The following conclusions on the work of the Hardinge mill are based on data furnished to the writer by the Hardinge Conical Mill Co. in the form of the mesh cards hereto appended. Energy units (E. U.) and relative mechanical efficiencies (R. M. E.) are computed by the “volume method” of Stadler. Screen apertures used are the average apertures of testing screens of the meshes given.

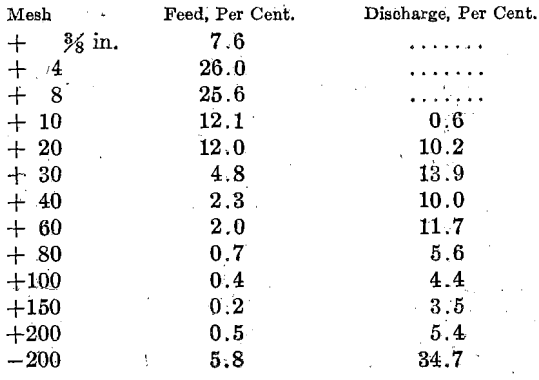

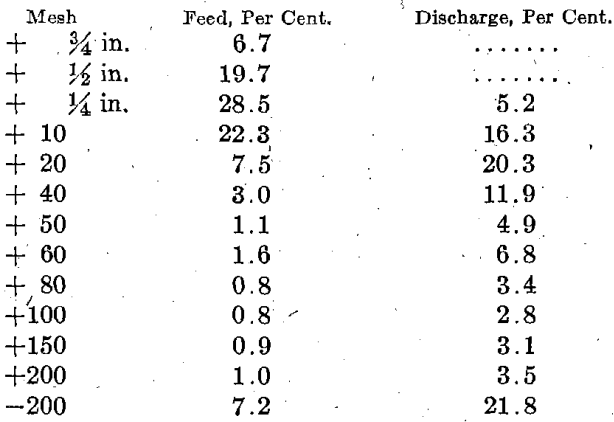

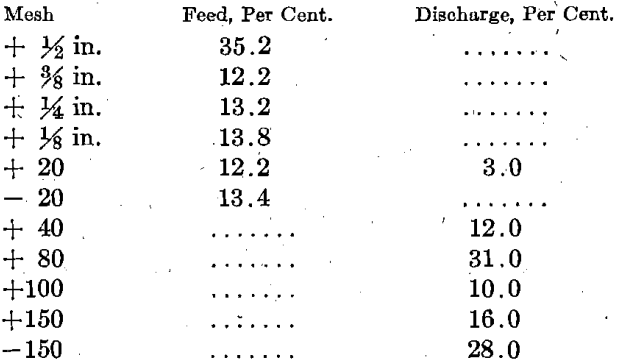

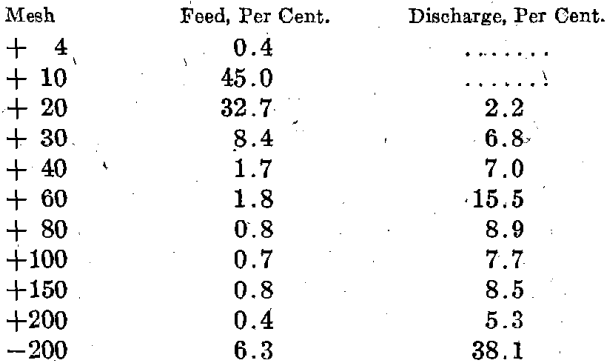

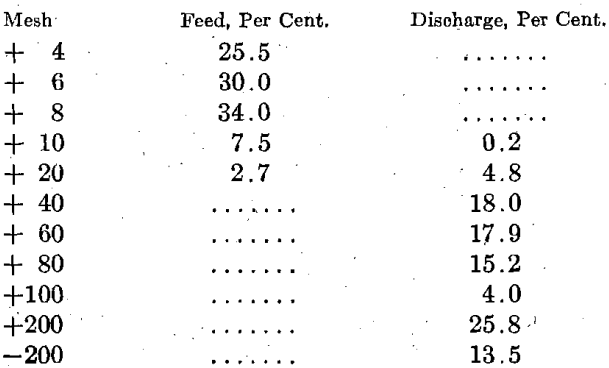

Card 122. June 28, 1912. Vipond Porcupine Mines Co., Ltd., Schumacher, Ont., Canada.

Ore from mill bin. Gangue, quartz and basalt.

4.5 ft. by 13 in. ball mill,

Capacity, 48 tons per 24 hr.

Charge, 4,000 lb. balls.

Speed, 33 rev. per minute.

Horsepower, 15 to 17.

Water, 100 per cent, by weight. (50 per cent. ?)

Product deslimed and oversize reground in pebble mill, see Card 113.

Feed to mill through 2-in. mesh.

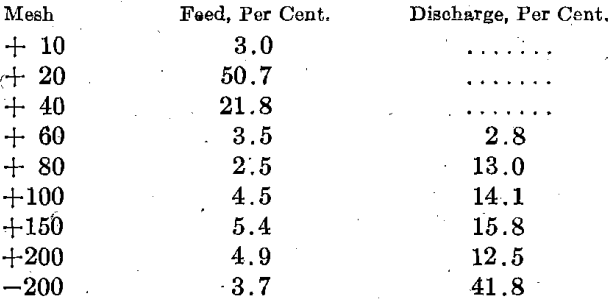

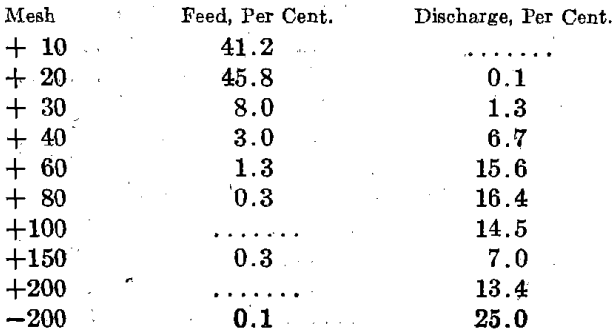

Card 107. Jan. 30, 1912. Miami Copper Co., Miami, Ariz.

Material from mill bin. Gangue, siliceous porphyry.

6 ft. by 16 in. ball mill.

Capacity, 351 tons per 24 hr.

Charge, 4 tons balls.

Speed, 28 rev. per minute.

Horsepower, 35 net.

Water, 50 per cent, (approx.).

Elevation of feed end, 2 in.

Consumption of balls, 0.578 lb. per ton of ore crushed.

Feed to mill through 1.5-in. mesh.

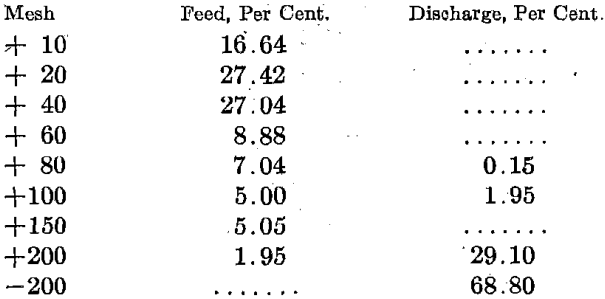

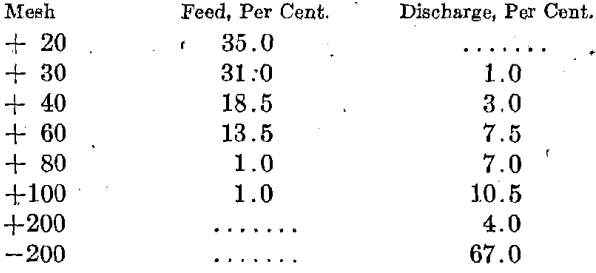

Card 155. Aug. 3, 1914. Britannia Mining & Smelting Co., Britannia Beach, B. C., Canada.

Jig tailing. Gangue quartzose, very hard,

6 ft. by 16 in. ball mill.

Capacity, 251 tons per 24 hr., average of six tests.

Charge, 8,200 lb. of 2-in. cast-iron balls.

Speed, 28 rev. per minute.

Horsepower, 38 to 40.

Water, 40 per cent.

Elevation of feed end, 0

Consumption of balls, 0.72 lb. per ton of ore.

Lining in first-class condition after 3 months’ run.

This mill is taking “pebble mill feed” (all through ¼-in. aperture), but using small balls instead of pebbles as a grinding medium. Those data are, therefore, not included in the averages in Table II.

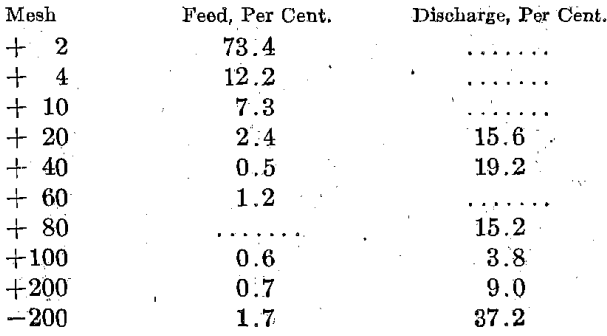

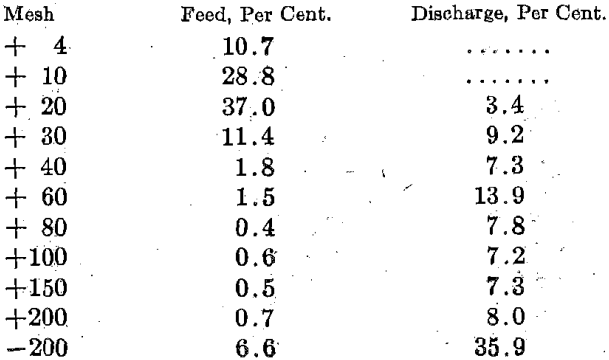

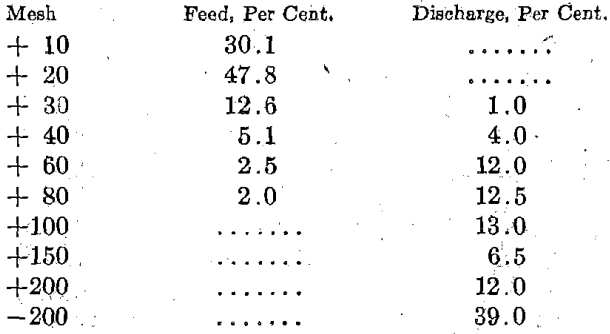

Card 192. Nov. 17, 1914. McIntyre Porcupine Mines, Schumacher, Ont., Canada.

Quartz and schist.

6 ft. by 16 in. ball mill.

Capacity, 150 tons per 24 hr.

Charge, 8,000 lb. of balls.

Speed, 28 rev. per minute.

Horsepower, 36.

Water, 50 per cent.

Elevation of feed end, 1.25 in.

Consumption of balls, 0.5 lb., per ton of ore ground.

Feed to mill through 2-in. mesh.

Card 156. June 25, 1914. McIntyre Porcupine Mines, Schumacher, Ont., Canada.

Quartz and schist, hard.

6 ft. by 16 in. ball mill.

Capacity, 150 tons per 24 hr., average of nine months.

Charge, 4 tons of balls.

Speed, 28 rev. per minute.

Horsepower, 36.

Water, 1.5 tons KCN solution to 1 ton of dry ore.

Elevation of feed end, 1.25 in.

Consumption of balls, 0.5 lb. per ton of ore.

Feed to mill through 2-in. mesh.

Card 191. Sept. 14, 1914. Buckhorn Mines Co., Buckhorn, Nev.

Soft talcose gold ore. Gangue, decomposed porphyry and basalt.

6 ft. by 16 in. ball mill.

Capacity, 160 tons per 24 hr.

Charge, 8,000 lb. of balls.

Speed, 28 rev. per minute.

Horsepower, 33.25 input to motor.

Water, 4 to 1.

Elevation of feed, end, 1.5 in.

Consumption of balls, 0.45 lb. per ton of ore.

Feed to mill through 1.5-in. mesh.

Card 121. Bunker Hill & Sullivan Mining & Concentrating Co., Kellogg, Idaho.

Middling from 3-mm. jigs and tables. , Gangue, quartzite and siderite.

6 ft. by 22 in. pebble mill.

Capacity, 60.3 tons per 24 hr.

Speed, 32 rev. per minute.

Horsepower, 16 (?).

Water, not taken. Previous test gave 75 per cent.

Elevation of feed end, 0.5 in.

Pebble load, 4,000 lb. (?). ‘

Feed to mill through 3-mm. mesh.

Card 113; June 28, 1912. Vipond Porcupine Mines Co., Ltd., Schumacher, Ont., Canada.

Oversize of Colbath classifier. Gangue, quartz and basalt.

6 ft. by 72 in. pebble mill.

Capacity, 40 tons per 24 hr.

Charge, 9,000 lb. of pebbles.

Speed, 27 rev. per minute.

Horsepower, 30.

Water, 50 per cent.

Elevation of feed end, 0.

Product deslimed and oversize returned.

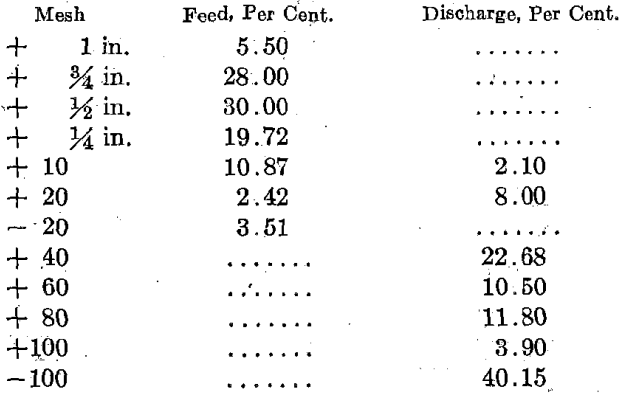

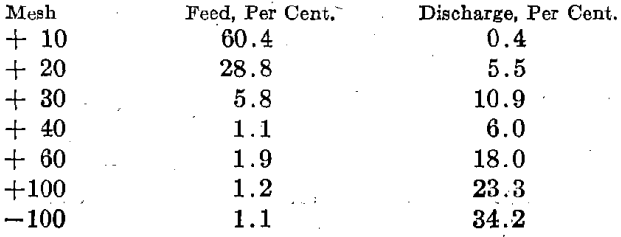

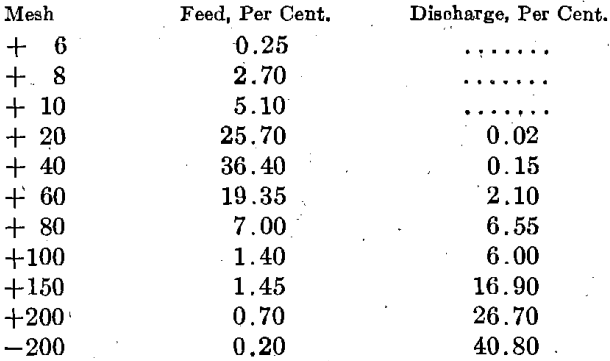

Card 108. Jan. 30, 1912. Miami Copper Co., Miami, Ariz.

Product from 16 by 42 in. rolls. Gangue, altered schist.

8 ft. by 22 in. pebble mill.

Capacity, 101 tons per 24 hr.

Charge, 10,000 lb. of pebbles.

Speed, 27 rev. per minute.

Horsepower, 36.

Water, 63 per cent.

Elevation of feed end, 1.5 in.

Product desired to pass 30 mesh with a minimum of slime.

Feed through ½-in. mesh.

Card 80. Aug. 16, 1911. Miami Copper Co., Miami, Ariz.

Product from 16 by 42 in. rolls. Gangue, altered schist.

8 ft. by 22 in. pebble mill.

Capacity, 180 tons, per 24 hr.

Charge, 10,000 lb. of pebbles.

Speed, 27 rev. per minute,

Horsepower, 36.

Water, 60 to 65 per cent.

Elevation of feed end, 1.5 in.

Product desired to pass 30 mesh with a minimum of slime.

Card 109. Federal Mining & Smelting Co., Wallace, Idaho.

Middling from jigs. Gangue, quartzite and siderite.

8 ft. by 22 in. pebble mill.

Capacity, 110 to 115 tons per 24 hr.

Charge, 10,000 lb. of pebbles.

Speed, 28 rev. per minute.

Horsepower, 35.8 net.

Water, 60 per cent.

Elevation of feed end, 0.

Consumption of pebbles, 2 lb, per ton.

Silex lining, life 13 months.

Feed to mill through 3/16-in. mesh.

Card 75. Sept. 7 to 9, 1911. Federal Mining & Smelting Co., Wallace, Idaho.

Coarse Wilfley middling. Gangue, quartzite and siderite.

8 ft. by 22 in. pebble mill.

Capacity, 99.36 tons per 24 hr.

Charge, 5 tons of pebbles (approx.)

Speed, 28 rev. per minute.

Horsepower, 35.3 net.

Water, 55 per cent.

Elevation of feed end, 0.

Consumption of pebbles, 1.5 to 2 lb. per ton

Feed to mill through 5-mm. mesh.

Card 136. Federal Mining & Smelting Co., Wallace, Idaho.

Jig middling. Gangue, quartzite.

8 ft. by 22 in. pebble mill.

Capacity, 111.5 tons per 24 hr.

Charge, 5 tons of pebbles.

Speed, 28 rev. per minute.

Horsepower, 35.3.

Water, 71.8 per cent.

Elevation of feed end, 2 in.

Consumption of pebbles, 2 lb. per ton.

Feed to mill through 4 mesh.

Card 150. Sept. 8, 1913. Vieille Montagne Zinc Co., Cumberland, England.

Zinc-lead ore. Gangue, siliceous limestone.

8 ft. by 22 in. pebble mill.

Capacity, 120 tons per 24 hr.

Charge, 3 tons of pebbles.

Speed, 29.5 rev. per minute.

Elevation of feed end, 4 in.

Feed to mill through ½-in. mesh.

Card 34. Nov. 2, 1910. Calumet & Hecla Mining Co., Lake Linden, Mich.

Tailing from jigs. Gangue, Lake conglomerate. 8 ft. by 22 in. pebble mill.

Capacity 40 to 45 tons per 24 hr.

Charge, 3 tons of pebbles.

Speed, 27 rev. per minute.

Horsepower, 34 to 37.

Water, 40 per cent.

Elevation of feed end, 0.

Consumption of pebbles, 2 lb. per ton of ore.

Feed to mill through ¼-in. mesh.

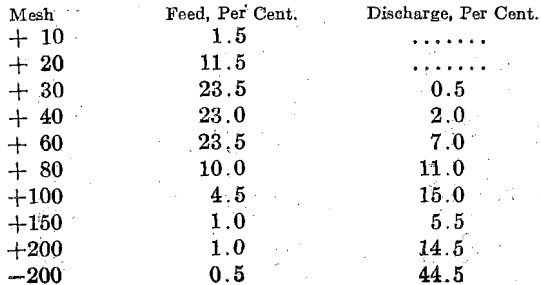

Card 135. Oct. 26,1912. Federal Mining & Smelting Co., Morning, Idaho.

Wilfley middling. Gangue, quartzite.

7* ft. by 12 ft. tube mill.

Capacity, 124 tons per 24 hr.

Charge, 9 tons of pebbles.

Speed, 22.25 rev. per minute.

Horsepower, 86.

Water, 58.8 per cent.

Elevation of feed end, 0.

Consumption of pebbles, 4 to 5 lb. per ton of ore.,

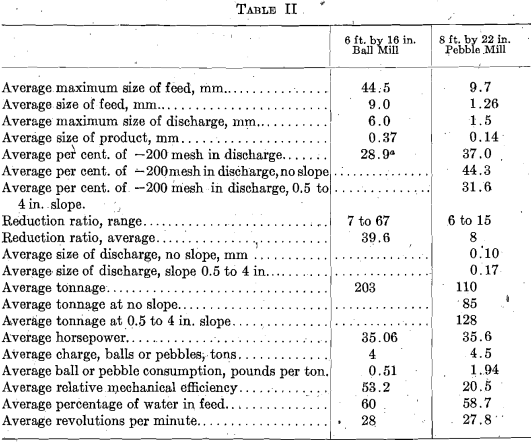

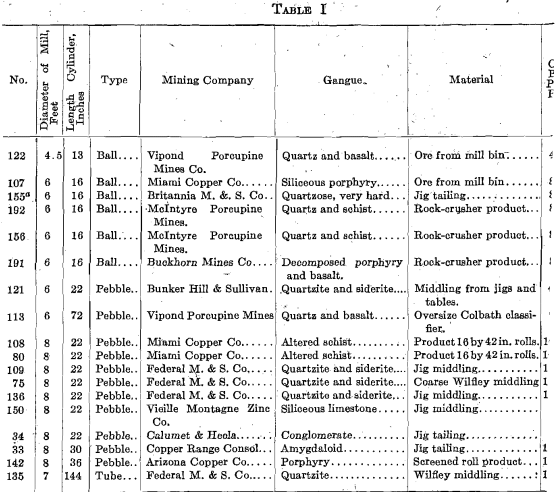

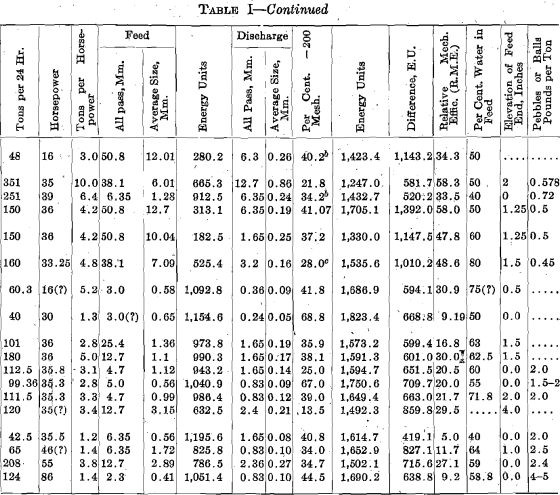

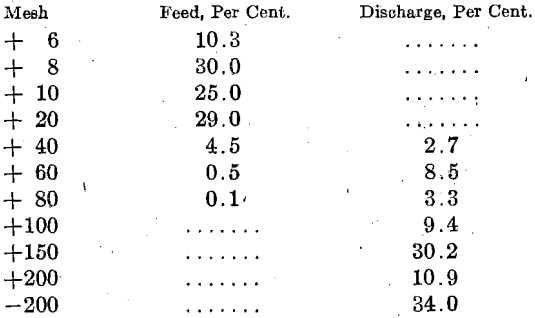

Table I is a summary of the data presented on the mesh cards. Table II is taken from Table I.

Apparently the ball mill does more work per unit of power input than the pebble mill, while the pebble milk is, in the same way, more efficient than the tube mill in the one instance cited. Nos. 107 and 142 show the effect of overloading the mill. The relative mechanical efficiencies in these two cases are raised above the average at the expense of the character of the product.

Card 33. Nov. 3, 1910. Copper Range Consolidated, Freda, Mich.

Tailing from jigs. Gangue, Lake amygdaloid.

8 ft. by 30 in. pebble mill.

Capacity, 65 tons per 24 hr.

Charge, 5 tons of pebbles.

Speed, 28 rev. per minute.

Water, 64 per cent.

Elevation of feed end, 1 in.

Consumption of pebbles, 2.5 lb. per ton of ore.

Feed to mill through ¼-in. mesh.

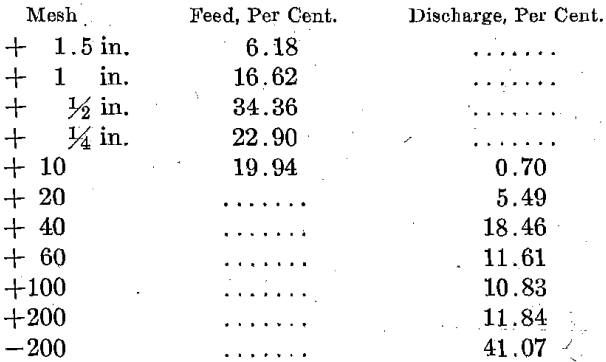

Card 142. Oct. 9, 1913. Arizona Copper Co., Morenci, Ariz.

Screened roll product. Gangue, porphyry.

8 ft. by 36 in. pebble mill.

Capacity, 208 tons per 24 hr.

Charge, 10,500 lb. of pebbles.

Speed, 29 rev. per minute.

Horsepower, 55.

Water, 59 per cent.

Elevation of feed end, 0.

Consumption of pebbles, 2.4 lb. per ton.

Feed to mill through ½-in. mesh.