The method of making silver ingots in use at this Mint being radically different from that employed at any other Mint of the United States or, so far as known to me, any Mint in the world, there may be some interest in a description of the apparatus used and a brief history of its distinguishing feature, viz., the rotary ingot- mould, which, though not a recent improvement, is comparatively unknown.

The furnaces used for silver-ingot-melting are four in number and have a capacity of some seventy thousand standard ounces of silver per day of eight hours. This output is increased, when the exigencies of the service demand it, to one hundred thousand ounces. They are built of fire-brick and elevated 2½ feet from the floor of the melting-room, in order to have space to place iron boxes and to work, in case a crucible breaks in the furnace and its contents run into the ash-pit. The furnaces are circular in horizontal section, 2½ feet in diameter and 2¼ feet high inside in the clear, and rest on cast iron plates, with top-plates of the same, and sides encased in boiler- iron. The furnace-covers are also of cast-iron, dome-shaped, and are handled by means of a small crane and lever. The furnaces stand in sets of two, and one crane and one ingot-machine serves two furnaces.

The crucibles used are made specially for this purpose of a mixture of black-lead and fire-clay; the size known as No. 200 will contain and safely melt, without danger of slopping over, from 8600 to nearly 10,000 ounces of standard silver; and this is the usual weight of the ingot-melt at this Mint, as against 1800 ounces at the Carson City mint and 2600 to 3000 ounces at Philadelphia and San Francisco. Each crucible will endure, on the average, ten melts.

The crucible stands in the center of the furnace, on the bottom of an old one, cut down to a height of about three inches. The fuel used is coke. Experience has shown that, notwithstanding the higher first cost, Connellsville coke is cheaper than Alabama coke and much more suitable to the work. A small triangular black-lead crucible, holding about forty ounces of silver, is used as a pouring-cup.

The tongs and other implements in use at the furnaces are the same as those generally employed for such work, with the exception of the stirrer, which is a wrought-iron rod five feet long and three-

qnarters inch in diameter, divided at the bottom for about six inches into three parts or prongs, to which is riveted a circular dished wrought-iron plate, six inches in diameter and perforated with half-inch holes.

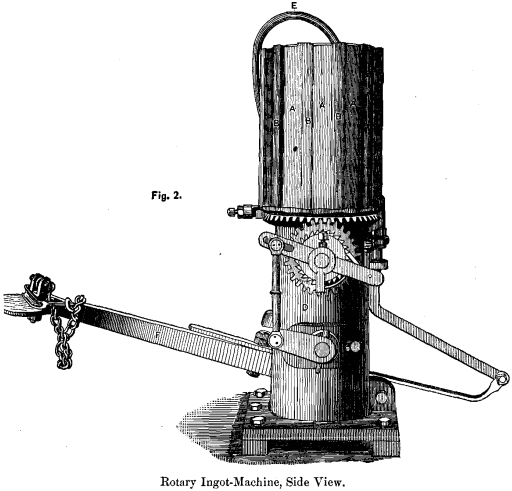

On a cast-iron platform, 4 1/3 feet x 8 feet, in front of the furnace and 2½ feet above the floor, stands the rotary ingot-machine shown in Figs. 1 and 2, which consists of a hollow vertical revolving cylinder of cast-iron with slots A A, cast in the outer circumference, 12 3/8″ long and 1 5/8″ wide and ½” deep, separated by lugs

B B, 7/8″ wide, extending the full height of the cylinder. The slots are open at the top and outer side, and when closed by the block C form the moulds for the standard silver dollar ingots. The cylinder for this size of ingot has twelve moulds on its circumference. It is supported by a cast-iron standard D, and revolved by a gear-wheel bolted to its base. The cast-iron block C, which closes the moulds, has a motion to and from the cylinder of one-quarter inch. Both cylinder and block are kept cool by a half-inch stream of cold water E, constantly flowing through them. This cooling is rendered necessary by the strong tendency of silver-copper alloys to segregate, and can only be partially overcome by cooling the ingot as quickly as possible after casting. The machine is operated by a foot-treadle (F, shown in Fig. 2, but omitted from Fig. 1 because the photographic original distorted it), and is as follows :

The workman presses down the treadle, which first retracts the block from its position in contact with the lugs on the cylinder, where it has been left during and after the pouring of the preceding ingot; then rotates the cylinder one-twelfth of a revolution, bringing one of the moulds on its circumference exactly opposite the block; then locks the cylinder in place; and finally releases the block from its retracted position, and allows it to be forced (by means of powerful steel springs) firmly against the lugs on the cylinder. So close a joint is obtained that no silver escapes through it, and only a slight feather-edge forms on the ingot after a cylinder has been in use for months. The silver is now poured into the open top of the mould, where, owing to the cooling by water, it immediately sets. The cylinder is again revolved as before, and the ingot at a dull red heat is exposed to view. This ingot remains in the mould until the third or fourth succeeding ingot is poured, when it is removed and placed in a cast-iron box.

This machine was invented by Dr. J. L. Riddell, the Melter and Refiner of this Mint from 1839 to 1849. Dr. Riddell had already achieved distinction by the invention of the binocular microscope; and his desire to improve the slow, laborious and expensive method of casting ingots in hand-moulds, then universally practiced, resulted in this simple and efficient machine. The idea was developed about the year 1844; but from various causes, among others the expense incidental to the proposed change, and the fear expressed by Mint officials that the machine would not prove successful, nothing was done until 1847, when the Coiner, Mr. Philos B. Tyler, resigned to accept the superintendency of the American machine- works at Springfield, Mass. On his departure, he agreed to build a complete ingot-machine, as proposed by Dr. Riddell, for $500. But Mr. Tyler himself possessed a most ingenious mind. He was the inventor of the Tyler cotton compress; had built the first steam coining-presses used in America, and much other Mint and general machinery. Hence it naturally followed that his mechanical ability perfected the crude ideas of his colleague; and the machine, as built in 1847 and in use here for some years afterwards, was really the joint invention of these two gentlemen. It appears to have been successful from the first. The original machine was in use here for many years; the hand-moulds were immediately discarded and have never since been used in this Mint for casting silver-ingots. Dr. M. F. Bonzano, the able and efficient officer who succeeded Dr. Riddell as Melter and Refiner, made several important improvements to the machine during his term of office, which extended from 1849 to 1883.

The advantages derived from the use of the rotary ingot-machine are obvious. Only four large furnaces are required, instead of a large number of small ones ; the number of workmen required is also greatly reduced; and the weight of each melt is increased to an average of 8600 standard ounces, while by the hand-mould method the limit appears to have been reached at 3000 ounces, and the average weight by that method was about 2600 ounces.

An objection is urged against making so large a melt of standard silver, based upon the supposition that the alloy will vary in fineness between the first and last ingots or from top to bottom of the melt, the difference being caused either by segregation or by an increase in fineness caused by a portion of the copper being burnt out, during the relatively long exposure of the melt in the furnace. Both these sources of error are avoided in our practice: the first, by a thorough mixing just previous to the pouring; and the last, by keeping the melt constantly covered with a thick layer of finely ground charcoal, and by the use of the ingot-machine, which enables us to take out a melt in twenty minutes. Years of successful practice have shown that no greater deviations of fineness exist in these large melts than in the smaller ones.

The Melter and Refiner bases his calculations for the amount of copper and silver necessary to form ingots conformable to law, upon the report of the Assayer of the fineness of the bullion, and makes up his melt accordingly. As the ingots made from fine silver and copper alone are not quite as ductile as those containing a certain proportion of previously melted alloy, it is customary to add to each melt a certain amount of “clippings” and “ planchets.” Clippings are the remainder of the ingots after the blank coins have been cut from them, and planchets are the blanks. A melt, as sent to the melting-room, will be composed about as follows : 5835 ounces of fine silver; 3000 ounces of clippings and planchets; and 577 ounces of copper. All calculations for melts are made independently and in duplicate by two clerks, in order to avoid error; the bullion and copper are exactly weighed in ounces and decimals for each melt, put in boxes and taken to the melting-room, where the furnace and crucible are already hot. The bars of fine silver, weighing about 1200 ounces each, are carefully lowered into the crucible with a block and tackle. Two bars on end will fill the bottom of a No. 200 crucible. The interstices are then filled with clippings, another bar is put in and clippings and planchets are added until the pot is full. When this is melted down, the silver is “thickened” by adding clippings until they appear above the molten silver; this forms a bed to receive the remaining bars, and prevents splashing, should the bars slip from the tongs in filling. The remaining bars and clippings are then added. When all the silver is in and thoroughly melted, the copper is added. The furnace is closed again for a short time, and the fire urged, in order to get a hot and fluid melt. When this has been secured, the furnace and crucible are again opened, the previously-heated stirrer is introduced, and the whole mass is thoroughly mixed by churning the stirrer up and down some four hundred times through the molten alloy. Count is kept, and all melts are stirred in this manner. From the time that the silver was first melted it has been constantly covered by a coating of charcoal-dust, renewed from time to time as it is burned off. During the stirring the amount used for covering is increased; but after this operation is finished, the melt is skimmed so that only a thin layer remains. Care is taken, however, that the surface is kept always covered, up to the pouring of the last ingot. The stirring being completed, the pouring begins by the melter grasping the hot pouring-crucible in his long-handled tongs and ladling out the silver. The first dip of about six ounces is poured into a copper cup containing ice-water, which granulates the alloy. This sample is numbered and set aside for assay. The next dip is cast as the first ingot. During the pouring five samples are taken for assay : one at the beginning, one at the end, and the other three at intermediate stages, so as to insure a fair sample of the whole melt. These are assayed separately ; and when there is a greater difference between the first and last granulations than three-tenths of a millieme, the whole melt is condemned and remelted. Such is the thoroughness of the work that but very few melts are condemned for this cause. Although the law allows a variation, in the case of silver ingots, of three milliemes from the standard of 900, it is the practice at this Mint to condemn ingots when below 898½ or above 900½, the aim being to hold the coin as issued as close to the lawful standard as possible.

The pouring being completed, the ingots are spread upon the floor to cool, after which they are “ topped ” and the edges are filed, so as to leave a smooth, clean ingot with a solid top. If passed by the Assayer they are delivered to the Superintendent, to be formed into standard silver dollars.