be so used in the future. The Los Angeles machine is for evaluating the abrasion resistance of aggregates, such as those used for concrete or asphalt paving. The tests, ASTM C131-81 and C565, are not pertinent to the thrust of the Bureau’s research on wear of mining equipment.

Abrasive Wear

Abrasive wear tests are frequently classified by the type of test equipment used; however, they can be classified in more general terms by the stress level and the geometrical arrangement of the components of the system. If the load is sufficient to fracture the abrasive particles, the wear is called high-stress abrasive wear; if the particles do not fracture significantly, it is called low-stress abrasive wear. The distinction between low-stress and high-stress conditions is not sharp. As for geometrical arrangement, if the abrasive particle is in contact with only one other object, it is called two-body abrasive wear. If the particle is engaged by more than one other object, such as another wear surface or other abrasive particles, it is called three-body wear. Although the abrasive material is normally harder than the wear object, this is not a necessary condition for classifying the wear as abrasive wear. Erosive wear is often categorized separately from abrasive wear. However, the erosive wear described in this report involves only solid particle erosion and therefore is considered as a type of abrasive wear.

- Dry-Sand, Rubber-Wheel Abrasive Wear Test

- Taber Abraser Test

- Dry-Particle Erosive Wear Test

- Elevated-Temperature, Dry-Particle Erosive Wear Test

- Low-Angle Slurry Pot Test

- Jaw Crusher Gouging Abrasion Test

- Ball Mill Wear Test

- Pin-on-Drum Abrasive Wear Test

- High-Speed Impact-Gouging Test

- Impact-Spalling Wear

The research laboratories of the Bureau of Mines have the capability to conduct a large variety of wear tests relevant to the mining and minerals processing industries. The tests include several pertinent ASTM standard tests and proposed standard tests. The abrasive wear tests include one low-stress, three-body wear test (dry-sand, rubber-wheel abrasive wear test); five low-stress, two-body wear tests; two high-stress, three-body wear tests (jaw crusher and ball mill); and two high-stress, two-body wear tests (pin-on-drum and high-speed impact¬gouging).

The repetitive impact tests include a ball-on-block impact-spalling test and a novel ball-on-ball impact spalling test. The latter is capable of producing impacts at a much faster rate than previ¬ous tests of this type.

Comparisons of the tests, test conditions, and other parameters are summarized in tables 10 and 11.